Effect of Aging Temperature on the Impact Wear Properties and Wear Mechanism of Lightweight Wear-Resistant Steel

Abstract

1. Introduction

2. Experimental Materials and Methods

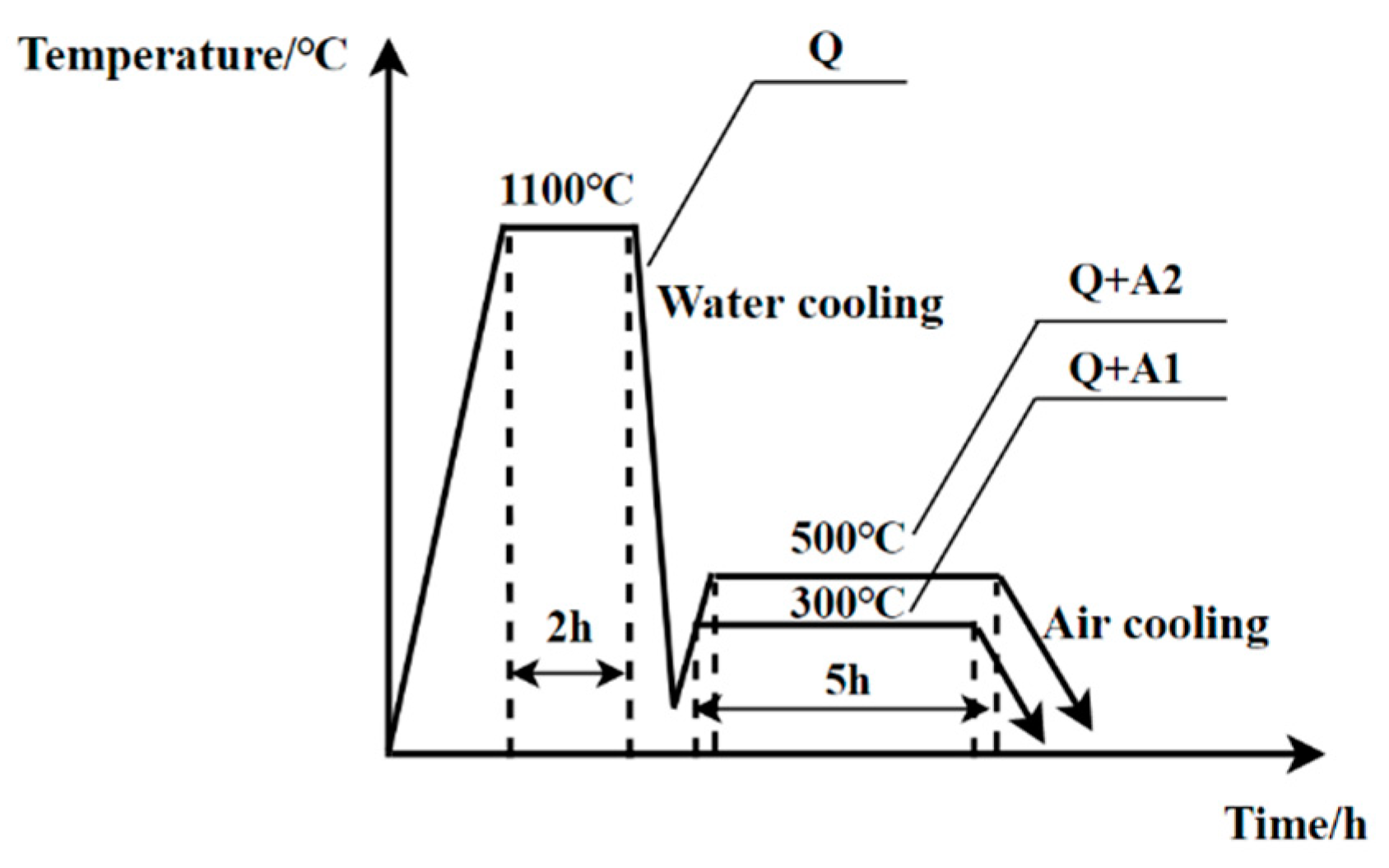

2.1. Raw Material Processing and Heat Treatment Technology

