Deformation-Induced Martensitic Transformation in Cu-Zr-Zn Bulk Metallic Glass Composites

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

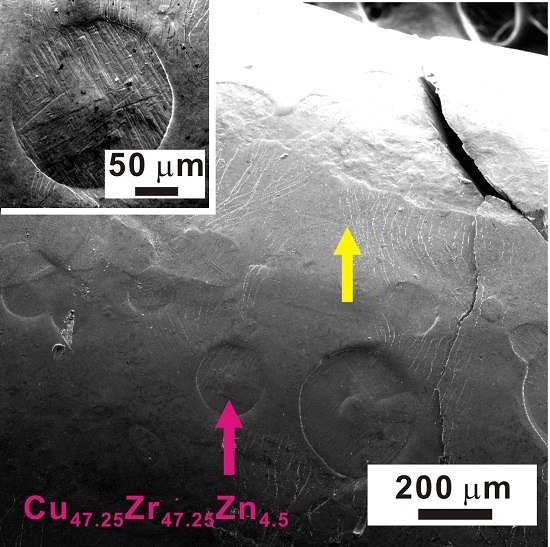

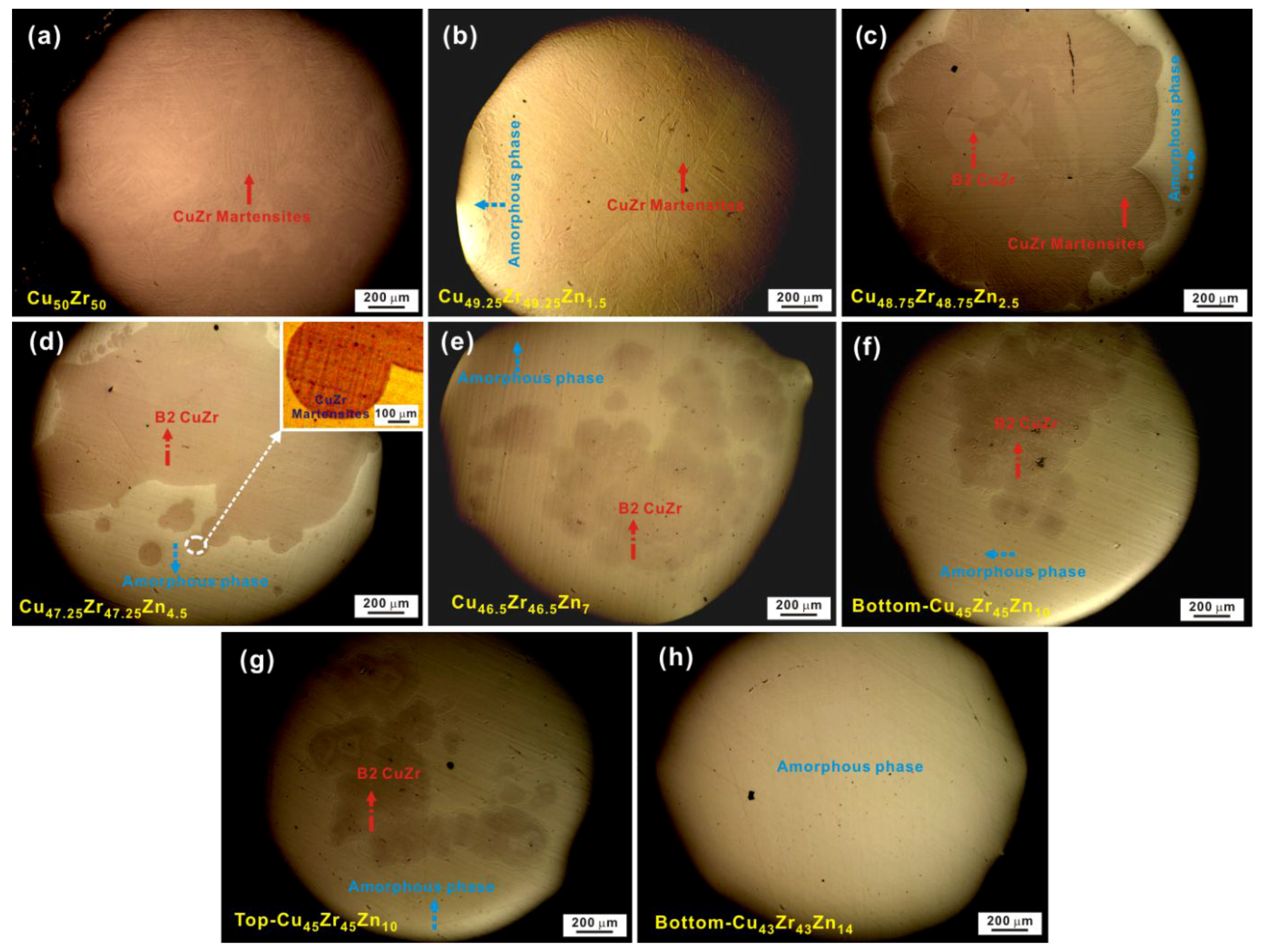

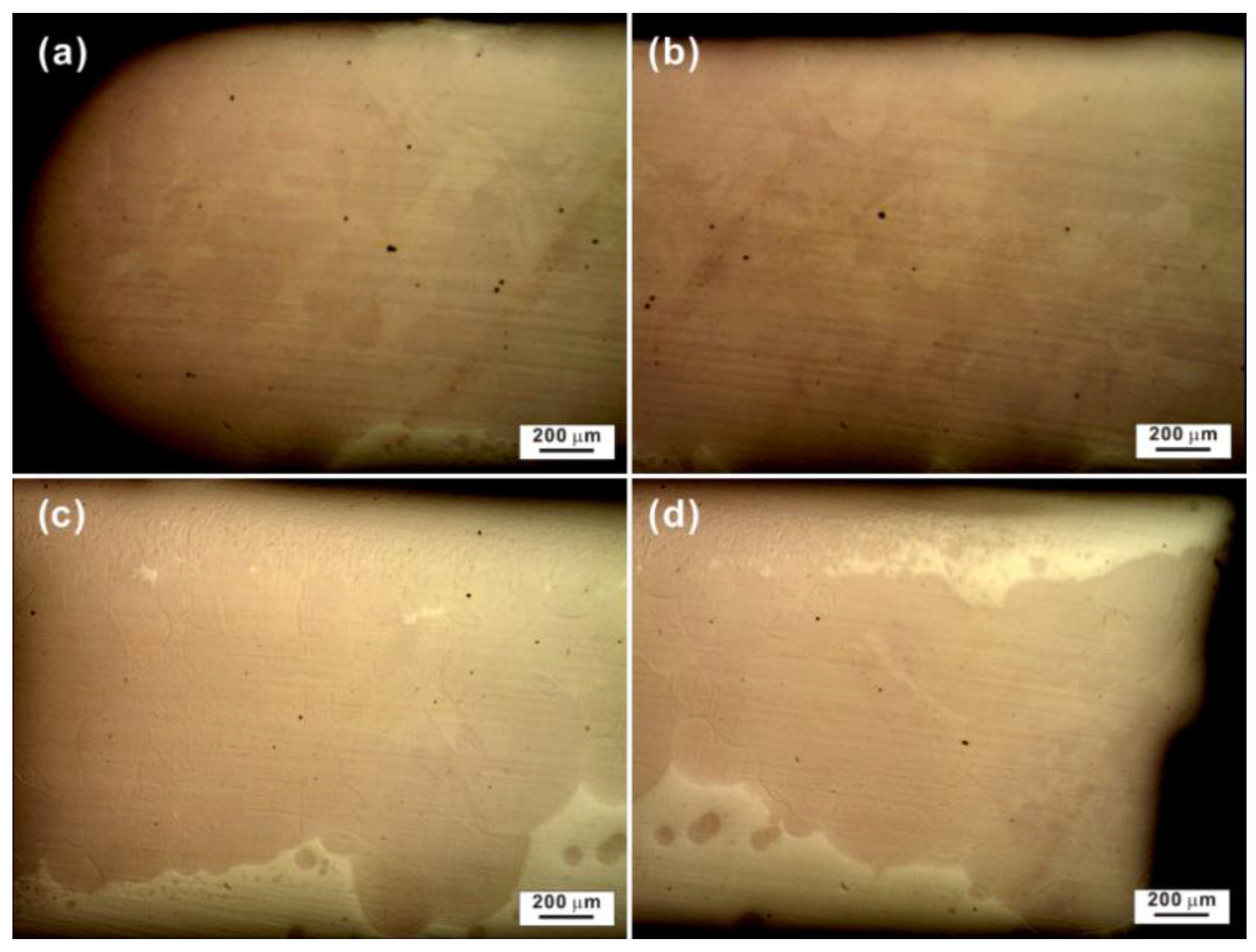

3.1. Phase Formation in the As-Cast Cu-Zr-Zn Rods

3.2. Mechanical Properties of the As-Cast Cu-Zr-Zn Samples

| Samples | Yield Strength (MPa) | Fracture Strength (MPa) | Plastic Strain (%) | Average Yield Strength (MPa) | Average Fracture Strength (MPa) | Average Plastic Strain (%) |

|---|---|---|---|---|---|---|

