Composition Optimization in Alloy Design for Nickel-Based Single Crystal Superalloy: A Review

Abstract

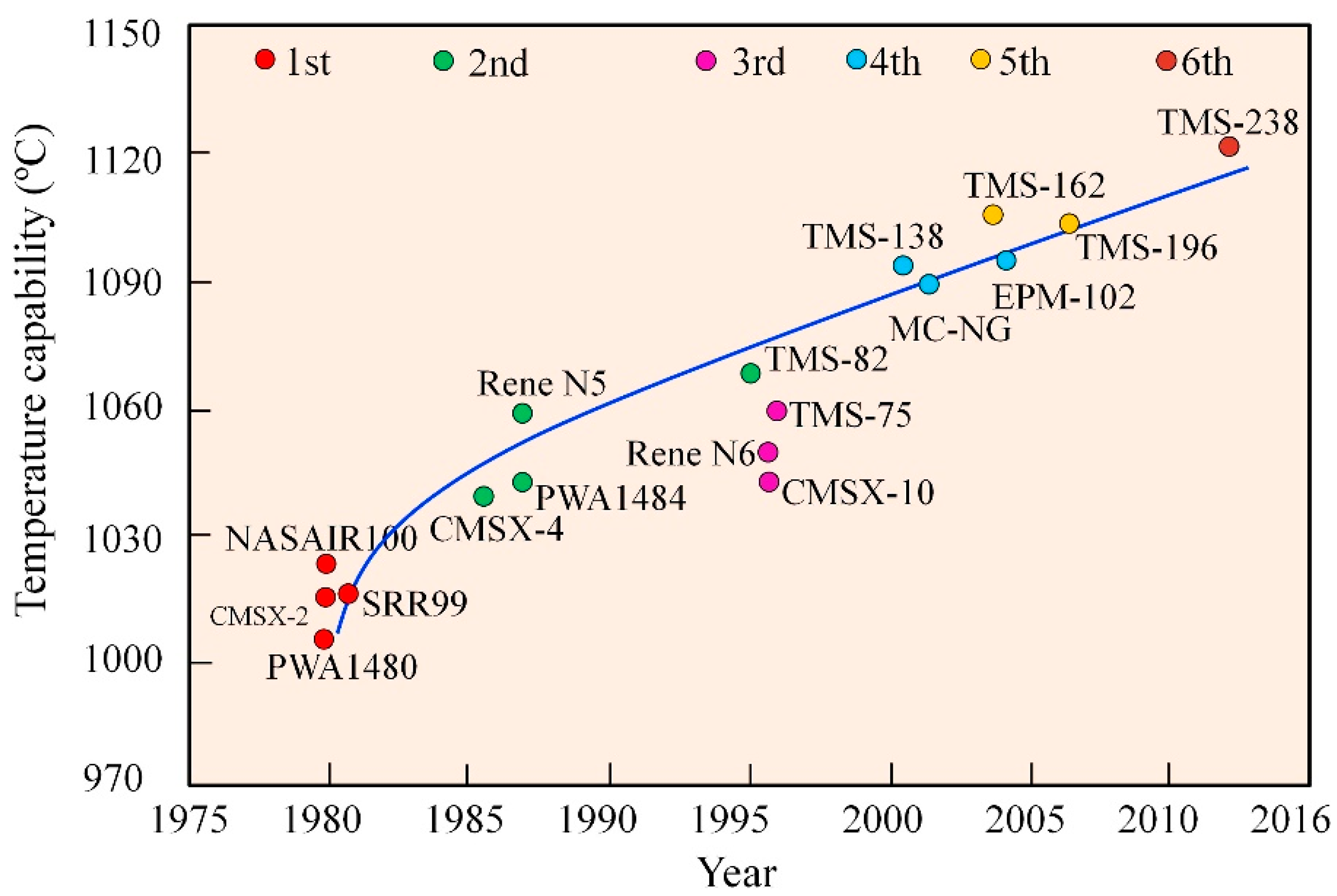

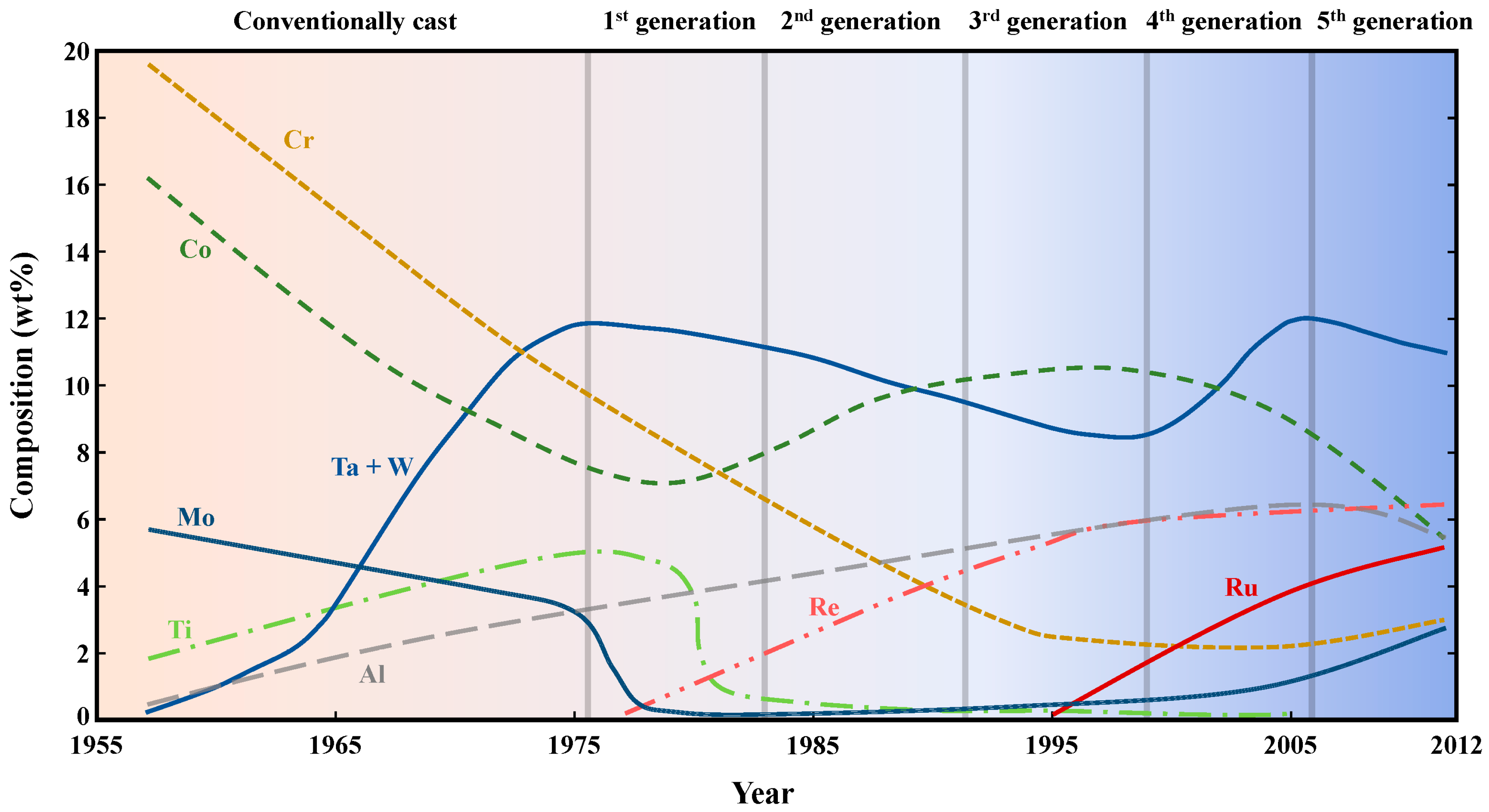

1. Introduction

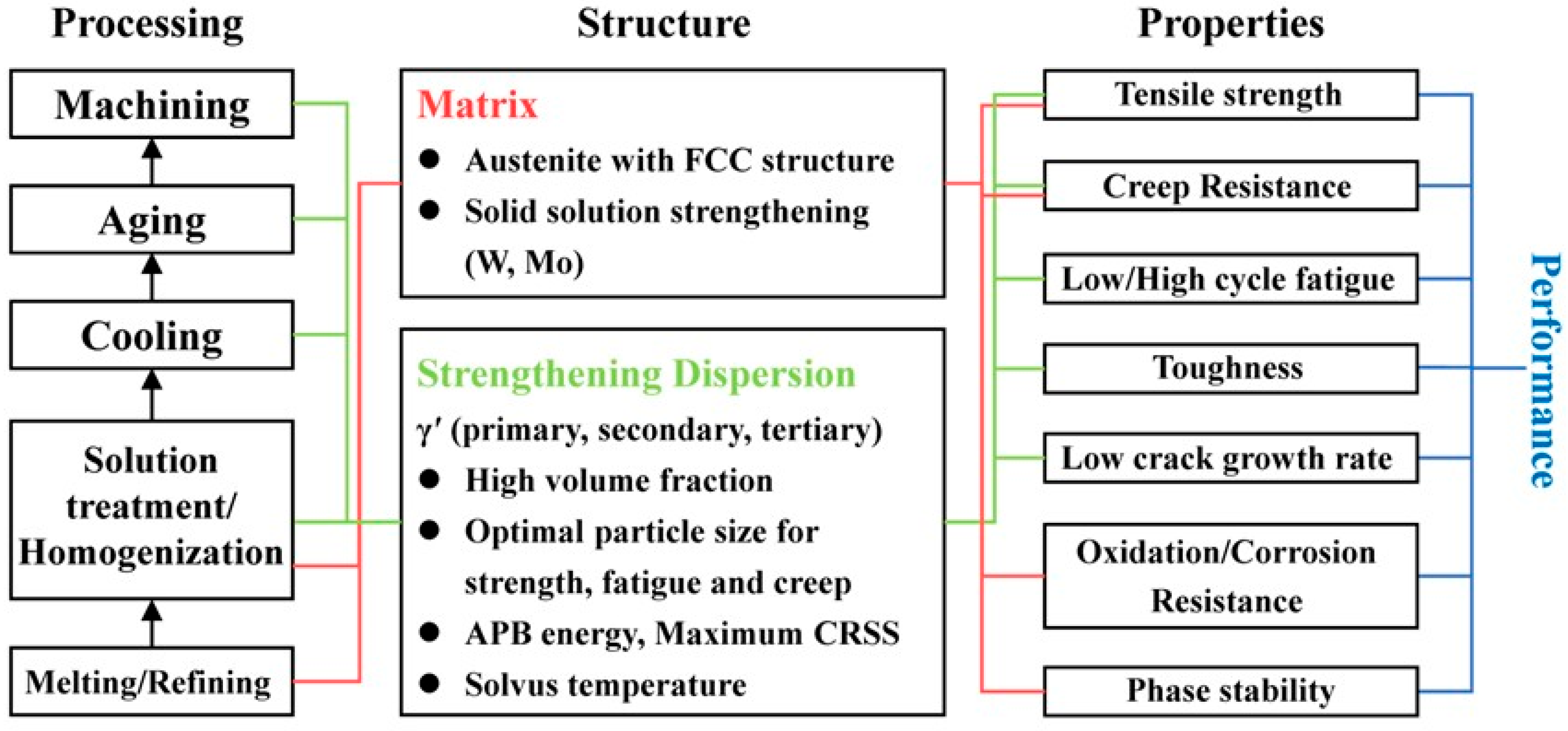

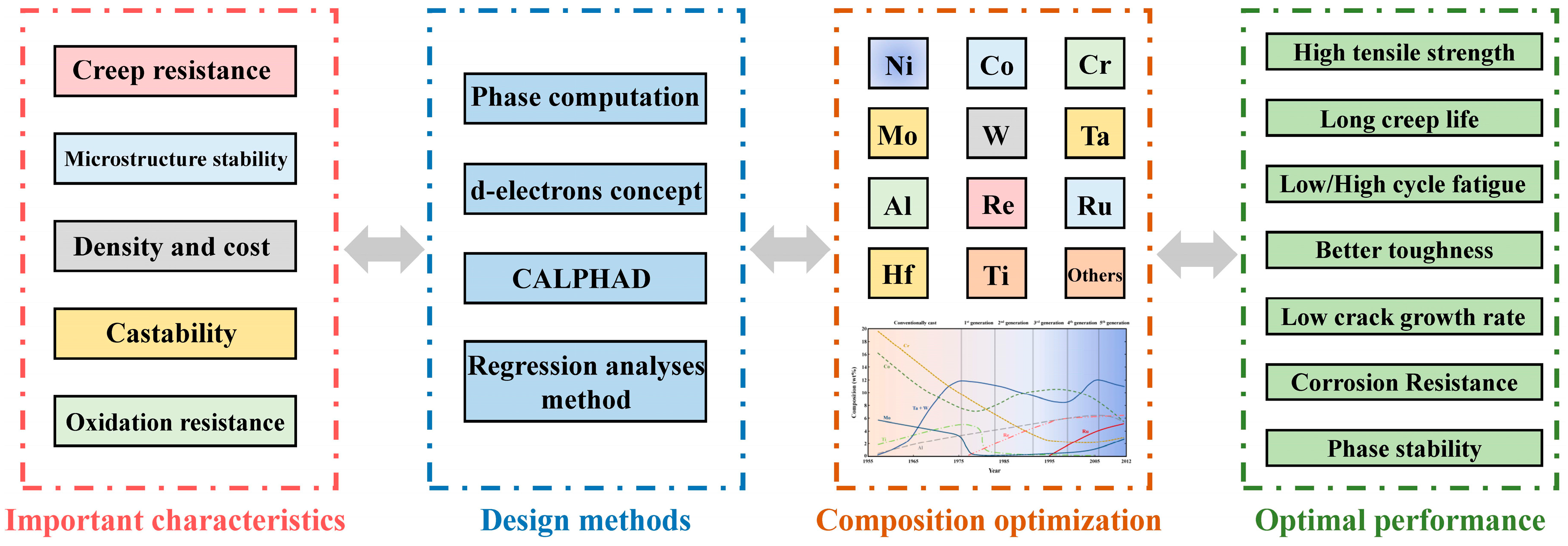

2. Design Method of Composition Optimization in Superalloy

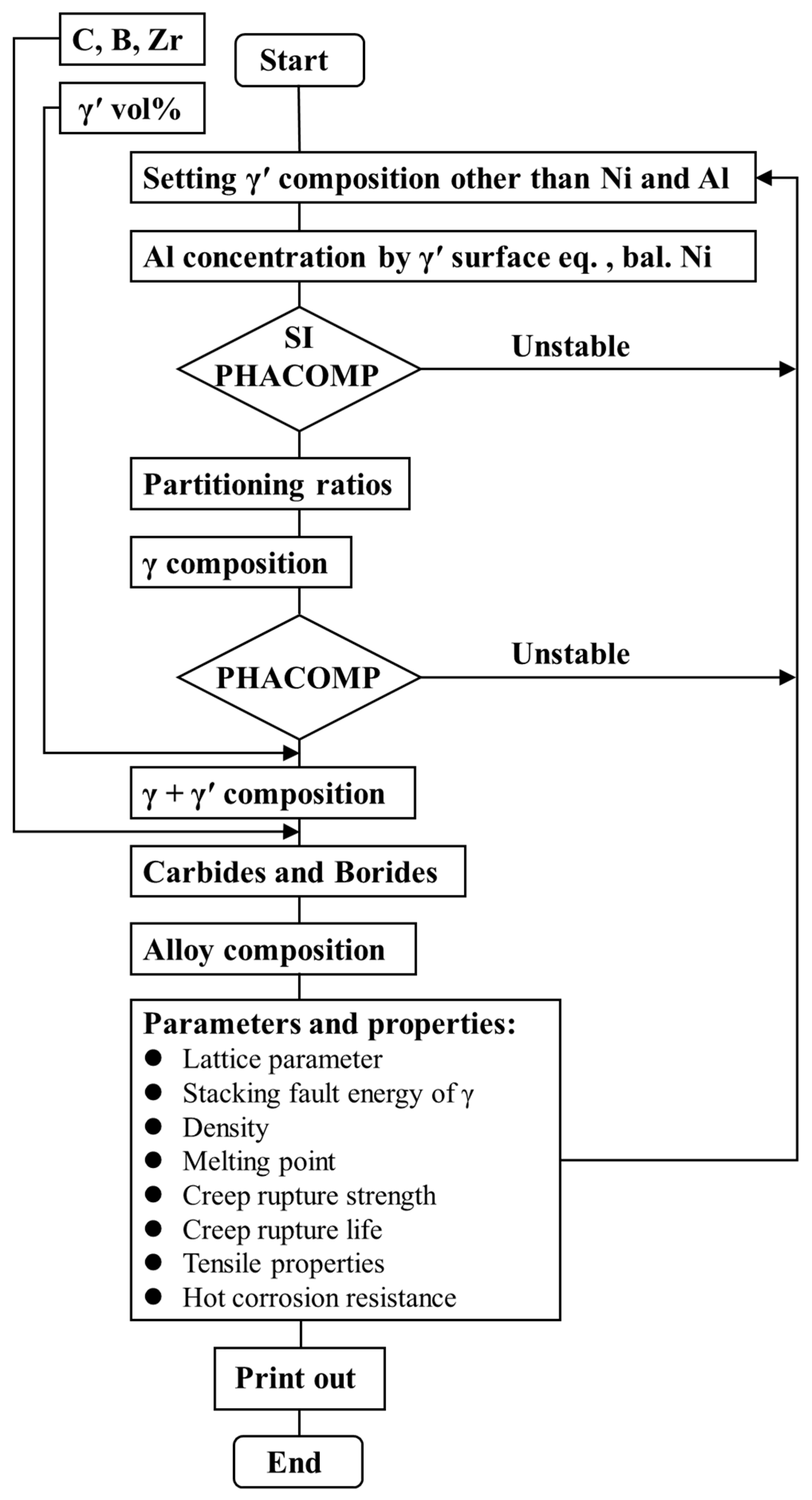

2.1. Phase Computation

2.2. d-Electrons Concept

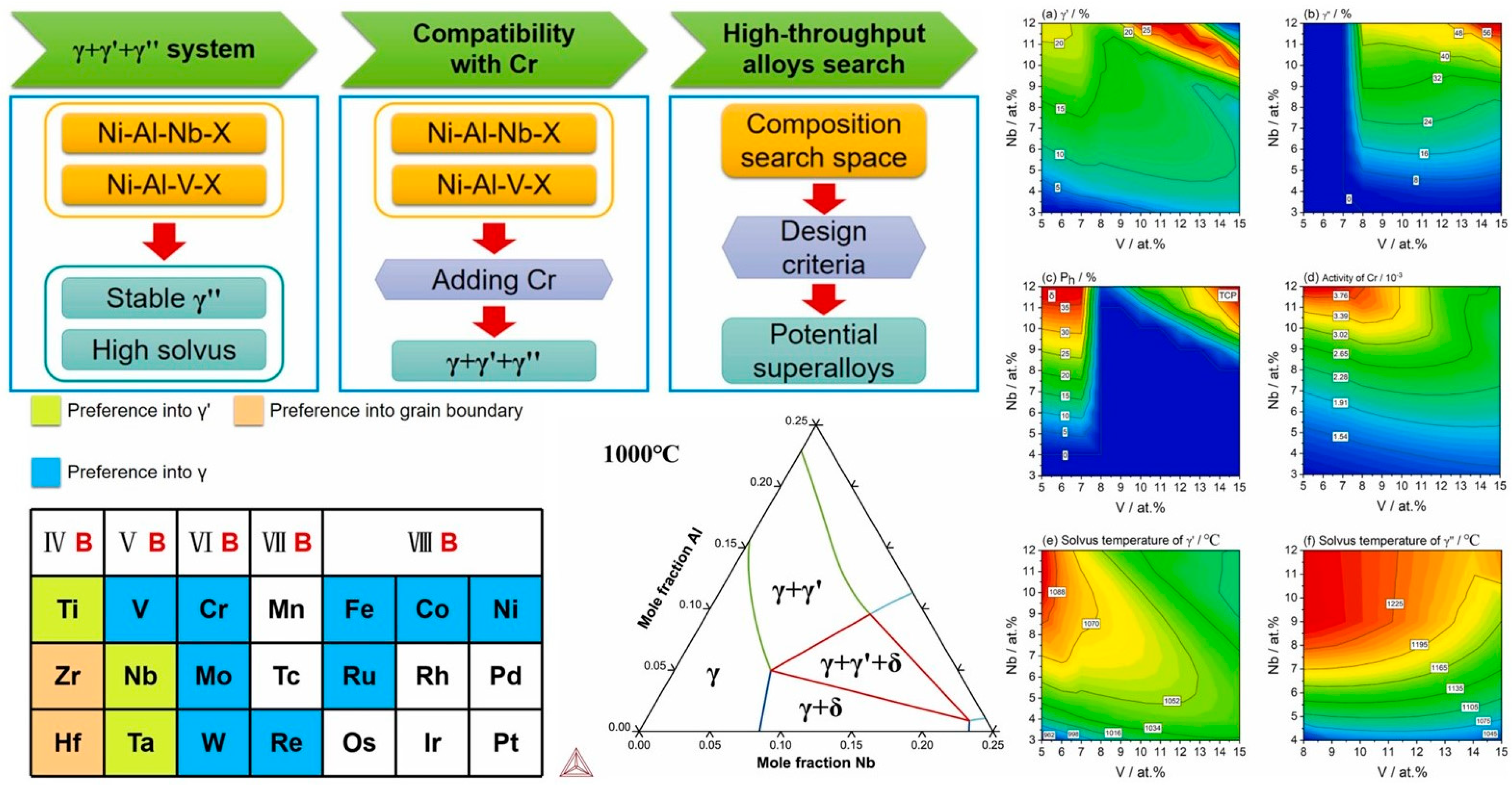

2.3. The Calculation of the Phase Diagram

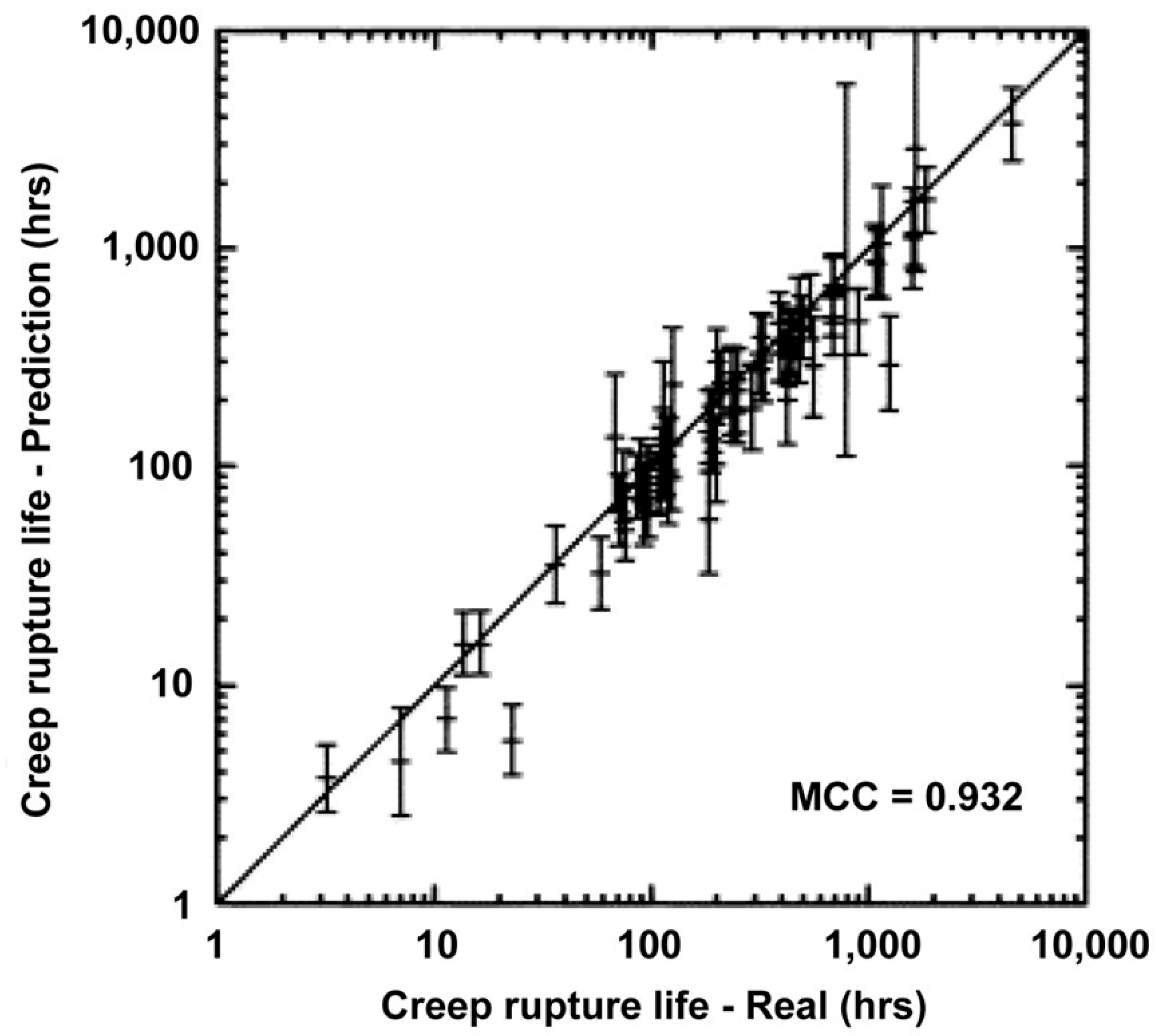

2.4. Regression Analyses Method

3. Key Factors of Composition Optimization in the Alloy Design Process

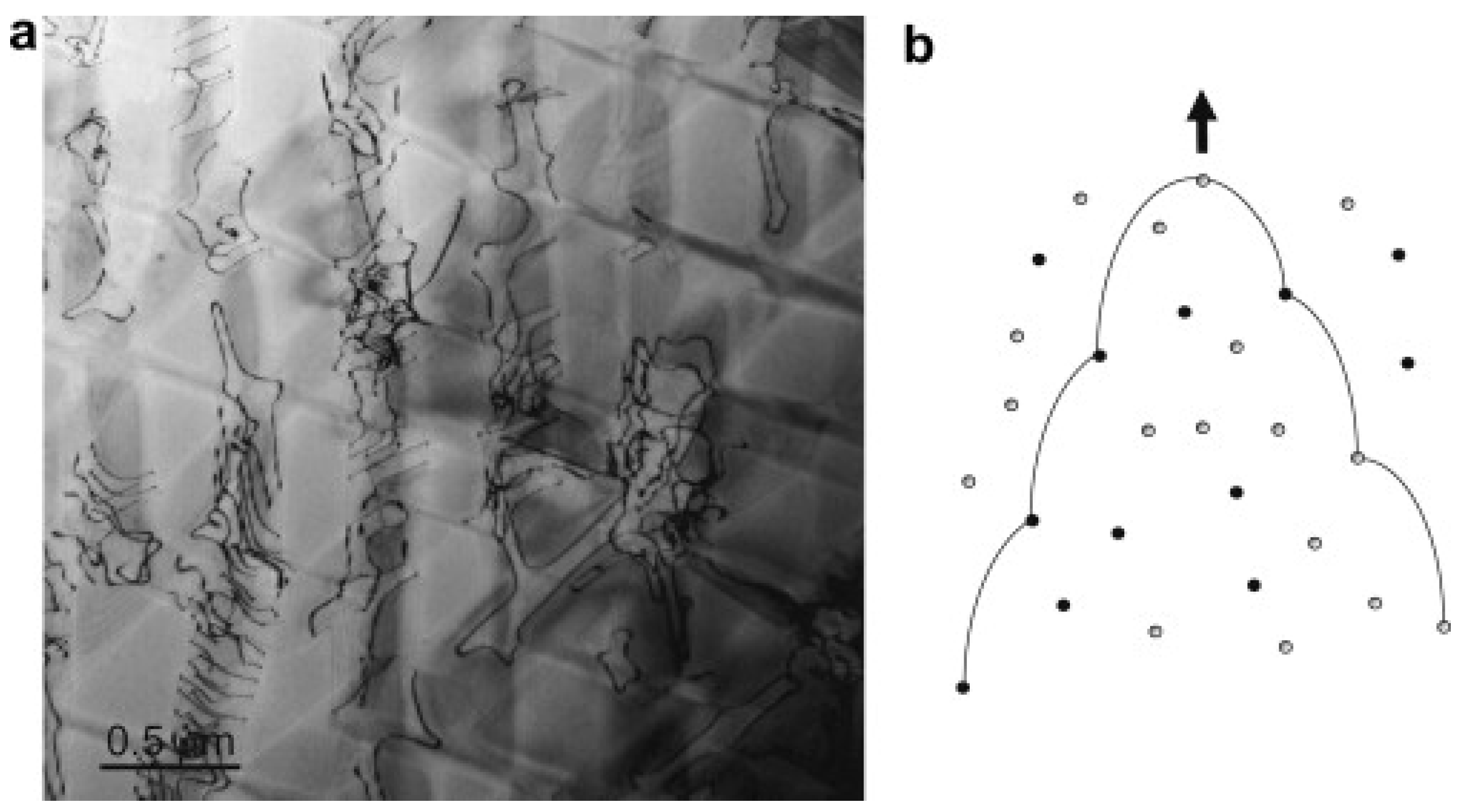

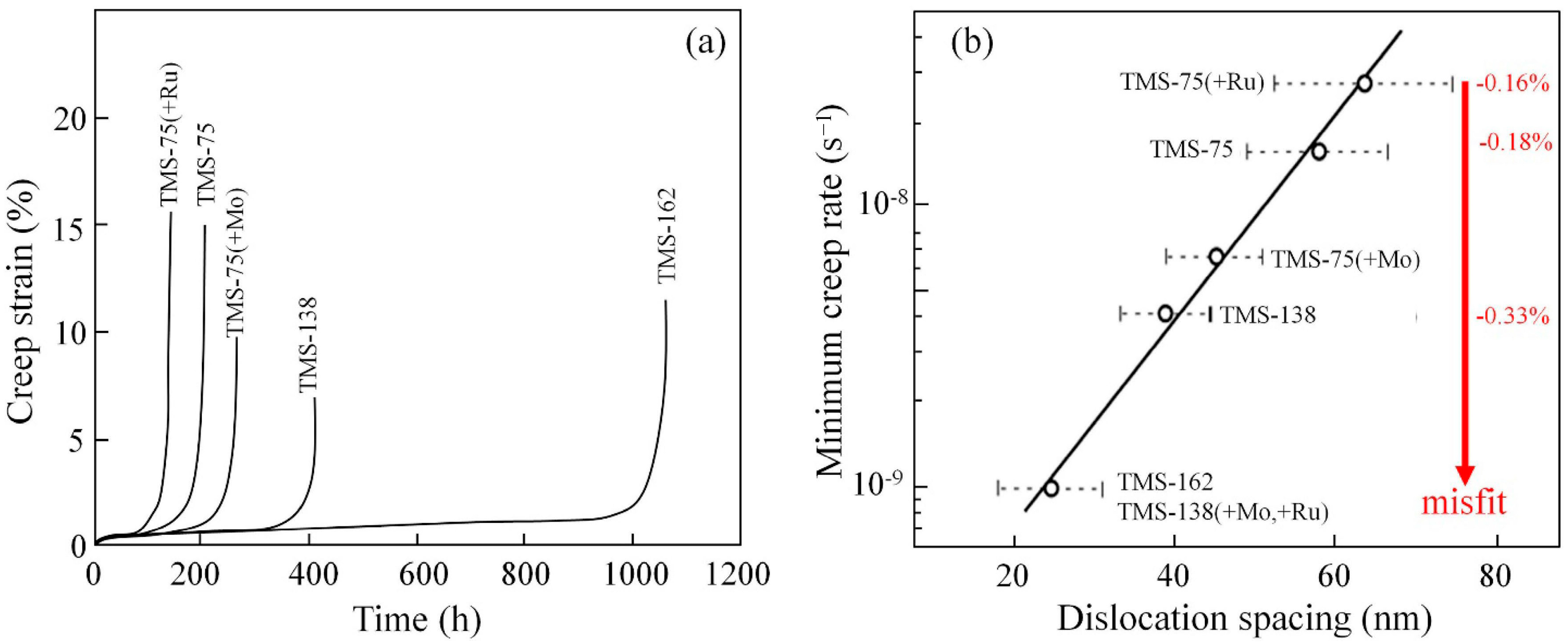

3.1. Creep Resistance

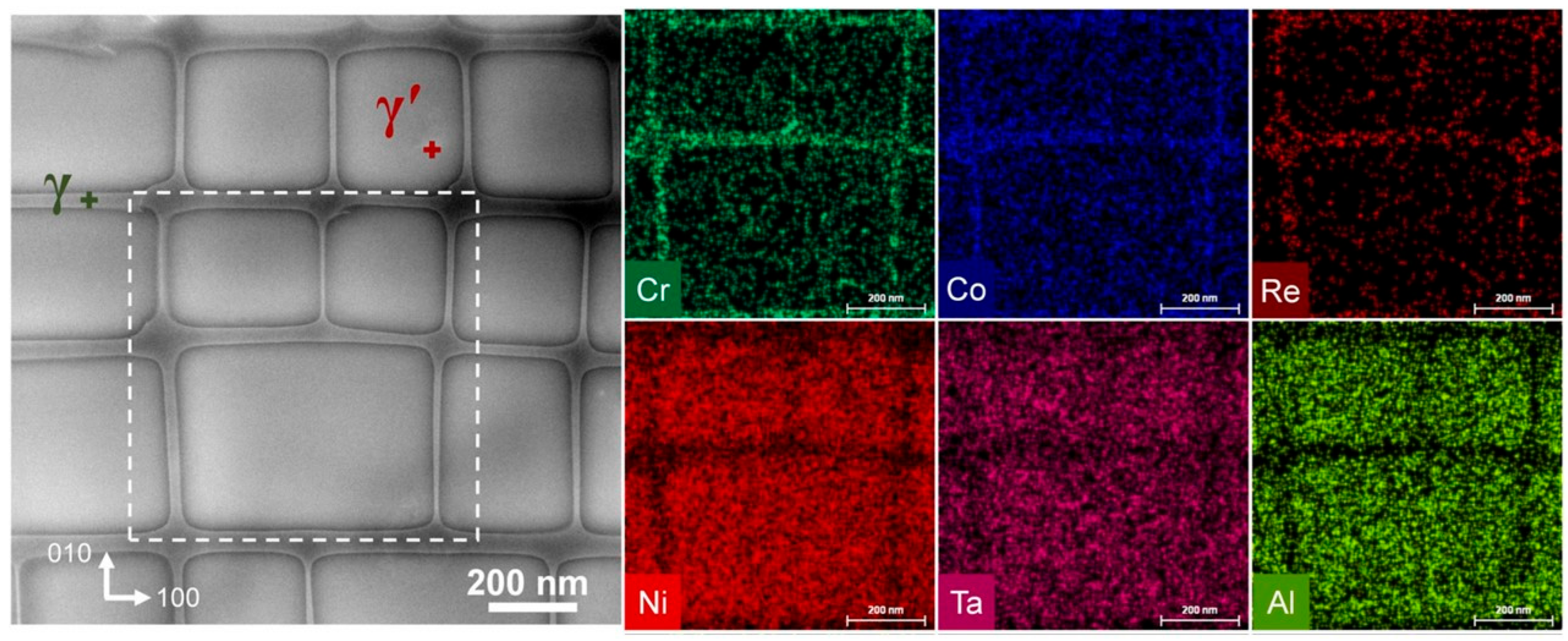

3.2. Microstructure Characteristics

3.2.1. Volume Fraction of the γ′ Phase

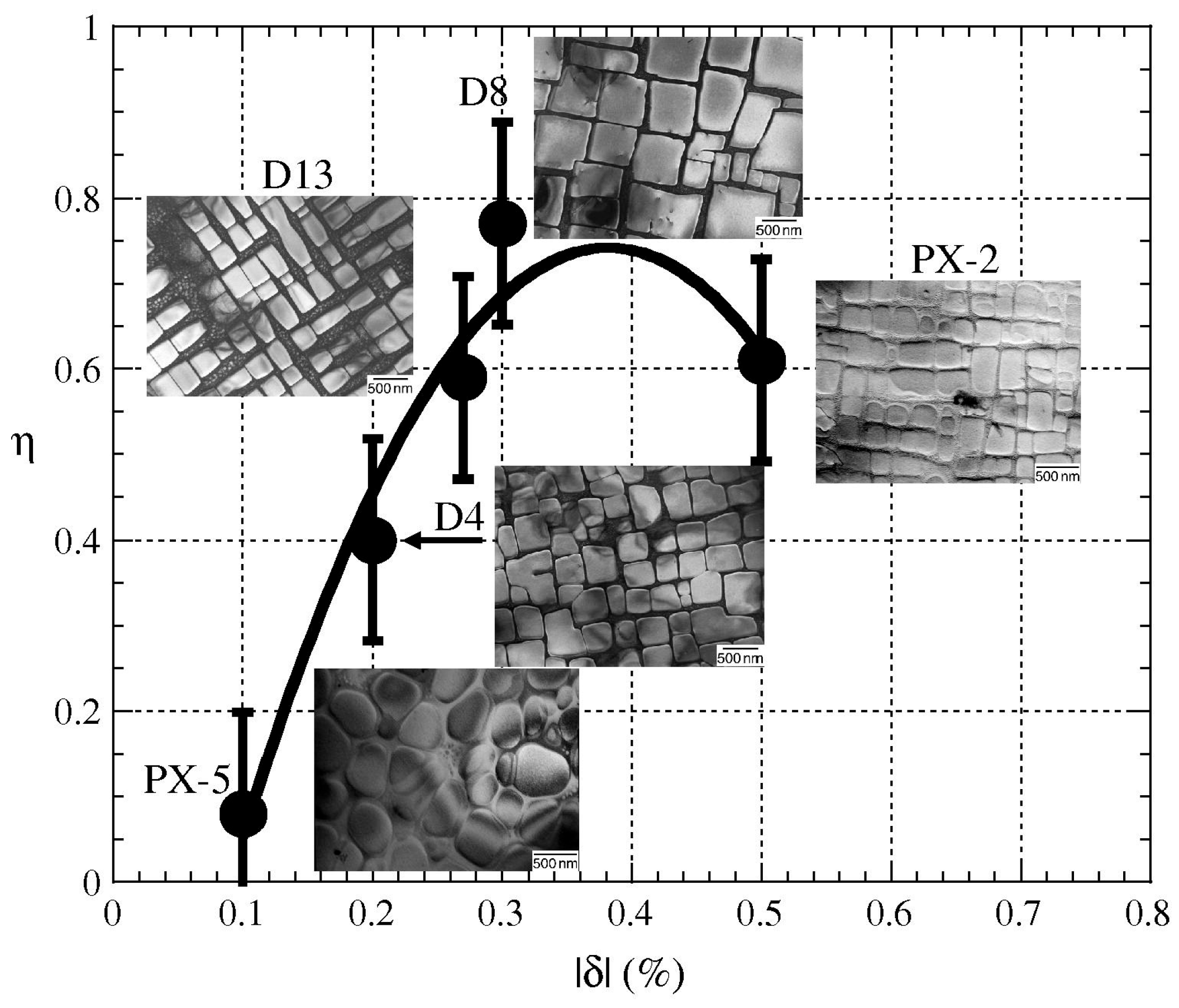

3.2.2. The Lattice Misfit of the γ/γ′ Phase Microstructure

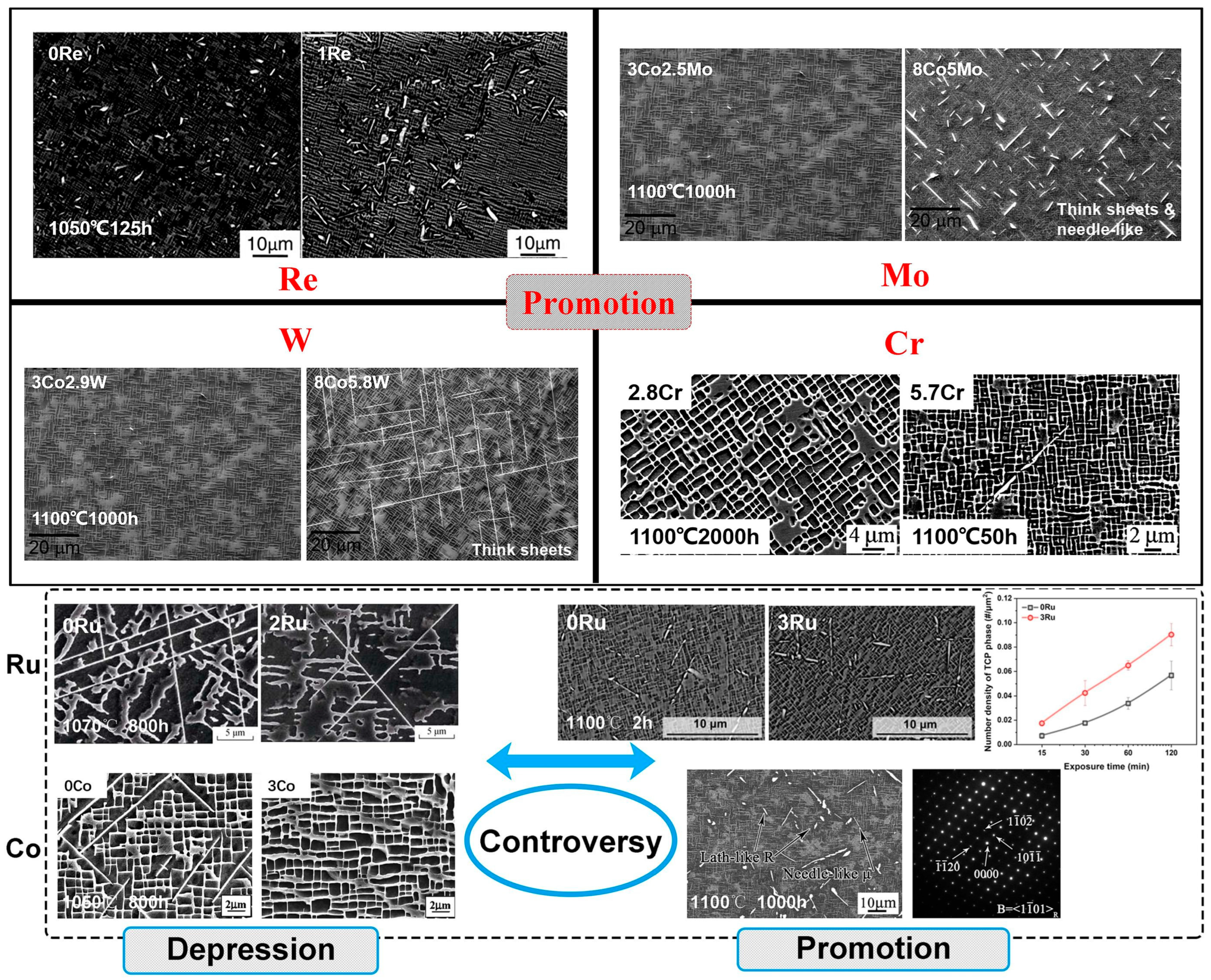

3.2.3. The Formation of TCP Phases

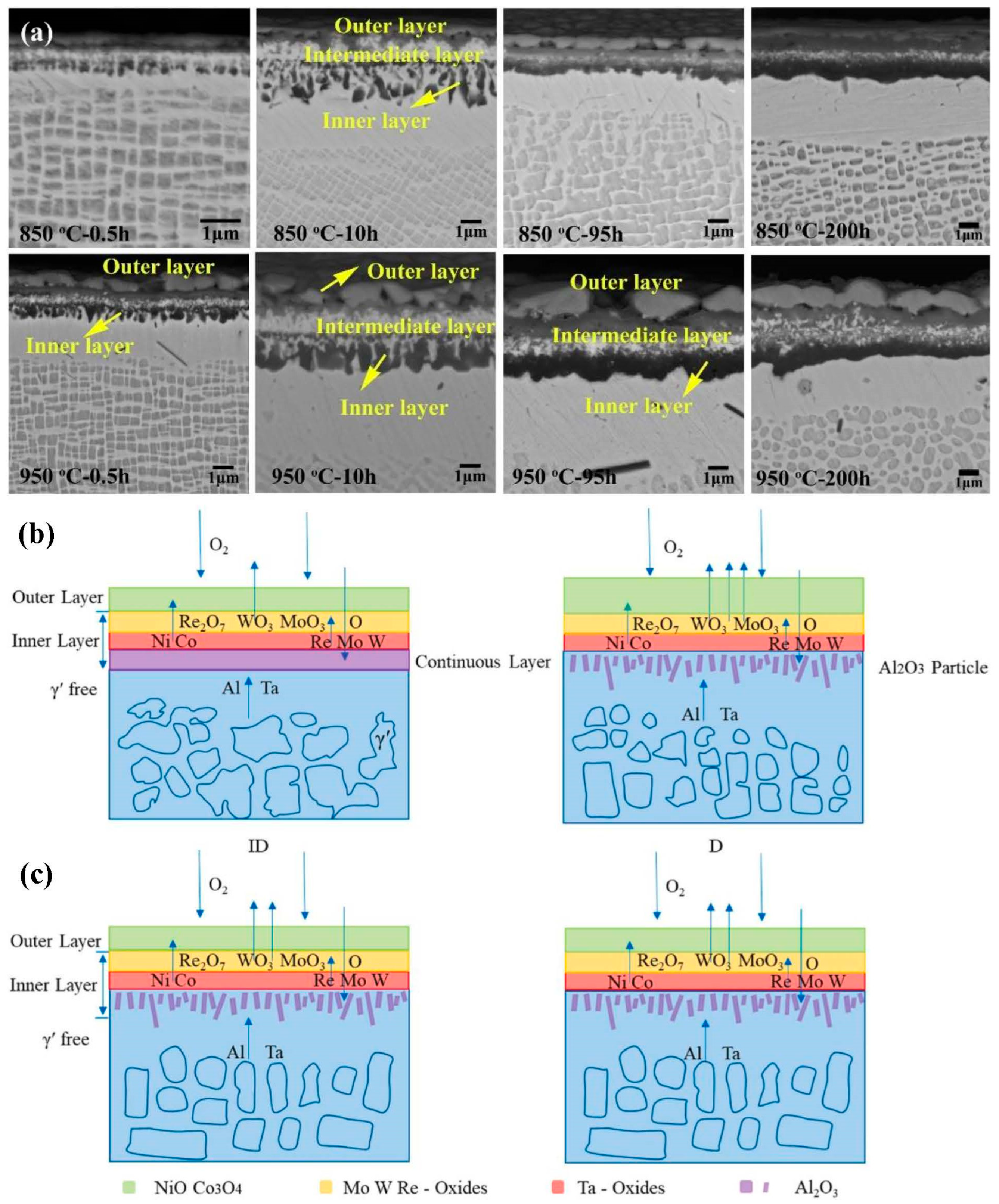

3.3. Oxidation Resistance

3.4. Castability

3.5. Density and Cost

4. Summary and Perspective