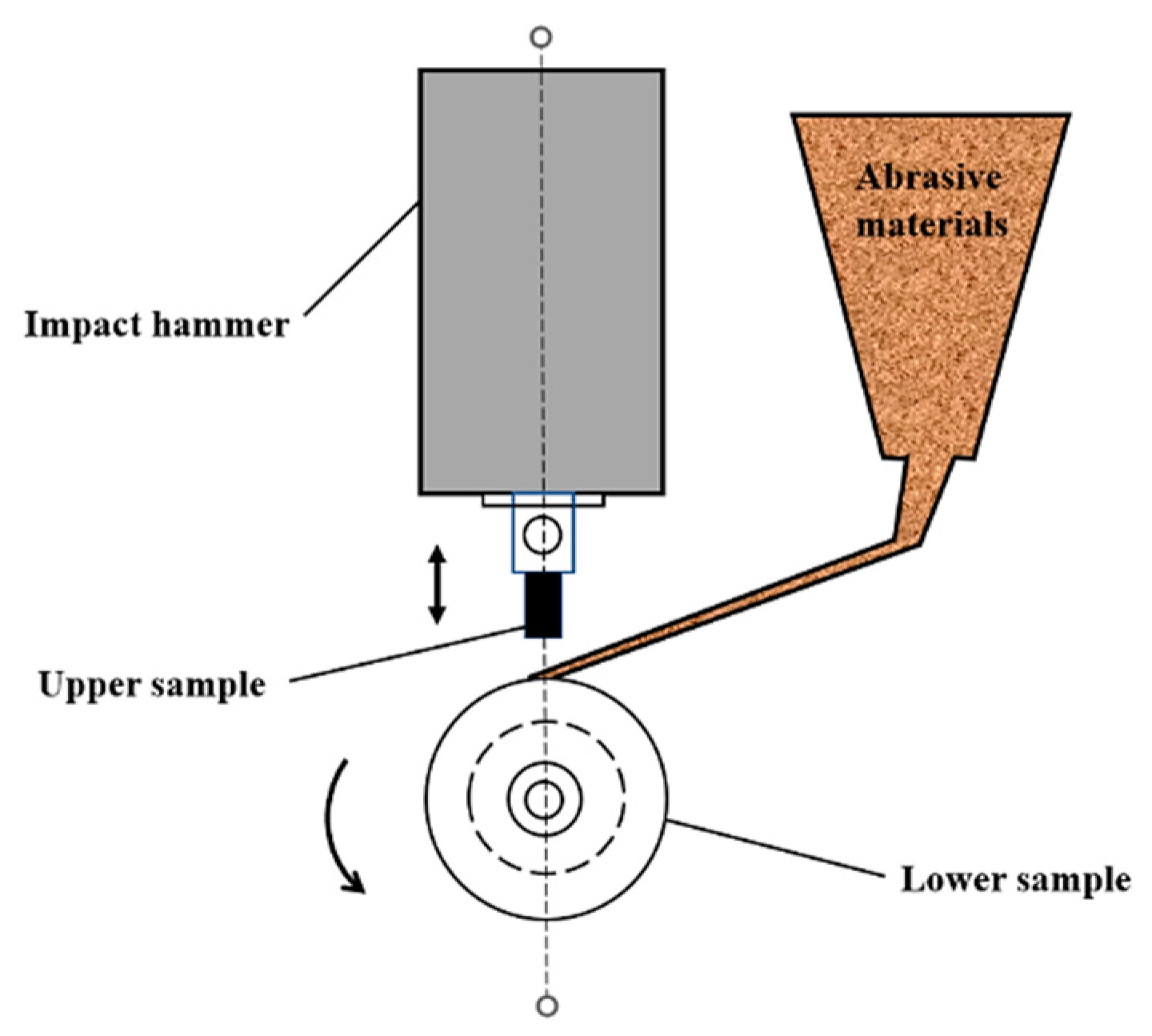

2.2. Impact Abrasive Wear Test

2.3. Analysis Method

3. Results and Discussion

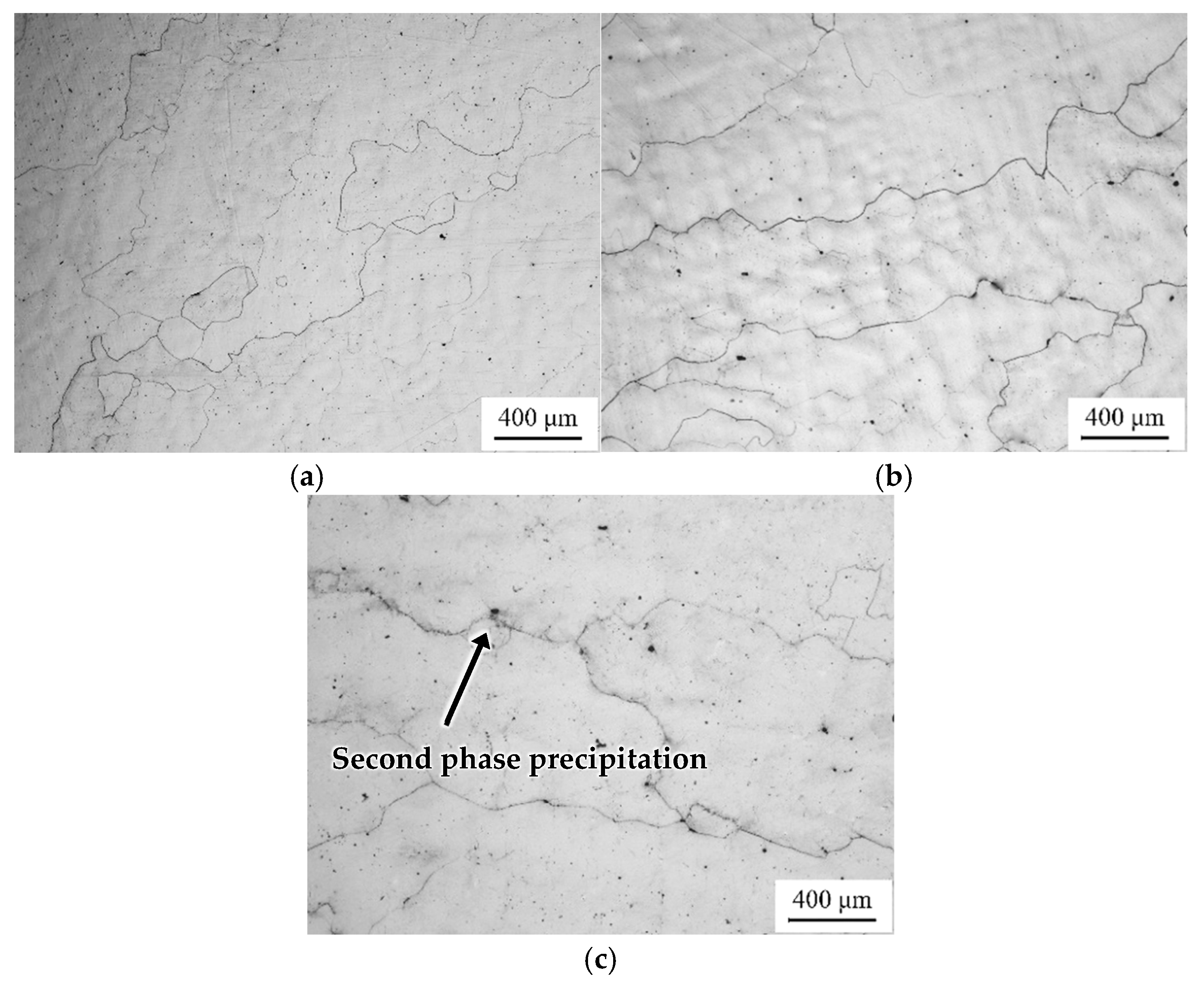

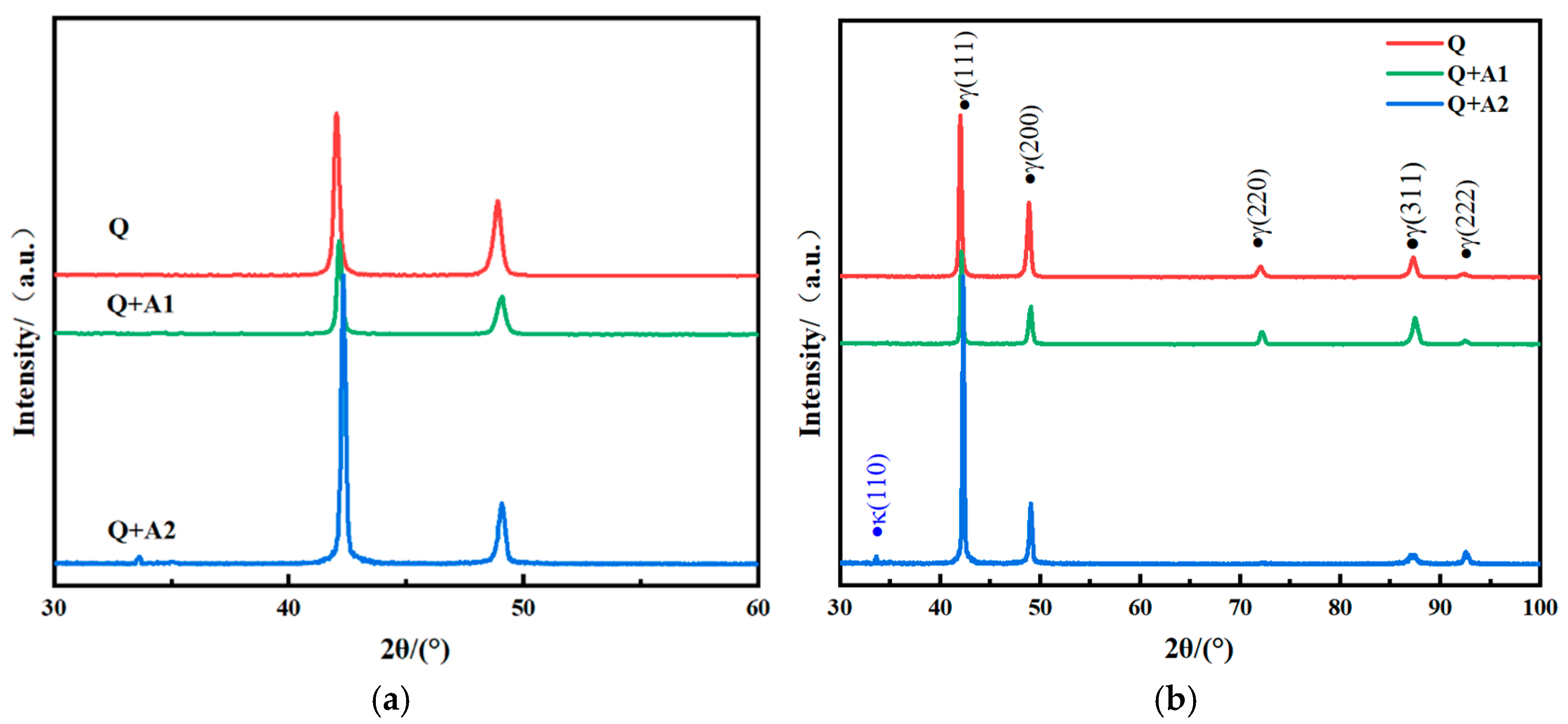

3.1. Microstructure and Mechanical Properties

3.2. Impact Wear Resistance

