Characterization of EAF and LF Slags Through an Upgraded Stationary Flowsheet Model of the Electric Steelmaking Route

Abstract

:1. Introduction

2. Materials and Methods

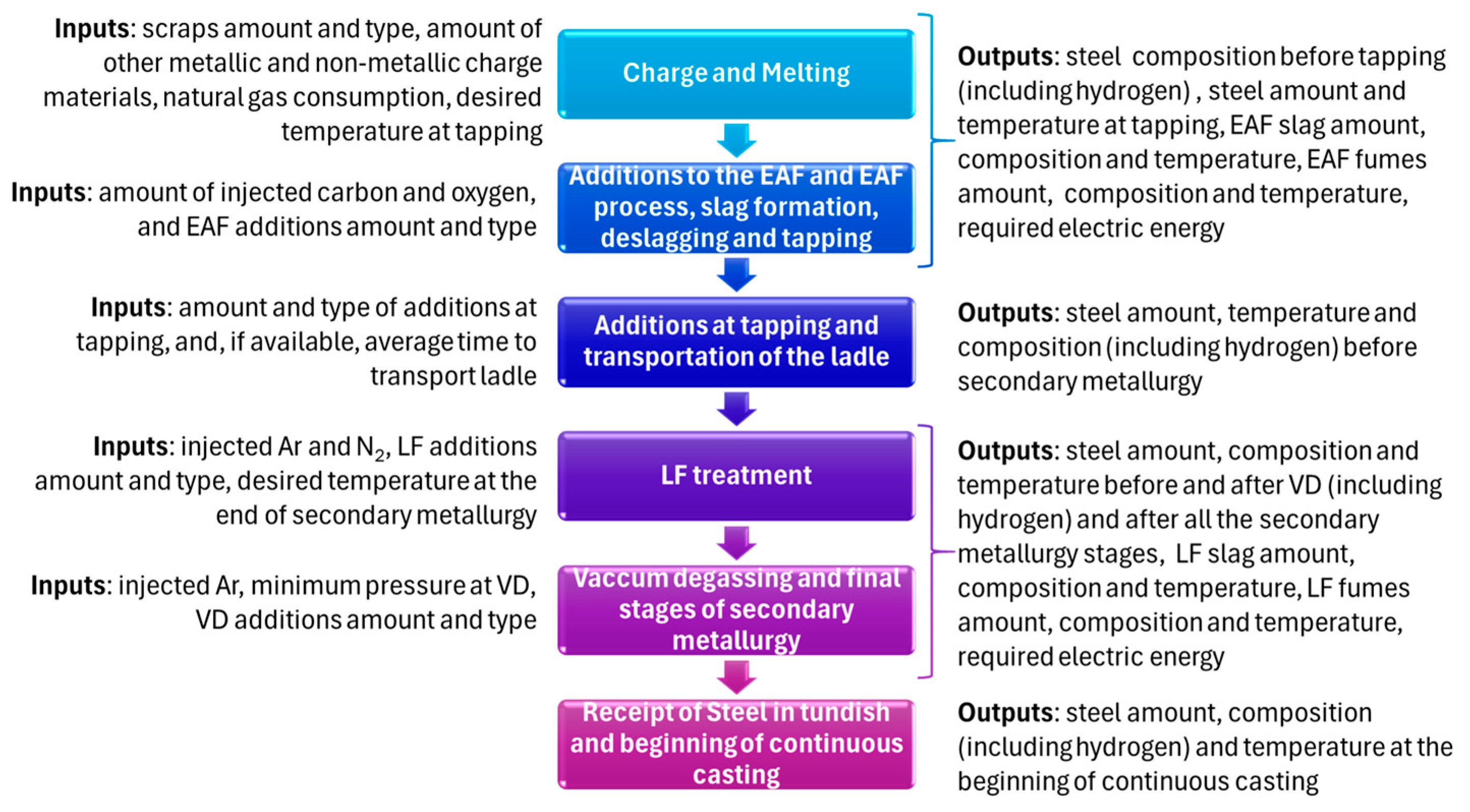

2.1. Brief Description of the Initial Version of the Model

2.2. Upgraded Model

| 7.58 · 10−10∙Arin6 − 6.78 · 10−8∙Arin5 + 2.55 · 10−6∙Arin4 − 1.18 · 10−4 ∙ Arin3 + 6.34 · 10−3 ∙ Arin2 − 1.97 · 10−1∙ Arin + 2.85, | H2in = 2.8 ppm | (38) | |

