CFD Modelling of Flow and Solids Distribution in Carbon-in-Leach Tanks

Abstract

:1. Introduction

2. Literature Review

3. Model Description

3.1. Governing Equations

| Description | Equations |

|---|---|

| Liquid-phase stress tensor | |

| Solid-phase stress tensor | |

| Solid shear viscosity | |

| Collisional viscosity | |

| Kinetic viscosity | |

| Frictional viscosity | |

| Solids pressure | |

| Radial distribution function | |

| Diffusion coefficient of granular temperature | |

| where | |

| Collision dissipation energy |

3.2. Turbulent Dispersion Force

3.3. Interphase Drag Force

4. Methodology and Boundary Conditions

4.1. Vessel Geometry

| Tank (m) | PBTD (m) | HA-715 | |||

|---|---|---|---|---|---|

| T | 0.288, 10 | D | T/2 | D | T/2, T/3 |

| H | T | Bl | 0.055 | Dshaft | 0.01152 |

| W | T/10 | Bw | 0.041 | - | - |

| Ci | T/2, T/3, T/4, T/6, T/8 | Dshaft | 0.01 | - | - |

| Dhub | 0.034 | - | - | ||

| Name of Case | X (wt. %) | N = Njs (RPM) | ρl (kg/m3) | µl (Pa·s) | ρp (kg/m3) | dp (mm) |