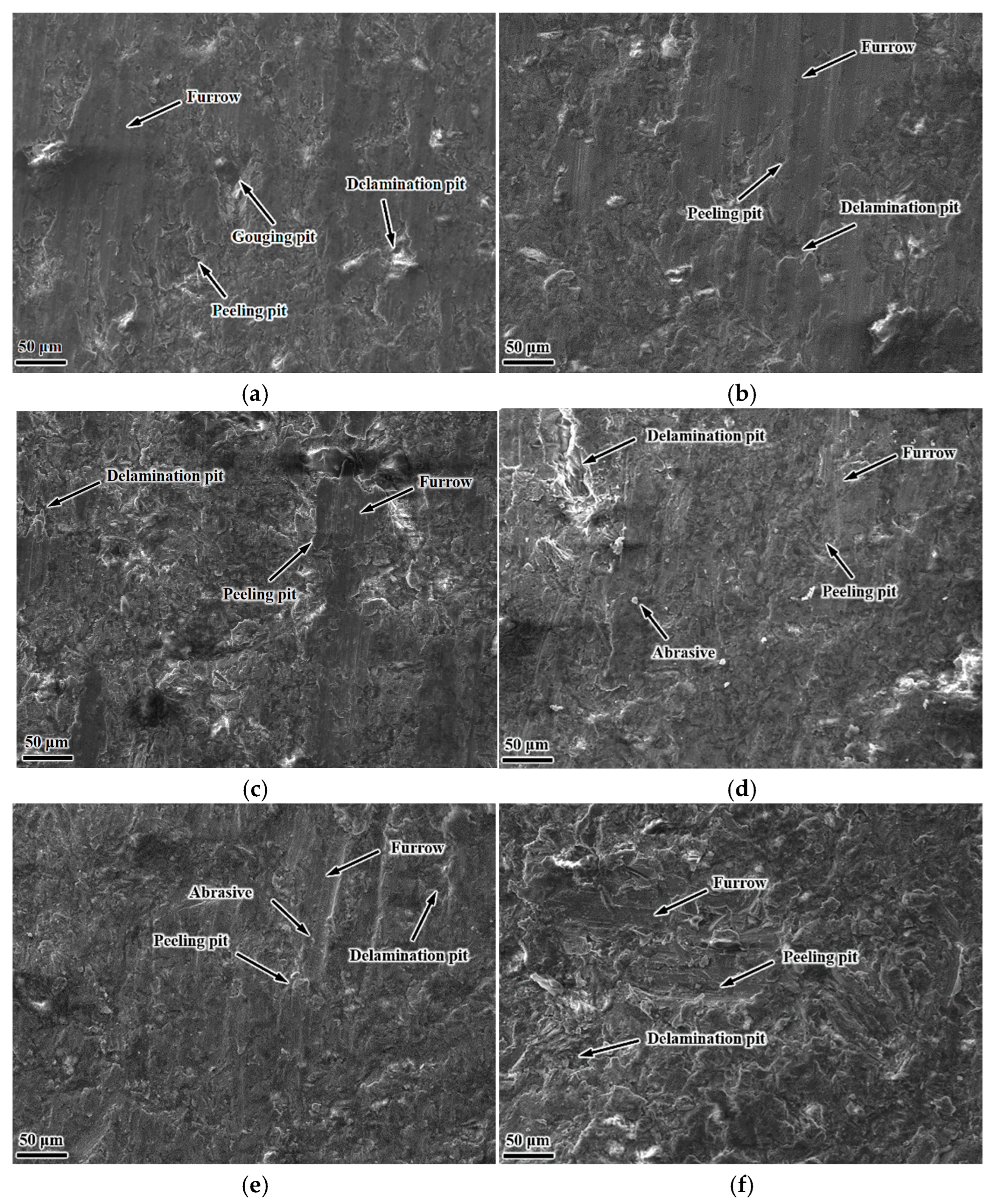

3.3. Impact Wear Mechanism

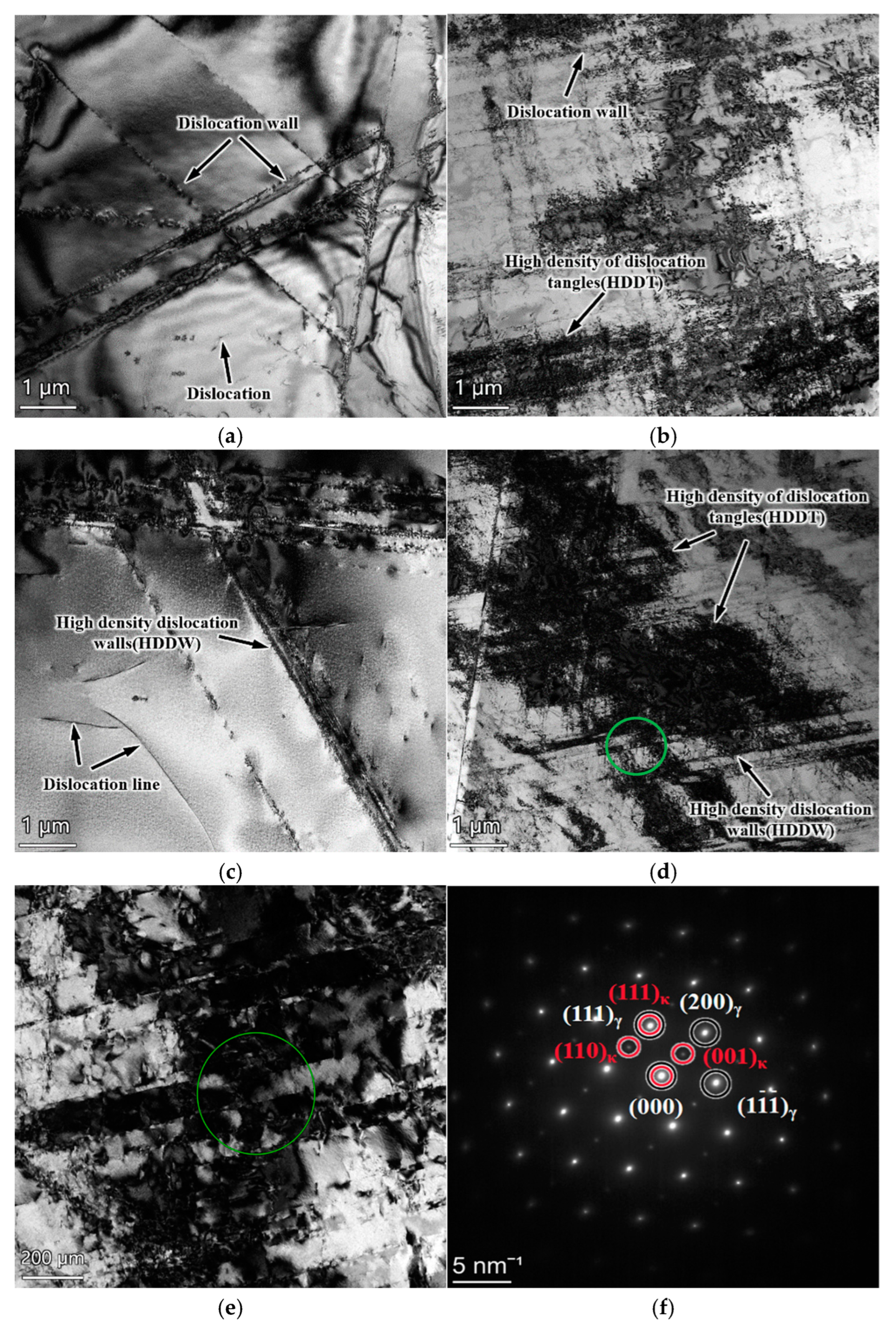

3.4. Work-Hardening Mechanism

4. Conclusions

- After solution treatment (Q) at 1100 °C and heat treatment at different aging temperatures, the matrix structure of Fe-28Mn-8.5Al-1.0C steel is austenite. After aging treatment, nanoscale κ-carbide is precipitated in the crystal and at the grain boundary. With an increase in aging temperature, the quantity and size of κ-carbide increase. After aging treatment (Q + A2) at 500 °C for 5 h, the average area ratio of κ-carbide can reach 1.83%.

