Post Neutron Irradiation Recovery and Recrystallization of ITER Grade Forged Tungsten Bar

Abstract

1. Introduction

2. Materials and Methods

2.1. Material, Neutron Irradiation, and Post-Irradiation Annealing

2.2. X-Ray Diffraction (XRD) and Grazing Incidence X-Ray Diffraction (GIXRD)

2.3. Scanning Electron Microscopy (SEM)

2.4. Positron Annihilation Lifetime Spectroscopy (PALS)

2.5. DC Electrical Resistivity

2.6. Hardness

3. Experimental Results

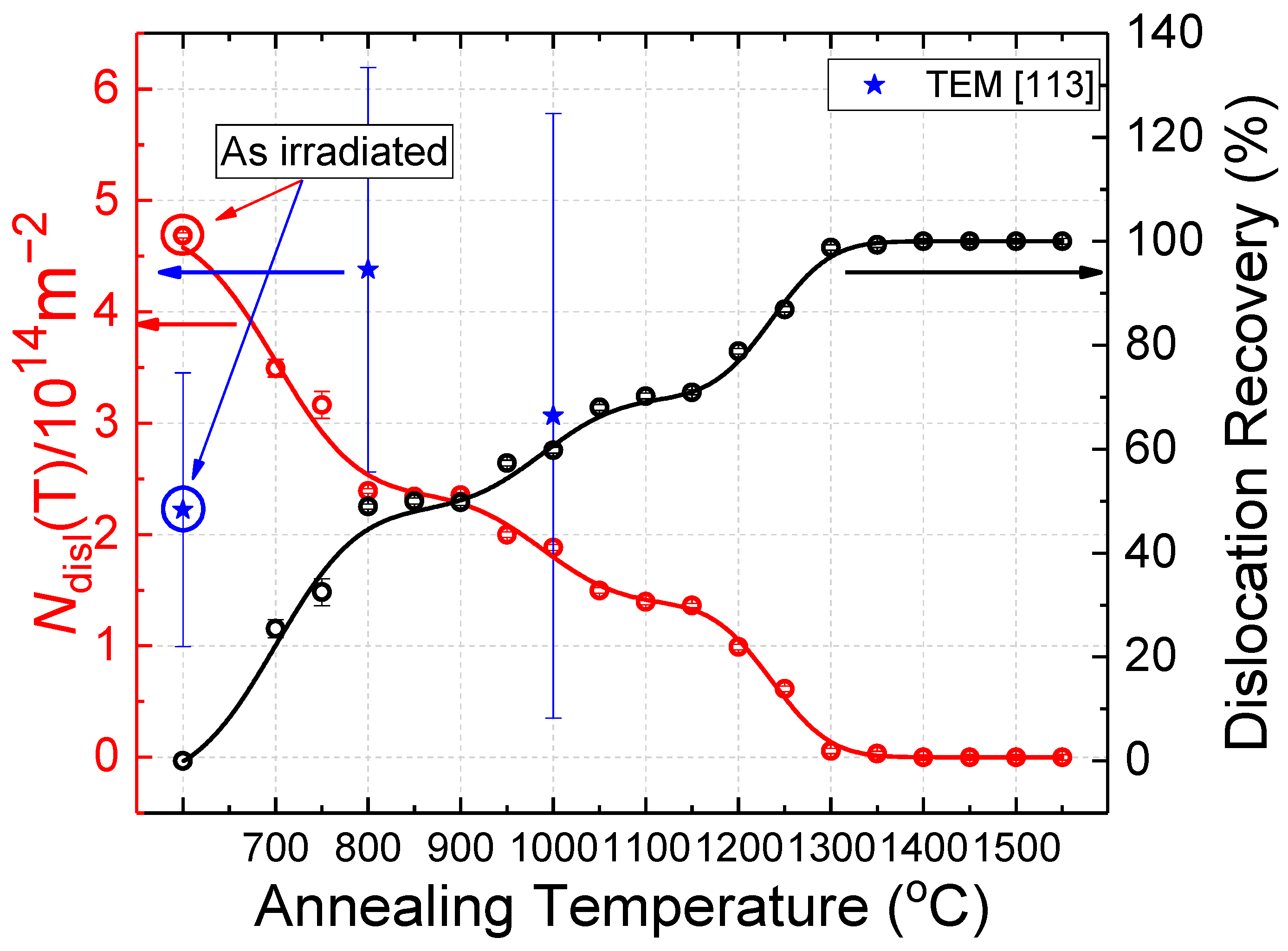

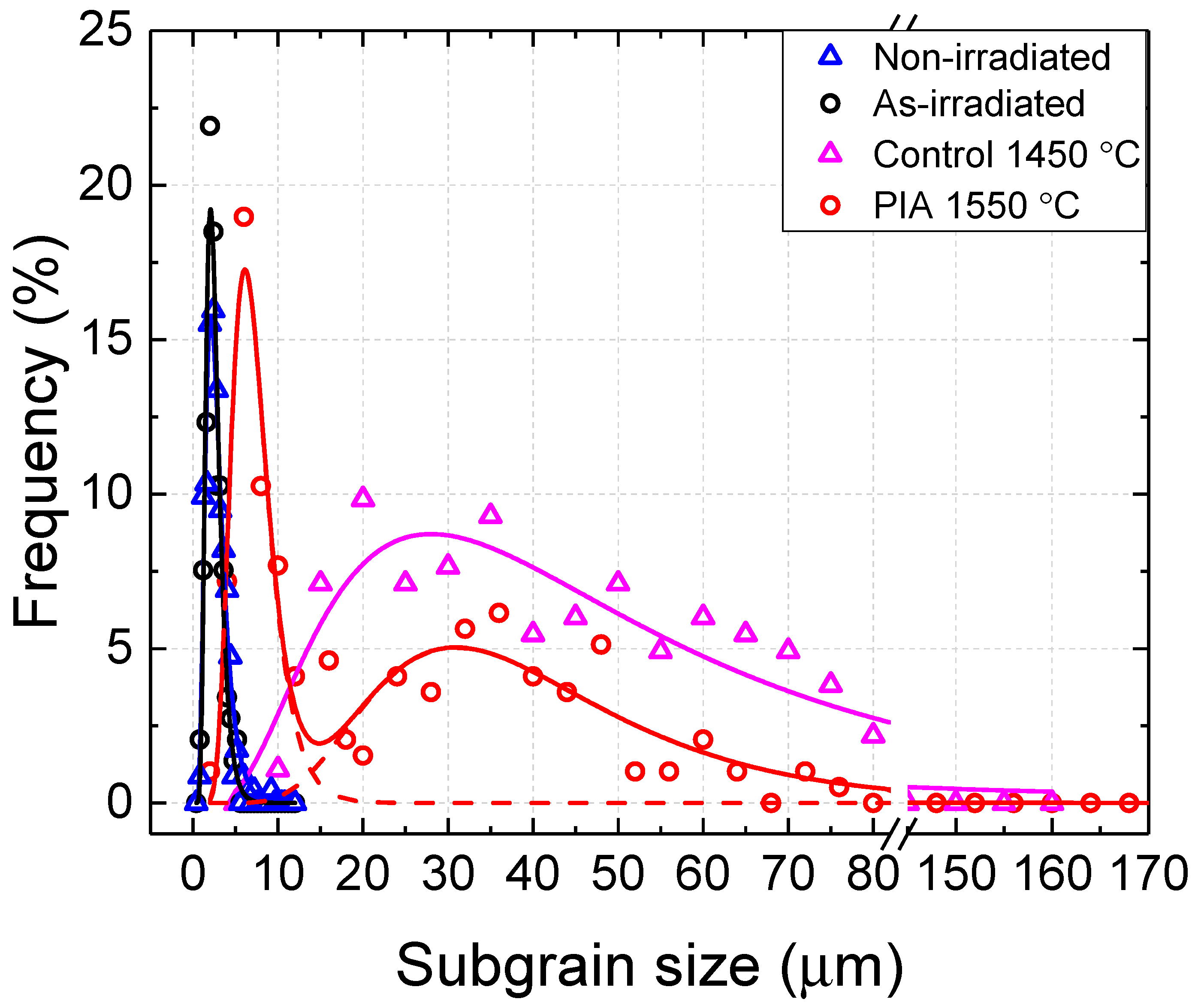

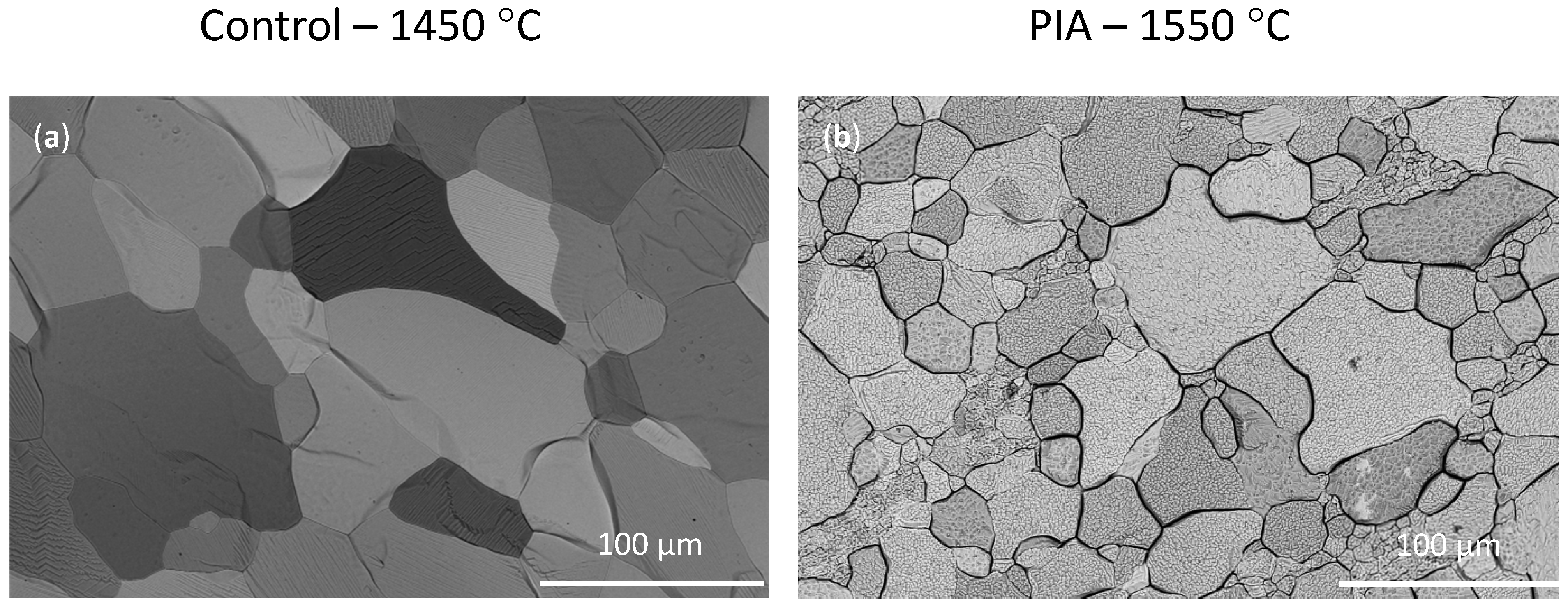

3.1. Grain Structure

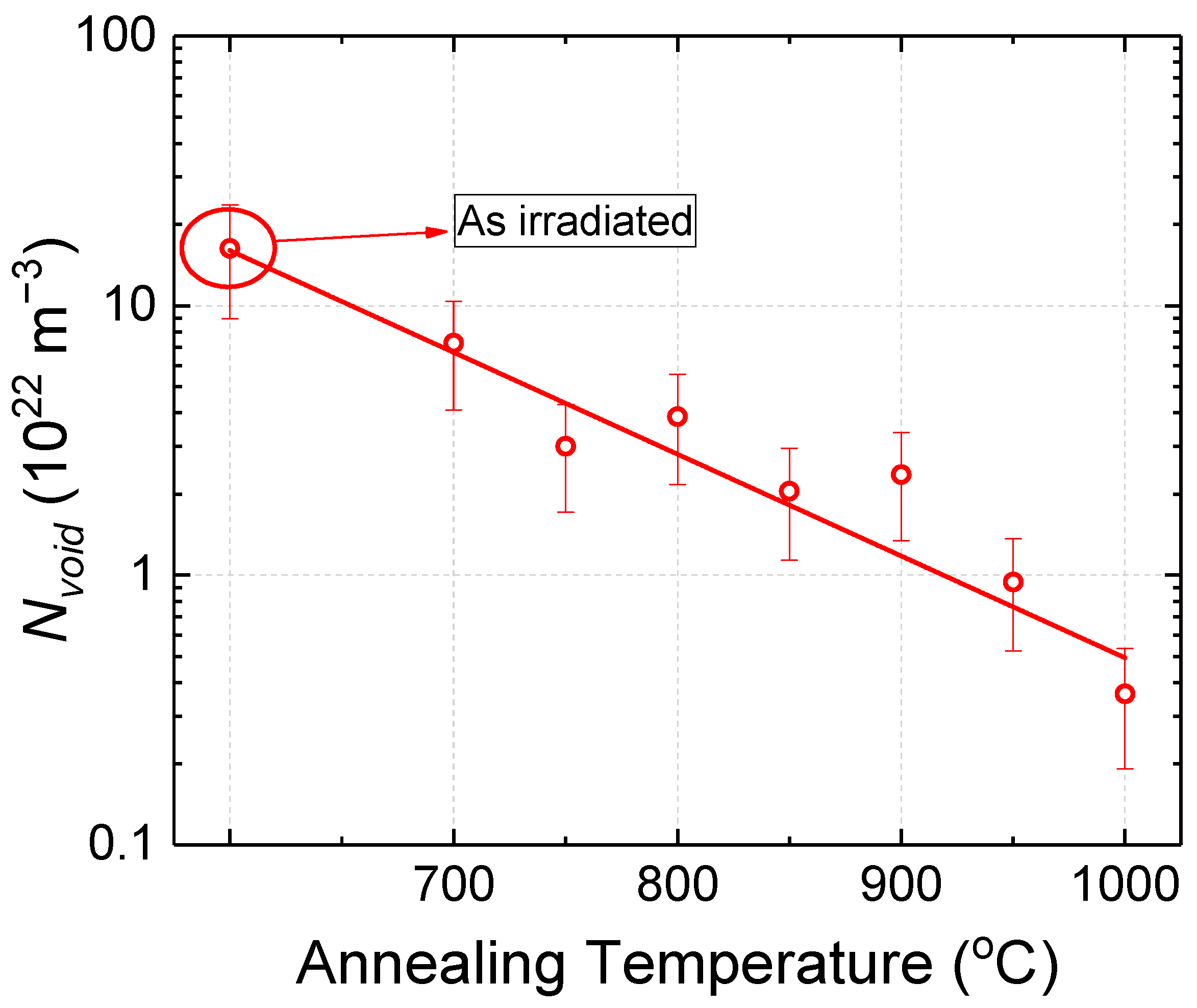

3.2. Open Volume Defect Evolution Versus Annealing

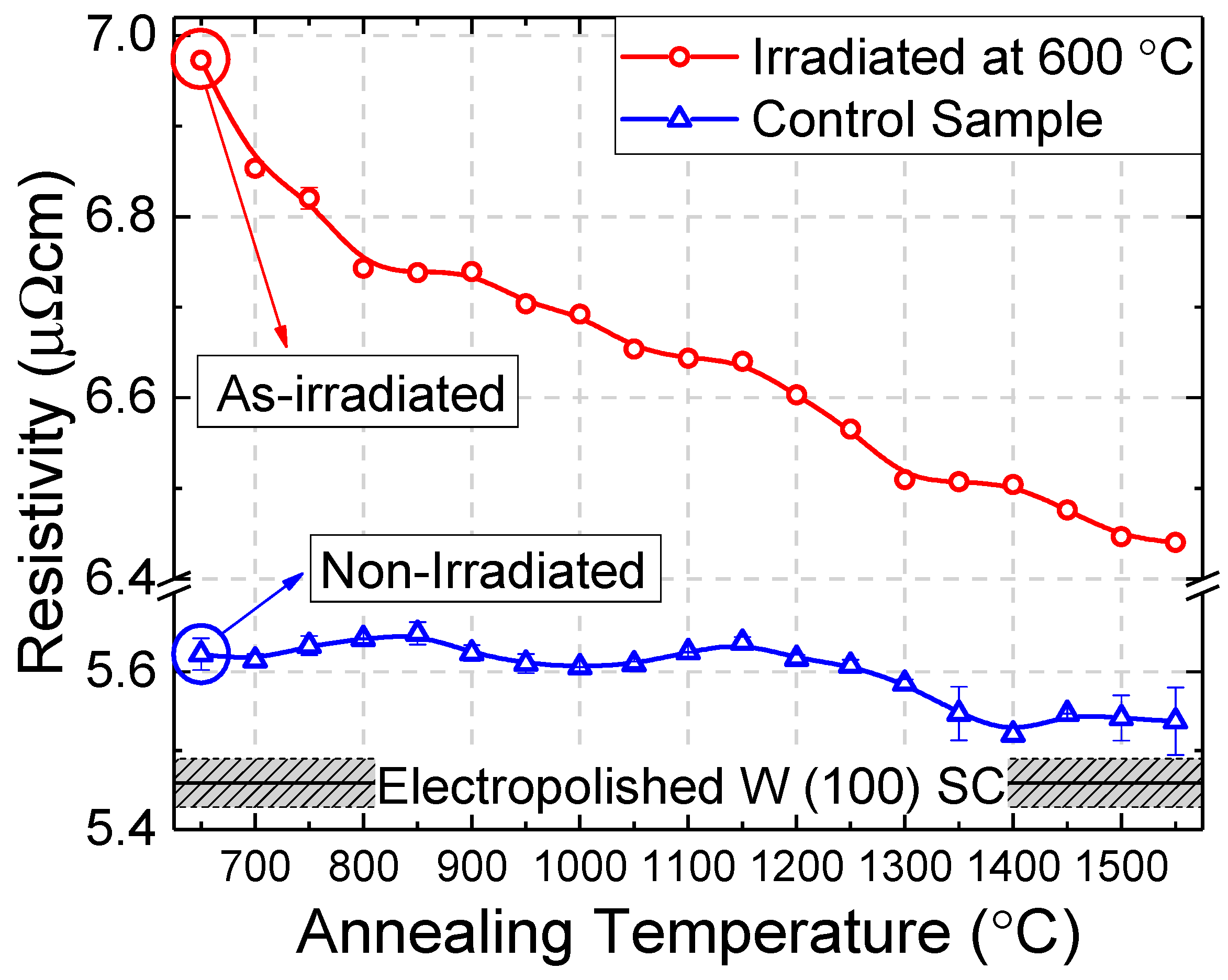

3.3. DC Electrical Resistivity