|---|---|---|---|---|---|---|

| PBTD-Validation | 40 | 589.8 | 1150 | 0.001 | 2585 | 3 |

| CIL tanks (Lab Scale) | 50 | 200–700 | 1000 | 0.001 | 2550 | 0.075 |

| CIL tanks (Full Scale) | 50 | 22.15 | 1000 | 0.001 | 2550 | 0.075 |

4.2. Numerical Simulations

5. Results and Discussion

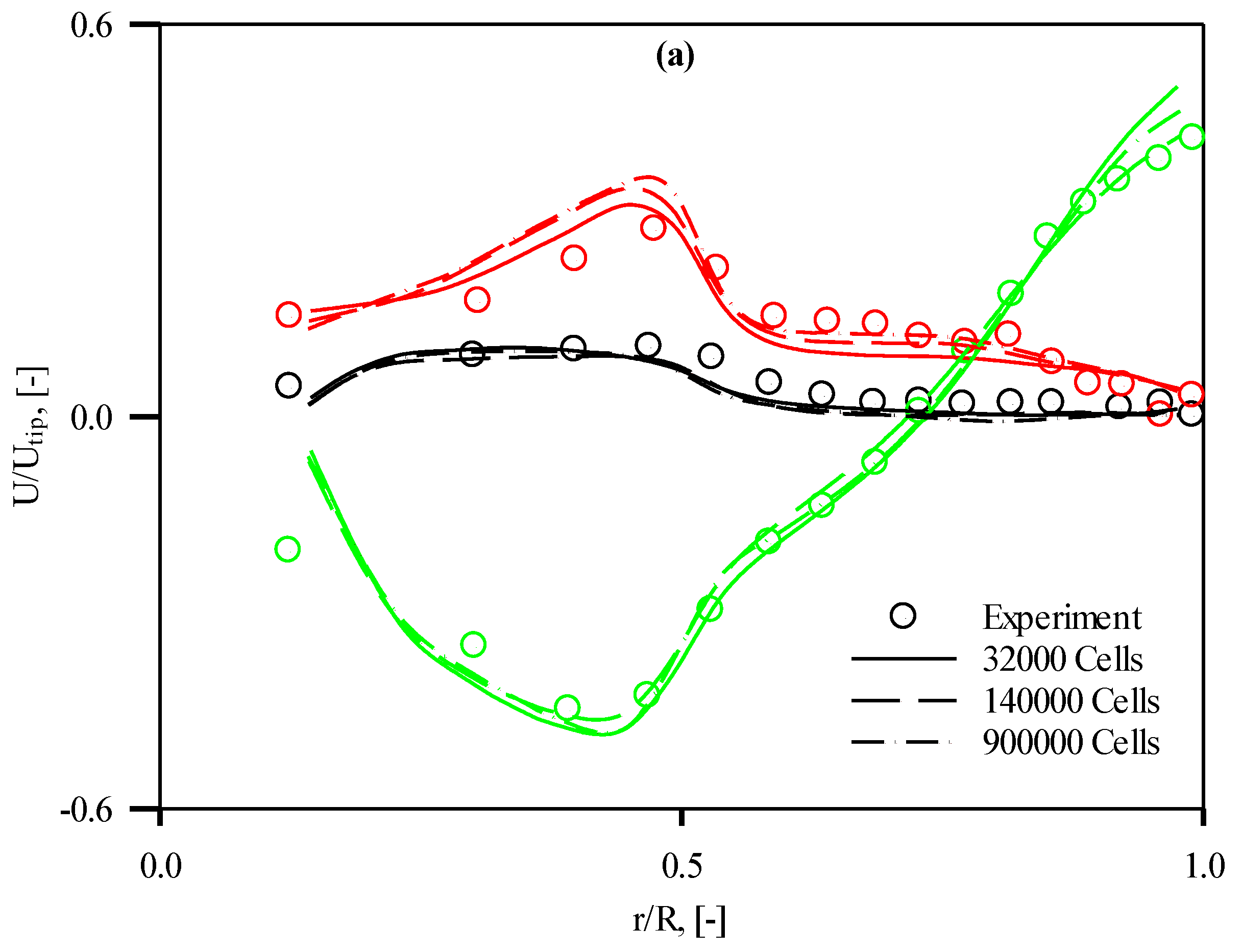

5.1. Grid Independency and Validation

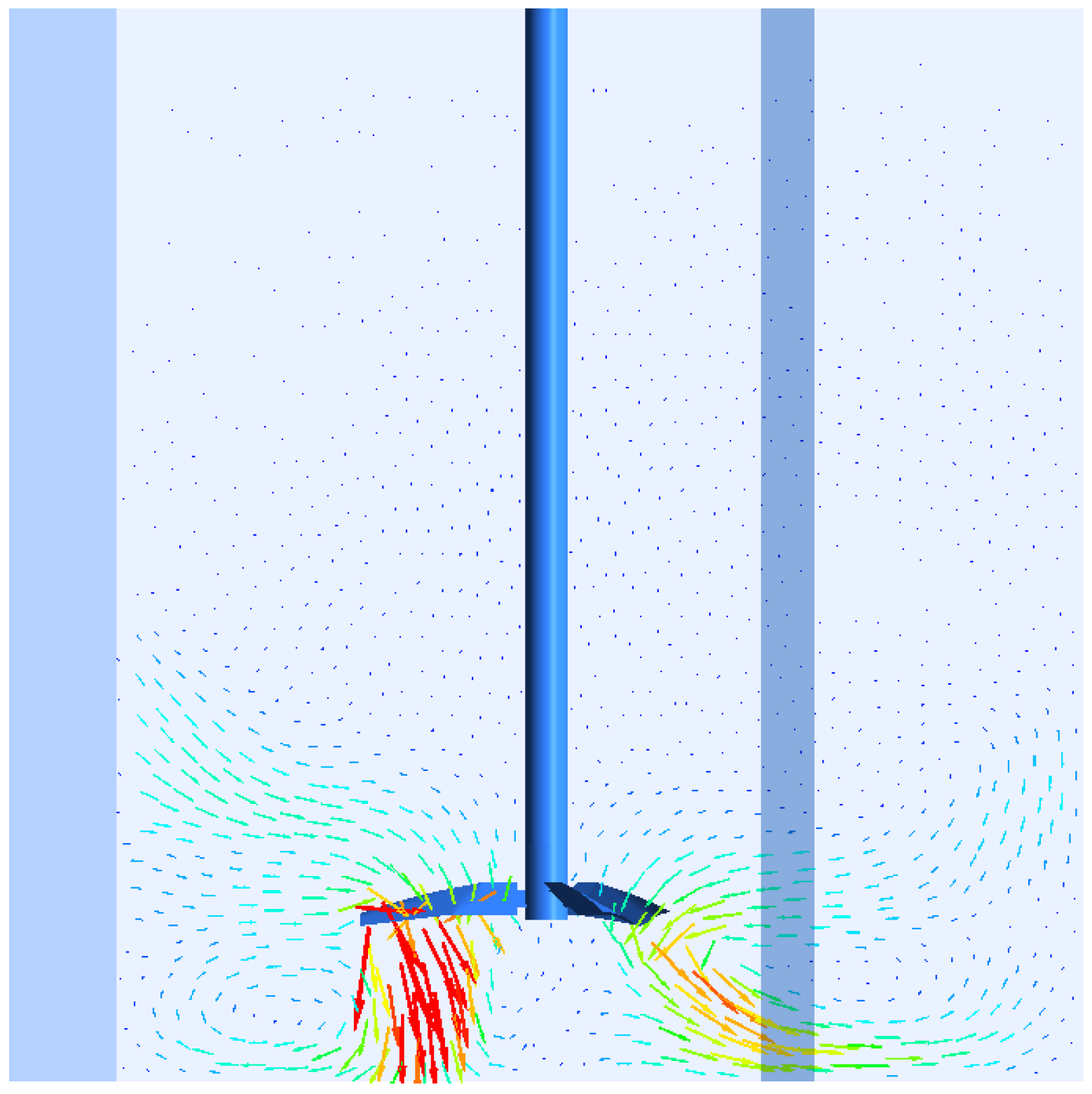

5.2. Flow Field

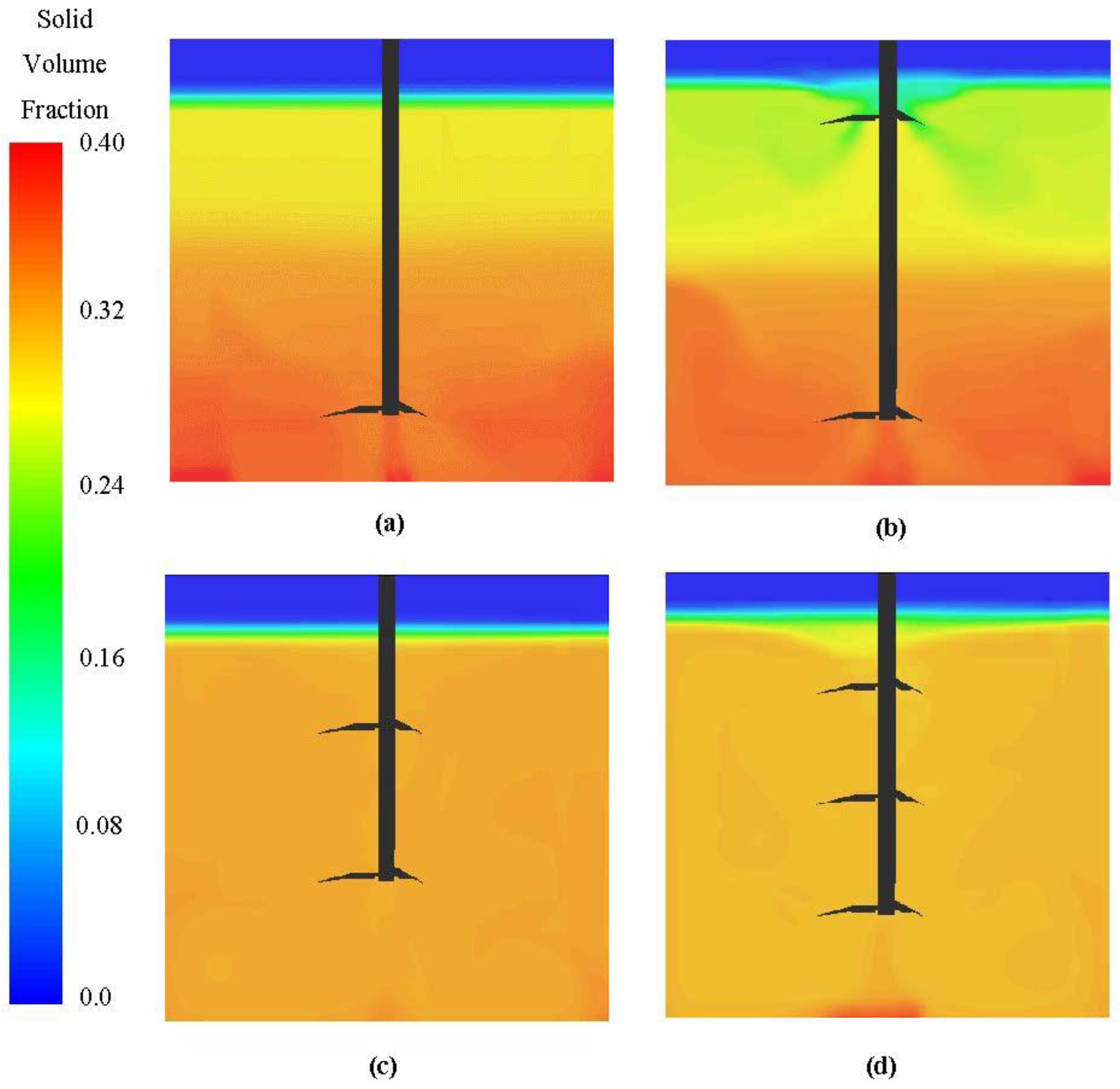

5.3. Concentration Profiles

5.4. Suspension Quality and Power Consumption

5.5. Scale-Up

5.6. Multiple-Impeller Systems

| Variable | Twin-CT6 | Twin-CT3 | Triple-CT4 |

|---|---|---|---|

| Off-bottom clearance, Ci | T/6 | T/3 | T/4 |

| Distance between impellers, CiD | 2T/3 | T/3 | T/4 |

6. Conclusions

- The Euler-Euler simulation approach with KTGF, Syamlal drag model, RSM turbulence model and turbulent dispersion force model appropriately predict the local hydrodynamics in high solid loading stirred tank systems.

- For a given power consumption, the flow generated by the HA-715 impeller is more dominant than the PBTD.

- The low off-bottom clearance is favorable in achieving homogeneity at low impeller speed for lab scale CIL tanks.

- For scale-up, multiple impeller systems are necessary for providing kinetic energy in the upper half of the CIL tanks.

- While a low off-bottom clearance is suitable for solid suspension, solids can however accumulate at the bottom center in full scale CIL tanks due to weak secondary loops.

- The dual impeller configuration with T/3 clearance and triple impeller configuration with T/4 clearance minimize the problems encountered in the CIL tanks. Additional impellers require approximately 6 kW of extra power in CIL tanks.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Bl | blade length, m |