| H2out = | 1.05 · 10−8∙Arin6 − 1.38 · 10−6∙Arin5 + 7.40 · 10−5∙Arin4 − 2.13 · 10−3 ∙ Arin3 + 3.90 · 10−2 ∙ Arin2 − 5.20 · 10−1∙Arin + 4.71, | H2in = 4.7 ppm | |

| 2.46 · 10−8∙Arin6 − 3.46 · 10−6∙Arin5 + 1.96 · 10−4∙Arin4 − 5.77 · 10−3 ∙ Arin3 + 9.64 · 10−2 ∙ Arin2 − 9.86 · 10−1∙Arin + 6.55, | H2in = 6.7 ppm |

| 5.26 · 10−9∙Arin6 − 5.44 · 10−7∙Arin5 + 1.74 · 10−5∙Arin4 − 1.81 · 10−4∙Arin3 + 5.96 · 10−3∙Arin2 − 3.67 · 10−1∙Arin + 21.02, | N2in = 20 ppm | (39) | |

| −6.79 · 10−9∙Arin6 + 9.70 · 10−7∙Arin5 − 5.14 · 10−5∙Arin4 + 1.19 · 10−3∙Arin3 − 5.17 · 10−3∙Arin2 − 5.11 · 10−1∙Arin + 30.56, | N2in = 30 ppm | ||

| 2.39 · 10−8∙Arin6 − 2.67 · 10−6∙Arin5 + 1.16 · 10−4∙Arin4 − 2.80 · 10−3∙Arin3 + 5.49 · 10−2∙Arin2 − 1.21∙Arin + 40.35, | N2in = 40 ppm | ||

| N2out = | 1.77 · 10−8∙Arin6 − 2.03 · 10−6∙Arin5 + 9.07 · 10−5∙Arin4 − 2.16 · 10−3∙Arin3 + 4.71 · 10−2∙Arin2 − 1.46∙Arin + 49.79, | N2in = 50 ppm | |

| 1.74 · 10−8∙Arin6 − 1.32 · 10−6∙Arin5 + 1.10 · 10−5∙Arin4 + 9.09 · 10−4∙Arin3 + 6.25 · 10−3∙Arin2 − 1.61∙Arin + 59.08, | N2in = 60 ppm | ||

| 2.65 · 10−8∙Arin6 − 2.34 · 10−6∙Arin5 + 5.94 · 10−5∙Arin4 − 5.34 · 10−4∙Arin3 + 3.91 · 10−3∙Arin2 − 2.21∙Arin + 68.46, | N2in = 70 ppm | ||

| 6.68 · 10−8∙Arin6 − 8.54 · 10−6∙Arin5 + 4.44 · 10−4∙Arin4 + 1.26 · 10−2∙Arin3 − 2.38 · 10−1∙Arin2 − 3.99∙Arin + 79.73, | N2in = 80 ppm |

