The Influence of Process Parameters on the Density, Microstructure, and Mechanical Properties of TA15 Titanium Alloy Fabricated by Selective Laser Melting

Abstract

:1. Introduction

2. Experimental Details

2.1. Powder Material

2.2. SLM Experimental Platform

2.3. Experimental Characterization Method

2.3.1. Surface Morphology Observation

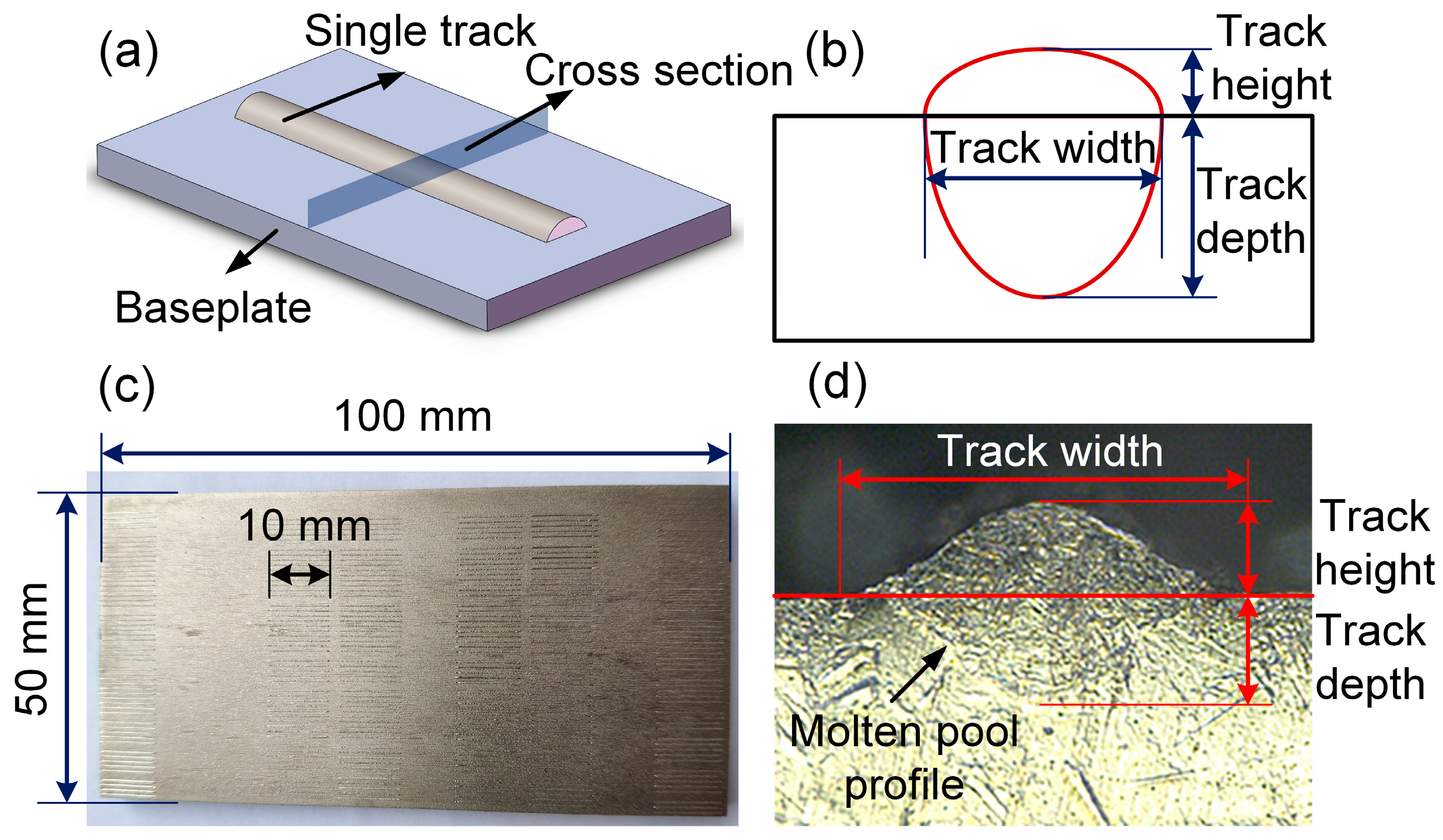

2.3.2. Single-Track Morphology Observation and Characteristic Size Testing

2.3.3. Relative Density Testing

2.3.4. Microstructure Characterization Methods

- Observation of microstructure

- 2.