4.1. Summary

- The design methods for composition optimization for superalloy mainly include PHACOMP, the d-electrons concept, CALPHAD, and the regression analyses method. One or more of the above design methods may be used in the composition design process of SC superalloys. With the help of these methods, many kinds of SC superalloys with excellent performance have been designed, such as TMS series, CMSX series, DD series, and so on.

- Analyzing how alloying elements affect the creep resistance, microstructure, oxidation resistance, castability, density, and cost of superalloys is essential in alloy design to narrow down the vast combination space to a few optimal compositions.

- In order to obtain better high-temperature performance, the content of refractory elements (Ta + Re + W + Mo) increased gradually during the composition evolution of nickel-based SC superalloys. Ru was added into the fourth-generation nickel-based SC superalloy to inhibit the formation of the TCP phase and maintain the stability of the microstructures [35,156]. In addition, the content of Cr decreased significantly and the content of Co gradually increased to further improve the structural stability of high-generation SC superalloys.

- The optimization process of alloy composition has focused more on the presence of antioxidant elements (Al, Cr, Ta) to enhance oxidation resistance while balancing mechanical properties. In the process of alloy design, the influence of Ta, Mo, Re, and W content on castability also needs to be considered. Considering the cost and density of SC superalloys, the content of refractory elements needs to be appropriately reduced in the alloy’s design without affecting the key properties.

4.2. Outlook and Perspective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008; Volume 353, pp. 1–8. ISBN 978-1-139-45863-4. [Google Scholar]

- Caron, P.; Khan, T. Evolution of Ni-Based Superalloys for Single Crystal Gas Turbine Blade Applications. Aerosp. Sci. Technol. 1999, 3, 513–523. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in Structural Materials for Aerospace systems11The Golden Jubilee Issue—Selected Topics in Materials Science and Engineering: Past, Present and Future, Edited by S. Suresh. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Gibbons, T.B.; Hopkins, B.E. Creep Behaviour and Microstructure of Ni-Cr Base Alloys. Met. Sci. 1984, 18, 273–280. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep Behaviour of Ni-Base Single-Crystal Superalloys with Various γ’ Volume Fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Blavette, D.; Caron, P.; Khan, T. An Atom Probe Investigation of the Role of Rhenium Additions in Improving Creep Resistance of Ni-Base Superalloys. Scr. Metall. 1986, 20, 1395–1400. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Liu, Y.; Zhang, Z.; Han, X. Microstructural and Compositional Design of Ni-Based Single Crystalline Superalloys―A Review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Kawagishi, K.; Yeh, A.-C.; Yokokawa, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Development of an Oxidation-Resistant High-Strength Sixth-Generation Single-Crystal Superalloy TMS-238. In Superalloys 2012; Wiley: Hoboken, NJ, USA, 2012; pp. 189–195. ISBN 978-0-470-94320-5. [Google Scholar]

- Durand-Charre, M. The Microstructure of Superalloys; Routledge: London, UK, 2017; ISBN 978-0-203-73638-8. [Google Scholar]

- Alkmin, L.B.; Utada, S.; Chaia, N.; Reis, D.A.; Coelho, G.C.; Cormier, J.; Nunes, C.A. Creep Behavior of Conventional and Nb-Modified as-Cast MAR-M246 Superalloy. Mater. Sci. Eng. A 2021, 813, 141170. [Google Scholar] [CrossRef]