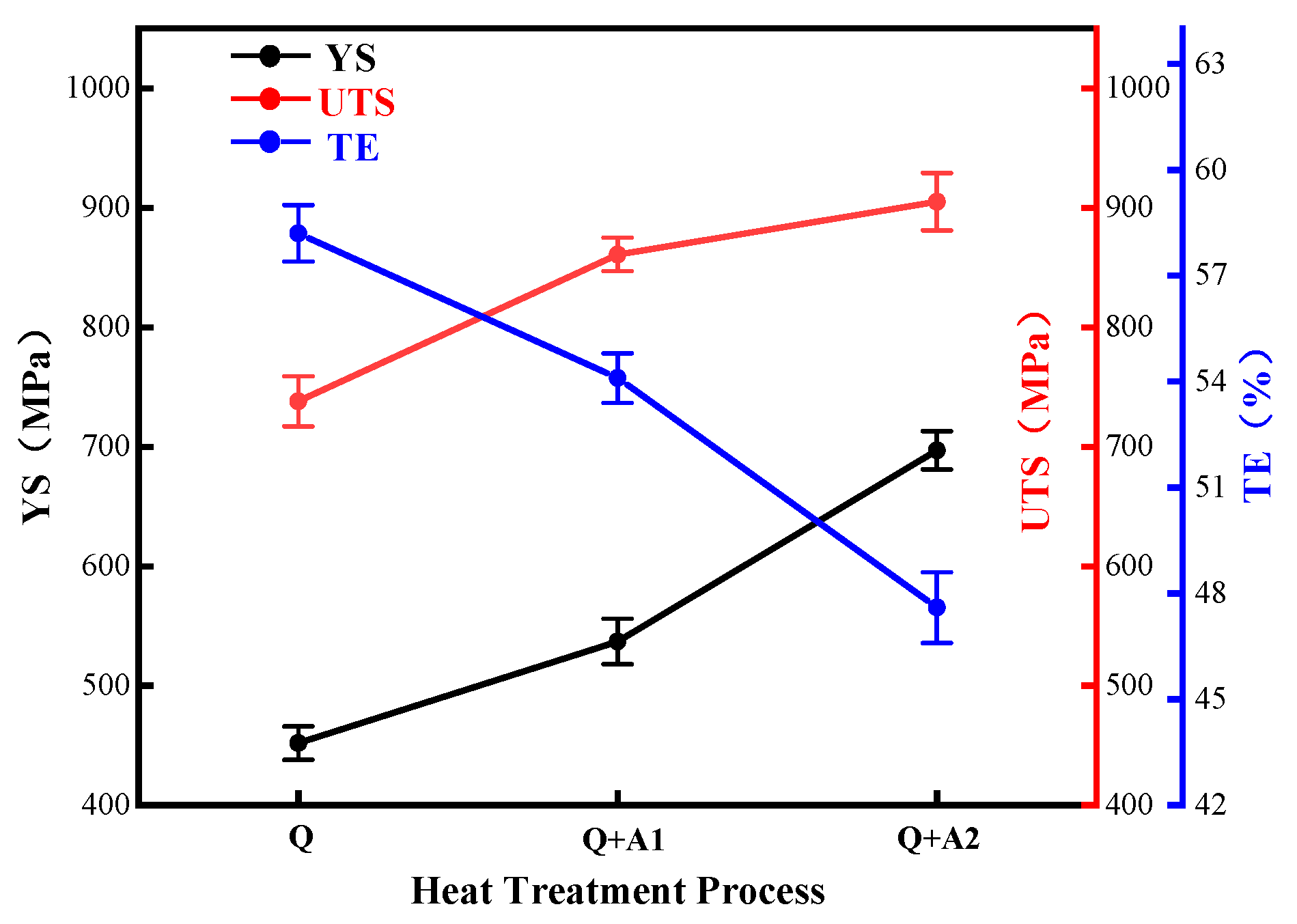

- The second-phase strengthening effect of nanometer-sized κ-carbides is the main reason for the increase in strength and hardness, and the strengthening effect increases with the increase in aging temperature. The yield strength, tensile strength, and hardness of the Q + A2 process are 697 MPa, 905 MPa, and 294 HB, respectively, which are 29.8%, 5.1%, and 6.5% higher than that of the Q + A1 process. However, the continuous precipitation of large-sized κ-carbide at the grain boundary reduces the material’s toughness. Compared with the aging temperature of 500 °C and 300 °C, the elongation and impact energy at −40 °C decrease by 12.0% and 47.1%, respectively.