3. Results

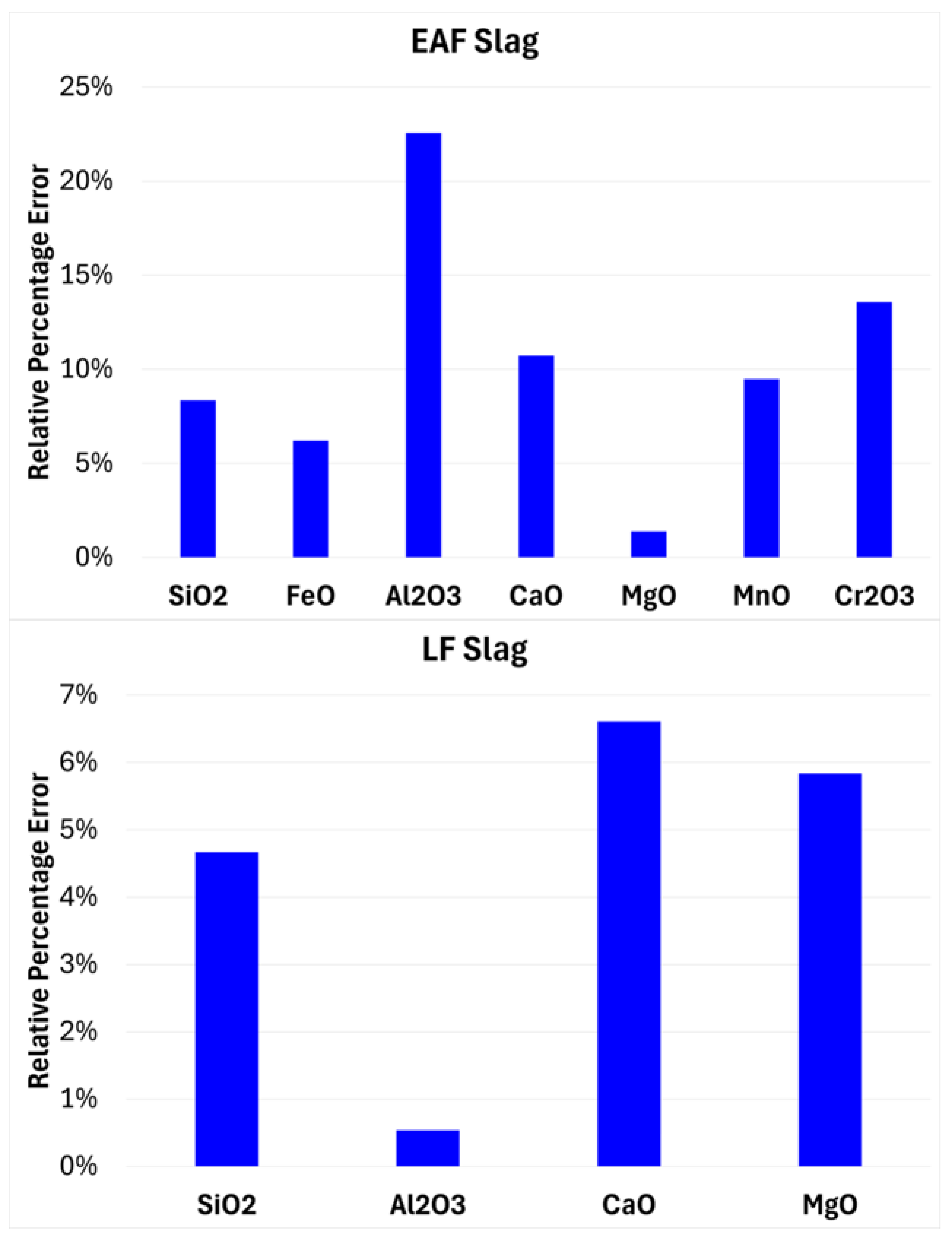

- lower than 25% in the case of FeO, CaO, MgO, MnO and Cr2O3 for EAF slag and of SiO2 and CaO for LF slag;

- lower than 40% in the case of SiO2 and Al2O3 for EAF slag and of Al2O3 for LF slag;

- lower than 50% in the case of MgO for LF slag.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. The European Green Deal—Striving to Be the First Climate-Neutral Continent. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 22 November 2024).

- European Commission. Circular Economy Action Plan—The EU’s New Circular Action Plan Paves the Way for a Cleaner and More Competitive Europe. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 22 November 2024).

- ESTEP. Improve the EAF Scrap Route for a Sustainable Value Chain in the EU Circular Economy Scenario–ROADMAP—An Evolution Document for a Strategic Look to the Future of European EAF Steelmaking. Available online: https://www.estep.eu/assets/Publications/Improve-the-EAF-scrap-route-Roadmap-Final-V2-3.pdf (accessed on 8 November 2024).