- Zhu, L.; Yu, X.; Li, W.; Zhang, L.; Zhang, N.; Lv, Y.; Zhao, L.; Zhang, W.; Wang, Z.; Yu, H.; et al. High-Throughput Investigation of Nb and Ta Alloying Effects on the Microstructure and Properties of a Novel Ni-Co-Based Superalloy. Scr. Mater. 2023, 226, 115215. [Google Scholar] [CrossRef]

- Yeh, A.C.; Kawagishi, K.; Harada, H.; Yokokawa, T.; Koizumi, Y.; Kobayashi, T.; Ping, D.H.; Fujioka, J.; Suzuki, T. Development of Si-Bearing 4th Generation Ni-Base Single Crystal Superalloys. In Proceedings of the International Symposium on Superalloys; TMS: Pittsburgh, PA, USA, 2008; pp. 619–628. [Google Scholar] [CrossRef]

- Sato, A.; Moverare, J.J.; Hasselqvist, M.; Reed, R.C. On the Mechanical Behavior of a New Single-Crystal Superalloy for Industrial Gas Turbine Applications. Metall. Mater. Trans. A 2012, 43, 2302–2315. [Google Scholar] [CrossRef]

- Sato, A.; Chiu, Y.-L.; Reed, R.C. Oxidation of Nickel-Based Single-Crystal Superalloys for Industrial Gas Turbine Applications. Acta Mater. 2011, 59, 225–240. [Google Scholar] [CrossRef]

- Zhu, H.Q.; Guo, S.R.; Guan, H.R.; Zhu, V.X.; Hu, Z.Q.; Murata, V.; Morinaga, M. The Effect of Silicon on the Microstructure and Segregation of Directionally Solidified IN738 Superalloy. Mater. High Temp. 1994, 12, 285–291. [Google Scholar] [CrossRef]

- Reed, R.C.; Tao, T.; Warnken, N. Alloys-By-Design: Application to Nickel-Based Single Crystal Superalloys. Acta Mater. 2009, 57, 5898–5913. [Google Scholar] [CrossRef]

- Wu, Q.; Li, S. Alloying Element Additions to Ni3Al: Site Preferences and Effects on Elastic Properties from First-Principles Calculations. Comput. Mater. Sci. 2012, 53, 436–443. [Google Scholar] [CrossRef]

- Yan, J.; Gu, Y.; Dang, Y.; Zhao, X.; Lu, J.; Yuan, Y.; Yang, Z.; Yin, H. Effect of Carbon on the Microstructure Evolution and Mechanical Properties of Low Si-Containing Centrifugal Casting 20Cr32Ni1Nb Alloy. Mater. Chem. Phys. 2016, 175, 107–117. [Google Scholar] [CrossRef]

- Bagot, P.A.J.; Silk, O.B.W.; Douglas, J.O.; Pedrazzini, S.; Crudden, D.J.; Martin, T.L.; Hardy, M.C.; Moody, M.P.; Reed, R.C. An Atom Probe Tomography Study of Site Preference and Partitioning in a Nickel-Based Superalloy. Acta Mater. 2017, 125, 156–165. [Google Scholar] [CrossRef]

- Christofidou, K.A.; Jones, N.G.; Pickering, E.J.; Flacau, R.; Hardy, M.C.; Stone, H.J. The Microstructure and Hardness of Ni-Co-Al-Ti-Cr Quinary Alloys. J. Alloys Compd. 2016, 688, 542–552. [Google Scholar] [CrossRef]

- Matysiak, H.; Zagorska, M.; Andersson, J.; Balkowiec, A.; Cygan, R.; Rasinski, M.; Pisarek, M.; Andrzejczuk, M.; Kubiak, K.; Kurzydlowski, K.J. Microstructure of Haynes® 282® Superalloy after Vacuum Induction Melting and Investment Casting of Thin-Walled Components. Materials 2013, 6, 5016–5037. [Google Scholar] [CrossRef]

- Yao, X.; Ding, Q.; Wei, X.; Wang, J.; Zhang, Z.; Bei, H. The Effects of Key Elements Re and Ru on the Phase Morphologies and Microstructure in Ni-Based Single Crystal Superalloys. J. Alloys Compd. 2022, 926, 166835. [Google Scholar] [CrossRef]

- Chen, J.; Huo, Q.; Chen, J.; Wu, Y.; Li, Q.; Xiao, C.; Hui, X. Tailoring the Creep Properties of Second-Generation Ni-Based Single Crystal Superalloys by Composition Optimization of Mo, W and Ti. Mater. Sci. Eng. A 2021, 799, 140163. [Google Scholar] [CrossRef]

- Chen, J.; Chen, J.; Wang, Q.; Wu, Y.; Li, Q.; Xiao, C.; Li, S.; Wang, Y.; Hui, X. Enhanced Creep Resistance Induced by Minor Ti Additions to a Second Generation Nickel-Based Single Crystal Superalloy. Acta Mater. 2022, 232, 117938. [Google Scholar] [CrossRef]

- Morinaga, M.; Yukawa, N.; Ezaki, H.; Adachi, H. Solid Solubilities in Transition-Metal-Based f.c.c. Alloys. Philos. Mag. A 1985, 51, 223–246. [Google Scholar] [CrossRef]

- Zhang, J.X.; Harada, H.; Ro, Y.; Koizumi, Y.; Kobayashi, T. Thermomechanical Fatigue Mechanism in a Modern Single Crystal Nickel Base Superalloy TMS-82. Acta Mater. 2008, 56, 2975–2987. [Google Scholar] [CrossRef]

- Hemmersmeier, U.; Feller-Kniepmeier, M. Element Distribution in the Macro- and Microstructure of Nickel Base Superalloy CMSX-4. Mater. Sci. Eng. A 1998, 248, 87–97. [Google Scholar] [CrossRef]

- Wahl, J.B.; Harris, K. Cmsx-4® Plus Single Crystal Alloy Development, Characterization and Application Development. In Superalloys 2016; TMS: Pittsburgh, PA, USA, 2016; pp. 25–33. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, X.; Yue, L.; Zhang, Z. A Review of Composition Evolution in Ni-Based Single Crystal Superalloys. J. Mater. Sci. Technol. 2020, 44, 76–95. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Koizumi, Y.; Kobayashi, T.; Harada, H. Strengthening by γ/γ’ Interfacial Dislocation Networks in TMS-162—Toward a Fifth-Generation Single-Crystal Superalloy. Metall. Mater. Trans. A 2004, 35, 1911–1914. [Google Scholar] [CrossRef]

- Mottura, A.; Warnken, N.; Miller, M.K.; Finnis, M.W.; Reed, R.C. Atom Probe Tomography Analysis of the Distribution of Rhenium in Nickel Alloys. Acta Mater. 2010, 58, 931–942. [Google Scholar] [CrossRef]

- Yagi, R.; Okabe, T.H. Current Status and Smelting Technologies of Rhenium. Nippon. Kinzoku Gakkaishi J. Jpn. Inst. Met. 2016, 80, 341–349. [Google Scholar] [CrossRef]

- Lv, P.; Liu, L.; Zhou, Z.; Ge, C.; Zhang, J.; Zhao, Y. Insights in Improving Creep Resistance of Low-Cost 2nd-Generation Nickel Based Single Crystal Superalloys at Intermediate Temperature. Scr. Mater. 2025, 257, 116481. [Google Scholar] [CrossRef]

- Tan, X.; Liu, J.; Jin, T.; Hu, Z.; Hong, H.U.; Choi, B.G.; Kim, I.S.; Yoo, Y.S.; Jo, C.Y. Effect of Ruthenium on Precipitation Behavior of the Topologically Close-Packed Phase in a Single-Crystal Ni-Based Superalloy During High-Temperature Exposure. Metall. Mater. Trans. A 2012, 43, 3608–3614. [Google Scholar] [CrossRef]

- Sato, A.; Harada, H.; Yokokawa, T.; Murakumo, T.; Koizumi, Y.; Kobayashi, T.; Imai, H. The Effects of Ruthenium on the Phase Stability of Fourth Generation Ni-Base Single Crystal Superalloys. Scr. Mater. 2006, 54, 1679–1684. [Google Scholar] [CrossRef]

- Emokpaire, S.O.; Wang, N.; Liu, J.; Zhu, C.; Wang, X.; Li, J.; Zhou, Y. Effect of Ru on Deformation Mechanism and Microstructure Evolution of Single-Crystal Superalloys under Medium-Temperature and High-Stress Creep. Materials 2023, 16, 2732. [Google Scholar] [CrossRef]

- Boesch, W.J.; Canada, H.B. Phases Present in the Wrought Superalloy Udimet 700. JOM 1968, 20, 46–50. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, Q.; Xie, M.; Qin, H.; Yuan, X.; Xie, J. Influence of Ru on the Solidification and Microstructure Characteristics of Co-Free Nickel-Based Single Crystal Superalloys. J. Alloys Compd. 2025, 1033, 181168. [Google Scholar] [CrossRef]

- Murata, Y.; Miyazaki, S.; Morinaga, M.; Hashizume, R. Hot Corrosion Resistant and High Strength Nickel-Based Single Crystal and Directionally-Solidified Superalloys Developed by the d-Electrons Concept. In Superalloys 1996; TMS: Pittsburgh, PA, USA, 1996; pp. 61–70. [Google Scholar]

- Moniruzzaman, M.; Murata, Y.; Morinaga, M.; Hashizume, R.; Yoshinari, A.; Fukui, Y. Alloy Design of Ni-Based Single Crystal Superalloys for the Combination of Strength and Surface Stability at Elevated Temperatures. ISIJ Int. 2003, 43, 1244–1252. [Google Scholar] [CrossRef]

- Sugiyama, K.; Sumi, Y.; Kanno, N.; Higashi, M.; Takai, R.; Ishikawa, S.; Sasaki, K. Alloy Design and Microstructural Evolution During Heat Treatment of Newly Developed Cast and Wrought Ni-Base Superalloy M647 for Turbine Disk Application. In Proceedings of the Superalloys 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 91–102. [Google Scholar]

- Boesch, W.J.; Cremisio, R.S.; Richmond, F.M. Progress in Superalloys for SST Jet Engines. JOM 1967, 19, 8–10. [Google Scholar] [CrossRef]

- Guo, J. Application of electron vacancy theory in superalloys. PHYSICS 1982, 11, 661–666. [Google Scholar]

- Woodyatt, L.R.; Sims, C.T.; Beattie, H.J., Jr. Prediction of Sigma-Type Phase Occurrence-from Compositions in Austenitic Superalloys. Trans Met. Soc AIME 1966, 236, 519–527. [Google Scholar]

- Li, J.R.; Zhong, Z.G.; Tang, D.Z.; Liu, S.Z.; Wei, P.; Wei, P.Y.; Wu, Z.T.; Huang, D.; Han, M. A Low-Cost Second Generation Single Crystal Superalloy DD6. In Superalloys 2020; TMS: Pittsburgh, PA, USA, 2000; pp. 777–783. [Google Scholar]

- Matsugi, K.; Murata, Y.; Morinaga, M.; Yukawa, N. Nickel-base Single Crystal Superalloys Designed by A d- Electrons Concept. In Computer Aided Innovation of New Materials; Doyama, M., Suzuki, T., Kihara, J., Yamamoto, R., Eds.; Elsevier: Oxford, UK, 1991; pp. 831–834. ISBN 978-0-444-88864-8. [Google Scholar]

- Morinaga, M.; Yukawa, N.; Adachi, H.; Ezaki, H. New Phacomp and Its Applications to Alloy Design. In Superalloys 1984; TMS: Pittsburgh, PA, USA, 1984; pp. 523–532. [Google Scholar] [CrossRef]

- Yukawa, N.; Morinaga, M.; Murata, Y.; Ezaki, H.; Inoue, S. High Performance Single Crystal Superalloys Developed by the D-Electrons Concept. In Superalloys 1988; TMS: Pittsburgh, PA, USA, 1988; pp. 225–234. [Google Scholar] [CrossRef]

- Matsugi, K.; Murata, Y.; Morinaga, M.; Yukawa, N. Realistic Advancement for Nickel-Based Single Crystal Superalloys by the d-Electrons Concept. In Superalloys 1992; TMS: Pittsburgh, PA, USA, 1992; pp. 307–316. [Google Scholar] [CrossRef]

- Jishan, Z.; Hua, C.U.I.; Zhuangqi, H.U.; Murata, Y.; Morinaga, M.; Yukawa, N. Application of d-Electron Alloy Design Theory to Development of Hot Corrosion resistant Ni-based single crystal superalloys—I. Characterization of Phase Stability. Acta Met. Sin 1993, 29, 5–12. [Google Scholar]

- Jishan, Z.; Hua, C.U.I.; Zhuangqi, H.U.; Murata, Y.; Morinaga, M.; Yukawa, N. Application of d-Electron Alloy Design Theory to Development of Hot Corrosion resistant Ni-based single crystal superalloys—II. Effects of Refractory Metals Ti, Ta and Nb on Microstructure and Properties. Acta Met. Sin 1993, 29, 13–22. [Google Scholar]