- EBSD analysis

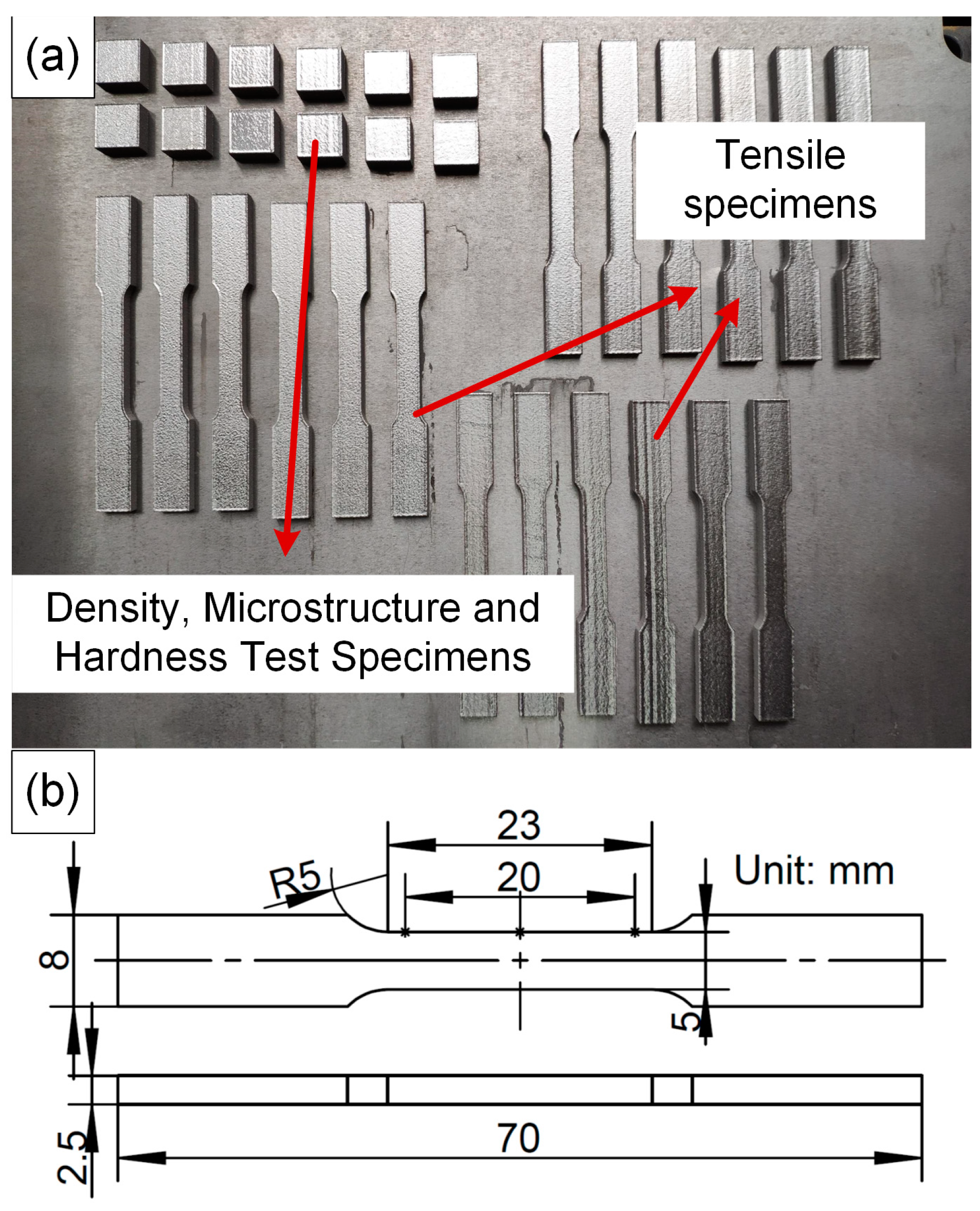

2.3.5. Mechanical Performance Characterization Methods

- Hardness test

- 2.