| Zn0-Top | 770 ± 10 | 1752 ± 10 | 10.0 ± 0.2 | 819 ± 60 | 1821 ± 75 | 9.7 ± 0.2 |

| Zn0-Bottom | 820 ± 10 | 1821 ± 10 | 9.7 ± 0.2 | |||

| Zn2.5-Top | 834 ± 10 | 1646 ± 10 | 6.8 ± 0.2 | 839 ± 200 | 1772 ± 120 | 7.7 ± 0.5 |

| Zn2.5-Bottom | 843 ± 10 | 1892 ± 10 | 8.2 ± 0.2 | |||

| Zn4.5-Top | 781 ± 10 | 1783 ± 10 | 6.9 ± 0.2 | 830 ± 220 | 1713 ± 75 | 6.8 ± 0.8 |

| Zn4.5-Bottom | 1058 ± 10 | 1643 ± 10 | 6.0 ± 0.5 | |||

| Zn7-Top | 860 ± 10 | 1932 ± 10 | 7.6 ± 0.5 | 906 ± 115 | 1884 ± 60 | 6.6 ± 0.8 |

| Zn7-Bottom | 1086 ± 10 | 1819 ± 10 | 5.0 ± 0.5 | |||

| Zn10-Top | 1420 ± 10 | 1881 ± 10 | 3.7 ± 0.5 | 1515 ± 200 | 1906 ± 100 | 2.8 ± 1.2 |

| Zn10-Bottom | 1773 ± 10 | 1940 ± 10 | 1.2 ± 0.5 | |||

| Zn14-Top | 1464 ± 10 | 2051 ± 10 | 6.0 ± 0.5 | 1636 ± 200 | 1943 ± 100 | 3 ± 3 |

| Zn14-Bottom | 1815 ± 10 | 1840 ± 10 | 0.1 ± 0.02 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Greer, A.L.; Cheng, Y.Q.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Yavari, A.R.; Lewandowski, J.J.; Eckert, J. Mechanical properties of bulk metallic glasses. MRS Bull. 2007, 32, 635–638. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent Progress in Bulk Glassy Alloys. Mater. Trans. 2002, 43, 1892–1906. [Google Scholar] [CrossRef]