- Jishan, Z.; Hua, C.U.I.; Zhuangqi, H.U.; Murata, Y.; Morinaga, M.; Yukawa, N. Application of d-Electron Alloy Design Theory to Development of Hot Corrosion resistant Ni-based single crystal superalloys—III. Characterization of Properties. Acta Met. Sin 1994, 30, 70–78. [Google Scholar]

- Ågren, J. CALPHAD and the Materials Genome A 10 Year Anniversary. Calphad 2023, 80, 102532. [Google Scholar] [CrossRef]

- Xu, B.; Yin, H.; Jiang, X.; Zhang, C.; Zhang, R.; Wu, M.; Qu, X.; Huangfu, W. CALPHAD Design and High-Throughput Search of Novel Ni-Based Superalloys That Are Reinforced by γ′ + γ″. Mater. Today Commun. 2022, 30, 103164. [Google Scholar] [CrossRef]

- Crudden, D.J.; Raeisinia, B.; Warnken, N.; Reed, R.C. Analysis of the Chemistry of Ni-Base Turbine Disk Superalloys Using An Alloys-By-Design Modeling Approach. Metall. Mater. Trans. A 2013, 44, 2418–2430. [Google Scholar] [CrossRef]

- Zhu, N.-Q.; Liu, W.; Wang, Z.-C.; Lu, X.-G. Modeling of Molar Volume for the Ni–Al γ/Γ’ Binary Phases within the Framework of CALPHAD Method. Calphad 2020, 71, 101792. [Google Scholar] [CrossRef]

- Conduit, B.D.; Jones, N.G.; Stone, H.J.; Conduit, G.J. Design of a Nickel-Base Superalloy Using a Neural Network. Mater. Des. 2017, 131, 358–365. [Google Scholar] [CrossRef]

- Kitashima, T.; Wang, J.; Harada, H. Phase-Field Simulation with the CALPHAD Method for the Microstructure Evolution of Multi-Component Ni-Base Superalloys. Intermetallics 2008, 16, 239–245. [Google Scholar] [CrossRef]

- Harada, H.; Yamazaki, M.; Koizumi, Y.; Sakuma, N.; Furuya, N.; Kamiya, H. Alloy Design for Nickel-Base Superalloys. In Proceedings of the High Temperature Alloys for Gas Turbines 1982; Brunetaud, R., Coutsouradis, D., Gibbons, T.B., Lindblom, Y., Meadowcroft, D.B., Stickler, R., Eds.; Springer: Dordrecht, The Netherlands, 1982; pp. 721–735. [Google Scholar]

- Yamazaki, M. Design and Development of Superalloys in Japan. In Transactions of the Materials Research Society of Japan; Sōmiya, S., Doyama, M., Hasegawa, M., Agata, Y., Eds.; Springer: Dordrecht, The Netherlands, 1990; pp. 105–118. ISBN 978-94-009-0789-8. [Google Scholar]

- Harada, H.; Ohno, K.; Yamagata, T.; Yokokawa, T.; Yamazaki, M. Phase Calculation and Its Use in Alloy Design Program for Nickel-Base Superalloys. In Superalloys 1988; TMS: Pittsburgh, PA, USA, 1988; pp. 733–742. [Google Scholar]

- Sato, A.; Harada, H.; Yeh, A.-C.; Kawagishi, K.; Kobayashi, T.; Koizumi, Y.; Yokokawa, T.; Zhang, J.-X. A 5th Generation SC Superalloy with Balanced High Temperature Properties and Processability. In Superalloys 2008; TMS: Pittsburgh, PA, USA, 2008; pp. 131–138. [Google Scholar] [CrossRef]

- Koizumi, Y.; Kobayashi, T.; Yokokawa, T.; Zhang, J.; Osawa, M.; Harada, H.; Aoki, Y.; Arai, M. Development of Next-Generation Ni-Base Single Crystal Superalloys. In Superalloys 2004; TMS: Pittsburgh, PA, USA, 2004; Volume 67, pp. 35–43. [Google Scholar]

- Saito, T.; Yuyama, M.; Murakami, H. Effect of Cobalt Presence on Creep Properties of Ni-Based Single Crystal Superalloys at Intermediate Temperature. J. Alloys Compd. 2025, 1022, 179871. [Google Scholar] [CrossRef]

- Nowotnik, A.; Kubiak, K.; Sieniawski, J.; Rokicki, P.; Pędrak, P.; Mrówka, G. Development of Nickel Based Superalloys for Advanced Turbine Engines. Mater. Sci. Forum 2014, 783–786, 2491–2496. [Google Scholar] [CrossRef]

- Yoo, Y.S.; Jo, C.Y.; Jones, C.N. Compositional Prediction of Creep Rupture Life of Single Crystal Ni Base Superalloy by Bayesian Neural Network. Mater. Sci. Eng. A 2002, 336, 22–29. [Google Scholar] [CrossRef]

- Karunaratne, M.S.A.; Reed, R.C. Interdiffusion of the Platinum-Group Metals in Nickel at Elevated Temperatures. Acta Mater. 2003, 51, 2905–2919. [Google Scholar] [CrossRef]

- Koizumi, Y.; Kobayashi, T.; Yokokawa, T.; Osawa, M.; Harada, H.; Aoki, Y.; Arai, M. Effects of Alloying Additions on the Creep Strength of a Fourth generationSingle-Crystal Superalloy. J Jpn. Inst Met. 2004, 68, 206–209. [Google Scholar] [CrossRef]

- Kobayashi, T.; Harada, H.; Osawa, M.; Sato, A. Creep Strength of Co-Free Ni-Base Single Crystal Superalloys. J Jpn. Inst Met. 2005, 69, 707–710. [Google Scholar] [CrossRef]

- Nabarro, F.R.N. Rafting in Superalloys. Metall. Mater. Trans. A 1996, 27, 513–530. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, X.; Yue, Q.; Xuan, W.; Pan, Q.; Wang, J.; Ding, Q.; Bei, H.; Zhang, Z. Competitive Deformation Induced by TCP Precipitation and Creep Inconsistency on Dendritic Structures in a Nickel-Based Single Crystal Superalloy Crept at High Temperatures. Mater. Charact. 2022, 187, 111855. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, X.; Yue, L.; Zhang, Z. Microstructural Evolution and Creep Mechanisms in Ni-Based Single Crystal Superalloys: A Review. J. Alloys Compd. 2020, 819, 152954. [Google Scholar] [CrossRef]

- Agudo Jácome, L.; Nörtershäuser, P.; Heyer, J.-K.; Lahni, A.; Frenzel, J.; Dlouhy, A.; Somsen, C.; Eggeler, G. High-Temperature and Low-Stress Creep Anisotropy of Single-Crystal Superalloys. Acta Mater. 2013, 61, 2926–2943. [Google Scholar] [CrossRef]

- Mottura, A.; Reed, R.C. What Is the Role of Rhenium in Single Crystal Superalloys. In Proceedings of the MATEC Web of Conferences; Guédou, J.Y., Choné, J., Eds.; EDP Sciences: Hyères, France, 2014; Volume 14, p. 01001. [Google Scholar]

- Cheng, Y.; Zhao, X.; Yue, Q.; Xia, W.; Gu, Y.; Zhang, Z. Research Progress of Effects of Mo and W on Ni-based Single Crystal Superalloys. Rare Met. Mater. Eng. 2023, 52, 2599–2611. [Google Scholar] [CrossRef]

- Crudden, D.J.; Mottura, A.; Warnken, N.; Raeisinia, B.; Reed, R.C. Modelling of the Influence of Alloy Composition on Flow Stress in High-Strength Nickel-Based Superalloys. Acta Mater. 2014, 75, 356–370. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, S.; Fu, H.; Zhou, F.; Xie, J. Effects of Ta and Ti Content on Microstructure and Properties of Multicomponent Co–Ni-Based Superalloys. Mater. Sci. Eng. A 2022, 855, 143829. [Google Scholar] [CrossRef]

- Peng, P.; Lu, L.; Liu, Z.; Xu, Y.; Zhang, X.; Ma, Z.; Zhang, H.; Guo, M.; Liu, L. Investigation on Influence of Ta on Microstructure Evolution of Directionally Solidified Ni-Based Superalloys. J. Alloys Compd. 2022, 927, 167009. [Google Scholar] [CrossRef]

- Milhet, X.; Arnoux, M.; Cormier, J.; Mendez, J.; Tromas, C. On the Influence of the Dendritic Structure on the Creep Behavior of a Re-Containing Superalloy at High Temperature/Low Stress. Mater. Sci. Eng. A 2012, 546, 139–145. [Google Scholar] [CrossRef]

- Wollgramm, P.; Buck, H.; Neuking, K.; Parsa, A.B.; Schuwalow, S.; Rogal, J.; Drautz, R.; Eggeler, G. On the Role of Re in the Stress and Temperature Dependence of Creep of Ni-Base Single Crystal Superalloys. Mater. Sci. Eng. A 2015, 628, 382–395. [Google Scholar] [CrossRef]

- Sundman, B.; Ågren, J. A Regular Solution Model for Phases with Several Components and Sublattices, Suitable for Computer Applications. J. Phys. Chem. Solids 1981, 42, 297–301. [Google Scholar] [CrossRef]

- Andersson, J.-O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, Computational Tools for Materials Science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Dyson, B.F. Microstructure Based Creep Constitutive Model for Precipitation Strengthened Alloys: Theory and Application. Mater. Sci. Technol. 2009, 25, 213–220. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, X.; Xia, W.; Qiao, L.; Cheng, Y.; Liu, H.; Yue, Q.; Gu, Y.; Zhang, Z. Coarsening Transitional Kinetics of γ’ Precipitates in a Nickel-Based Single Crystal Superalloy during Thermal Exposure. J. Alloys Compd. 2024, 1002, 175380. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, X.; Wang, J.; Yue, Q.; Cheng, Y.; Kong, L.; Zhang, Y.; Gu, Y.; Bei, H.; Zhang, Z. New Strategy to Improve the Overall Performance of Single-Crystal Superalloys by Designing a Bimodal γ’ Precipitation Microstructure. Acta Mater. 2023, 257, 119200. [Google Scholar] [CrossRef]

- Nathal, M.V. Effect of Initial Gamma Prime Size on the Elevated Temperature Creep Properties of Single Crystal Nickel Base Superalloys. Metall. Trans. A 1987, 18, 1961–1970. [Google Scholar] [CrossRef]

- Fan, H.; Long, H.; Zhao, J.; Yuan, X.; Zhao, Y.; Liu, Y.; Mao, S.; Wang, L.; Zhang, Z.; Han, X. Effect of γ’ Size on the High-Temperature Low-Stress Creep of Nickel-Based Single-Crystal Superalloys. Mater. Sci. Eng. A. 2025, 921, 147603. [Google Scholar] [CrossRef]

- Ai, C.; Li, K.; Xu, X.; Ru, Y.; Zhang, H.; Li, S.; Gong, S.; Jiang, H.; Guo, M.; Huang, T.; et al. Effects of Substituting Mo for W and Temperature on γ/γ’ Lattice Misfits of Second Generation Ni Based Single Crystal Superalloys. Intermetallics 2025, 180, 108710. [Google Scholar] [CrossRef]

- Mughrabi, H.; Tetzlaff, U. Microstructure and High-Temperature Strength of Monocrystalline Nickel-Base Superalloys. Adv. Eng. Mater. 2000, 2, 319–326. [Google Scholar] [CrossRef]

- MacSleyne, J.P.; Simmons, J.P.; De Graef, M. On the Use of 2-D Moment Invariants for the Automated Classification of Particle Shapes. Acta Mater. 2008, 56, 427–437. [Google Scholar] [CrossRef]

- Song, D.; Zou, J.; Shang, Z.; Zhu, L.; Zhang, Y.; Shi, L.; Liu, G.; Lei, Y.; Lan, T.; Nie, L.; et al. Unveiling the Re Effect on Compression Behavior and Stacking Faults of γ’-Phase in Ni-Based Single Crystal Superalloys. J. Mater. Res. Technol. 2025, 35, 3924–3936. [Google Scholar] [CrossRef]

- Royer, A.; Bastie, P.; Veron, M. In Situ Determination of Γ′ Phase Volume Fraction and of Relations between Lattice Parameters and Precipitate Morphology in Ni-Based Single Crystal Superalloy. Acta Mater. 1998, 46, 5357–5368. [Google Scholar] [CrossRef]

- Völkl, R.; Glatzel, U.; Feller-Kniepmeier, M. Measurement of the Lattice Misfit in the Single Crystal Nickel Based Superalloys CMSX-4, SRR99 and SC16 by Convergent Beam Electron Diffraction. Acta Mater. 1998, 46, 4395–4404. [Google Scholar] [CrossRef]