- Tensile test

3. Results and Analysis

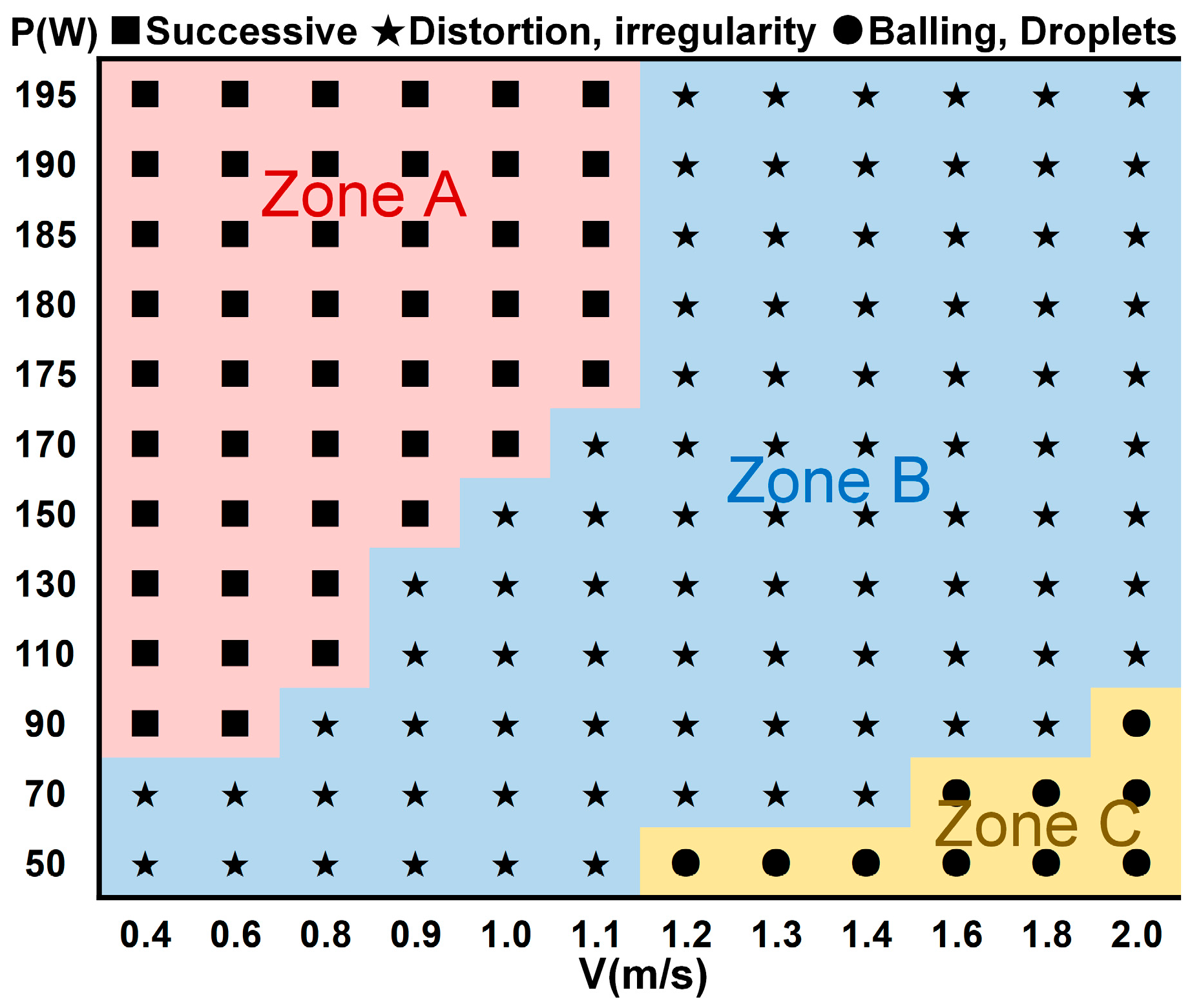

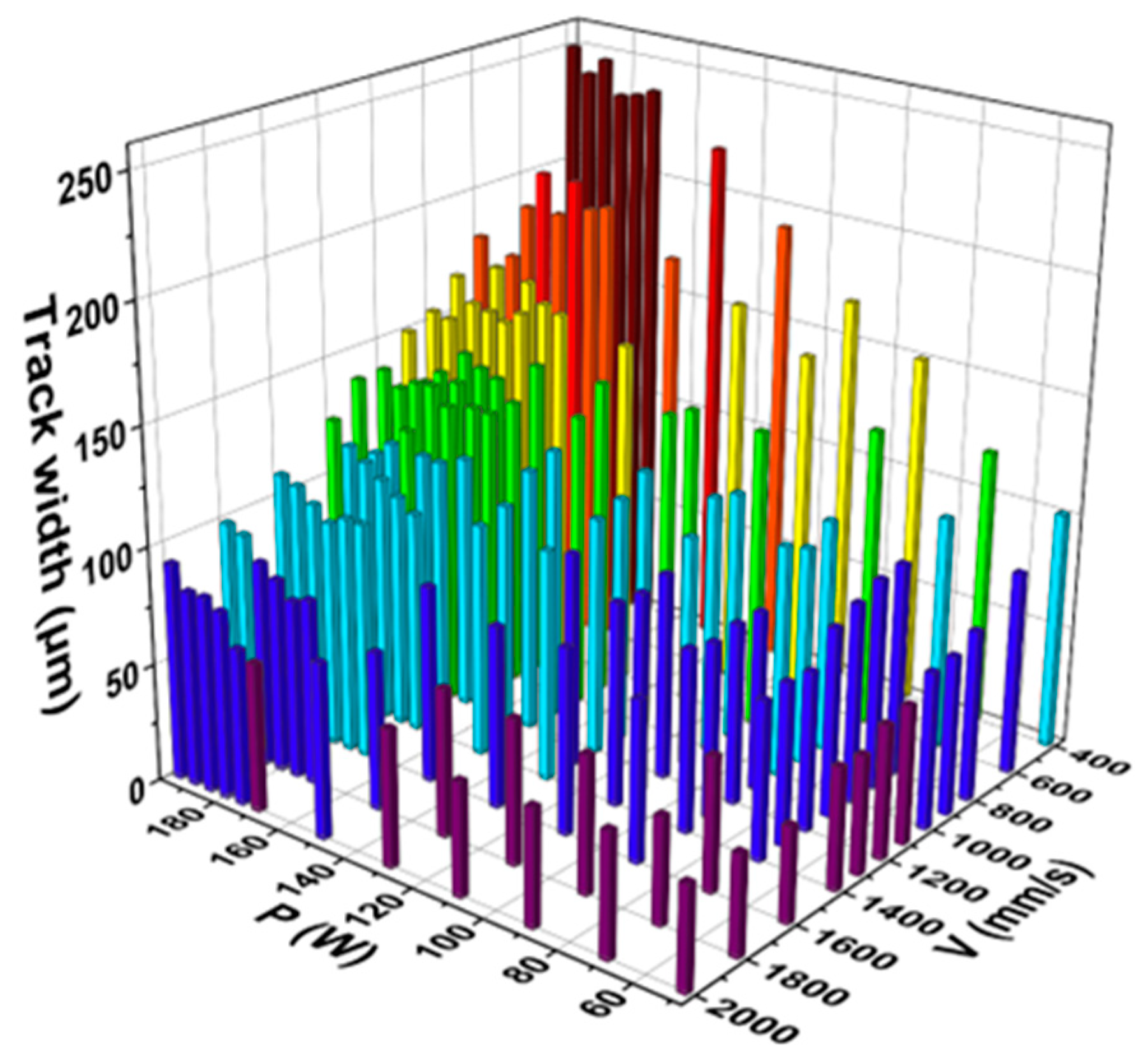

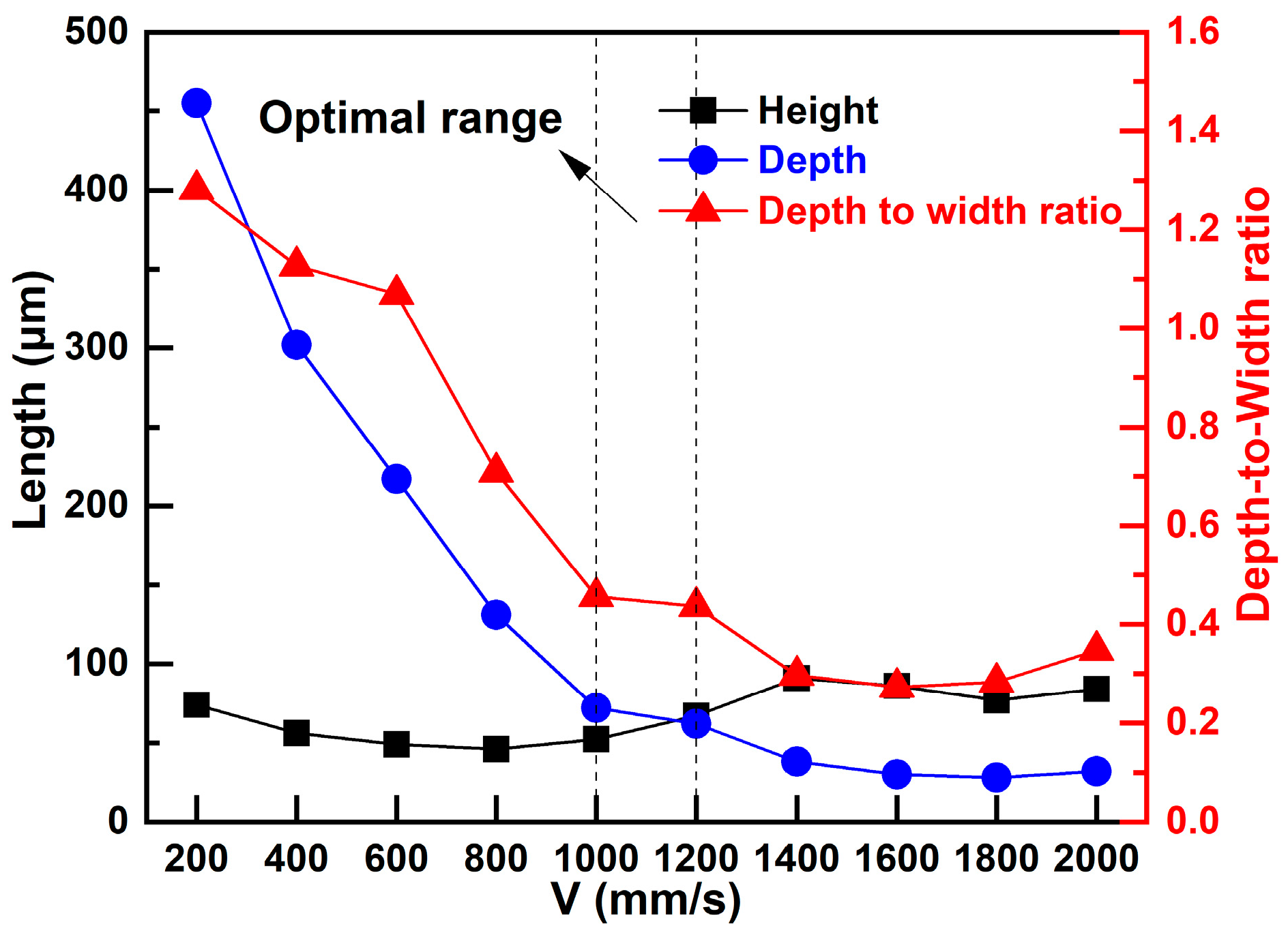

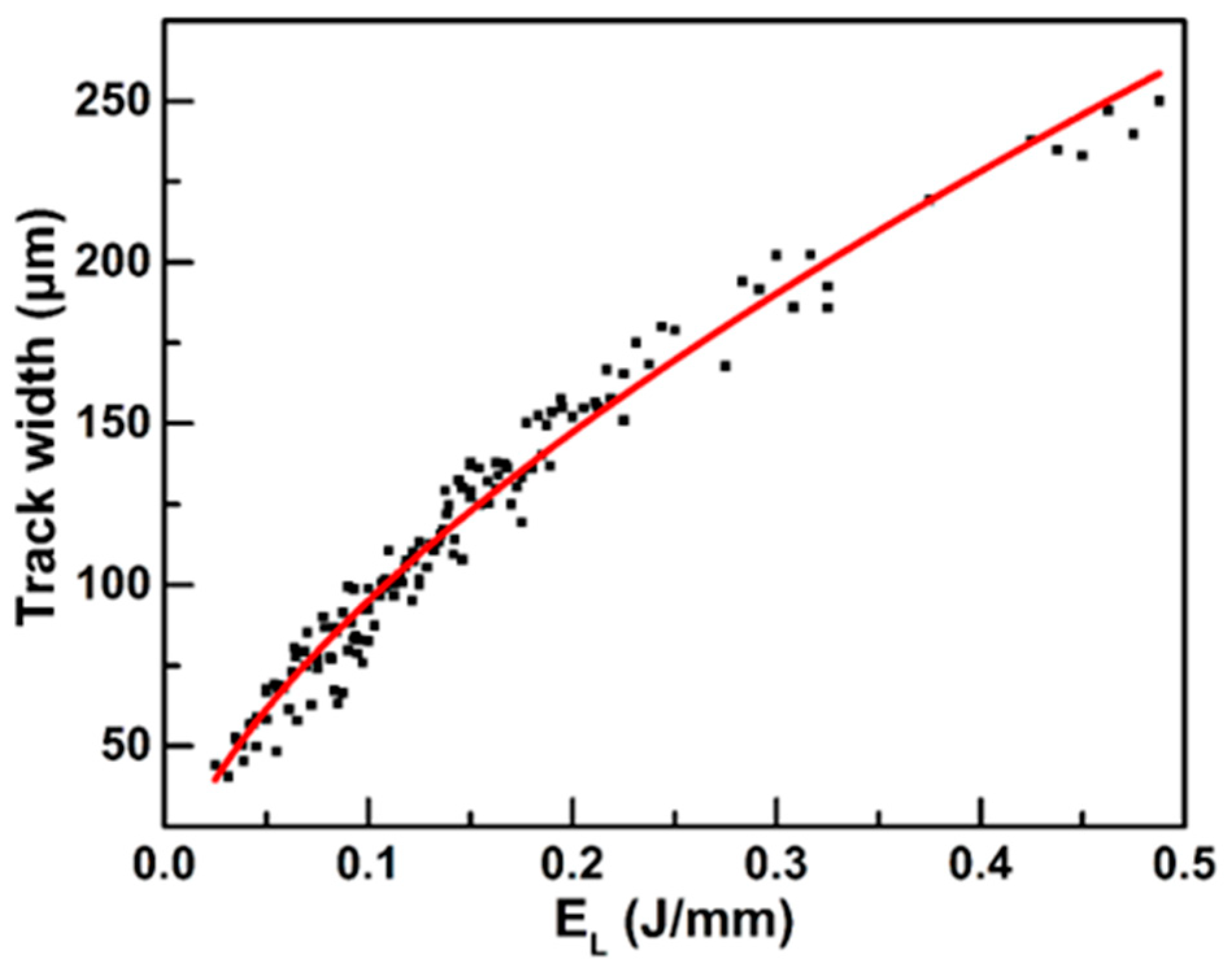

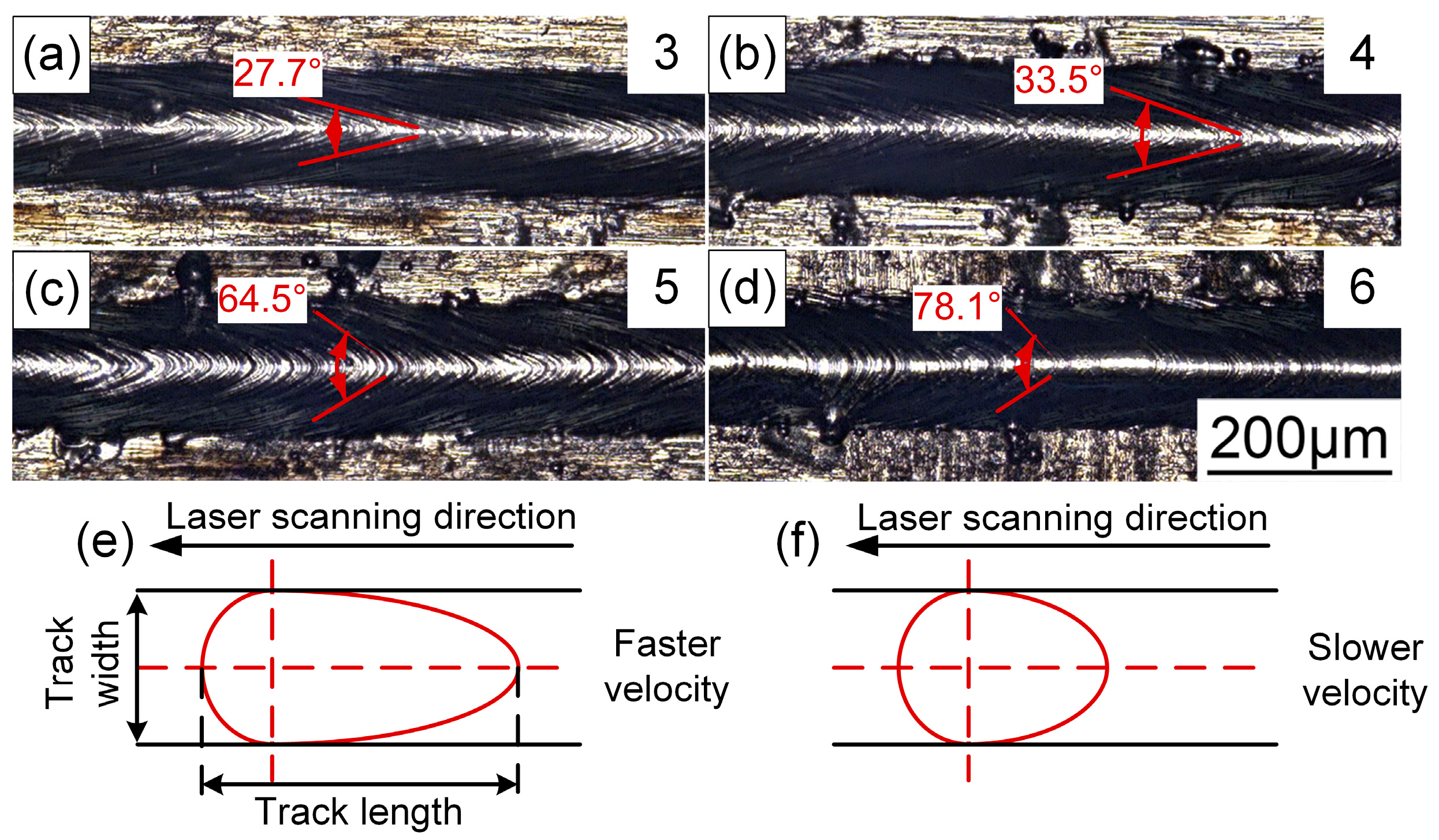

3.1. SLM Forming TA15 Single-Track Experiment

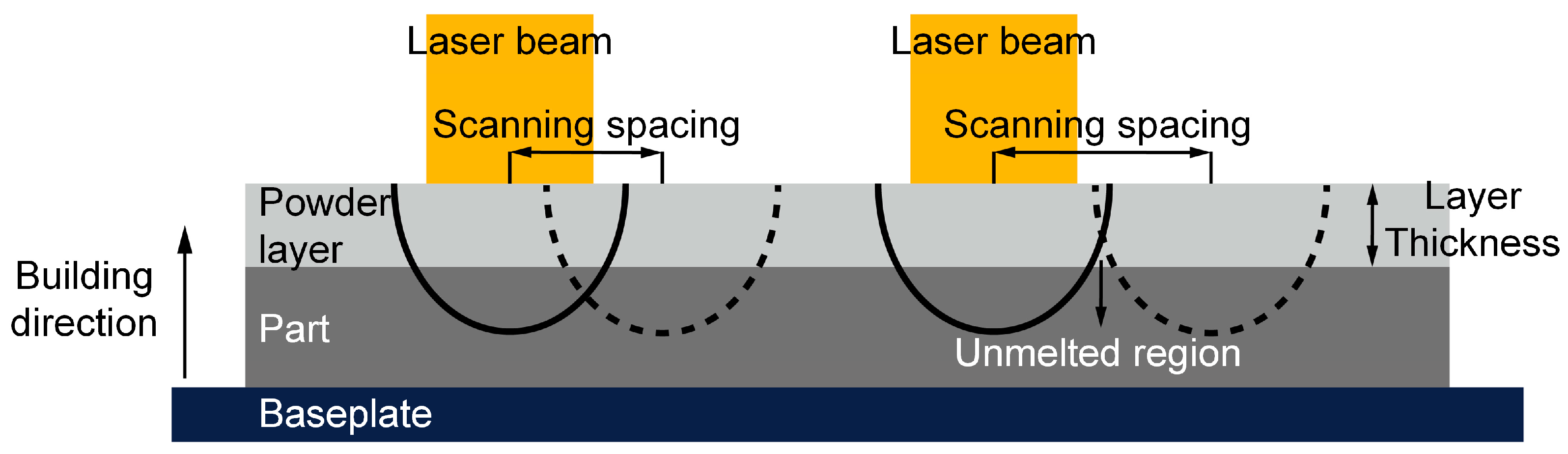

3.2. Research on the Formability of TA15 Blocks Formed by SLM

3.3. The Influence of Process Parameters on the Mechanical Properties and Microstructure of SLMed TA15

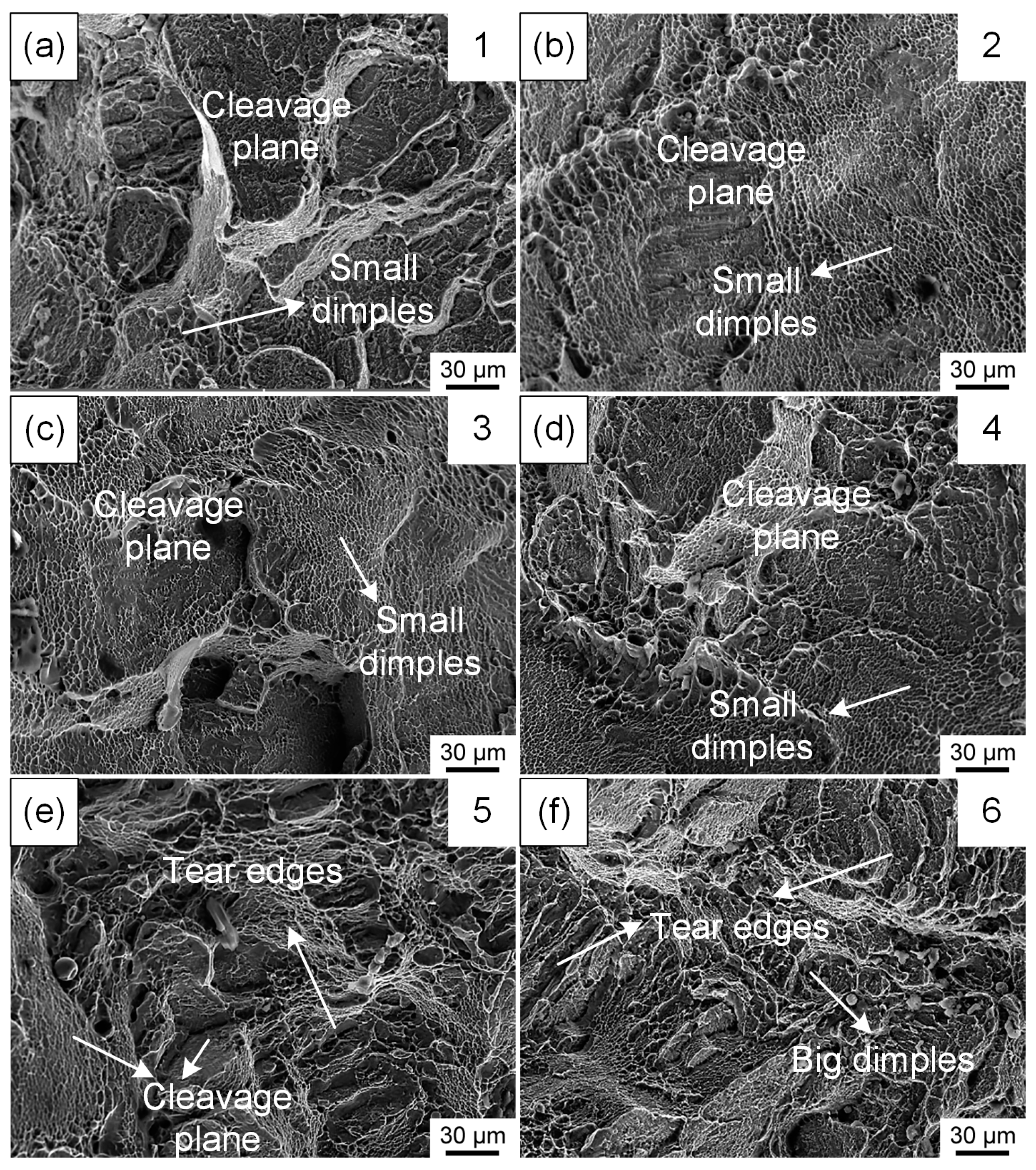

4. Conclusions

- The single-track width of SLMed TA15 increases with a higher laser power or lower scanning speed. At the same linear energy