- Egami, T.; Iwashita, T.; Dmowski, W. Mechanical Properties of Metallic Glasses. Metals 2013, 3, 77–113. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V.; Louzguina-Luzgina, L.V.; Churyumo, A.Y. Mechanical properties and deformation behavior of bulk metallic glasses. Metals 2013, 3, 1–22. [Google Scholar] [CrossRef]

- Mu, J.; Zhu, Z.W.; Su, R.; Wang, Y.D.; Zhang, H.F.; Ren, Y. In situ high-energy X-ray diffraction studies of deformation-induced phase transformation in Ti-based amorphous alloy composites containing ductile dendrites. Acta Mater. 2013, 61, 5008–5017. [Google Scholar] [CrossRef]

- Pan, D.G.; Zhang, H.F.; Wang, A.M.; Hu, Z.Q. Enhanced plasticity in Mg-based bulk metallic glass composite reinforced with ductile Nb particles. Appl. Phys. Lett. 2006. [Google Scholar] [CrossRef]

- Fu, H.M.; Wang, H.; Zhang, H.F.; Hu, Z.Q. In situ TiB-reinforced Cu-based bulk metallic glass composites. Scr. Mater. 2006, 54, 1961–1966. [Google Scholar] [CrossRef]

- Choi-Yim, H.; Conner, R.D.; Szuecs, F.; Johnson, W.L. Processing, microstructure and properties of ductile metal particulate reinforced Zr57Nb5Al10Cu15.4Ni12.6 bulk metallic glass composites. Acta Mater. 2002, 50, 2737–2745. [Google Scholar] [CrossRef]

- Oh, Y.S.; Kim, C.P.; Lee, S.; Kim, N.J. Microstructure and tensile properties of high-strength high-ductility Ti-based amorphous matrix composites containing ductile dendrites. Acta Mater. 2011, 59, 7277–7286. [Google Scholar] [CrossRef]

- Qiao, J.W.; Sun, A.C.; Huang, E.W.; Zhang, Y.; Liaw, P.K.; Chuang, C.P. Tensile deformation micromechanisms for bulk metallic glass matrix composites: From work-hardening to softening. Acta Mater. 2011, 59, 4126–4137. [Google Scholar] [CrossRef]

- Eckert, J.; Das, J.; Pauly, S.; Duhamel, C. Processing routes, microstructure and mechanical properties of metallic glasses and their composites. Adv. Eng. Mater. 2007, 9, 443–453. [Google Scholar] [CrossRef]

- Choi-Yim, H.; Johnson, W.L. Bulk metallic glass matrix composites. Appl. Phys. Lett. 1997, 71, 3808–3810. [Google Scholar] [CrossRef]

- Ma, H.; Xu, J.; Ma, E. Mg-based bulk metallic glass composites with plasticity and high strength. Appl. Phys. Lett. 2003, 83, 2793–2795. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Duan, G.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.F.; Li, S.T.; Zhang, G.A.; Wu, X.F.; Lin, P. Plastic stability of metallic glass composites under tension. Appl. Phys. Lett. 2013. [Google Scholar] [CrossRef]

- Qiao, J.W.; Zhang, Y.; Liaw, P.K.; Chen, G.L. Micromechanisms of plastic deformation of a dendrite/Zr-based bulk-metallic-glass composite. Scr. Mater. 2009, 61, 1087–1090. [Google Scholar] [CrossRef]

- Gargarella, P.; Pauly, S.; Song, K.K.; Hu, J.; Barekar, N.S.; Khoshkhoo, M.S.; Teresiak, A.; Wendrock, H.; Kühn, U.; Ruffing, C.; et al. Ti-Cu-Ni shape memory bulk metallic glass composites. Acta Mater. 2013, 61, 151–162. [Google Scholar] [CrossRef]

- Pauly, S.; Liu, G.; Wang, G.; Kühn, U.; Mattern, N.; Eckert, J. Microstructural heterogeneities governing the deformation of Cu47.5Zr47.5Al5 bulk metallic glass composites. Acta Mater. 2009, 57, 5445–5453. [Google Scholar] [CrossRef]