- Rodríguez Diez, J.; Tomé-Torquemada, S.; Vicente, A.; Reyes, J.; Orcajo, G.A. Decarbonization Pathways, Strategies, and Use Cases to Achieve Net-Zero CO2 Emissions in the Steelmaking Industry. Energies 2023, 16, 7360. [Google Scholar] [CrossRef]

- Kazmi, B.; Taqvi, S.A.A.; Juchelková, D. State-of-the-art review on the steel decarbonization technologies based on process system engineering perspective. Fuel 2023, 347, 128459. [Google Scholar] [CrossRef]

- Conde, A.S.; Rechberger, K.; Spanlang, A.; Wolfmeir, H.; Harris, C. Decarbonization of the steel industry. A techno-economic analysis. Matér. Tech. 2021, 109, 305. [Google Scholar] [CrossRef]

- Dettori, S.; Matino, I.; Colla, V.; Speets, R. A Deep Learning-based approach for forecasting off-gas production and consumption in the blast furnace. Neural Comput. Appl. 2022, 34, 911–923. [Google Scholar] [CrossRef]

- Na, H.; Yuan, Y.; Sun, J.; Zhang, L.; Du, T. Integrative optimization for energy efficiency, CO2 reduction, and economic gains in the iron and steel industry: A holistic approach. Resour. Conserv. Recycl. 2025, 212, 107992. [Google Scholar] [CrossRef]

- Dettori, S.; Matino, I.; Colla, V.; Weber, V.; Salame, S. Neural network-based modeling methodologies for energy transformation equipment in integrated steelworks processes. Energy Procedia 2019, 158, 4061–4066. [Google Scholar] [CrossRef]

- Porzio, G.F.; Colla, V.; Fornai, B.; Vannucci, M.; Larsson, M.; Stripple, H. Process integration analysis and some economic-environmental implications for an innovative environmentally friendly recovery and pre-treatment of steel scrap. Appl. Energy 2016, 161, 656–672. [Google Scholar] [CrossRef]

- Mapelli, C.; Dall’Osto, G.; Mombelli, D.; Barella, S.; Gruttadauria, A. Future scenarios for reducing emissions and consumption in the Italian steelmaking industry. Steel Res. Int. 2022, 93, 2100631. [Google Scholar] [CrossRef]

- Echterhof, T. Review on the use of alternative carbon sources in EAF steelmaking. Metals 2021, 11, 222. [Google Scholar] [CrossRef]

- Di Giovanni, C.; Echterhof, T. Progress Toward Biocarbon Utilization in Electric Arc Furnace Steelmaking: Current Status and Future Prospects. J. Sustain. Metall. 2024, 10, 2047–2067. [Google Scholar] [CrossRef]

- Henriques, J.; Castro, P.M.; Dias, R.; Magalhães, B.; Estrela, M. Potential Industrial Synergies in the Steelmaking and Metal-Processing Industry: By-Products Valorization and Associated Technological Processes. Sustainability 2023, 15, 15323. [Google Scholar] [CrossRef]

- Matino, I.; Branca, T.A.; Fornai, B.; Colla, V.; Romaniello, L. Scenario Analyses for By-Products Reuse in Integrated Steelmaking Plants by Combining Process Modeling, Simulation, and Optimization Techniques. Steel Res. Int. 2019, 90, 1900150. [Google Scholar] [CrossRef]

- Branca, T.A.; Fornai, B.; Colla, V.; Pistelli, M.I.; Faraci, E.L.; Cirilli, F.; Schröder, A.J. Industrial symbiosis and energy efficiency in european process industries: A review. Sustainability 2021, 13, 9159. [Google Scholar] [CrossRef]

- Worldsteel Association. Fact Sheet-Steel Industry Co-Products. Available online: https://worldsteel.org/wp-content/uploads/Fact-sheet-Steel-industry-co-products.pdf (accessed on 15 November 2024).

- Worldsteel Association. Public Policy Paper—Steel Industry Co-Products. Available online: https://worldsteel.org/publications/bookshop/steel-industry-co-products-ppp/ (accessed on 15 November 2024).