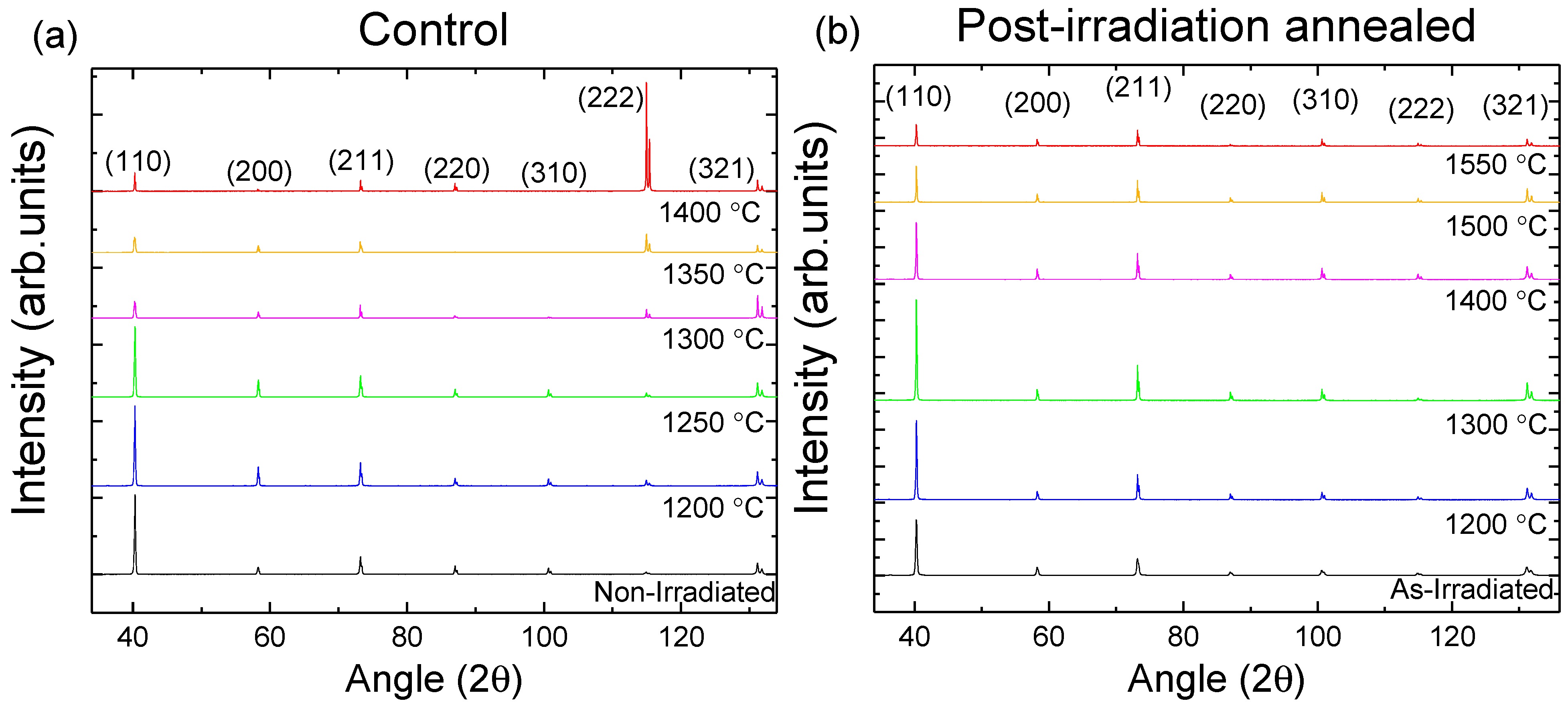

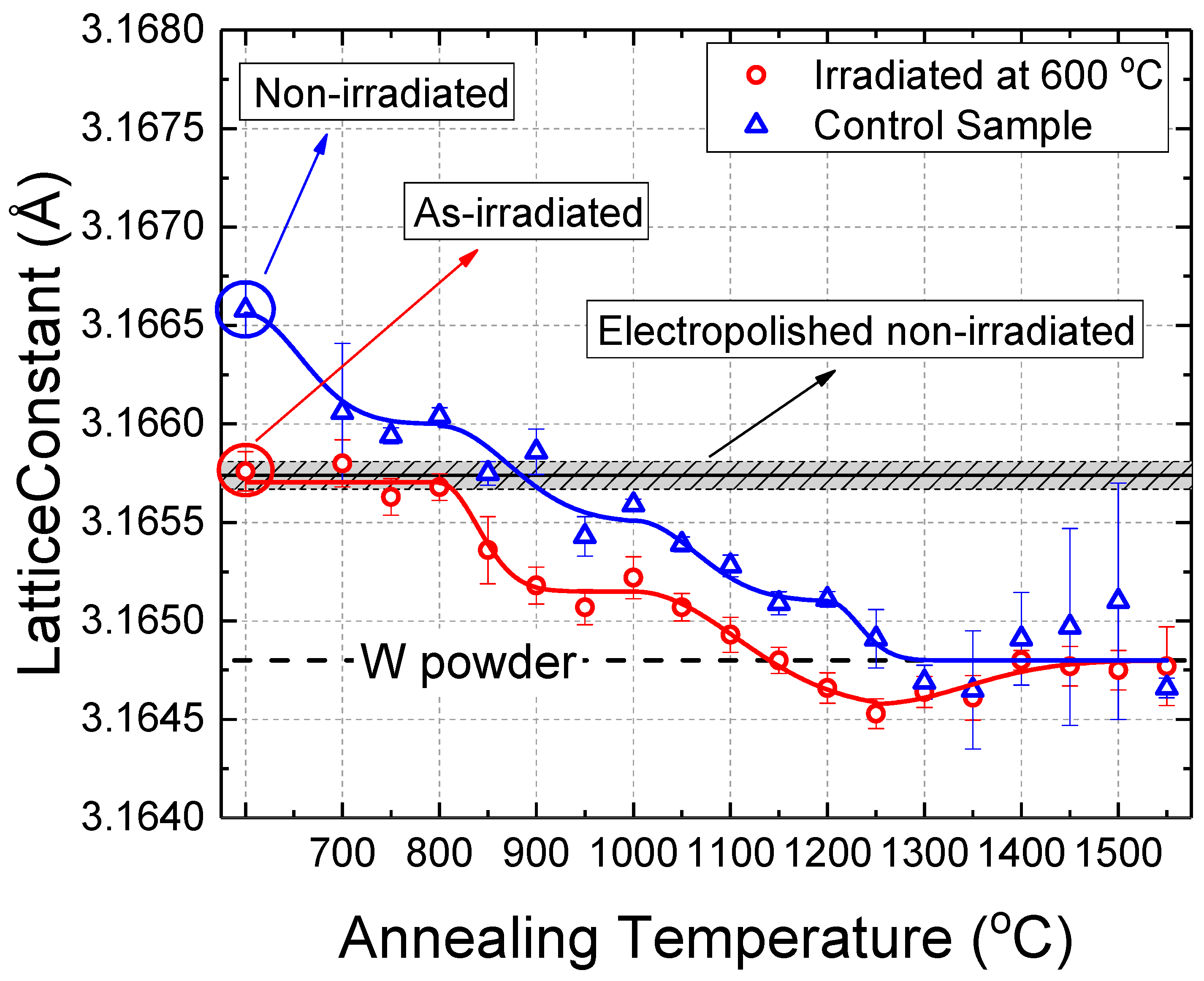

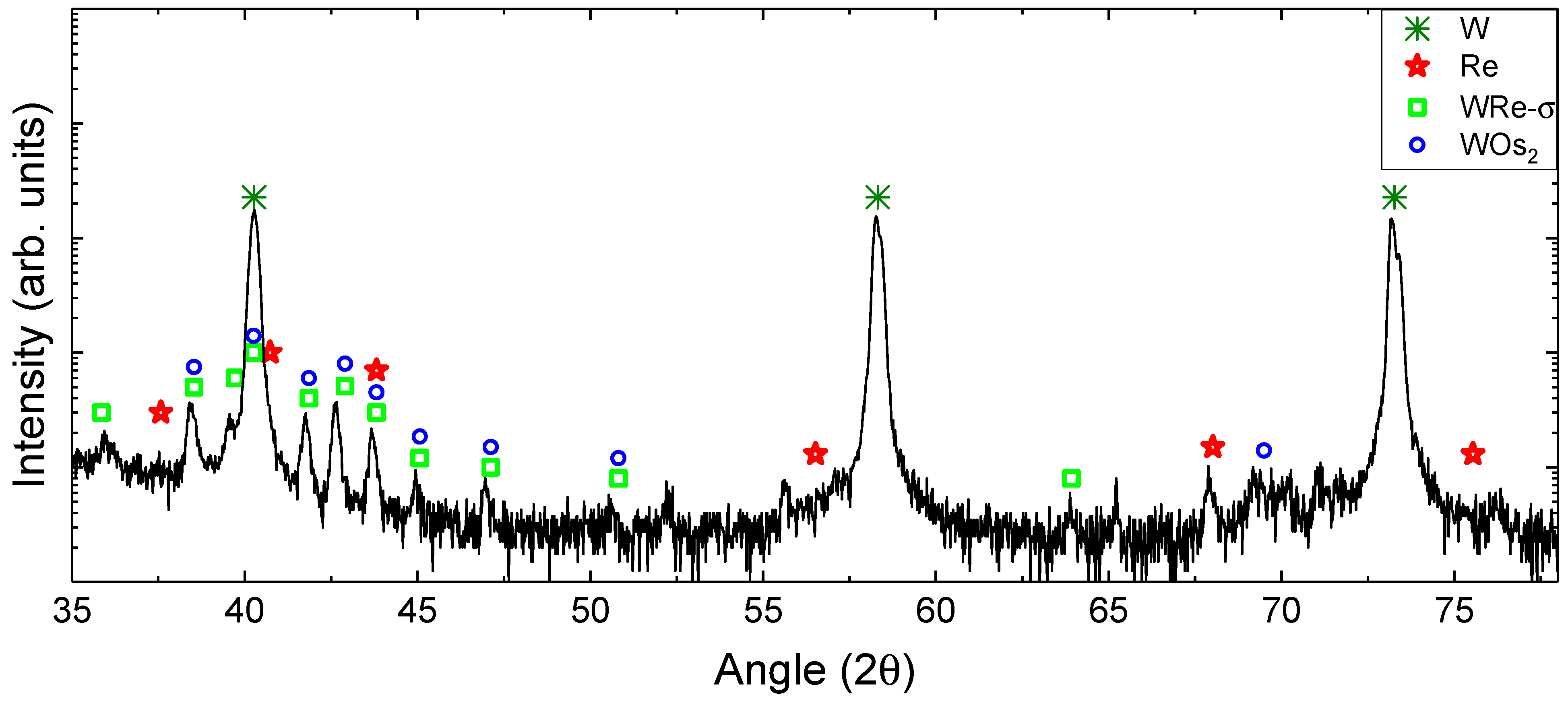

3.4. Crystalline Structure Evolution Versus Annealing (XRD, GIXRD)

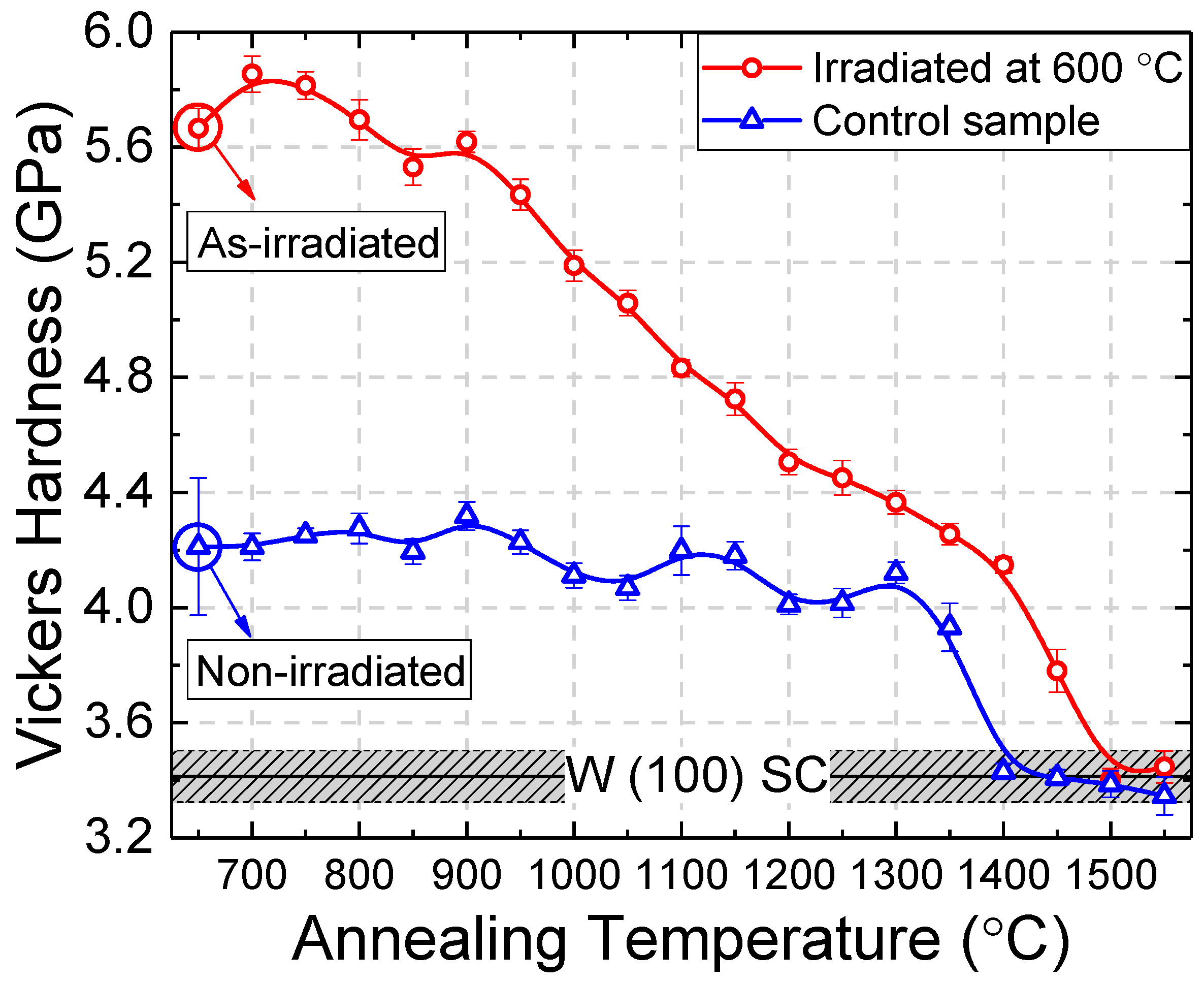

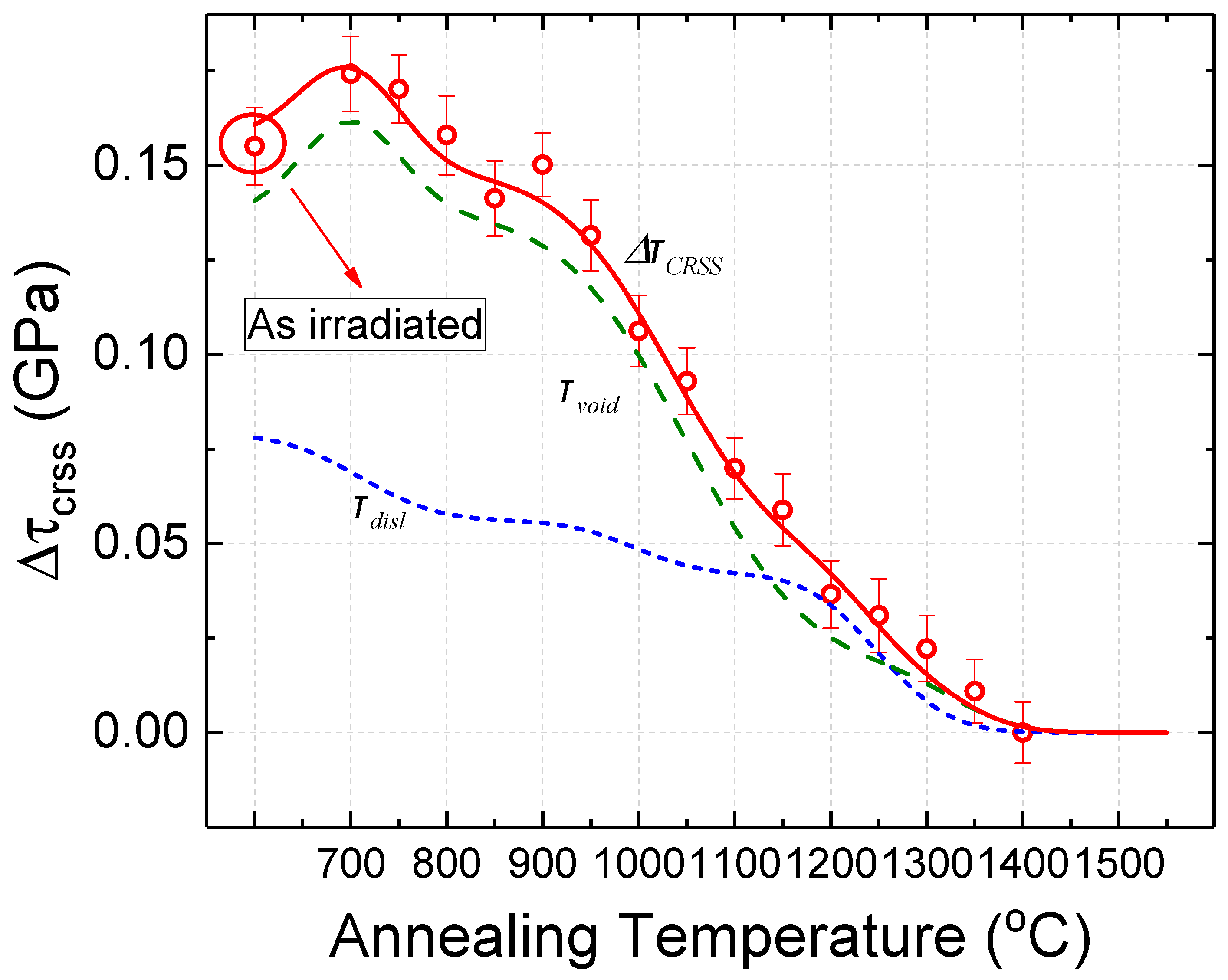

3.5. Vickers Hardness

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pitts, R.A.; Loarte, A.; Wauters, T.; Dubrov, M.; Gribov, Y.; Köchl, F.; Pshenov, A.; Zhang, Y.; Artola, J.; Bonnin, X.; et al. Plasma-wall interaction impact of the ITER re-baseline. Nucl. Mater. Energy 2025, 42, 101854. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Yoshida, N. Materials for the plasma-facing components of fusion reactors. J. Nucl. Mater. 2004, 329–333, 66–73. [Google Scholar] [CrossRef]