- Song, K.K.; Pauly, S.; Zhang, Y.; Li, R.; Gorantla, S.; Narayanan, N.; Kühn, U.; Gemming, T.; Eckert, J. Triple yielding and deformation mechanisms in metastable Cu47.5Zr47.5Al5 composites. Acta Mater. 2012, 60, 6000–6012. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, H.; Wu, H.H.; Zhang, Z.Y.; Hui, X.D.; Chen, G.L.; Ma, D.; Wang, X.L.; Lu, Z.P. Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties. Acta Mater. 2011, 59, 2928–2936. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y.H.; Chen, G.L.; Liu, C.T.; Lu, Z.P. Bulk Metallic Glass Composites with Transformation-Mediated Work-Hardening and Ductility. Adv. Mater. 2010, 22, 2770–2773. [Google Scholar] [CrossRef] [PubMed]

- Song, K.K.; Pauly, S.; Sun, B.A.; Tan, J.; Stoica, M.; Kühn, U.; Eckert, J. Correlation between the microstructures and the deformation mechanisms of CuZr-based bulk metallic glass composites. AIP Adv. 2013. [Google Scholar] [CrossRef]

- Wu, F.F.; Chan, K.C.; Jiang, S.S.; Chen, S.H.; Wang, G. Bulk metallic glass composite with good tensile ductility, high strength and large elastic strain limit. Sci. Rep. 2014. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.Q.; Li, R.; Liu, G.; Su, W.H.; Wang, H.; Li, Y.; Shi, M.J.; Luo, X.K.; Wu, G.J.; Zhang, T. Microstructural tailoring and improvement of mechanical properties in CuZr-based bulk metallic glass composites. Acta Mater. 2012, 60, 3128–3139. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Liu, G.; Qu, R.T.; Zhang, Z.F.; Wu, S.J.; Zhang, T. Microstructural percolation assisted breakthrough of trade-off between strength and ductility in CuZr-based metallic glass composites. Sci. Rep. 2014. [Google Scholar] [CrossRef] [PubMed]

- Li, C.J.; Tan, J.; Wang, G.; Bednarčík, J.; Zhu, X.K.; Zhang, Y.; Stoica, M.; Kühn, U.; Eckert, J. Enhanced strength and transformation-induced plasticity in rapidly solidified Zr-Co-(Al) alloys. Scr. Mater. 2013, 68, 897–900. [Google Scholar] [CrossRef]

- Pauly, S.; Das, J.; Bednarcik, J.; Mattern, N.; Kim, K.B.; Kim, D.H.; Eckert, J. Deformation-induced martensitic transformation in Cu-Zr-(Al, Ti) bulk metallic glass composites. Scr. Mater. 2009, 60, 431–434. [Google Scholar] [CrossRef]

- Song, K.K.; Pauly, S.; Zhang, Y.; Sun, B.A.; He, J.; Ma, G.Z.; Kühn, U.; Eckert, J. Thermal stability and mechanical properties of Cu46Zr46Ag8 bulk metallic glass and its composites. Mater. Sci. Eng. A 2013, 559, 711–718. [Google Scholar] [CrossRef]

- Song, K.K.; Pauly, S.; Sun, B.A.; Zhang, Y.; Tan, J.; Kühn, U.; Stoica, M.; Eckert, J. Formation of Cu-Zr-Al-Er bulk metallic glass composites with enhanced deformability. Intermetallics 2012, 30, 132–138. [Google Scholar] [CrossRef]

- Wu, Y.; Song, W.L.; Zhang, Z.Y.; Hui, X.D.; Ma, D.; Wang, X.L.; Shang, X.C.; Lu, Z.P. Relationship between composite structures and compressive properties in CuZr-based bulk metallic glass system. Chin. Sci. Bull. 2011, 56, 3960–3964. [Google Scholar] [CrossRef]