density, the single-track width tends to decrease as the laser power decreases, indicating a distinct relationship between linear energy density and single-track width.

- At the same laser power, the depth of the melt pool in SLMed TA15 increases as the scanning speed decreases, while the depth-to-width ratio also increases sharply. When the aspect ratio exceeds 0.5, the molten pool transitions from “conduction mode” to “keyhole mode”. When the linear energy density is the same, a single melt pool has a similar aspect ratio.

- When the linear energy density and single-track width are close, combined with an appropriate overlapping rate, high-density TA15 alloy samples can be effectively formed.

- Under similar laser linear energy density conditions, lower scanning speeds lead to heat accumulation during the SLM process, resulting in the in situ decomposition of α’ martensite. This results in more β phase and coarser α layer lamellar microstructures in the samples, leading to a decrease in strength and hardness while improving plasticity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Q.J.; Xie, X. Microstructure and mechanical properties of TA15 alloy after thermo-mechanical processing. Mater. Sci. Eng. A 2018, 724, 493–501. [Google Scholar] [CrossRef]

- Wu, H.; Sun, Z.; Cao, J.; Yin, Z. Formation and evolution of tri-modal microstructure during dual heat treatment for TA15 Ti-alloy. J. Alloys Compd. 2019, 786, 894–905. [Google Scholar] [CrossRef]

- Huang, D.M.; Wang, H.L.; Chen, X.; Chen, Y.; Guo, H. Influence of forging process on microstructure and mechanical properties of large section Ti–6.5Al–1Mo–1V–2Zr alloy bars. Trans. Nonferrous Met. Soc. China 2013, 23, 2276–2282. [Google Scholar] [CrossRef]

- Zhichao, S.; He, Y. Microstructure and mechanical properties of TA15 titanium alloy under multi-step local loading forming. Mater. Sci. Eng. A 2009, 523, 184–192. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Bai, C. Titanium Alloy and Its Applications; Chemical Industry Press: Beijing, China, 2005. [Google Scholar]