- Das, P.; Upadhyay, S.; Dubey, S.; Singh, K.K. Waste to wealth: Recovery of value-added products from steel slag. J. Environ. Chem. Eng. 2021, 9, 105640. [Google Scholar] [CrossRef]

- Ye, G.; Burström, E.; Kuhn, M.; Piret, J. Reduction of steel-making slags for recovery of valuable metals and oxide materials. Scand. J. Metall. 2003, 32, 7–14. [Google Scholar] [CrossRef]

- Motz, H.; Geiseler, J. Products of steel slags an opportunity to save natural resources. Waste Manag. 2001, 21, 285–293. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Valentini, R. A way to reduce environmental impact of ladle furnace slag. Ironmak. Steelmak. 2009, 36, 597–602. [Google Scholar] [CrossRef]

- Herbelin, M.; Bascou, J.; Lavastre, V.; Guillaume, D.; Benbakkar, M.; Peuble, S.; Baron, J.P. Steel slag characterisation—Benefit of coupling chemical, mineralogical and magnetic techniques. Minerals 2020, 10, 705. [Google Scholar] [CrossRef]

- Menad, N.E.; Kana, N.; Seron, A.; Kanari, N. New eaf slag characterization methodology for strategic metal recovery. Materials 2021, 14, 1513. [Google Scholar] [CrossRef]

- Petersson, J.; Gilbert-Gatty, M.; Bengtson, A. Rapid chemical analysis of steel slag by laser-induced breakdown spectroscopy for near-the-line applications. J. Anal. At. Spectrom. 2020, 35, 1848–1858. [Google Scholar] [CrossRef]

- Dong, C.; Yu, H.; Sun, L.; Li, Y.; Liu, X.; Zhou, P.; Huang, S. Characteristics of laser-induced breakdown spectroscopy of liquid slag. Plasma Sci. Technol. 2024, 26, 025502. [Google Scholar] [CrossRef]

- Long, S.; Li, M.-G.; Chou, J.-J.; Zhang, T.L.; Tang, H.-S.; Li, H. Rapid quantitative analysis of slag acidity by laser induced breakdown spectroscopy combined with random forest. Chin. J. Anal. Chem. 2023, 51, 100210. [Google Scholar] [CrossRef]

- Murua, M.; Boto, F.; Anglada, E.; Cabero, J.M.; Fernandez, L. A slag prediction model in an electric arc furnace process for special steel production. Procedia Manuf. 2021, 54, 178–183. [Google Scholar] [CrossRef]

- Hay, T.; Reimann, A.; Echterhof, T. Improving the Modeling of Slag and Steel Bath Chemistry in an Electric Arc Furnace Process Model. Metall. Mater. Trans. B 2019, 50, 2377–2388. [Google Scholar] [CrossRef]

- Fathi, A.; Saboohi, Y.; Škrjanc, I.; Logar, V. Comprehensive Electric Arc Furnace Model for Simulation Purposes and Model-Based Control. Steel Res. Int. 2017, 88, 1600083. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and validation of an electric arc furnace: Part 1, heat and mass transfer. ISIJ Int. 2012, 52, 402–412. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and validation of an electric arc furnace: Part 2, thermo-chemistry. ISIJ Int. 2012, 52, 413–423. [Google Scholar] [CrossRef]

- Harada, A.; Maruoka, N.; Shibata, H.; Kitamura, S.Y. A kinetic model to predict the compositions of metal, slag and inclusions during ladle refining: Part 1. Basic concept and application. ISIJ Int. 2013, 53, 2110–2117. [Google Scholar] [CrossRef]

- Harada, A.; Maruoka, N.; Shibata, H.; Kitamura, S.Y. A kinetic model to predict the compositions of metal, slag and inclusions during ladle refining: Part2. Condition to control the inclusion composition. ISIJ Int. 2013, 53, 2118–2125. [Google Scholar] [CrossRef]

- Publications Office of the European Union. Final Report of GA: RFSR-CT-2013-00030. Environmental Impact Evaluation and Effective Management of Resources in the EAF Steelmaking–EIRES. Available online: https://op.europa.eu/en/publication-detail/-/publication/b9552f10-5a49-11e8-ab41-01aa75ed71a1 (accessed on 1 December 2024).