- Sun, Y.F.; Wei, B.C.; Wang, Y.R.; Li, W.H.; Cheung, T.L.; Shek, C.H. Plasticity-improved Zr-Cu-Al bulk metallic glass matrix composites containing martensite phase. Appl. Phys. Lett. 2005. [Google Scholar] [CrossRef]

- Song, K.K.; Pauly, S.; Zhang, Y.; Gargarella, P.; Li, R.; Barekar, N.S.; Kühn, U.; Stoica, M.; Eckert, J. Strategy for pinpointing the formation of B2 CuZr in metastable CuZr-based shape memory alloys. Acta Mater. 2011, 59, 6620–6630. [Google Scholar] [CrossRef]

- Kuo, C.N.; Huang, J.C.; Du, X.H.; Chen, Y.C.; Liu, X.J.; Nieh, T.G. Effects of V on phase formation and plasticity improvement in Cu-Zr-Al glassy alloys. Mater. Sci. Eng. A 2013, 561, 245–251. [Google Scholar] [CrossRef]

- Xie, M.T.; Zhang, P.N.; Song, K.K. Thermal Stability and Transformation-mediated Deformability of Cu-Zr-Al-Ni Bulk Metallic Glass Composite. J. Mater. Sci. Technol. 2013, 29, 868–872. [Google Scholar] [CrossRef]

- Song, K.K.; Pauly, S.; Wang, Z.; Kühn, U.; Eckert, J. Effect of TaW particles on the microstructure and mechanical properties of metastable Cu47.5Zr47.5Al5 alloys. Mater. Sci. Eng. A 2013, 587, 372–380. [Google Scholar] [CrossRef]

- Javid, F.A.; Mattern, N.; Khoshkhoo, M.S.; Stoica, M.; Pauly, S.; Eckert, J. Phase formation of Cu50−xCoxZr50 (x = 0–20 at. %) alloys: Influence of cooling rate. J. Alloys Compd. 2014, 590, 428–434. [Google Scholar] [CrossRef]

- Wu, D.Y.; Song, K.K.; Gargarella, P.; Cao, C.D.; Li, R.; Kaban, I.; Eckert, J. Glass-forming Ability, Thermal stability of B2 CuZr phase, and crystallization kinetics for rapidly solidified Cu-Zr-Zn alloys. J. Alloys Compd. submitted for publication. 2015. [Google Scholar]

- Seo, J.W.; Schryvers, D. TEM investigation of the microstructure and defects of CuZr martensite. Part I: Morphology and twin systems. Acta Mater. 1998, 46, 1165–1175. [Google Scholar] [CrossRef]

- Schryvers, D.; Firstov, G.S.; Seo, J.W.; Humbeeck, J.V.; Koval, Y.N. Unit cell determination in CuZr martensite by electron microscopy and X-ray diffraction. Scr. Mater. 1997, 36, 1119–1125. [Google Scholar] [CrossRef]

- Firstov, G.S.; Humbeeck, J.V.; Koval, Y.N. Peculiarities of the martensitic transformation in ZrCu intermetallic compound - potential high temperature SMA. J. Phys. IV 2001, 11, 481–486. [Google Scholar] [CrossRef]

- Kalay, I.; Kramer, M.; Napolitano, R. Crystallization Kinetics and Phase Transformation Mechanisms in Cu56Zr44 Glassy Alloy. Metall. Mater. Trans. A 2015, 46, 3356–3364. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials, 1st ed.; Cambridge University Press: Cambridge, UK, 1998; pp. 1–49. [Google Scholar]

- Wang, G.; Pauly, S.; Gorantla, S.; Mattern, N.; Eckert, J. Plastic Flow of a Cu50Zr45Ti5 Bulk Metallic Glass Composite. J. Mater. Sci. Tech. 2014, 30, 609–615. [Google Scholar] [CrossRef]