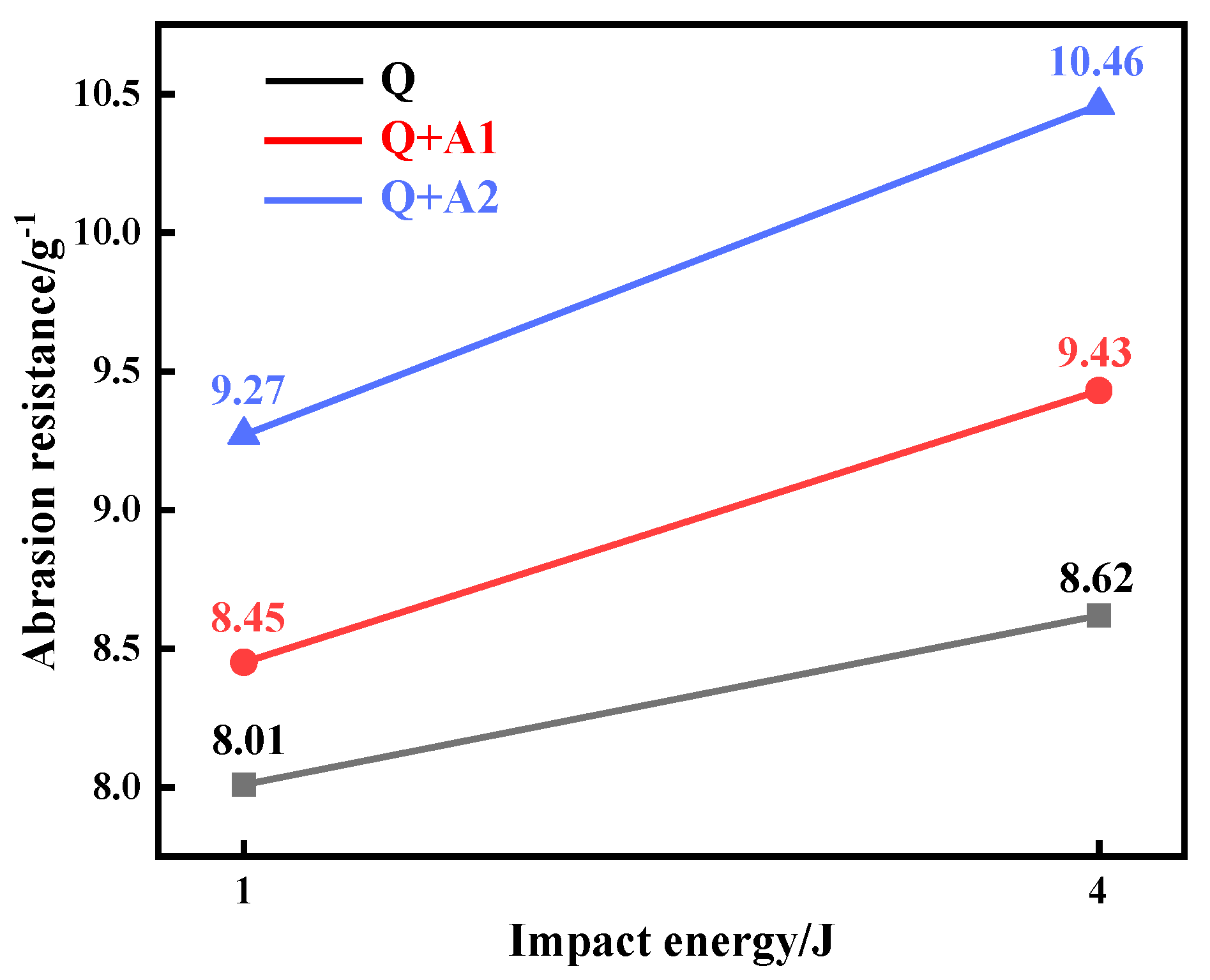

- After aging treatment, the wear resistance of Fe-28Mn-8.5Al-1.0C material is improved. The wear resistance of Fe-28Mn-8.5al-1.0c material under the Q + A2 process is the best, and the wear resistance under 1 J and 4 J of impact energy is 9.27 g−1 and 10.46 g−1, respectively, which is 9.7% and 10.9% higher than that under the Q + A1 process, respectively. The dominant wear mechanism of the material under 4J impact energy after Q + A2 process treatment is plastic deformation. Under the different impact energy wear conditions of Q and Q + A1 heat treatment, the dominant wear mechanism of the material is micro-cutting, followed by fatigue-peeling.

- After aging treatment, the hardening mechanism of the subsurface of the material is the entanglement of the dislocation wall and high-density dislocation, respectively, under different impact work. With an increase in aging temperature, the blocking effect of κ-carbide on dislocation movement is enhanced, which leads to an improvement in the work-hardening effect of the wear surface of the material. Dislocation strengthening caused by the second-phase strengthening and κ-carbide hindering dislocation movement is the main reason for the improvement in the wear resistance of the material, and the combined effect of the two has a significant effect on the comprehensive properties of Fe-28Mn-8.5Al-1.0C steel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, W.; Ning, L. Measures to improve the performance of high manganese steel crushing teeth. Cast. Equip. Technol. 2011, 4, 30–32. [Google Scholar]

- Lin, Y.C.; Wang, S.W.; Chen, T.M. A study on the wear behavior of hardened medium carbon steel. J. Mater. Process. Technol. 2002, 120, 126–132. [Google Scholar] [CrossRef]

- Dastur, Y.N.; Leslie, W.C. Mechanism of work hardening in Hadfield manganese steel. Met. Trans. A 1981, 12, 749–759. [Google Scholar] [CrossRef]

- Abbasi, M.; Kheirandish, S.; Kharrazi, Y.; Hejazi, J. On the comparison of the abrasive wear behavior of aluminum alloyed and standard Hadfield steels. Wear 2010, 268, 202–207. [Google Scholar] [CrossRef]

- Tianfu, J.; Fucheng, Z. The Work-hardening behavior of medium manganese steel under impact abrasive wear condition. Mater. Lett. 1997, 31, 275–279. [Google Scholar] [CrossRef]

- Yan, W.; Fang, L.; Sun, K.; Xu, Y. Effect of surface work hardening on wear behavior of hadfield steel. Mater. Sci. Eng. A 2007, 460–461, 542–549. [Google Scholar] [CrossRef]

- Zhang, G.-S.; Xing, J.-D.; Gao, Y.-M. Impact wear resistance of WC/Hadfield steel composite and its interfacial characteristics. Wear 2006, 260, 728–734. [Google Scholar] [CrossRef]

- Lu, D.S.; Liu, Z.Y.; Li, W.; Liao, Z.; Tian, H.; Xian, J.Z. Influence of carbon content on wear resistance and wear mechanism of Mn13Cr2 and Mn18Cr2 cast steels. China Foundry 2015, 12, 39–47. [Google Scholar]

- Yan, H.; Xie, W.; Wang, W.; Li, J.; Wang, A.; Li, L. Study on microstructure and properties of alloyed high manganese steel ZGMn13CrMo. Hot Work. Technol. 2006, 35, 11–13. [Google Scholar]

- Brüx, U.; Frommeyer, G.; Grässel, O.; Meyer, L.W.; Weise, A. Development and characterization of high strength impact resistant Fe-Mn-(Al-, Si) TRIP/TWIP steels. Steel Res. 2002, 73, 294–298. [Google Scholar] [CrossRef]

- Liu, C.; Peng, Q.; Xue, Z.; Wu, T. Research status of Fe-Mn-Al-C series low density high strength steels. Mater. Rev. 2019, 33, 2572–2581. [Google Scholar]

- Lins, V.F.; Freitas, M.A.; e Silva, E.M. Corrosion resistance study of Fe–Mn–Al–C alloys using immersion and potentiostatic tests. Appl. Surf. Sci. 2005, 250, 124–134. [Google Scholar] [CrossRef]

- Wang, C.-J.; Chang, Y.-C. NaCl-induced hot corrosion of Fe–Mn–Al–C alloys. Mater. Chem. Phys. 2002, 76, 151–161. [Google Scholar] [CrossRef]

- Cheng, W.C.; Cheng, C.Y.; Hsu, C.W.; Laughlin, D.E. Phase transformation of the L1 2 phase to Kappa-carbide after spinodal decomposition and ordering in an Fe–C–Mn–Al austenitic steel. Mater. Sci. Eng. A 2015, 642, 128–135. [Google Scholar] [CrossRef]

- Wang, F.; Sun, T.; Wang, M.; Zhou, X.; Shi, J. Research progress of Fe-Mn-Al-C series Austenitic low density steels. Iron Steel 2021, 56, 89–102. [Google Scholar]