- Wu, X.; Cai, C.; Yang, L.; Liu, W.; Li, W.; Li, M.; Liu, J.; Zhou, K.; Shi, Y. Enhanced mechanical properties of Ti-6Al-2Zr-1Mo-1V with ultrafine crystallites and nano-scale twins fabricated by selective laser melting. Mater. Sci. Eng. A 2018, 738, 10–14. [Google Scholar] [CrossRef]

- Jiang, J.; Ren, Z.; Ma, Z.; Zhang, T.; Zhang, P.; Zhang, D.Z.; Mao, Z. Mechanical properties and microstructural evolution of TA15 Ti alloy processed by selective laser melting before and after annealing. Mater. Sci. Eng. A Struct. Mater. Prop. Misrostruct. Process. 2020, 772, 138742. [Google Scholar] [CrossRef]

- Huang, S.; Sun, B.; Guo, S. Microstructure and property evaluation of TA15 titanium alloy fabricated by selective laser melting after heat treatment. Opt. Laser Technol. 2021, 144, 107422. [Google Scholar] [CrossRef]

- Cai, C.; Wu, X.; Liu, W.; Zhu, W.; Chen, H.; Qiu, J.C.D.; Sun, C.-N.; Liu, J.; Wei, Q.; Shi, Y. Selective laser melting of near-α titanium alloy Ti-6Al-2Zr-1Mo-1V: Parameter optimization, heat treatment and mechanical performance. J. Mater. Sci. Technol. 2020, 57, 51–64. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, J.; Ren, Z.; Mao, Z.; Ma, X.; Zhang, D.Z. The Influence of Process Parameters and Scanning Strategy on Lower Surface Quality of TA15 Parts Fabricated by Selective Laser Melting. Metals 2020, 10, 1228. [Google Scholar] [CrossRef]

- Yin, A.; Yu, W.; Li, W.; Zhu, W.; Ji, V.; Jiang, C.; Wang, C. Microstructural and thermal relaxation of residual stress in dual peened TA15 titanium alloy fabricated by SLM. Mater. Charact. 2024, 218, 114496. [Google Scholar] [CrossRef]

- Xu, W.; Du, Z.; Wang, Z.; Ran, X.; Li, Z.; Chen, R.; Zhu, X.; Zhang, X.; Zhang, J.; Lu, X. A comparative study on the corrosion, wear, and tribocorrosion performances of Ti-6.5Al–2Zr–1Mo–1V (TA15) alloy fabricated by selective laser melting and laser metal deposition. J. Mater. Res. Technol. 2024, 30, 6245–6253. [Google Scholar] [CrossRef]

- Xu, W.; Zhu, X.; Wang, Z.; Ran, X.; Li, Z.; Chen, R.; Du, Z.; Zhang, X.; Singh, H.; Zhang, J. Comparative study of Ti-6.5Al-2Zr-1Mo-1V (TA15) alloy fabricated by selective laser melting and laser metal deposition. Opt. Laser Technol. 2024, 176, 111052. [Google Scholar] [CrossRef]

- Zhou, L.; Yuan, T.; Li, R.; Tang, J.; Wang, G.; Guo, K.; Yuan, J. Densification, microstructure evolution and fatigue behavior of Ti-13Nb-13Zr alloy processed by selective laser melting. Powder Technol. 2019, 342, 11–23. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method. Opt. Laser Technol. 2013, 49, 118–124. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Awan, U.S.; Ghaderi, A. The effect of SLM process parameters on density, hardness, tensile strength and surface quality of Ti-6Al-4V. Addit. Manuf. 2019, 25, 176–186. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, S.F.; Song, B.; Zhou, X.; Teng, Q.; Wei, Q.S.; Shi, Y.S. A novel titanium alloy manufactured by selective laser melting: Microstructure, high temperature oxidation resistance. Mater. Des. 2016, 89, 1199–1204. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; Zeng, X. Preliminary investigation on selective laser melting of Ti-5Al-2.5Sn α-Ti alloy: From single tracks to bulk 3D components. J. Mater. Process. Technol. 2017, 244, 73–85. [Google Scholar] [CrossRef]

- Hang, B.; Li, C.; Shi, L.; Qiu, G. China Materials Engineering Canon. Volume 4, Nonferrous Metal Materials Engineering. Part One; Chemical Industry Press: Beijing, China, 2006. [Google Scholar]

- GB/T 228.1-2010; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2010.

- Yang, J.; Han, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6A1-4V alloy. Mater. Des. 2016, 110, 558–570. [Google Scholar] [CrossRef]

- Rai, R.R.; Elmer, J.; Palmer, T.; Debroy, T. Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti–6Al–4V, 304L stainless steel and vanadium. J. Phys. D Appl. Phys. 2007, 40, 5753. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; Zeng, X. Effect of heat treatment on microstructure and mechanical properties of the selective laser melting processed Ti-5Al-2.5Sn α titanium alloy. Mater. Sci. Eng. A 2018, 709, 301–311. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Effects of processing parameters on consolidation and microstructure of W–Cu components by DMLS. J. Alloys Compd. 2009, 473, 107–115. [Google Scholar] [CrossRef]

- Bäuerle, D. Laser Processing and Chemistry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of Hatch Spacing on Melt Pool and As-built Quality During Selective Laser Melting of Stainless Steel: Modeling and Experimental Approaches. Materials 2018, 12, 50. [Google Scholar] [CrossRef]

- Xia, M.; Gu, D.; Yu, G.; Dai, D.; Chen, H.; Shi, Q. Influence of hatch spacing on heat and mass transfer, thermodynamics and laser processability during additive manufacturing of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2016, 109, 147–157. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, D.; Guo, Y.; Zhang, T.; Liu, Z. Microstructure and mechanical evolution behavior of LPBF (laser powder bed fusion)-fabricated TA15 alloy. J. Alloys Compd. 2021, 873, 159639. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Chen, X.; Jiang, L. The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2019, 266, 26–36. [Google Scholar] [CrossRef]

- Chen, S.; Guillemot, G.; Gandin, C.-A. Three-dimensional cellular automaton-finite element modeling of solidification grain structures for arc-welding processes. Acta Mater. 2016, 115, 448–467. [Google Scholar] [CrossRef]