- Schulze, C.; Feller-Kniepmeier, M. Transmisson Electron Microscopy of Phase Composition and Lattice Misfit in the Re-Containing Nickel-Base Superalloy CMSX-10. Mater. Sci. Eng. A 2000, 281, 204–212. [Google Scholar] [CrossRef]

- Van Sluytman, J.S.; Pollock, T.M. Optimal Precipitate Shapes in Nickel-Base γ–γ′ Alloys. Acta Mater. 2012, 60, 1771–1783. [Google Scholar] [CrossRef]

- Harada, H.; Murakami, H. Design of Ni-Base Superalloys. In Computational Materials Design; Saito, T., Ed.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 1999; pp. 39–70. ISBN 978-3-662-03923-6. [Google Scholar]

- Du, B.; Wen, J.; Ru, Y.; Hu, Y.; Yang, F.; Cao, Y.; Geng, L.; Pei, Y.; Li, S.; Gong, S. Role of Dislocation Behavior during Aging in High-Temperature Microstructural Evolution and Creep Property of Single Crystal Superalloys. Mater. Sci. Eng. A 2024, 916, 147384. [Google Scholar] [CrossRef]

- Zhang, J.X.; Wang, J.C.; Harada, H.; Koizumi, Y. The Effect of Lattice Misfit on the Dislocation Motion in Superalloys during High-Temperature Low-Stress Creep. Acta Mater. 2005, 53, 4623–4633. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. The Precipitation of Topologically Close-Packed Phases in Rhenium-Containing Superalloys. Acta Mater. 2001, 49, 4113–4125. [Google Scholar] [CrossRef]

- Lv, X.; Zhang, J.; Feng, Q. The Promotion of Ru on Topologically Close-Packed Phase Precipitation in the High Cr-Containing (∼9wt.%) Nickel-Base Single Crystal Superalloy. J. Alloys Compd. 2015, 648, 853–857. [Google Scholar] [CrossRef]

- Ru, Y.; Li, S.; Pei, Y.; Zhou, J.; Gong, S.; Xu, H. Interdendritic Mo Homogenization and Sub-Solidus Melting during Solution Treatment in the Mo-Strengthening Single Crystal Superalloys. J. Alloys Compd. 2016, 662, 431–435. [Google Scholar] [CrossRef]

- Cheng, K.; Jo, C.; Jin, T.; Hu, Z. Precipitation Behavior of μ Phase and Creep Rupture in Single Crystal Superalloy CMSX-4. J. Alloys Compd. 2011, 509, 7078–7086. [Google Scholar] [CrossRef]

- Biss, V.; Kirby, G.N.; Sponseller, D.L. The Relative Effects of Chromium, Molybdenum, Tungsten, and Tantalum on the Occurrence of σ Phase in Cast Ni-Co-Cr Alloys. Metall. Trans. A 1976, 7, 1251–1261. [Google Scholar] [CrossRef]

- Cao, K.; Yang, W.; Liu, C.; Qu, P.; Qin, J.; Zhang, J.; Liu, L. Precipitation of TCP Phases with R/P Intergrowth Structure during Directional Solidification in a Ru-Containing Nickel-Based Single Crystal Superalloy. J. Alloys Compd. 2023, 942, 168951. [Google Scholar] [CrossRef]

- Miller, M.K.; Babu, S.S.; Vitek, J.M. Stability of γ’ Precipitates in a PWA1480 Alloy. Intermetallics 2007, 15, 757–766. [Google Scholar] [CrossRef]

- Chen, J.Y.; Feng, Q.; Cao, L.M.; Sun, Z.Q. Improvement of Stress–Rupture Property by Cr Addition in Ni-Based Single Crystal Superalloys. Mater. Sci. Eng. A 2011, 528, 3791–3798. [Google Scholar] [CrossRef]

- Liu, X.G.; Wang, L.; Lou, L.H.; Zhang, J. Effect of Mo Addition on Microstructural Characteristics in a Re-Containing Single Crystal Superalloy. J. Mater. Sci. Technol. 2015, 31, 143–147. [Google Scholar] [CrossRef]

- Zheng, Y. Primary μ Phase in Cast Nickel Base Superalloys. Acta Metall. Sin. 1999, 35, 1242–1245. [Google Scholar]

- Huo, J.; Shi, Q.; Zheng, Y.; Feng, Q. Microstructural Characteristics of σ Phase and P Phase in Ru-Containing Single Crystal Superalloys. Mater. Charact. 2017, 124, 73–82. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, J.; Huang, Z.; Huang, R.; Liu, S.; Zhang, Q.; Yue, Z.; Li, X. Directional Migration Behavior of Alloying Elements in the Rafting Process of the Single Crystal Superalloy DD6. Rare Met. Mater. Eng. 2016, 45, 1147–1151. [Google Scholar]

- Zhang, H.W.; Qin, X.Z.; Wu, Y.S.; Zhou, L.Z.; Li, X.W. Effects of Cr Content on the Microstructure and Stress Rupture Property of a Directionally Solidified Ni-Based Superalloy during Long-Term Thermal Exposure. Mater. Sci. Eng. A 2018, 718, 449–460. [Google Scholar] [CrossRef]

- Pan, Q.; Zhao, X.; Yue, Q.; Xia, W.; Gu, Y.; Ding, Q.; Zhang, Z. Effects of Cobalt on Solidification Characteristics and As-Cast Microstructure of an Advanced Nickel-Based Single Crystal Superalloys. J. Mater. Res. Technol. 2022, 20, 3074–3082. [Google Scholar] [CrossRef]

- Pan, Q.; Zhao, X.; Xia, W.; Cheng, Y.; Zhou, Y.; Fan, Y.; Yue, Q.; Gu, Y.; Zhang, Z. Homogenization Effects by Co Additions to High Temperature and Low Stress Creep Performance of a 4th-Generation Ni-Based Single Crystal Superalloys. Mater. Sci. Eng. A 2024, 898, 146373. [Google Scholar] [CrossRef]

- Pan, Q.; Zhao, X.; Xia, W.; Yue, Q.; Song, Y.; Gu, Y.; Zhang, Z. Dual Effects of Co on Microstructure Stability in a Ru-Containing Ni-Based Single Crystal Superalloys. Prog. Nat. Sci. Mater. Int. 2025, 35, 313–321. [Google Scholar] [CrossRef]

- Burgel, R.; Grossmann, J.; Lusebrink, O.; Mughrabi, H.; Pyczak, F.; Singer, R.F.; Volek, A. Development of a New Alloy for Directional Solidification of Large Industrial Gas Turbine Blades. In Superalloys 2004; TMS: Pittsburgh, PA, USA, 2000; pp. 25–34. [Google Scholar] [CrossRef]

- Lee, S.; Do, J.; Jang, K.; Jun, H.; Park, Y.; Choi, P.-P. Promotion of Topologically Close-Packed Phases in a Ru-Containing Ni-Based Superalloy. Scr. Mater. 2023, 222, 115041. [Google Scholar] [CrossRef]

- Chen, J.Y.; Feng, Q.; Sun, Z.Q. Topologically Close-Packed Phase Promotion in a Ru-Containing Single Crystal Superalloy. Scr. Mater. 2010, 63, 795–798. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhao, X.; Xia, W.; Yue, Q.; Gu, Y.; Zhang, Z. The Overview of the Formation Mechanisms of Topologically Close-Packed Phases in Ni-Based Single Crystal Superalloys. Mater. Des. 2024, 237, 112582. [Google Scholar] [CrossRef]

- Pang, H.T.; Hobbs, R.A.; Stone, H.J.; Rae, C.M.F. A Study of the Effects of Alloying Additions on TCP Phase Formation in 4th Generation Nickel-Base Single-Crystal Superalloys. Adv. Mater. Res. 2011, 278, 54–59. [Google Scholar] [CrossRef]

- Huo, J.J.; Shi, Q.Y.; Zheng, Y.R.; Feng, Q. Microstructural Nature and Stability of Co-Rich TCP Phases in Ru-Containing Single Crystal Superalloys. J. Alloys Compd. 2017, 715, 460–470. [Google Scholar] [CrossRef]

- Wang, W.Z.; Jin, T.; Liu, J.L.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Role of Re and Co on Microstructures and γ′ Coarsening in Single Crystal Superalloys. Mater. Sci. Eng. A 2008, 479, 148–156. [Google Scholar] [CrossRef]

- Shi, Z.; Li, J.; Liu, S. Effects of Ru on the Microstructure and Phase Stability of a Single Crystal Superalloy. Int. J. Miner. Metall. Mater. 2012, 19, 1004–1009. [Google Scholar] [CrossRef]

- Dubiel, B.; Indyka, P.; Kalemba-Rec, I.; Kruk, A.; Moskalewicz, T.; Radziszewska, A.; Kąc, S.; Kopia, A.; Berent, K.; Gajewska, M. The Influence of High Temperature Annealing and Creep on the Microstructure and Chemical Element Distribution in the γ, Γ’ and TCP Phases in Single Crystal Ni-Base Superalloy. J. Alloys Compd. 2018, 731, 693–703. [Google Scholar] [CrossRef]

- MacKay, R.A.; Nathal, M.V.; Pearson, D.D. Influence of Molybdenum on the Creep Properties of Nickel-Base Superalloy Single Crystals. Metall. Trans. A 1990, 21, 381–388. [Google Scholar] [CrossRef]

- Narita, T.; Zaini, K.; Lang, F.; Hayashi, S.; Murakami, H.; Gleeson, B.; Young, D. Development of Re-based Diffusion Barrier Coatings on Nickel Based Superalloys. Mater. Corros. 2005, 56, 923–929. [Google Scholar] [CrossRef]

- Cavaletti, E.; Naveos, S.; Mercier, S.; Josso, P.; Bacos, M.P.; Monceau, D. Ni–W Diffusion Barrier: Its Influence on the Oxidation Behaviour of a β-(Ni,Pt)Al Coated Fourth Generation Nickel-Base Superalloy. Surf. Coat. Technol. 2009, 204, 761–765. [Google Scholar] [CrossRef]

- Li, W.; Sun, J.; Liu, S.B.; Liu, Y.D.; Fu, L.B.; Wang, T.G.; Jiang, S.M.; Gong, J.; Sun, C. Preparation and Cyclic Oxidation Behaviour of Re Doped Aluminide Coatings on a Ni-Based Single Crystal Superalloy. Corros. Sci. 2020, 164, 108354. [Google Scholar] [CrossRef]

- Göbel, M.; Rahmel, A.; Schütze, M. The Isothermal-Oxidation Behavior of Several Nickel-Base Single-Crystal Superalloys with and without Coatings. Oxid. Met. 1993, 39, 231–261. [Google Scholar] [CrossRef]

- Yang, Y.Q.; Yang, L.; Zhao, Y.C.; Pei, H.Q.; Wen, Z.X.; Zhou, Y.C. Study on the Salt-Corrosion and Oxidation Role Mechanism of Ni-Based Single Crystal Superalloy in the Long-Term Hot Corrosion Environment. J. Mater. Res. Technol. 2025, 37, 25–40. [Google Scholar] [CrossRef]

- Sun, B.; Zhang, T.; Song, L.; Zhang, L. Oxidation Behavior in Static Air and Its Effect on Tensile Properties of a Powder Metallurgy EP962NP Nickel-Based Superalloy. J. Alloys Compd. 2023, 934, 167795. [Google Scholar] [CrossRef]

- Fu, H.; Yang, W.; Wang, Q.; Liu, C.; Qin, J.; Lu, Y.; Shen, J.; Su, H.; Liu, L. Oxidation Behavior of a Low-Cost Second-Generation Ni-Based Single Crystal Superalloy at 900 °C and 1000 °C. J. Mater. Res. Technol. 2025, 34, 797–806. [Google Scholar] [CrossRef]

- Kawagishi, K.; Sato, A.; Kobayashi, T.; Harada, H. Temperature Dependence of Oxidation Properties for 5th Generation Ni-Base Single-Crystal Superalloys. J. Jpn. Inst. Met. 2006, 70, 686–689. [Google Scholar] [CrossRef]

- Kawagishi, K.; Sato, A.; Kobayashi, T.; Harada, H. Oxidation Properties for 2nd-5th Generation Ni-Base Single-Crystal Superalloys at 1023, 1173 and 1373 K. J. Jpn. Inst. Met. 2007, 71, 313–319. [Google Scholar] [CrossRef]

- Hu, Y.-B.; Cheng, C.-Q.; Cao, T.-S.; Zhang, L.; Zhao, J. A Study on the Multiple Stages of Oxidation Kinetics in a Single Crystal Nickel-Based Superalloy. Corros. Sci. 2021, 188, 109512. [Google Scholar] [CrossRef]