| Bw | blade width, m |

| Ci | impeller clearance, m |

| CiD | impeller-impeller distance, m |

| C | concentration in volume percent, (-) |

| Cav | average concentration in volume percent, (-) |

| CD | drag coefficient, (-) |

| CDo | particle drag coefficient in still fluid |

| CH | cloud height, m |

| D or Di | impeller diameter, m |

| Dshaft | shaft diameter, m |

| Dhub | hub diameter, m |

| dP | particle diameter, m |

| force due to turbulent dissipation, kg·m/s2 | |

| external force, kg·m/s2 | |

| lift force, kg·m/s2 | |

| virtual mass force, kg·m/s2 | |

| interphase interaction force, kg·m/s2 | |

| g | acceleration due to gravity, m/s2 |

| production of turbulence kinetic energy, kg·m2/s2 | |

| H | tank height, m |

| unit stress tensor, Pa | |

| k | turbulence kinetic energy per unit mass, m2/s2 |

| M | torque, N·m |

| N | impeller speed, 1/min |

| Njs | speed of just suspension, 1/min |

| NRe | Reynolds number, (-) |

| NP | power number, (-) |

| NQ | pumping number, (-) |

| p | pressure and is shared by both the phases, Pa |

| P | power delivered to the fluid, W |

| T | tank diameter, m |

| velocity vector, m/s | |

| drift velocity, m/s | |

| Utip | Impeller tip velocity, m/s |

| Greek Letters | |

| α | volume fraction |

| γ | shear rate, 1/s |

| ε | turbulence dissipation rate, m2/s3 |

| εb | bulk turbulence dissipation rate, m2/s3 |

| λ | Kolmogorov length scale, m |

| μ | shear viscosity, Pa·s |

| μt | turbulent viscosity, m2/s |

| ρ | density kg/m3 |

| σ | Prandtl numbers |

| σsl | dispersion Prandtl number |

| τ | shear stress, Pa |

| stress tensor, Pa | |

| θm | mixing time, s |

| υ | bulk viscosity |

| Subscripts | |

| 1 or l | continuous or primary phase |

| 2 or s | dispersed or secondary phase |

| m | mixture properties |

| z | axial point |

References

- Barigou, M. Particle tracking in opaque mixing systems: An overview of the capabilities of PET and PEPT. Chem. Eng. Res. Des. 2004, 82, 1258–1267. [Google Scholar] [CrossRef]

- Stevenson, R.; Harrison, S.T.L.; Mantle, M.D.; Sederman, A.J.; Moraczewski, T.L.; Johns, M.L. Analysis of partial suspension in stirred mixing cells using both MRI and ERT. Chem. Eng. Sci. 2010, 65, 1385–1393. [Google Scholar] [CrossRef]

- Guida, A.; Nienow, A.W.; Barigou, M. PEPT measurements of solid-liquid flow field and spatial phase distribution in concentrated monodisperse stirred suspensions. Chem. Eng. Sci. 2010, 65, 1905–1914. [Google Scholar] [CrossRef]

- Altway, A.; Setyawan, H.; Winardi, S. Effect of particle size on simulation of three-dimensional solid dispersion in stirred tank. Chem. Eng. Res. Des. 2001, 79, 1011–1016. [Google Scholar] [CrossRef]

- Micale, G.; Grisafi, F.; Rizzuti, L.; Brucato, A. CFD simulation of particle suspension height in stirred vessels. Chem. Eng. Res. Des. 2004, 82, 1204–1213. [Google Scholar] [CrossRef]

- Ochieng, A.; Lewis, A.E. Nickel solids concentration distribution in a stirred tank. Miner. Eng. 2006, 19, 180–189. [Google Scholar] [CrossRef]

- Fradette, L.; Tanguy, P.A.; Bertrand, F.; Thibault, F.; Ritz, J.-B.; Giraud, E. CFD phenomenological model of solid-liquid mixing in stirred vessels. Comput. Chem. Eng. 2007, 31, 334–345. [Google Scholar] [CrossRef]

- Ochieng, A.; Onyango, M.S. Drag models, solids concentration and velocity distribution in a stirred tank. Powder Technol. 2008, 181, 1–8. [Google Scholar] [CrossRef]

- Kasat, G.R.; Khopkar, A.R.; Ranade, V.V.; Pandit, A.B. CFD simulation of liquid-phase mixing in solid-liquid stirred reactor. Chem. Eng. Sci. 2008, 63, 3877–3885. [Google Scholar] [CrossRef]

- Fletcher, D.F.; Brown, G.J. Numerical simulation of solid suspension via mechanical agitation: Effect of the modelling approach, turbulence model and hindered settling drag law. Int. J. Comput. Fluid Dyn. 2009, 23, 173–187. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Micale, G.; Ciofalo, M.; Brucato, A. Dense solid-liquid off-bottom suspension dynamics: Simulation and experiment. Chem. Eng. Res. Des. 2009, 87, 587–597. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Micale, G.; Brucato, A.; Ciofalo, M. CFD simulations of dense solid-liquid suspensions in baffled stirred tanks: Prediction of suspension curves. Chem. Eng. J. 2011, 178, 324–341. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Micale, G.; Brucato, A.; Ciofalo, M. CFD simulations of dense solid-liquid suspensions in baffled stirred tanks: Prediction of the minimum impeller speed for complete suspension. Chem. Eng. J. 2012, 193–194, 234–255. [Google Scholar] [CrossRef]