- Pitts, R.A.; Carpentier, S.; Escourbiac, F.; Hirai, T.; Komarov, V.; Lisgo, S.; Kukushkin, A.S.; Loarte, A.; Merola, M.; Sashala Naik, A.; et al. A full tungsten divertor for ITER: Physics issues and design status. J. Nucl. Mater. 2013, 438, S48–S56. [Google Scholar] [CrossRef]

- Pintsuk, G. Tungsten as a Plasma-Facing Material. In Comprehensive Nuclear Materials; Elsevier: Amsterdam, The Netherlands, 2012; Volume 4, pp. 551–581. ISBN 9780080560335. [Google Scholar]

- Davis, J.; Barabash, V.; Makhankov, A.; Plöchl, L.; Slattery, K. Assessment of tungsten for use in the ITER plasma facing components. J. Nucl. Mater. 1998, 258–263, 308–312. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Yu, J.H.; Tanigawa, H.; Hamaguchi, D.; Nozawa, T. Mechanical properties of three kinds of ITER-Grade pure tungsten with different manufacturing processes. Fusion Eng. Des. 2020, 157, 111679. [Google Scholar] [CrossRef]

- Reiser, J.; Hoffmann, J.; Jäntsch, U.; Klimenkov, M.; Bonk, S.; Bonnekoh, C.; Rieth, M.; Hoffmann, A.; Mrotzek, T. Ductilisation of tungsten (W): On the shift of the brittle-to-ductile transition (BDT) to lower temperatures through cold rolling. Int. J. Refract. Met. Hard Mater. 2016, 54, 351–369. [Google Scholar] [CrossRef]

- Bonnekoh, C.; Hoffmann, A.; Reiser, J. The brittle-to-ductile transition in cold rolled tungsten: On the decrease of the brittle-to-ductile transition by 600 K to −65 °C. Int. J. Refract. Met. Hard Mater. 2018, 71, 181–189. [Google Scholar] [CrossRef]

- Yin, C.; Terentyev, D.; Pardoen, T.; Bakaeva, A.; Petrov, R.; Antusch, S.; Rieth, M.; Vilémová, M.; Matějíček, J.; Zhang, T. Tensile properties of baseline and advanced tungsten grades for fusion applications. Int. J. Refract. Met. Hard Mater. 2018, 75, 153–162. [Google Scholar] [CrossRef]

- Motojima, O. The ITER project construction status. Nucl. Fusion 2015, 55, 104023. [Google Scholar] [CrossRef]

- Hirai, T.; Panayotis, S.; Barabash, V.; Amzallag, C.; Escourbiac, F.; Durocher, A.; Merola, M.; Linke, J.; Loewenhoff, T.; Pintsuk, G.; et al. Use of tungsten material for the ITER divertor. Nucl. Mater. Energy 2016, 9, 616–622. [Google Scholar] [CrossRef]

- Rau, R.C.; Ladd, R.L.; Moteff, J. Voids in irradiated tungsten and molybdenum. J. Nucl. Mater. 1969, 33, 324–327. [Google Scholar] [CrossRef]

- Rieth, M.; Dudarev, S.L.; Gonzalez De Vicente, S.M.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef]

- Buswell, J.T. Vacancy damage in heavy ion and neutron-irradiated tungsten. Philos. Mag. 1970, 22, 787–802. [Google Scholar] [CrossRef]

- Brinkman, J.A. On the Nature of Radiation Damage in Metals. J. Appl. Phys. 1954, 25, 961–970. [Google Scholar] [CrossRef]

- Hu, X.; Koyanagi, T.; Fukuda, M.; Katoh, Y.; Snead, L.L.; Wirth, B.D. Defect evolution in single crystalline tungsten following low temperature and low dose neutron irradiation. J. Nucl. Mater. 2016, 470, 278–289. [Google Scholar] [CrossRef]

- Ogorodnikova, O.V.; Majerle, M.; Čížek, J.; Simakov, S.; Gann, V.V.; Hruška, P.; Kameník, J.; Pospíšil, J.; Štefánik, M.; Vinš, M. Positron annihilation spectroscopy study of radiation-induced defects in W and Fe irradiated with neutrons with different spectra. Sci. Rep. 2020, 10, 18898. [Google Scholar] [CrossRef]

- Gilbert, M.R.R.; Sublet, J.-C. Neutron-induced transmutation effects in W and W-alloys in a fusion environment. Nucl. Fusion 2011, 51, 43005. [Google Scholar] [CrossRef]

- Klimenkov, M.; Jäntsch, U.; Rieth, M.; Schneider, H.C.C.; Armstrong, D.E.J.E.J.; Gibson, J.; Roberts, S.G.G. Effect of neutron irradiation on the microstructure of tungsten. Nucl. Mater. Energy 2016, 9, 480–483. [Google Scholar] [CrossRef]

- Lloyd, M.J.; Abernethy, R.G.; Gilbert, M.R.; Griffiths, I.; Bagot, P.A.J.; Nguyen-Manh, D.; Moody, M.P.; Armstrong, D.E.J. Decoration of voids with rhenium and osmium transmutation products in neutron irradiated single crystal tungsten. Scr. Mater. 2019, 173, 96–100. [Google Scholar] [CrossRef]

- Klimenkov, M.; Dürrschnabel, M.; Jäntsch, U.; Lied, P.; Rieth, M.; Schneider, H.C.; Terentyev, D.; Van Renterghem, W. Microstructural analysis of W irradiated at different temperatures. J. Nucl. Mater. 2022, 572, 154018. [Google Scholar] [CrossRef]

- Fujitsuka, M.; Tsuchiya, B.; Mutoh, I.; Tanabe, T.; Shikama, T. Effect of neutron irradiation on thermal diffusivity of tungsten–rhenium alloys. J. Nucl. Mater. 2000, 283–287, 1148–1151. [Google Scholar] [CrossRef]

- Dubinko, A.; Terentyev, D.; Yin, C.; Van Renterghem, W.; Rossaert, B.; Rieth, M.; Zhurkin, E.E.E.; Zinovev, A.; Chang, C.C.C.; Van Dyck, S.; et al. Microstructure and hardening induced by neutron irradiation in single crystal, ITER specification and cold rolled tungsten. Int. J. Refract. Met. Hard Mater. 2021, 98, 105522. [Google Scholar] [CrossRef]

- Hu, X. Recent progress in experimental investigation of neutron irradiation response of tungsten. J. Nucl. Mater. 2022, 568, 153856. [Google Scholar] [CrossRef]

- Hasegawa, A.; Fukuda, M.; Yabuuchi, K.; Nogami, S. Neutron irradiation effects on the microstructural development of tungsten and tungsten alloys. J. Nucl. Mater. 2016, 471, 175–183. [Google Scholar] [CrossRef]

- Sikka, V.K.; Moteff, J. Superlattice of voids in neutron-irradiated tungsten. J. Appl. Phys. 1972, 43, 4942–4944. [Google Scholar] [CrossRef]

- Fukuda, M.; Yabuuchi, K.; Nogami, S.; Hasegawa, A.; Tanaka, T. Microstructural development of tungsten and tungsten-rhenium alloys due to neutron irradiation in HFIR. J. Nucl. Mater. 2014, 455, 460–463. [Google Scholar] [CrossRef]

- Wielunska, B.; Płociński, T.; Schwarz-Selinger, T.; Mayer, M.; Jacob, W.; Ciupiński, L. Dislocation structure of tungsten irradiated by medium to high-mass ions. Nucl. Fusion 2022, 62, 096003. [Google Scholar] [CrossRef]

- Dube, C.L.; Kulriya, P.K.; Dutta, D.; Pujari, P.K.; Patil, Y.; Mehta, M.; Patel, P.; Khirwadkar, S.S. Positron annihilation lifetime measurement and X-ray analysis on 120 MeV Au+7 irradiated polycrystalline tungsten. J. Nucl. Mater. 2015, 467, 406–412. [Google Scholar] [CrossRef]

- Grzonka, J.; Ciupiński, Ł.; Smalc-Koziorowska, J.; Ogorodnikova, O.V.; Mayer, M.; Kurzydłowski, K.J. Electron microscopy observations of radiation damage in irradiated and annealed tungsten. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2014, 340, 27–33. [Google Scholar] [CrossRef]

- Yi, X.; Jenkins, M.L.; Kirk, M.A.; Zhou, Z.; Roberts, S.G. In-situ TEM studies of 150 keV W+ ion irradiated W and W-alloys: Damage production and microstructural evolution. Acta Mater. 2016, 112, 105–120. [Google Scholar] [CrossRef]

- Yi, X.; Jenkins, M.L.; Briceno, M.; Roberts, S.G.; Zhou, Z.; Kirk, M.A. In situ study of self-ion irradiation damage in W and W-5Re at 500 °C. Philos. Mag. 2013, 93, 1715–1738. [Google Scholar] [CrossRef]