- Li, W.; Zhao, X.; Xu, J.; Liu, H.; Cheng, Y.; Yue, Q.; Gu, Y.; Zhang, Y.; Zhang, Z. Effect of Elements Distribution on Oxidation Behavior of a Nickel-Based Single Crystal Superalloy. Vacuum 2023, 209, 111780. [Google Scholar] [CrossRef]

- Liu, C.T.; Ma, J.; Sun, X.F. Oxidation Behavior of a Single-Crystal Ni-Base Superalloy between 900 and 1000 °C in Air. J. Alloys Compd. 2010, 491, 522–526. [Google Scholar] [CrossRef]

- Li, M.H.; Sun, X.F.; Li, J.G.; Zhang, Z.Y.; Jin, T.; Guan, H.R.; Hu, Z.Q. Oxidation Behavior of a Single-Crystal Ni-Base Superalloy in Air. I: At 800 and 900 °C. Oxid. Met. 2003, 59, 591–605. [Google Scholar] [CrossRef]

- Wu, Y.; Narita, T. Oxidation Behavior of the Single Crystal Ni-Based Superalloy at 900 °C in Air and Water Vapor. Surf. Coat. Technol. 2007, 202, 140–145. [Google Scholar] [CrossRef]

- Kawagishi, K.; Harada, H.; Sato, A.; Sato, A.; Kobayashi, T. The Oxidation Properties of Fourth Generation Single-Crystal Nickel-Based Superalloys. JOM 2006, 58, 43–46. [Google Scholar] [CrossRef]

- Du, B.; Ru, Y.; Wen, J.; Li, X.; Cao, Y.; Hu, Y.; Yang, F.; Pei, Y.; Li, S.; Gong, S. Improving Oxidation Resistance Property of Single-Crystal Ni-Based Superalloy via Utilizing High Temperature Aging-Induced Dislocations. J. Mater. Res. Technol. 2025, 35, 504–513. [Google Scholar] [CrossRef]

- Kim, D.; Jang, C.; Ryu, W. Oxidation Characteristics and Oxide Layer Evolution of Alloy 617 and Haynes 230 at 900 °C and 1100 °C. Oxid. Met. 2009, 71, 271–293. [Google Scholar] [CrossRef]

- Wang, J.; Chen, M.; Zhu, S.; Wang, F. Ta Effect on Oxidation of a Nickel-Based Single-Crystal Superalloy and Its Sputtered Nanocrystalline Coating at 900–1100 °C. Appl. Surf. Sci. 2015, 345, 194–203. [Google Scholar] [CrossRef]

- Gao, S.; He, B.; Zhou, L.; Hou, J. Effects of Ta on the High Temperature Oxidation Behavior of IN617 Alloy in Air. Corros. Sci. 2020, 170, 108682. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, K.-H.; Seo, S.-M.; Jeong, H.-W.; Yoo, Y.-S.; Jang, H. Statistics of Oxidation Resistance of Ni–(0–15)Co–(8–15)Cr–(0–5)Mo–(0–10)W–(3–8)Al–(0–5)Ti–(0–10)Ta–0.1C–0.01B Superalloys at 1000 °C by Compositional Variations. Rare Met. 2020, 39, 918–927. [Google Scholar] [CrossRef]

- Ye, X.; Yang, B.; Nie, Y.; Yu, S.; Li, Y. Influence of Nb Addition on the Oxidation Behavior of Novel Ni-Base Superalloy. Corros. Sci. 2021, 185, 109436. [Google Scholar] [CrossRef]

- Smialek, J.; Garg, A.; Gabb, T.; MacKay, R. Cyclic Oxidation of High Mo, Reduced Density Superalloys. Metals 2015, 5, 2165–2185. [Google Scholar] [CrossRef]

- Romain, C.; Texier, D.; Desgranges, C.; Cormier, J.; Knittel, S.; Monceau, D.; Delagnes, D. Oxidation of Thin Nickel-Based Superalloy Specimens: Kinetics Study and Mechanical Integrity. Oxid. Met. 2021, 96, 169–182. [Google Scholar] [CrossRef]

- Cheng, C.-Q.; Hu, Y.; Cao, T.-S.; Zhang, L.; Zhu, Y.-W.; Zhao, J. Two Typical Oxidation Models on Nickel-Based Superalloys under Different Initial Surface Roughness. Corros. Sci. 2020, 176, 108942. [Google Scholar] [CrossRef]

- Archana, M.; Jagadeeswara Rao, C.; Ningshen, S.; Philip, J. High-Temperature Air and Steam Oxidation and Oxide Layer Characteristics of Alloy 617. J. Mater. Eng. Perform. 2021, 30, 931–943. [Google Scholar] [CrossRef]

- Alhatab, K.; Al-Bukhaiti, M.; Krupp, U.; Kantehm, M. Cyclic Oxidation Behavior of IN 718 Superalloy in Air at High Temperatures. Oxid. Met. 2011, 75, 209–228. [Google Scholar] [CrossRef]

- Khalid, F.A.; Hussain, N.; Shahid, K.A. Microstructural Characteristics of High-Temperature Oxidation in Nickel-Base Superalloy. J. Mater. Eng. Perform. 1997, 6, 219–222. [Google Scholar] [CrossRef]

- Park, S.-J.; Seo, S.-M.; Yoo, Y.-S.; Jeong, H.; Jang, H. Statistical Study of the Effects of the Composition on the Oxidation Resistance of Ni-Based Superalloys. J. Nanomater. 2015, 2015, 1–11. [Google Scholar] [CrossRef]

- Hobbs, R.A.; Tin, S.; Rae, C.M.F. A Castability Model Based on Elemental Solid-Liquid Partitioning in Advanced Nickel-Base Single-Crystal Superalloys. Metall. Mater. Trans. A 2005, 36, 2761–2773. [Google Scholar] [CrossRef]

- Xu, W.; Wang, F.; Ma, D.; Bührig–Polaczek, A. Effect of Ru on Macro-/Micro-Structure Evolution within Platform of Ni-Based Superalloy Single Crystal Blades. J. Alloys Compd. 2020, 817, 153337. [Google Scholar] [CrossRef]

- Grodzki, J.; Hartmann, N.; Rettig, R.; Affeldt, E.; Singer, R.F. Effect of B, Zr, and C on Hot Tearing of a Directionally Solidified Nickel-Based Superalloy. Metall. Mater. Trans. A 2016, 47, 2914–2926. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Koizumi, Y.; Kobayashi, T.; Harada, H.; Masaki, S. Interfacial Dislocation Networks Strengthening a Fourth-Generation Single-Crystal TMS-138 Superalloy. Metall. Mater. Trans. A 2002, 33, 3741–3746. [Google Scholar] [CrossRef]

| Generation | Alloy | Cr | Co | Mo | W | Al | Ti | Ta | Re | Ru | Hf | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1st | PWA1480 | 10.0 | 5.0 | - | 4.0 | 5.0 | 1.5 | 12.0 | - | - | - | Bal. |

| RR2000 | 10.0 | 15.0 | 3.0 | - | 5.5 | 4.0 | - | - | - | - | Bal. | |

| CMSX-2 | 8.0 | 5.0 | 0.6 | 8.0 | 5.6 | 1.0 | 6.0 | - | - | - | Bal. | |

| René N4 | 9.0 | 8.0 | 2.0 | 6.0 | 3.7 | 4.2 | 4.0 | - | - | - | Bal. | |

| 2nd | PWA1484 | 5.0 | 10.0 | 2.0 | 6.0 | 5.6 | - | 9.0 | 3.0 | - | 0.1 | Bal. |

| CMSX-4 | 6.5 | 9.0 | 0.6 | 6.0 | 5.6 | 1.0 | 6.5 | 3.0 | - | 0.1 | Bal. | |

| MC2 | 8.0 | 5.0 | 2.0 | 8.0 | 5.0 | 1.5 | 6.0 | - | - | - | Bal. | |

| René N5 | 7.0 | 8.0 | 2.0 | 5.0 | 6.2 | - | 7.0 | 3.0 | - | 0.2 | Bal. | |

| 3rd | CMSX-4 Plus | 3.5 | 10.0 | 0.6 | 6.0 | 5.7 | 0.85 | 8.0 | 4.8 | - | 0.1 | Bal. |

| CMSX-10 | 2.0 | 3.0 | 0.4 | 5.0 | 5.7 | 0.2 | 8.0 | 6.0 | - | 0.03 | Bal. | |

| René N6 | 4.2 | 12.5 | 1.4 | 6.0 | 5.75 | - | 7.2 | 5.4 | - | 0.15 | Bal. | |

| TMS-75 | 3.0 | 12.0 | 2.0 | 6.0 | 6.0 | - | 6.0 | 5.0 | - | 0.1 | Bal. | |

| TMS-82 | 5.0 | 7.8 | 3.4 | 8.7 | 5.2 | 0.5 | 4.4 | 2.4 | - | 0.1 | Bal. | |

| 4th | MC-NG | 4.0 | 0 | 1.0 | 5.0 | 6.0 | 0.5 | 5.0 | 4.0 | 4.0 | 0.1 | Bal. |

| PWA1497/MX-4 | 2.0 | 16.5 | 2.0 | 6.0 | 5.6 | - | 8.3 | 6.0 | 3.0 | 0.15 | Bal. | |

| TMS-138 | 3.2 | 5.8 | 2.9 | 5.9 | 5.8 | - | 5.6 | 5.0 | 2.0 | 0.1 | Bal. | |

| EPM-102 | 2.0 | 16.5 | 2.0 | 6.0 | 5.55 | - | 8.25 | 5.95 | 3.0 | 0.15 | Bal. | |

| TMS-138A | 3.2 | 5.8 | 2.9 | 5.6 | 5.7 | - | 5.6 | 5.8 | 3.6 | 0.1 | Bal. | |

| 5th | TMS-162 | 3.0 | 5.8 | 3.9 | 5.8 | 5.8 | - | 5.6 | 4.9 | 6.0 | 0.1 | Bal. |

| TMS-173 | 3.0 | 5.6 | 2.8 | 5.6 | 5.6 | - | 5.6 | 6.9 | 5.0 | 0.1 | Bal. | |

| TMS-196 | 4.6 | 5.6 | 2.4 | 5.0 | 5.6 | - | 5.6 | 6.4 | 5.0 | 0.1 | Bal. | |

| 6th | TMS-238 | 4.6 | 6.5 | 1.1 | 4.0 | 5.9 | - | 7.6 | 6.4 | 5.0 | 0.1 | Bal. |

| Element | Cr | Co | Mo | W | Al | Ta | Re | Ru | Hf | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Electron vacancy number | 4.66 | 1.71 | 4.66 | 4.66 | 7.66 | 5.66 | 3.66 | 2.66 | 6.66 | 0.61 |

| Element | (eV) | Element | (eV) | ||||

|---|---|---|---|---|---|---|---|

| 3d | Ti | 2.271 | 1.098 | 4d | Mo | 1.550 | 1.611 |

| Cr | 1.142 | 1.278 | Ru * | 1.006 * | - | ||

| Mn | 0.957 | 1.001 | 5d | Hf | 3.020 | 1.518 | |

| Fe | 0.858 | 0.857 | Ta | 2.224 | 1.670 | ||

| Co | 0.777 | 0.697 | W | 1.655 | 1.730 | ||

| Ni | 0.717 | 0.514 | Re | 1.267 | 1.692 | ||

| Cu | 0.615 | 0.272 | Other | Al | 1.900 | 0.533 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zhao, X.; Fan, Y.; Yue, Q.; Xia, W.; Pan, Q.; Cheng, Y.; Li, W.; Gu, Y.; Zhang, Z. Composition Optimization in Alloy Design for Nickel-Based Single Crystal Superalloy: A Review. Metals 2025, 15, 793. https://doi.org/10.3390/met15070793

Zhou Y, Zhao X, Fan Y, Yue Q, Xia W, Pan Q, Cheng Y, Li W, Gu Y, Zhang Z. Composition Optimization in Alloy Design for Nickel-Based Single Crystal Superalloy: A Review. Metals. 2025; 15(7):793. https://doi.org/10.3390/met15070793

Chicago/Turabian StyleZhou, Yu, Xinbao Zhao, Yunpeng Fan, Quanzhao Yue, Wanshun Xia, Qinghai Pan, Yuan Cheng, Weiqi Li, Yuefeng Gu, and Ze Zhang. 2025. "Composition Optimization in Alloy Design for Nickel-Based Single Crystal Superalloy: A Review" Metals 15, no. 7: 793. https://doi.org/10.3390/met15070793

APA StyleZhou, Y., Zhao, X., Fan, Y., Yue, Q., Xia, W., Pan, Q., Cheng, Y., Li, W., Gu, Y., & Zhang, Z. (2025). Composition Optimization in Alloy Design for Nickel-Based Single Crystal Superalloy: A Review. Metals, 15(7), 793. https://doi.org/10.3390/met15070793