- Gohel, S.; Joshi, S.; Azhar, M.; Horner, M.; Padron, G. CFD modeling of solid suspension in a stirred tank: Effect of drag models and turbulent dispersion on cloud height. Int. J. Chem. Eng. 2012. [Google Scholar] [CrossRef]

- Liu, L.; Barigou, M. Numerical modelling of velocity field and phase distribution in dense monodisperse solid-liquid suspensions under different regimes of agitation: CFD and PEPT experiments. Chem. Eng. Sci. 2013, 101, 837–850. [Google Scholar] [CrossRef]

- Gidaspow, D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions; Academic Press: San Diego, CA, USA, 1994. [Google Scholar]

- Dagadu, C.P.K.; Akaho, E.H.K.; Danso, K.A.; Stegowski, Z.; Furman, L. Radiotracer investigation in gold leaching tanks. Appl. Radiat. Isot. 2012, 70, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Dagadu, C.P.K.; Stegowski, Z.; Furman, L.; Akaho, E.H.K.; Danso, K.A. Determination of flow structure in a gold leaching tank by CFD simulation. J. Appl. Math. Phys. 2014, 2, 510–519. [Google Scholar] [CrossRef]

- Dagadu, C.P.K.; Stegowski, Z.; Sogbey, B.J.A.Y.; Adzaklo, S.Y. Mixing analysis in a stirred tank using computational fluid dynamics. J. Appl. Math. Phys. 2015, 3, 637–642. [Google Scholar] [CrossRef] [Green Version]

- Aubin, J.; Fletcher, D.F.; Xuereb, C. Modeling turbulent flow in stirred tanks with CFD: The influence of the modeling approach, turbulence model and numerical scheme. Exp. Therm. Fluid Sci. 2004, 28, 431–445. [Google Scholar] [CrossRef]

- Montante, G.; Magelli, F. Modelling of solids distribution in stirred tanks: Analysis of simulation strategies and comparison with experimental data. Int. J. Comput. Fluid Dyn. 2005, 19, 253–262. [Google Scholar] [CrossRef]

- Fan, L.; Mao, Z.; Wang, Y. Numerical simulation of turbulent solid-liquid two-phase flow and orientation of slender particles in a stirred tank. Chem. Eng. Sci. 2005, 60, 7045–7056. [Google Scholar] [CrossRef]

- Khopkar, A.R.; Kasat, G.R.; Pandit, A.B.; Ranade, V.V. Computational fluid dynamics simulation of the solid suspension in a stirred slurry reactor. Ind. Eng. Chem. Res. 2006, 45, 4416–4428. [Google Scholar] [CrossRef]

- Ljungqvist, M.; Rasmuson, A. Numerical simulation of the two-phase flow in an axially stirred vessel. Chem. Eng. Res. Des. 2001, 79, 533–546. [Google Scholar] [CrossRef]

- Micale, G.; Montante, G.; Grisafi, F.; Brucato, A.; Godfrey, J. CFD simulation of particle distribution in stirred vessels. Chem. Eng. Res. Des. 2000, 78, 435–444. [Google Scholar] [CrossRef]

- Murthy, B.N.; Joshi, J.B. Assessment of standard k-ε, RSM and LES turbulence models in a baffled stirred vessel agitated by various impeller designs. Chem. Eng. Sci. 2008, 63, 5468–5495. [Google Scholar] [CrossRef]

- Derksen, J.; Akker, V.D.; Harry, E.A. Large eddy simulations on the flow driven by a rushton turbine. AlChE J. 1999, 45, 209–221. [Google Scholar] [CrossRef]

- Burns, A.D.; Frank, T.; Hamill, I.; Shi, J.-M. The favre averaged drag model for turbulent dispersion in eulerian multi-phase flows. In Proceedings of the 5th International Conference on Multiphase Flow, ICMF, Yokohama, Japan, 30 May–4 June 2004. Paper No. 392.

- Syamlal, M.; Rogers, W.; O’Brien, T.J. Mfix Documentation: Theory Guide. Available online: https://mfix.netl.doe.gov/documentation/Theory.pdf (accessed on 26 October 2015).