- Peng, S.; Song, R.; Cai, C.; Pei, Z.; Guo, K.; Wangn, Z.; Gao, J. Impact wear properties and mechanism of new lightweight Austenitic wear-resistant steels. Chin. J. Mater. Res. 2017, 31, 537–546. [Google Scholar]

- Ba, Q.; Song, R.; Zhou, N.; Pei, Z.; Feng, Y.; Song, R. Revealing working hardening behavior and substructure evolutions of ultrahigh strength and enhanced wear resistance Fe-25Mn-7Al-1C steel treated by explosion processing. J. Mater. Sci. 2020, 55, 1256–1268. [Google Scholar] [CrossRef]

- Zheng, Z.B.; Yang, H.K.; Shatrava, A.P.; Long, J.; Wang, Y.H.; Li, J.X.; Zheng, K.H. Work hardening behavior and fracture mechanisms of Fe-18Mn-1.3C-2Cr low-density steel castings with varying degrees proportions of aluminum alloying. Mater. Sci. Eng. A 2023, 862, 144467. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Z.; Li, J.; Wang, P. Effect of Solution and Aging Treatment on Microstructure and Hardness of Fe-Mn-Al-C Light steel. Heat Treat. Met. 2022, 47, 34–39. [Google Scholar]

- Liu, S.; Li, S.; Bai, H.; Zhang, X.; Ding, H. Effect of Annealing and Aging on Microstructure and Properties of Fe-12Mn-7Al-0.6C-0.5V Low Density Steel. J. Mater. Metall. 2020, 12, 134–141. [Google Scholar]

- Wang, H.T.; Tao, N.R.; Lu, K. Strengthening an austenitic Fe–Mn steel using nanotwinned austenitic grains. Acta Mater. 2012, 60, 4027–4040. [Google Scholar]

- Shin, J.-H.; Rim, G.-Y.; Kim, S.-D.; Jang, J.H.; Park, S.-J.; Lee, J. Effects of aging Heat-treatment on dynamic strain aging behavior in high-Mn lightweight steel. Mater. Charact. 2020, 164, 110316. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, C.Y.; Park, I.J.; Lee, Y.K. Isothermal precipitation behavior of κ-carbide in the Fe–9Mn–6Al–0.15C lightweight steel with a multiphase microstructure. J. Alloys Compd. 2013, 574, 299–304. [Google Scholar] [CrossRef]

- Lu, W.J.; Zhang, X.F.; Qin, R.S. κ-carbide hardening in a low-density high-Al high-Mn multiphase steel. Mater. Lett. 2015, 138, 96–99. [Google Scholar]

- Kim, J.; Estrin, Y.; De Cooman, B.C. Application of a dislocation density-based constitutive model to Al-alloyed TWIP steel. Met. Mater. Trans. A 2013, 44, 4168–4182. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.-W.; Kim, N.J. Fe–Al–Mn–C lightweight structural alloys: A review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 014205. [Google Scholar]

- Kalashnikov, I.; Acselrad, O.; Shalkevich, A.; Chumakova, L.; Pereira, L. Heat treatment and thermal stability of FeMnAlC alloys. J. Mech. Work. Technol. 2003, 136, 72–79. [Google Scholar] [CrossRef]

- Hwang, C.N.; Liu, T.F. The as-quenched microstructures of Fe-9Al-30Mn-1.2C-xSi alloys. Scr. Mater. 1997, 36, 853–859. [Google Scholar] [CrossRef]

- Bartlett, L.N.; Van Aken, D.C.; Medvedeva, J.; Isheim, D.; Medvedeva, N.I.; Song, K. An atom probe study of kappa carbide precipitation and the effect of silicon addition. Met. Mater. Trans. A 2014, 45, 2421–2435. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar]

- Zhang, X.; Li, J.; Wan, Y.; Wu, X.; Huang, Z. Research progress of ordered precipitates in low density steels. Mater. Rev. 2019, 33, 3979–3989. [Google Scholar]

- Lu, W.J.; Qin, R.S. Influence of κ-carbide interface structure on the formability of lightweight steels. Mater. Des. 2016, 104, 211–216. [Google Scholar]

- Ren, P.; Chen, X.P.; Mei, L.; Nie, Y.Y.; Cao, W.Q.; Liu, Q. Intragranular brittle precipitates improve strain hardening capability of Fe–30Mn–11Al–1.2C low-density steel. Mater. Sci. Eng. A 2020, 775, 138984. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brüx, U. Microstructures and Mechanical Properties of High-Strength Fe-Mn-Al-C Light-Weight TRIPLEX steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar]

- Cheng, W.-C. Phase transformations of an Fe-0.85 C-17.9 Mn-7.1 Al austenitic steel after quenching and annealing. JOM 2014, 66, 1809–1820. [Google Scholar]

- Wu, H.; Ju, B.; Tang, D.; Hu, R.; Guo, A.; Kang, Q.; Wang, D. Effect of Nb addition on the microstructure and mechanical properties of an 1800MPa ultrahigh strength steel. Mater. Sci. Eng. A 2015, 622, 61–66. [Google Scholar] [CrossRef]

- Ji, F.Q.; Li, C.N.; Tang, S.; Liu, Z.Y.; Wang, G.D. Effects of carbon and niobium on microstructure and properties for Ti bearing steels. Mater. Sci. Technol. 2015, 31, 695–702. [Google Scholar]

- Li, Z.; Wang, Y.; Cheng, X.; Li, Z.; Du, J.; Li, S. The effect of Ti-Mo-Nb on the microstructures and tensile properties of a Fe-Mn-Al-C austenitic steel. Mater. Sci. Eng. A 2020, 780, 139220. [Google Scholar] [CrossRef]

- Yao, M.; Welsch, E.; Ponge, D.; Haghighat, S.; Sandlöbes, S.; Choi, P.; Herbig, M.; Bleskov, I.; Hickel, T.; Lipinska-Chwalek, M.; et al. Strengthening and strain hardening mechanisms in a precipitation-hardened high-Mn lightweight steel. Acta Mater. 2017, 140, 258–273. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S.-J.; De Cooman, B.C. Effect of Al on the stacking fault energy of Fe–18Mn–0.6C twinning-induced plasticity. Scr. Mater. 2011, 65, 363–366. [Google Scholar]