- Pauly, S.; Gorantla, S.; Wang, G.; Kühn, U.; Eckert, J. Transformation-mediated ductility in CuZr-based bulk metallic glasses. Nat. Mater. 2010, 9, 473–477. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Yang, H.; Wu, W.F.; Li, Y. Invariant critical stress for shear banding in a bulk metallic glass. Appl. Phys. Lett. 2008. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Eckert, J.; Schultz, L. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass. Acta Mater. 2003, 51, 1167–1179. [Google Scholar] [CrossRef]

- Sun, B.A.; Wang, W.H. The fracture of bulk metallic glasses. Prog. Mater. Sci. 2015, 74, 211–307. [Google Scholar] [CrossRef]

- Argon, A.S.; Salama, M. The mechanism of fracture in glassy materials capable of some inelastic deformation. Mater. Sci. Eng. 1976, 23, 219–230. [Google Scholar] [CrossRef]

- Sun, B.A.; Tan, J.; Pauly, S.; Kuhn, U.; Eckert, J. Stable fracture of a malleable Zr-based bulk metallic glass. J. Appl. Phys. 2012. [Google Scholar] [CrossRef]

- Deibler, L.A.; Lewandowski, J.J. Model experiments to mimic fracture surface features in metallic glasses. Mater. Sci. Eng. A 2010, 527, 2207–2213. [Google Scholar] [CrossRef]

- Lewandoski, J.J.; Greer, A.L. Temperature rise at shear bands in metallic glasses. Nat. Mater. 2006, 5, 15–18. [Google Scholar] [CrossRef]

- Wu, F.F.; Chan, K.C.; Li, S.T.; Wang, G. Stabilized shear banding of ZrCu-based metallic glass composites under tensile loading. J. Mater. Sci. 2014, 49, 2164–2170. [Google Scholar] [CrossRef]

- Tong, X.; Wang, G.; Yi, J.; Ren, J.L.; Pauly, S.; Gao, Y.L.; Zhai, Q.J.; Mattern, N.; Dahmen, K.A.; Liaw, P.K.; et al. Shear avalanches in plastic deformation of a metallic glass composite. Int. J. Plast. 2016, 77, 141–155. [Google Scholar] [CrossRef]

- Song, K.K. Synthesis, microstructure, and deformation mechanisms of CuZr-based bulk metallic glass composites. In Doctoral Thesis Work; TU Dresden: Dresden, Germany, 2013. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Song, K.; Cao, C.; Li, R.; Wang, G.; Wu, Y.; Wan, F.; Ding, F.; Shi, Y.; Bai, X.; et al. Deformation-Induced Martensitic Transformation in Cu-Zr-Zn Bulk Metallic Glass Composites. Metals 2015, 5, 2134-2147. https://doi.org/10.3390/met5042134

Wu D, Song K, Cao C, Li R, Wang G, Wu Y, Wan F, Ding F, Shi Y, Bai X, et al. Deformation-Induced Martensitic Transformation in Cu-Zr-Zn Bulk Metallic Glass Composites. Metals. 2015; 5(4):2134-2147. https://doi.org/10.3390/met5042134

Chicago/Turabian StyleWu, Dianyu, Kaikai Song, Chongde Cao, Ran Li, Gang Wang, Yuan Wu, Feng Wan, Fuli Ding, Yue Shi, Xiaojun Bai, and et al. 2015. "Deformation-Induced Martensitic Transformation in Cu-Zr-Zn Bulk Metallic Glass Composites" Metals 5, no. 4: 2134-2147. https://doi.org/10.3390/met5042134

APA StyleWu, D., Song, K., Cao, C., Li, R., Wang, G., Wu, Y., Wan, F., Ding, F., Shi, Y., Bai, X., Kaban, I., & Eckert, J. (2015). Deformation-Induced Martensitic Transformation in Cu-Zr-Zn Bulk Metallic Glass Composites. Metals, 5(4), 2134-2147. https://doi.org/10.3390/met5042134