- Matino, I.; Alcamisi, E.; Colla, V.; Baragiola, S.; Moni, P. Process modelling and simulation of electric arc furnace steelmaking to allow prognostic evaluations of process environmental and energy impacts. Matér. Tech. 2016, 104, 104. [Google Scholar] [CrossRef]

- Colla, V.; Matino, I.; Cirilli, F.; Jochler, G.; Kleimt, B.; Rosemann, H.; Unamuno, I.; Tosato, S.; Gussago, F.; Baragiola, S.; et al. Improving energy and resource efficiency of electric steelmaking through simulation tools and process data analyses. Matér. Tech. 2016, 104, 602. [Google Scholar] [CrossRef]

- Matino, I.; Colla, V.; Baragiola, S. Internal slags reuse in an electric steelmaking route and process sustainability: Simulation of different scenarios through the EIRES monitoring tool. Waste Biomass Valorization 2018, 9, 2481–2491. [Google Scholar] [CrossRef]

- Heo, J.H.; Park, J.H. Effect of Slag Composition on Dephosphorization and Foamability in the Electric Arc Furnace Steelmaking Process: Improvement of Plant Operation. Metall. Mater. Trans. B 2021, 52, 3613–3623. [Google Scholar] [CrossRef]

- Violi, G. Processi Siderurgici—La Fabbricazione Della Ghisa e Dell’acciaio; ETAS KOMPASS: Milano, Italy, 1972. [Google Scholar]

- Nicodemi, W.; Mapelli, C. Siderurgia; AIM: Milano, Italy, 2011. [Google Scholar]

- Baghforth, R.G. The Manufacture of Iron and Steel Vol. II; Creative Media Partners, LLC: London, UK, 2017. [Google Scholar]