- Garrison, L.M.M.; Katoh, Y.; Kumar, N.A.P.K.A.P.K. Mechanical properties of single-crystal tungsten irradiated in a mixed spectrum fission reactor. J. Nucl. Mater. 2019, 518, 208–225. [Google Scholar] [CrossRef]

- Wang, G.; Li, H.; Li, X.; Li, C.; Li, X.; Xu, R.; Zhu, R.; Li, L.; Zhang, H.; Zhao, Y.; et al. Evolution of low-mode asymmetries introduced by x-ray P2 drive asymmetry during double shell implosions on the SG facility. Nucl. Fusion 2024, 64, 126002. [Google Scholar] [CrossRef]

- Papadakis, D.; Mergia, K.; Manios, E.; Chatzikos, V.; Dellis, S.; Terentyev, D.; Bonny, G.; Van Renterghem, W.; Chang, C.C.; Messoloras, S. Defect evolution of neutron irradiated ITER grade tungsten after annealing. Fusion Eng. Des. 2023, 189, 113486. [Google Scholar] [CrossRef]

- Papadakis, D.; Mergia, K.; Manios, E.; Chatzikos, V.; Dellis, S.; Messoloras, S. Post neutron irradiation annealing and defect evolution in single crystal tungsten. Nucl. Mater. Energy 2023, 34, 101357. [Google Scholar] [CrossRef]

- Lhuillier, P.E.; Barthe, M.F.; Desgardin, P.; Egger, W.; Sperr, P. Positron annihilation studies on the nature and thermal behaviour of irradiation induced defects in tungsten. Phys. Status Solidi C 2009, 6, 2329–2332. [Google Scholar] [CrossRef]

- Horvath, B.; Dai, Y.; Lee, Y. Annealing effect on the microstructure of tungsten irradiated in SINQ target. J. Nucl. Mater. 2018, 506, 19–25. [Google Scholar] [CrossRef]

- Nambissan, P.M.G.; Sen, P. Positron annihilation study of the annealing behaviour of alpha induced defects in tungsten. Radiat. Eff. Defects Solids 1992, 124, 215–221. [Google Scholar] [CrossRef]

- Ogorodnikova, V.O.; Dubov, L.Y.; Stepanov, V.S.; Terentyev, D.; Funtikov, V.Y.; Shtotsky, V.Y.; Stolbunov, V.S.S.; Efimov, V.; Gutorov, K.; Ogorodnikova, O.V.V.; et al. Annealing of radiation-induced defects in tungsten: Positron annihilation spectroscopy study. J. Nucl. Mater. 2019, 517, 148–151. [Google Scholar] [CrossRef]

- Zibrov, M.; Egger, W.; Heikinheimo, J.; Mayer, M.; Tuomisto, F. Vacancy cluster growth and thermal recovery in hydrogen-irradiated tungsten. J. Nucl. Mater. 2020, 531, 152017. [Google Scholar] [CrossRef]

- Ogorodnikova, O.V.; Gasparyan, Y.; Efimov, V.; Ciupiński; Grzonka, J. Annealing of radiation-induced damage in tungsten under and after irradiation with 20MeV self-ions. J. Nucl. Mater. 2014, 451, 379–386. [Google Scholar] [CrossRef]

- Chauhan, A.; Yuan, Q.; Litvinov, D.; Gaganidze, E.; Schneider, H.C.; Terentyev, D.; Aktaa, J. Effect of temperature on the neutron irradiation-induced cavities in tungsten. Philos. Mag. 2022, 102, 1665–1683. [Google Scholar] [CrossRef]

- Wang, S.; Guo, W.; Wang, H.; Yi, X.; Ge, L.; Sun, Y.; Cheng, L.; Zhang, X.; Yuan, Y.; Cao, X.; et al. Defect annealing in heavy-ion irradiated tungsten: Long-time thermal evolution of saturated displacement damage at different temperatures. J. Nucl. Mater. 2023, 581, 154454. [Google Scholar] [CrossRef]

- Breidi, A.; Dudarev, S.L. Dislocation dynamics simulation of thermal annealing of a dislocation loop microstructure. J. Nucl. Mater. 2022, 562, 153552. [Google Scholar] [CrossRef]

- Zakharova, M.I.; Artemov, N.A.; Bogdanov, V.V. Effects of neutron irradiation and annealing on the elastic moduli and electrical resistivity of molybdenum and tungsten single crystals. Inorg. Mater. 2001, 37, 786–789. [Google Scholar] [CrossRef]

- Zibrov, M.; Dürbeck, T.; Egger, W.; Mayer, M. High temperature recovery of radiation defects in tungsten and its effect on deuterium retention. Nucl. Mater. Energy 2020, 23, 100747. [Google Scholar] [CrossRef]

- Burke, J.E.; Turnbull, D. Recrystallization and grain growth. Prog. Met. Phys. 1952, 3, 220–292. [Google Scholar] [CrossRef]

- Pantleon, W. Thermal stability of the microstructure in rolled tungsten for fusion reactors. Phys. Scr. 2021, 96, 124036. [Google Scholar] [CrossRef]

- Alfonso, A.; Juul Jensen, D.; Luo, G.N.; Pantleon, W. Thermal stability of a highly-deformed warm-rolled tungsten plate in the temperature range 1100–1250 °C. Fusion Eng. Des. 2015, 98–99, 1924–1928. [Google Scholar] [CrossRef]

- Ciucani, U.M.; Thum, A.; Devos, C.; Pantleon, W. Recovery and recrystallization kinetics of differently rolled, thin tungsten plates in the temperature range from 1325 °C to 1400 °C. Nucl. Mater. Energy 2019, 20, 100701. [Google Scholar] [CrossRef]

- Yu, M.; Wang, K.; Zan, X.; Pantleon, W.; Luo, L.; Zhu, X.; Wu, Y. Hardness loss and microstructure evolution of 90% hot-rolled pure tungsten at 1200–1350 °C. Fusion Eng. Des. 2017, 125, 531–536. [Google Scholar] [CrossRef][Green Version]

- Richou, M.; Durif, A.; Lenci, M.; Mondon, M.; Minissale, M.; Gallais, L.; Kermouche, G.; De Temmerman, G. Recrystallization at high temperature of two tungsten materials complying with the ITER specifications. J. Nucl. Mater. 2020, 542, 152418. [Google Scholar] [CrossRef]

- Ciucani, U.M.; Pantleon, W. Stagnant recrystallization in warm-rolled tungsten in the temperature range from 1150 °C to 1300 °C. Fusion Eng. Des. 2019, 146, 814–817. [Google Scholar] [CrossRef]

- Alfonso, A.; Juul Jensen, D.; Luo, G.N.; Pantleon, W. Recrystallization kinetics of warm-rolled tungsten in the temperature range 1150–1350 °C. J. Nucl. Mater. 2014, 455, 591–594. [Google Scholar] [CrossRef]

- Levin, Z.S.; Brady, B.G.; Foley, D.C.; Hartwig, K.T. Recrystallization behavior of tungsten processed by equal channel angular extrusion at low homologues temperature: Microstructure, hardness, and texture. Int. J. Refract. Met. Hard Mater. 2019, 83, 104966. [Google Scholar] [CrossRef]

- Tsuchida, K.; Miyazawa, T.; Hasegawa, A.; Nogami, S.; Fukuda, M. Recrystallization behavior of hot-rolled pure tungsten and its alloy plates during high-temperature annealing. Nucl. Mater. Energy 2018, 15, 158–163. [Google Scholar] [CrossRef]

- Xia, F.Z.; Wei, H.G.; Wang, M.P.; Zhu, D.H. Investigation of normal recrystallization and abnormal recrystallization in pure tungsten sheet by EBSD. Int. J. Refract. Met. Hard Mater. 2015, 52, 98–103. [Google Scholar] [CrossRef]

- Nogami, S.; Hasegawa, A.; Fukuda, M.; Rieth, M.; Reiser, J.; Pintsuk, G. Mechanical properties of tungsten: Recent research on modified tungsten materials in Japan. J. Nucl. Mater. 2021, 543, 152506. [Google Scholar] [CrossRef]

- Wang, K.; Zan, X.; Yu, M.; Pantleon, W.; Luo, L.; Zhu, X.; Li, P.; Wu, Y. Effects of thickness reduction on recrystallization process of warm-rolled pure tungsten plates at 1350 °C. Fusion Eng. Des. 2017, 125, 521–525. [Google Scholar] [CrossRef]

- Wang, K.; Ren, D.; Zan, X.; Luo, L.; Zhu, X.; Wu, Y. Recrystallization behavior of pure tungsten hot-rolled with high accumulated strain during annealing at 1250 °C–1350 °C. Mater. Sci. Eng. A 2021, 806, 140828. [Google Scholar] [CrossRef]

- Tanure, L.; Terentyev, D.; Nikolić, V.; Riesch, J.; Verbeken, K. EBSD characterization of pure and K-doped tungsten fibers annealed at different temperatures. J. Nucl. Mater. 2020, 537, 152201. [Google Scholar] [CrossRef]

- Lied, P.; Bonnekoh, C.; Pantleon, W.; Stricker, M.; Hoffmann, A.; Reiser, J. Comparison of K-doped and pure cold-rolled tungsten sheets: As-rolled condition and recrystallization behaviour after isochronal annealing at different temperatures. Int. J. Refract. Met. Hard Mater. 2019, 85, 105047. [Google Scholar] [CrossRef]