- Liang, Z.; Sun, Z.; Zhang, W.; Wu, S.; Chang, H. The effect of heat treatment on microstructure evolution and tensile properties of selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2019, 782, 1041–1048. [Google Scholar] [CrossRef]

- Kumar, P.; Prakash, O.; Ramamurty, U. Micro-and meso-structures and their influence on mechanical properties of selectively laser melted Ti-6Al-4V. Acta Mater. 2018, 154, 246–260. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Fang, G.; Leeflang, S.; Böttger, A.J.; Zadpoor, A.A.; Zhou, J. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloys Compd. 2018, 735, 1562–1575. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Lu, S.; Li, Y.; Zhen, S.; Yu, D.; Zhang, L.; Chen, R.; Wang, Y.; Li, S. Influence of process parameters on the microstructures, residual stresses and mechanical properties of TA15 titanium alloy fabricated by L-PBF. Mater. Sci. Eng. A 2025, 927, 147990. [Google Scholar] [CrossRef]

| Element | Ti | Al | V | Zr | Mo | Si | Fe | C | O | N |

|---|---|---|---|---|---|---|---|---|---|---|

| As-received powders | Bal. | 6.37 | 2.17 | 2.16 | 1.3 | 0.017 | 0.072 | 0.029 | 0.1 | 0.02 |

| Standard [20] | Bal. | 5.5–7.0 | 0.8–2.5 | 1.5–2.5 | 0.5–2.0 | ≤0.15 | ≤0.25 | ≤0.1 | ≤0.15 | ≤0.05 |

| V (mm/s) | 1000 | 900 | 800 | 700 | 600 | 500 | 400 | 300 |

|---|---|---|---|---|---|---|---|---|

| P (W) | 195 | 176 | 156 | 137 | 117 | 98 | 78 | 59 |

| Single-track width (μm) | 155 | 153 | 156 | 156 | 155 | 153 | 147 | 142 |

| Sample | Scanning Speed (mm/s) | Laser Power (W) | Scanning Space (μm) | Linear Energy Density (J/mm) | Single-Track Width (μm) | Density (g/cm3) | Relative Density (%) |

|---|---|---|---|---|---|---|---|

| 1 | 1050 | 190 | 100 | 0.18 | 147 | 4.450 | 99.98 |

| 2 | 1000 | 175 | 100 | 0.175 | 147 | 4.446 | 99.89 |

| 3 | 900 | 160 | 100 | 0.178 | 146 | 4.444 | 99.84 |

| 4 | 800 | 150 | 100 | 0.189 | 149 | 4.447 | 99.91 |

| 5 | 600 | 110 | 100 | 0.183 | 152 | 4.450 | 99.98 |

| 6 | 400 | 90 | 100 | 0.225 | 151 | 4.449 | 99.96 |

| Sample | V (mm/s) | P (W) | H (μm) | σU (MPa) | σ0.2 (MPa) | ε (%) | HV1 |

|---|---|---|---|---|---|---|---|

| 1 | 1050 | 190 | 100 | 1299 ± 13 | 1170 ± 9 | 6.6 ± 0.6 | 389.2 ± 5.3 |

| 2 | 1000 | 175 | 100 | 1289 ± 6 | 1169 ± 3 | 6.8 ± 0.5 | 387.3 ± 5.3 |

| 3 | 900 | 160 | 100 | 1291 ± 1 | 1171 ± 5 | 6.4 ± 0.6 | 385.1 ± 5.2 |

| 4 | 800 | 150 | 100 | 1273 ± 7 | 1157 ± 8 | 7.2 ± 0.3 | 382.2 ± 4.5 |

| 5 | 600 | 110 | 100 | 1251 ± 11 | 1095 ± 6 | 7.6 ± 0.5 | 373.3 ± 1.9 |

| 6 | 400 | 90 | 100 | 1233 ± 2 | 1083 ± 2 | 8.4 ± 0.8 | 364.4 ± 5.1 |

| Processing | Microstructure | σU (MPa) | ε (%) | Ref. |

|---|---|---|---|---|

| SLM | Acicular α′ | 1350 ± 35 | 6.0 ± 0.9 | [13] |

| SLM | Acicular α′ | 1234.2 ± 53.1 | 7.3 ± 0.7 | [9] |

| SLM | Acicular α′ | 1214 (XY) 1234 (XY) | 9.2 (Z) 34.1 (Z) | [8] |

| SLM | Acicular α′ | 1250 | 3.1 | [32] |

| SLM | Acicular α′ | 1062.7–1294.9 | No tests. | [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Liang, C.; Chen, Y.; Wang, Y.; Cui, H.; Xu, J.; Zhou, F.; Wang, P.; Zhang, D.Z. The Influence of Process Parameters on the Density, Microstructure, and Mechanical Properties of TA15 Titanium Alloy Fabricated by Selective Laser Melting. Metals 2025, 15, 233. https://doi.org/10.3390/met15030233

Jiang J, Liang C, Chen Y, Wang Y, Cui H, Xu J, Zhou F, Wang P, Zhang DZ. The Influence of Process Parameters on the Density, Microstructure, and Mechanical Properties of TA15 Titanium Alloy Fabricated by Selective Laser Melting. Metals. 2025; 15(3):233. https://doi.org/10.3390/met15030233

Chicago/Turabian StyleJiang, Junjie, Chuang Liang, Yuanchao Chen, Yongbiao Wang, Hongyang Cui, Jianlin Xu, Fang Zhou, Pengpeng Wang, and David Z. Zhang. 2025. "The Influence of Process Parameters on the Density, Microstructure, and Mechanical Properties of TA15 Titanium Alloy Fabricated by Selective Laser Melting" Metals 15, no. 3: 233. https://doi.org/10.3390/met15030233

APA StyleJiang, J., Liang, C., Chen, Y., Wang, Y., Cui, H., Xu, J., Zhou, F., Wang, P., & Zhang, D. Z. (2025). The Influence of Process Parameters on the Density, Microstructure, and Mechanical Properties of TA15 Titanium Alloy Fabricated by Selective Laser Melting. Metals, 15(3), 233. https://doi.org/10.3390/met15030233