| Mn | P | S | Cu | Cr | Ni | Mo | Sn | |

|---|---|---|---|---|---|---|---|---|

| Scrap ID | w/w | |||||||

| S1 | - | 0.0100 | 0.0250 | 0.0400 | 0.0350 | 0.0350 | 0.0200 | 0.0050 |

| S2 | 0.0860 | 0.0004 | 0.0350 | 0.1400 | 0.0920 | 0.2720 | 0.0760 | 0.0090 |

| S3 | 0.1030 | 0.0070 | 0.0300 | 0.1850 | 0.1300 | 0.2010 | 0.0650 | 0.0090 |

| S4 | - | 0.0250 | 0.0400 | 0.3400 | 0.0700 | 0.1000 | 0.0250 | 0.0200 |

| S5 | 0.0790 | 0.0230 | 0.0560 | 0.3900 | 0.1000 | 0.1070 | 0.0200 | 0.0140 |

| S6 | 0.1440 | 0.0090 | 0.0310 | 0.2780 | 0.0920 | 0.1140 | 0.0310 | 0.0130 |

| S7 | - | 0.0150 | 0.0400 | 0.1700 | 0.0600 | 0.0700 | 0.0200 | 0.0130 |

| S8 | 0.0630 | 0.0020 | 0.0070 | 0.0490 | 0.0140 | 0.0320 | 0.0070 | 0.0070 |

| S9 | 0.0630 | 0.0040 | 0.0140 | 0.1030 | 0.0270 | 0.0590 | 0.0120 | 0.0070 |

| S10 | 0.1240 | 0.0080 | 0.0330 | 0.1980 | 0.1450 | 0.2260 | 0.0690 | 0.0100 |

| S11 | 0.1130 | 0.0050 | 0.0230 | 0.2030 | 0.2050 | 0.3120 | 0.1620 | 0.0100 |

| S12 | 0.1170 | 0.0050 | 0.0190 | 0.1960 | 0.2260 | 0.5660 | 0.1820 | 0.0100 |

| S13 | 0.0810 | 0.0080 | 0.0200 | 0.1060 | 0.0640 | 0.0890 | 0.0330 | 0.0070 |

| S14 | 0.0890 | 0.0150 | 0.0570 | 0.2750 | 0.1270 | 0.2610 | 0.0690 | 0.0130 |

| Steel Family | ACH | AQT | BEAR | CCH | CQT | FC | MA | SPR | |

|---|---|---|---|---|---|---|---|---|---|

| Compound | Accuracy Index & Deviation Index | ||||||||

| SiO2 | MRPE | 26.6% | 30.6% | 17.3% | 16.8% | 26.4% | 26.7% | 26.5% | 25.9% |

| RMSE | 0.024 | 0.027 | 0.023 | 0.018 | 0.025 | 0.024 | 0.022 | 0.021 | |

| SI | 33.3% | 36.4% | 17.5% | 22.1% | 32.5% | 31.1% | 30.6% | 29.6% | |

| PVC | 22.9% | 20.5% | 5.1% | 9.5% | 19.8% | 21.6% | 23.7% | 22.9% | |

| FeO | MRPE | 13.9% | 15.2% | 22.4% | 10.7% | 13.0% | 14.6% | 15.1% | 11.0% |

| RMSE | 0.080 | 0.081 | 0.063 | 0.052 | 0.074 | 0.072 | 0.085 | 0.072 | |

| SI | 16.7% | 17.5% | 26.3% | 11.6% | 15.8% | 16.0% | 18.0% | 16.1% | |

| PVC | 13.9% | 13.5% | 16.2% | 10.9% | 14.6% | 13.6% | 16.8% | 11.9% | |

| Al2O3 | MRPE | 38.8% | 40.3% | 15.7% | 46.0% | 30.9% | 21.7% | 38.9% | 20.5% |

| RMSE | 0.016 | 0.017 | 0.018 | 0.022 | 0.018 | 0.014 | 0.017 | 0.013 | |

| SI | 37.6% | 39.0% | 20.9% | 40.1% | 32.0% | 22.4% | 35.4% | 26.4% | |

| PVC | 32.8% | 35.0% | 14.2% | 32.8% | 24.5% | 23.2% | 31.1% | 22.1% | |

| CaO | MRPE | 17.5% | 19.3% | 6.7% | 15.9% | 18.3% | 20.8% | 19.6% | 13.8% |

| RMSE | 0.042 | 0.051 | 0.028 | 0.028 | 0.044 | 0.046 | 0.047 | 0.033 | |

| SI | 23.6% | 24.9% | 8.2% | 15.3% | 24.6% | 22.0% | 23.0% | 16.7% | |

| PVC | 24.7% | 23.5% | 3.1% | 19.0% | 29.0% | 28.2% | 25.2% | 20.8% | |

| MgO | MRPE | 14.1% | 14.6% | 10.0% | 14.4% | 12.5% | 14.6% | 13.0% | 15.3% |

| RMSE | 0.015 | 0.013 | 0.013 | 0.012 | 0.013 | 0.013 | 0.012 | 0.012 | |

| SI | 20.3% | 18.1% | 15.0% | 14.4% | 16.9% | 17.6% | 17.0% | 17.6% | |

| PVC | 9.8% | 9.7% | 12.0% | 0.9% | 10.9% | 13.3% | 12.8% | 12.8% | |

| MnO | MRPE | 11.7% | 10.5% | 12.0% | 11.0% | 12.5% | 13.7% | 12.1% | 9.1% |

| RMSE | 0.013 | 0.012 | 0.009 | 0.011 | 0.014 | 0.013 | 0.012 | 0.010 | |

| SI | 13.8% | 13.0% | 12.0% | 12.1% | 15.7% | 14.8% | 14.6% | 11.5% | |

| PCV | 14.8% | 13.3% | 2.5% | 8.3% | 12.1% | 21.8% | 16.4% | 12.0% | |

| Cr2O3 | MRPE | 24.6% | 18.2% | 22.9% | 9.4% | 13.6% | 7.5% | 17.2% | 13.4% |

| RMSE | 0.012 | 0.009 | 0.005 | 0.003 | 0.005 | 0.003 | 0.006 | 0.006 | |