- Pintsuk, G.; Antusch, S.; Weingaertner, T.; Wirtz, M. Recrystallization and composition dependent thermal fatigue response of different tungsten grades. Int. J. Refract. Met. Hard Mater. 2018, 72, 97–103. [Google Scholar] [CrossRef]

- Tanure, L.; Bakaeva, A.; Dubinko, A.; Terentyev, D.; Verbeken, K. Effect of annealing on microstructure, texture and hardness of ITER-specification tungsten analyzed by EBSD, vickers micro-hardness and nano-indentation techniques. J. Nucl. Mater. 2019, 524, 191–199. [Google Scholar] [CrossRef]

- Wang, K.; Sun, H.; Zan, X.; Ciucani, U.M.; Pantleon, W.; Luo, L.; Wu, Y. Evolution of microstructure and texture of moderately warm-rolled pure tungsten during annealing at 1300 °C. J. Nucl. Mater. 2020, 540, 152412. [Google Scholar] [CrossRef]

- Reiser, J.; Bonnekoh, C.; Karcher, T.; Pfleging, W.; Weygand, D.; Hoffmann, A. Recrystallisation towards a single texture component in heavily cold rolled tungsten (W) sheets and its impact on micromechanics. Int. J. Refract. Met. Hard Mater. 2020, 86, 105084. [Google Scholar] [CrossRef]

- Zhang, X.-X.; Yan, Q.-Z.; Yang, C.-T.; Wang, T.-N.; Xia, M.; Ge, C.-C. Recrystallization temperature of tungsten with different deformation degrees. Rare Met. 2016, 35, 566–570. [Google Scholar] [CrossRef]

- Ciucani, U.M.; Thum, A.; Devos, C.; Pantleon, W. Isothermal annealing of thin rolled tungsten plates in the temperature range from 1300 °C to 1400 °C. Nucl. Mater. Energy 2018, 15, 128–134. [Google Scholar] [CrossRef]

- Papadakis, D.; Mergia, K. The effect of microstructure on recovery and recrystallization after annealing of two neutron irradiated ITER specification tungsten. Int. J. Refract. Met. Hard Mater. 2024, 121, 106657. [Google Scholar] [CrossRef]

- Krimpalis, S.; Mergia, K.; Messoloras, S.; Dubinko, A.; Terentyev, D.; Triantou, K.; Reiser, J.; Pintsuk, G. Comparative study of the mechanical properties of different tungsten materials for fusion applications. Phys. Scr. 2017, T170, 014068. [Google Scholar] [CrossRef]

- Plansee SE Brochure: Tungsten, 663 DE 02.09 2000. Available online: https://www.plansee.com/en/materials/tungsten.html (accessed on 23 July 2019).

- Sublet, J.C.; Bondarenko, I.P.; Bonny, G.; Conlin, J.L.; Gilbert, M.R.; Greenwood, L.R.; Griffin, P.J.; Helgesson, P.; Iwamoto, Y.; Khryachkov, V.A.; et al. Neutron-induced damage simulations: Beyond defect production cross-section, displacement per atom and iron-based metrics. Eur. Phys. J. Plus 2019, 134, 350. [Google Scholar] [CrossRef]

- Pelowitz, D.; Durkee, J.; Elson, J.; Fensin, M.; Hendricks, J.; James, M.; Johns, R.; Mckinney, G.; Mashnik, S.; Verbeke, J.; et al. MCNPX 2.7.0 Extensions; Los Alamos National Laboratory (LANL): Los Alamos, NM, USA, 2011. [Google Scholar] [CrossRef]

- Norgett, M.J.; Robinson, M.T.; Torrens, I.M. A proposed method of calculating displacement dose rates. Nucl. Eng. Des. 1975, 33, 50–54. [Google Scholar] [CrossRef]

- Breidokaite, S.; Stankunas, G. Neutron Flux in EU DEMO Divertor Cassette Body Using HCPB and WCLL Breeding Blanket Models. J. Fusion Energy 2022, 41, 14. [Google Scholar] [CrossRef]

- Federici, G.; Biel, W.; Gilbert, M.R.; Kemp, R.; Taylor, N.; Wenninger, R. European DEMO design strategy and consequences for materials. Nucl. Fusion 2017, 57, 092002. [Google Scholar] [CrossRef]

- Chatzikos, V.; Mergia, K.; Bonny, G.; Terentyev, D.; Papadakis, D.; Pavlou, G.E.; Messoloras, S. Positron annihilation spectroscopy investigation of defects in neutron irradiated tungsten materials. Int. J. Refract. Met. Hard Mater. 2022, 105, 105838. [Google Scholar] [CrossRef]

- Sublet, J.-C.; Eastwood, J.W.; Morgan, J.G.; Gilbert, M.R.; Fleming, M.; Arter, W. FISPACT-II: An Advanced Simulation System for Activation, Transmutation and Material Modelling. Nucl. Data Sheets 2017, 139, 77–137. [Google Scholar] [CrossRef]

- Black, D.R.; Mendenhall, M.H.; Brown, C.M.; Henins, A.; Filliben, J.; Cline, J.P. Certification of Standard Reference Material 660c for powder diffraction. Powder Diffr. 2020, 35, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Mergia, K.; Chatzikos, V.; Manios, E.; Dellis, S.; Papadakis, D.; Terentyev, D.; Bonny, G.; Dubinko, A.; Stamatelatos, I.E.; Messoloras, S.; et al. Evolution of microstructure in neutron irradiated cold rolled tungsten and its correlation with hardness. Fusion Eng. Des. 2021, 172, 112784. [Google Scholar] [CrossRef]

- Giebel, D.; Kansy, J. A New Version of LT Program for Positron Lifetime Spectra Analysis. Mater. Sci. Forum 2010, 666, 138–141. [Google Scholar] [CrossRef]

- Giebel, D.; Kansy, J. LT10 Program for Solving Basic Problems Connected with Defect Detection. Phys. Procedia 2012, 35, 122–127. [Google Scholar] [CrossRef]

- Miccoli, I.; Edler, F.; Pfnür, H.; Tegenkamp, C. The 100th anniversary of the four-point probe technique: The role of probe geometries in isotropic and anisotropic systems. J. Phys. Condens. Matter 2015, 27, 223201. [Google Scholar] [CrossRef] [PubMed]

- ASTM E112-12; Standard Test Methods for Determining Average Grain Size. ASTM: West Conshohocken, PA, USA, 2024.

- Bassani, F.; Liedl, G.L.; Wyder, P. Encyclopedia of Condensed Matter Physics; Elsevier: Amsterdam, The Netherlands, 2005; ISBN 9780123694010. [Google Scholar]

- Hu, Z.; Desgardin, P.; Genevois, C.; Joseph, J.; Décamps, B.; Schäublin, R.; Barthe, M.-F. Effect of purity on the vacancy defects induced in self–irradiated tungsten: A combination of PAS and TEM. J. Nucl. Mater. 2021, 556, 153175. [Google Scholar] [CrossRef]

- Krsjak, V.; Kuriplach, J.; Shen, T.; Sabelova, V.; Sato, K.; Dai, Y. Helium behavior in ferritic/martensitic steels irradiated in spallation target. J. Nucl. Mater. 2015, 456, 382–388. [Google Scholar] [CrossRef]

- Pang, J.; Li, H.; Zhou, K.; Wang, Z. The correlation between dislocations and vacancy defects using positron annihilation spectroscopy. Plasma Sci. Technol. 2012, 14, 650–655. [Google Scholar] [CrossRef]

- Yabuuchi, A. Inverse change in positron lifetimes of vacancies in tungsten by binding of interstitial impurity atoms to a vacancy: A first-principles study. Nucl. Mater. Energy 2023, 34, 101364. [Google Scholar] [CrossRef]

- Yabuuchi, A.; Tanaka, M.; Kinomura, A. Short positron lifetime at vacancies observed in electron-irradiated tungsten: Experiments and first-principles calculations. J. Nucl. Mater. 2020, 542, 152473. [Google Scholar] [CrossRef]

- Sato, K.; Hirosako, A.; Ishibashi, K.; Miura, Y.; Xu, Q.; Onoue, M.; Fukutoku, Y.; Onitsuka, T.; Hatakeyama, M.; Sunada, S.; et al. Quantitative evaluation of hydrogen atoms trapped at single vacancies in tungsten using positron annihilation lifetime measurements: Experiments and theoretical calculations. J. Nucl. Mater. 2017, 496, 9–17. [Google Scholar] [CrossRef]

- Čížek, J. Characterization of lattice defects in metallic materials by positron annihilation spectroscopy: A review. J. Mater. Sci. Technol. 2018, 34, 577–598. [Google Scholar] [CrossRef]

- Papadakis, D.; Dellis, S.; Chatzikos, V.; Manios, E.; Stamatelatos, I.E.; Messoloras, S.; Mergia, K. Neutron irradiation effects in different tungsten microstructures. Phys. Scr. 2021, 96, 124041. [Google Scholar] [CrossRef]

- Eldrup, M.; Singh, B.N. Studies of defects and defect agglomerates by positron annihilation spectroscopy. J. Nucl. Mater. 1997, 251, 132–138. [Google Scholar] [CrossRef]

- Troev, T.; Popov, E.; Nankov, N.; Yoshiie, T. Model calculation of positron states in tungsten containing hydrogen and helium. J. Phys. Conf. Ser. 2010, 207, 012033. [Google Scholar] [CrossRef]