- Del Valle, V.H.; Kenning, D.B.R. Subcooled flow boiling at high heat flux. Int. J. Heat Mass Transfer 1985, 28, 1907–1920. [Google Scholar] [CrossRef]

- Zwietering, T.N. Suspending of solid particles in liquid by agitators. Chem. Eng. Sci. 1958, 8, 244–253. [Google Scholar] [CrossRef]

- Hicks, M.T.; Myers, K.J.; Bakker, A. Cloud height in solids suspension agitation. Chem. Eng. Commun. 1997, 160, 137–155. [Google Scholar] [CrossRef]

- Bittorf, K.J.; Kresta, S.M. Prediction of cloud height for solid suspensions in stirred tanks. Chem. Eng. Res. Des. 2003, 81, 568–577. [Google Scholar] [CrossRef]

- Zhao, H.-L.; Lv, C.; Liu, Y.; Zhang, T.-A. Process optimization of seed precipitation tank with multiple impellers using computational fluid dynamics. JOM 2015, 67, 1451–1458. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Micale, G.; Brucato, A.; Ciofalo, M. CFD simulations of dense solid-liquid suspensions in baffled stirred tanks: Prediction of solid particle distribution. Chem. Eng. J. 2013, 223, 875–890. [Google Scholar] [CrossRef]

- Armenante, P.M.; Mazzarotta, B.; Chang, G.-M. Power consumption in stirred tanks provided with multiple pitched-blade turbines. Ind. Eng. Chem. Res. 1999, 38, 2809–2816. [Google Scholar] [CrossRef]

- Buurman, C.; Resoort, G.; Plaschkes, A. Scaling-up rules for solids suspension in stirred vessels. Chem. Eng. Sci. 1986, 41, 2865–2871. [Google Scholar] [CrossRef]

- Magelli, F.; Fajner, D.; Nocentini, M.; Pasquali, G. Solid distribution in vessels stirred with multiple impellers. Chem. Eng. Sci. 1990, 45, 615–625. [Google Scholar] [CrossRef]

- Montante, G.; Pinelli, D.; Magelli, F. Scale-up criteria for the solids distribution in slurry reactors stirred with multiple impellers. Chem. Eng. Sci. 2003, 58, 5363–5372. [Google Scholar] [CrossRef]

- Barresi, A.; Baldi, G. Solid dispersion in an agitated vessel. Chem. Eng. Sci. 1987, 42, 2949–2956. [Google Scholar] [CrossRef]

- Montante, G.; Bourne, J.R.; Magelli, F. Scale-up of solids distribution in slurry, stirred vessels based on turbulence intermittency. Ind. Eng. Chem. Res. 2008, 47, 3438–3443. [Google Scholar] [CrossRef]

- Ibrahim, S.; Nienow, A.W. Comparing impeller performance for solid-suspension in the transitional flow regime with newtonian fluids. Chem. Eng. Res. Des. 1999, 77, 721–727. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wadnerkar, D.; Pareek, V.K.; Utikar, R.P. CFD Modelling of Flow and Solids Distribution in Carbon-in-Leach Tanks. Metals 2015, 5, 1997-2020. https://doi.org/10.3390/met5041997

Wadnerkar D, Pareek VK, Utikar RP. CFD Modelling of Flow and Solids Distribution in Carbon-in-Leach Tanks. Metals. 2015; 5(4):1997-2020. https://doi.org/10.3390/met5041997

Chicago/Turabian StyleWadnerkar, Divyamaan, Vishnu K. Pareek, and Ranjeet P. Utikar. 2015. "CFD Modelling of Flow and Solids Distribution in Carbon-in-Leach Tanks" Metals 5, no. 4: 1997-2020. https://doi.org/10.3390/met5041997

APA StyleWadnerkar, D., Pareek, V. K., & Utikar, R. P. (2015). CFD Modelling of Flow and Solids Distribution in Carbon-in-Leach Tanks. Metals, 5(4), 1997-2020. https://doi.org/10.3390/met5041997