| SI | 28.3% | 23.0% | 25.3% | 10.3% | 16.9% | 9.3% | 20.7% | 17.8% | |

| PVC | 34.7% | 27.0% | 15.2% | 4.3% | 18.5% | 15.5% | 21.7% | 20.2% | |

| Steel Family | ACH | AQT | BEAR | CCH | CQT | FC | MA | SPR | |

|---|---|---|---|---|---|---|---|---|---|

| Compound | Accuracy Index & Deviation Index | ||||||||

| SiO2 | MRPE | 13.1% | 10.3% | 34.8% | 13.7% | 14.9% | 6.2% | 11.4% | 12.4% |

| RMSE | 0.039 | 0.035 | 0.064 | 0.033 | 0.047 | 0.018 | 0.038 | 0.045 | |

| SI | 15.6% | 13.9% | 36.3% | 13.2% | 18.1% | 8.6% | 14.0% | 17.3% | |

| PVC | 9.3% | 10.5% | 10.3% | 18.1% | 11.1% | 6.2% | 7.0% | 10.0% | |

| Al2O3 | MRPE | 29.0% | 35.4% | 7.0% | 18.6% | 59.8% | 8.9% | 24.3% | 45.7% |

| RMSE | 0.020 | 0.024 | 0.010 | 0.009 | 0.035 | 0.009 | 0.016 | 0.027 | |

| SI | 36.9% | 38.6% | 7.5% | 18.2% | 62.0% | 10.6% | 32.7% | 51.4% | |

| PVC | 31.2% | 30.1% | 4.5% | 16.1% | 36.0% | 10.7% | 23.6% | 33.1% | |

| CaO | MRPE | 7.6% | 4.6% | 19.0% | 8.6% | 4.9% | 1.9% | 3.9% | 5.8% |

| RMSE | 0.056 | 0.040 | 0.122 | 0.063 | 0.038 | 0.016 | 0.030 | 0.048 | |

| SI | 8.9% | 6.3% | 19.2% | 10.1% | 6.1% | 2.4% | 4.8% | 7.8% | |

| PVC | 3.6% | 4.7% | 3.2% | 1.2% | 5.6% | 2.3% | 3.3% | 5.4% | |

| MgO | MRPE | 24.2% | 39.3% | 13.6% | 15.9% | 42.9% | 12.9% | 25.7% | 66.6% |

| RMSE | 0.015 | 0.028 | 0.007 | 0.005 | 0.029 | 0.007 | 0.058 | 0.037 | |

| SI | 35.1% | 61.6% | 16.6% | 15.0% | 56.3% | 15.8% | 34.5% | 60.9% | |

| PVC | 32.1% | 58.1% | 14.0% | 20.0% | 54.5% | 13.8% | 35.6% | 57.4% | |

| Variable | MRPE |

|---|---|

| Amount of Tapped Steel | 4.5% |

| Amount of Liquid Steel to CC | 3.4% |

| Amount of EAF Slag | 26.8% |

| Amount of LF Slag * | 9.7% |

| EAF Electrical Energy | 0.3% |

| LF Electrical Energy | 0.5% |

| C content (w/w) in Liquid Steel to CC | 6.1% |

| Mn content (w/w) in Liquid Steel to CC | 2.4% |

| Si content (w/w) in Liquid Steel to CC | 1.3% |

| Cr content (w/w) in Liquid Steel to CC | 11.2% |

| Ni content (w/w) in Liquid Steel to CC | 5.8% |

| Mo content (w/w) in Liquid Steel to CC | 2.3% |

| V content (w/w) in Liquid Steel to CC | 24.1% |

| Cu content (w/w) in Liquid Steel to CC | 0.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matino, I.; Petrucciani, A.; Zaccara, A.; Colla, V.; Prieto, M.F.; Pérez, R.A. Characterization of EAF and LF Slags Through an Upgraded Stationary Flowsheet Model of the Electric Steelmaking Route. Metals 2025, 15, 279. https://doi.org/10.3390/met15030279

Matino I, Petrucciani A, Zaccara A, Colla V, Prieto MF, Pérez RA. Characterization of EAF and LF Slags Through an Upgraded Stationary Flowsheet Model of the Electric Steelmaking Route. Metals. 2025; 15(3):279. https://doi.org/10.3390/met15030279

Chicago/Turabian StyleMatino, Ismael, Alice Petrucciani, Antonella Zaccara, Valentina Colla, Maria Ferrer Prieto, and Raquel Arias Pérez. 2025. "Characterization of EAF and LF Slags Through an Upgraded Stationary Flowsheet Model of the Electric Steelmaking Route" Metals 15, no. 3: 279. https://doi.org/10.3390/met15030279

APA StyleMatino, I., Petrucciani, A., Zaccara, A., Colla, V., Prieto, M. F., & Pérez, R. A. (2025). Characterization of EAF and LF Slags Through an Upgraded Stationary Flowsheet Model of the Electric Steelmaking Route. Metals, 15(3), 279. https://doi.org/10.3390/met15030279