- Brailsford, A.D.; Bullough, R. The rate theory of swelling due to void growth in irradiated metals. J. Nucl. Mater. 1972, 44, 121–135. [Google Scholar] [CrossRef]

- Dürrschnabel, M.; Klimenkov, M.; Jäntsch, U.; Rieth, M.; Schneider, H.C.; Terentyev, D. New insights into microstructure of neutron-irradiated tungsten. Sci. Rep. 2021, 11, 7572. [Google Scholar] [CrossRef] [PubMed]

- Brandt, W.; Paulin, R. Positron Diffusion in Solids. Phys. Rev. B 1972, 5, 2430–2435. [Google Scholar] [CrossRef]

- Eldeup, M.; Jensen, K.O. Positron Trapping Rates into Cavities in Al: Temperature and Size Effects. Phys. Status Solidi 1987, 102, 145–152. [Google Scholar] [CrossRef]

- Nieminen, R.M.; Laakkonen, J. Positron trapping rate into vacancy clusters. Appl. Phys. 1979, 20, 181–184. [Google Scholar] [CrossRef]

- Bakonyi, I. Accounting for the Resistivity Contribution of Grain Boundaries in Metals: Critical Analysis of Reported Experimental and Theoretical Data for Ni and Cu; Springer: Berlin/Heidelberg, Germany, 2021; Volume 136, ISBN 0123456789. [Google Scholar]

- Andrews, P.V. Resistivity due to grain boundaries in pure copper. Phys. Lett. 1965, 19, 558–560. [Google Scholar] [CrossRef]

- Echols, J.R.; Garrison, L.M.; Reid, N.; Parish, C.M.; Hasegawa, A.; Bhattacharya, A.; Zhong, W.; Morrall, D.; Lance, M.; Katoh, Y. Degradation of electrical resistivity of tungsten following shielded neutron irradiation. Acta Mater. 2023, 257, 119025. [Google Scholar] [CrossRef]

- Rossiter, P.L. The electrical resistivity of metals and alloys. Electr. Resist. Met. Alloy. 1987, 9–10. [Google Scholar] [CrossRef]

- Martin, J.W.; Paetsch, R. Electrical resistivity of voids. J. Phys. F Met. Phys. 1973, 3, 907–917. [Google Scholar] [CrossRef]

- Martin, J.W. The electrical resistivity due to structural defects. Philos. Mag. 1971, 24, 555–566. [Google Scholar] [CrossRef]

- Martin, J.W. The electrical resistivity of some lattice defects in FCC metals observed in radiation damage experiments. J. Phys. F Met. Phys. 1972, 2, 842–853. [Google Scholar] [CrossRef]

- Rasch, K.D.; Siegel, R.W.; Schultz, H. Quenching and recovery investigations of vacancies in tungsten. Philos. Mag. A Phys. Condens. Matter. Struct. Defects Mech. Prop. 1980, 41, 91–117. [Google Scholar] [CrossRef]

- Uray, L.; Tekula-Buxbaum, P. Resistivity contribution of solutes in tungsten. J. Less Common Met. 1986, 123, 95–100. [Google Scholar] [CrossRef]

- Tanno, T.; Hasegawa, A.; Fujiwara, M.; He, J.-C.; Nogami, S.; Satou, M.; Shishido, T.; Abe, K. Precipitation of Solid Transmutation Elements in Irradiated Tungsten Alloys. Mater. Trans. 2008, 49, 2259–2264. [Google Scholar] [CrossRef]

- Van Renterghem, W.; Bonny, G.; Terentyev, D. TEM investigation of neutron irradiated and post irradiation annealed tungsten materials. Fusion Eng. Des. 2022, 180, 113170. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Fundamentals of Materials Science and Engineering: An Integrated Approach; Wiley: Hoboken, NJ, USA, 2015; Volume 964. [Google Scholar]

- Chen, Y.; Ma, J.; Li, W. Understanding the thermal conductivity and Lorenz number in tungsten from first principles. Phys. Rev. B 2019, 99, 020305. [Google Scholar] [CrossRef]

- Tolias, P. Analytical expressions for thermophysical properties of solid and liquid tungsten relevant for fusion applications. Nucl. Mater. Energy 2017, 13, 42–57. [Google Scholar] [CrossRef]

- Harris, G.B. Quantitative measurement of preferred orientation in rolled uranium bars. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1952, 43, 113–123. [Google Scholar] [CrossRef]

- Birkholz, M. Thin Film Analysis by X-Ray Scattering; Wiley: Hoboken, NJ, USA, 2005; ISBN 9783527310524. [Google Scholar]

- Tabor, D. The physical meaning of indentation and scratch hardness. Br. J. Appl. Phys. 1956, 7, 159–166. [Google Scholar] [CrossRef]

- Stoller, R.E.E.; Zinkle, S.J.J. On the relationship between uniaxial yield strength and resolved shear stress in polycrystalline materials. J. Nucl. Mater. 2000, 283–287, 349–352. [Google Scholar] [CrossRef]

- Hu, X.; Koyanagi, T.; Fukuda, M.; Kumar, N.A.P.K.; Snead, L.L.; Wirth, B.D.; Katoh, Y. Irradiation hardening of pure tungsten exposed to neutron irradiation. J. Nucl. Mater. 2016, 480, 235–243. [Google Scholar] [CrossRef]

- Xiao, X.; Terentyev, D.; Ruiz, A.; Zinovev, A.; Bakaev, A.; Zhurkin, E.E. High temperature nano-indentation of tungsten: Modelling and experimental validation. Mater. Sci. Eng. A 2019, 743, 106–113. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Matsukawa, Y. Observation and analysis of defect cluster production and interactions with dislocations. J. Nucl. Mater. 2004, 329–333, 88–96. [Google Scholar] [CrossRef]

- Terentyev, D.; Xiao, X.; Dubinko, A.; Bakaeva, A.; Duan, H. Dislocation-mediated strain hardening in tungsten: Thermo-mechanical plasticity theory and experimental validation. J. Mech. Phys. Solids 2015, 85, 1–15. [Google Scholar] [CrossRef]

- Yi, X.; Sand, A.E.; Mason, D.R.; Kirk, M.A.; Roberts, S.G.; Nordlund, K.; Dudarev, S.L. Direct observation of size scaling and elastic interaction between nano-scale defects in collision cascades. EPL Europhys. Lett. 2015, 110, 36001. [Google Scholar] [CrossRef]

| Impurities | Ag | Al | As | Ba | Ca | Cd | Co | Cr | Cu | Fe | K | Mg | Mn | Na | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Guaranteed [μg/g] | 10 | 15 | 5 | 5 | 5 | 5 | 10 | 20 | 10 | 30 | 10 | 5 | 5 | 10 | 10 |

| Typical [μg/g] | <5 | 5 | <2 | <2 | <2 | <2 | <2 | <5 | <5 | 10 | 5 | <2 | <2 | <2 | <5 |

| Impurities | Ni | Pb | Ta | Ti | Zn | Zr | Mo | C | H | N | O | P | S | Si | |

| Guaranteed [μg/g] | 5 | 5 | 20 | 5 | 5 | 5 | 100 | 30 | 5 | 5 | 20 | 20 | 5 | 20 | |

| Typical [μg/g] | <2 | <2 | <10 | <2 | <2 | <2 | 20 | 10 | 2 | <2 | 5 | <10 | <2 | 5 |

| Sample | Mean Subgrain Size, μ (μm) | Standard Deviation, σ (μm) | |

|---|---|---|---|

| Non-irradiated | 2.85 ± 0.06 | 1.35 ± 0.04 | |

| As-irradiated | 2.54 ± 0.05 | 0.97 ± 0.03 | |

| Control—1450 °C | 46 ± 1 | 25.0 ± 0.7 | |

| PIA—1550 °C | Fine grain distrib. | 7.3 ± 0.2 | 2.6 ± 0.1 |

| Coarse grain distrib. | 41 ± 2 | 20 ± 2 | |

| Mechanism | Temperature (°C) |

|---|---|

| Vacancy de-trapping and migration | 700–750 |

| Dislocation Recovery I—loop growth | 700–900, 900–1150 |

| Dislocation Recovery II—loop dissolution | 1150–1550 |

| Nearly complete dislocation annihilation | ~1280 |

| Increase in void size—Ostwald ripening | 900–1150 |

| Void dissolution | 1250–1450 |

| Re-segregation and/or agglomeration | 1250–1450 |

| Recrystallization | 1450 |

| Re/WRe/WOs phase formation | 1550 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadakis, D.; Manios, E.; Mergia, K. Post Neutron Irradiation Recovery and Recrystallization of ITER Grade Forged Tungsten Bar. Metals 2025, 15, 172. https://doi.org/10.3390/met15020172

Papadakis D, Manios E, Mergia K. Post Neutron Irradiation Recovery and Recrystallization of ITER Grade Forged Tungsten Bar. Metals. 2025; 15(2):172. https://doi.org/10.3390/met15020172

Chicago/Turabian StylePapadakis, Dimitrios, Efthimios Manios, and Konstantina Mergia. 2025. "Post Neutron Irradiation Recovery and Recrystallization of ITER Grade Forged Tungsten Bar" Metals 15, no. 2: 172. https://doi.org/10.3390/met15020172

APA StylePapadakis, D., Manios, E., & Mergia, K. (2025). Post Neutron Irradiation Recovery and Recrystallization of ITER Grade Forged Tungsten Bar. Metals, 15(2), 172. https://doi.org/10.3390/met15020172