- Cao, C.; Wang, C.; Cao, W. Formation mechanism of κ-carbide in FeMnAlC low-density steel. Heat Treat. Met. 2021, 46, 1–6. [Google Scholar]

- Kim, C.; Terner, M.; Hong, H.U.; Lee, C.H.; Park, S.J.; Moon, J. Influence of inter/intra-granular κ-carbides on the deformation mechanism in lightweight Fe-20Mn-11.5Al-1.2C steel. Mater. Charact. 2020, 161, 110142. [Google Scholar]

- Lu, Z.-L.; Zhou, Y.-X.; Rao, Q.-C.; Jin, Z.-H. An investigation of the abrasive wear behavior of ductile cast iron. J. Mech. Work. Technol. 2001, 116, 176–181. [Google Scholar] [CrossRef]

- Yan, H.; Xie, J.; Wang, W.Y.; Li, J.; Li, L. Study on wear resistance of ultra-high manganese steel and wear behavior of impact abrasives. Foundry Technol. 2007, 28, 618–621+627. [Google Scholar]

- Liu, Y.; Wei, S.; Zang, M. Microstructure and wear resistance of Light weight high Manganese steel. Tribology 2018, 38, 291–298. [Google Scholar]

- Peng, S.-G.; Song, R.-B.; Tan, Z.-D.; Cai, C.H.; Guo, K.; Wang, Z.-H. Abrasive Wear behaviors of light-weight austenitic Fe-24Mn-7Al-1C steel and Mn13Cr2 steel. J. Iron Steel Res. Int. 2016, 23, 857–866. [Google Scholar] [CrossRef]

- Wang, Y.; Si, S. Study on work hardening law and mechanism of high manganese steel. Iron Steel 2001, 10, 54–56. [Google Scholar]

- Feng, Y. Study on Strengthening Mechanism and Impact Wear Behavior of Age-Hardened Lightweight Ultra-High Manganese Steel. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2021. [Google Scholar]

- Gutierrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar]

- Chang, K.M.; Chao, C.G.; Liu, T.F. Excellent combination of strength and ductility in an Fe–9Al–28Mn–1.8C alloy. Scr. Mater. 2010, 63, 162–165. [Google Scholar]

- Meng, L.; Liang, W.; Zhao, X.; Li, X. Effect of strain rate on the size of pure iron dislocation cells. J. Electron Microsc. 2005, 24, 295. [Google Scholar]

- He, F.; Wang, C.; Han, B.; Yeli, G.; Lin, X.; Wang, Z.; Wang, L.; Kai, J.-J. Deformation faulting and dislocation-cell refinement in a selective laser melted 316L stainless steel. Int. J. Plast. 2022, 156, 103346. [Google Scholar] [CrossRef]

- Tang, J.; He, S.; Mo, Y.; Jiang, F.; Fu, D.; Teng, J.; Zhang, H. Revealing the cryogenic-temperature toughness and deformation mechanisms in high manganese austenitic steels. Mater. Charact. 2022, 190, 112024. [Google Scholar] [CrossRef]

| Materials | Mn | C | Al | Si | P | S |

|---|---|---|---|---|---|---|

| Fe-28Mn-8.5Al-1.0C | 27.41 | 1.02 | 8.26 | 0.23 | 0.016 | 0.005 |

| Process | Rp0.2/MPa | Rm/MPa | A/% | −40 °C KV2/J | Hardness (HB) |

|---|---|---|---|---|---|

| Q | 452 ± 14 | 738 ± 21 | 58.2 ± 0.8 | 144 ± 4 | 257 ± 8 |

| Q + A1 | 537 ± 19 | 861 ± 14 | 54.1 ± 0.7 | 102 ± 6 | 276 ± 5 |

| Q + A2 | 697 ± 16 | 905 ± 24 | 47.6 ± 1.0 | 54 ± 6 | 294 ± 7 |

| Process | Impact Energy/J | Weight Before Wear/g (±0.3 mg) | Weight After Wear/g (±0.3 mg) | W/g | ε/g−1 | Initial Hardness | Final Hardness |

|---|---|---|---|---|---|---|---|

| Q | 1 | 19.7497 | 19.6249 | 0.1248 | 8.01 | 257 | 321 |

| 4 | 19.9729 | 19.8569 | 0.1160 | 8.62 | 405 | ||

| Q + A1 | 1 | 19.7738 | 19.6555 | 0.1183 | 8.45 | 276 | 377 |

| 4 | 19.8506 | 19.7446 | 0.1060 | 9.43 | 438 | ||

| Q + A2 | 1 | 19.8793 | 19.7714 | 0.1079 | 9.27 | 294 | 384 |

| 4 | 19.9323 | 19.8367 | 0.0956 | 10.46 | 452 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, L.; Sun, J.; Cheng, B.; Wang, S.; Chen, M.; Wang, Q. Effect of Aging Temperature on the Impact Wear Properties and Wear Mechanism of Lightweight Wear-Resistant Steel. Metals 2025, 15, 178. https://doi.org/10.3390/met15020178

Liang L, Sun J, Cheng B, Wang S, Chen M, Wang Q. Effect of Aging Temperature on the Impact Wear Properties and Wear Mechanism of Lightweight Wear-Resistant Steel. Metals. 2025; 15(2):178. https://doi.org/10.3390/met15020178

Chicago/Turabian StyleLiang, Liwen, Jianchang Sun, Ben Cheng, Suotao Wang, Mintao Chen, and Qingfeng Wang. 2025. "Effect of Aging Temperature on the Impact Wear Properties and Wear Mechanism of Lightweight Wear-Resistant Steel" Metals 15, no. 2: 178. https://doi.org/10.3390/met15020178

APA StyleLiang, L., Sun, J., Cheng, B., Wang, S., Chen, M., & Wang, Q. (2025). Effect of Aging Temperature on the Impact Wear Properties and Wear Mechanism of Lightweight Wear-Resistant Steel. Metals, 15(2), 178. https://doi.org/10.3390/met15020178