Similarities and Differences in Mechanical Alloying Processes of V-Si-B and Mo-Si-B Powders

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. Microstructure Evolution

3.2. Particle Size and Morphology

3.3. Microhardness

3.4. Description of the Occurring Process Mechanisms

3.5. Microstructure of Compact Materials

4. Summary and Conclusions

- MA is shown to be a beneficial process in providing the aimed homogeneous solid solution powders after a duration of 10–20 h of milling depending on the alloy and the process parameters.

- The progress of MA is significantly dependent on the rotational speed of the planetary ball mill; the material of the grinding balls and vials, i.e., stainless steel and tungsten carbide, are comparably less pronounced.

- The use of tungsten carbide vials and balls provides just slightly improved impact energies compared to the steel tools. However, tungsten carbide is a very hard and brittle material and contamination of the mechanically alloyed powders with flaked particles of WC is unavoidable, not even when processing with a lower rotational speed. Using grinding materials made of steel, Fe contaminations are detectable in the milled powders. Due to the solubility of Fe in the V and Mo lattice, respectively, these impurities are dissolved in the solid solution phases.

- The microstructural evolution in both types of alloys follows the same trend: During the first 2 h of milling, typical layered (lamellar) structures form due to high deformation (flattening) and welding of the ductile elements V or Mo, respectively, and fracturing of the brittle components. Longer milling or an increased rotational speed of the ball mill leads to the decrease of the lamellar spacing and the homogenization until a supersaturated solid solution phase forms.

- A balance between economic priorities (short duration of the milling process) and acceptable contamination is made by using milling equipment made of steel; a milling time of <20 h in the case of V-9Si-13B and 20 h in case of Mo-9Si-8B, and a rotational speed of 200 rpm.

- The evolution of the particle size and the morphology during the initial state of MA is affected by the properties of the individual components, which means that the ductile components flatten and weld during the initial state of MA and the brittle components tend to fracture. These mechanisms yield in irregular powder morphologies. After about 20 h of milling at 200 rpm nearly globular particles are formed which are seen as appropriate products for subsequent powder consolidation processes.

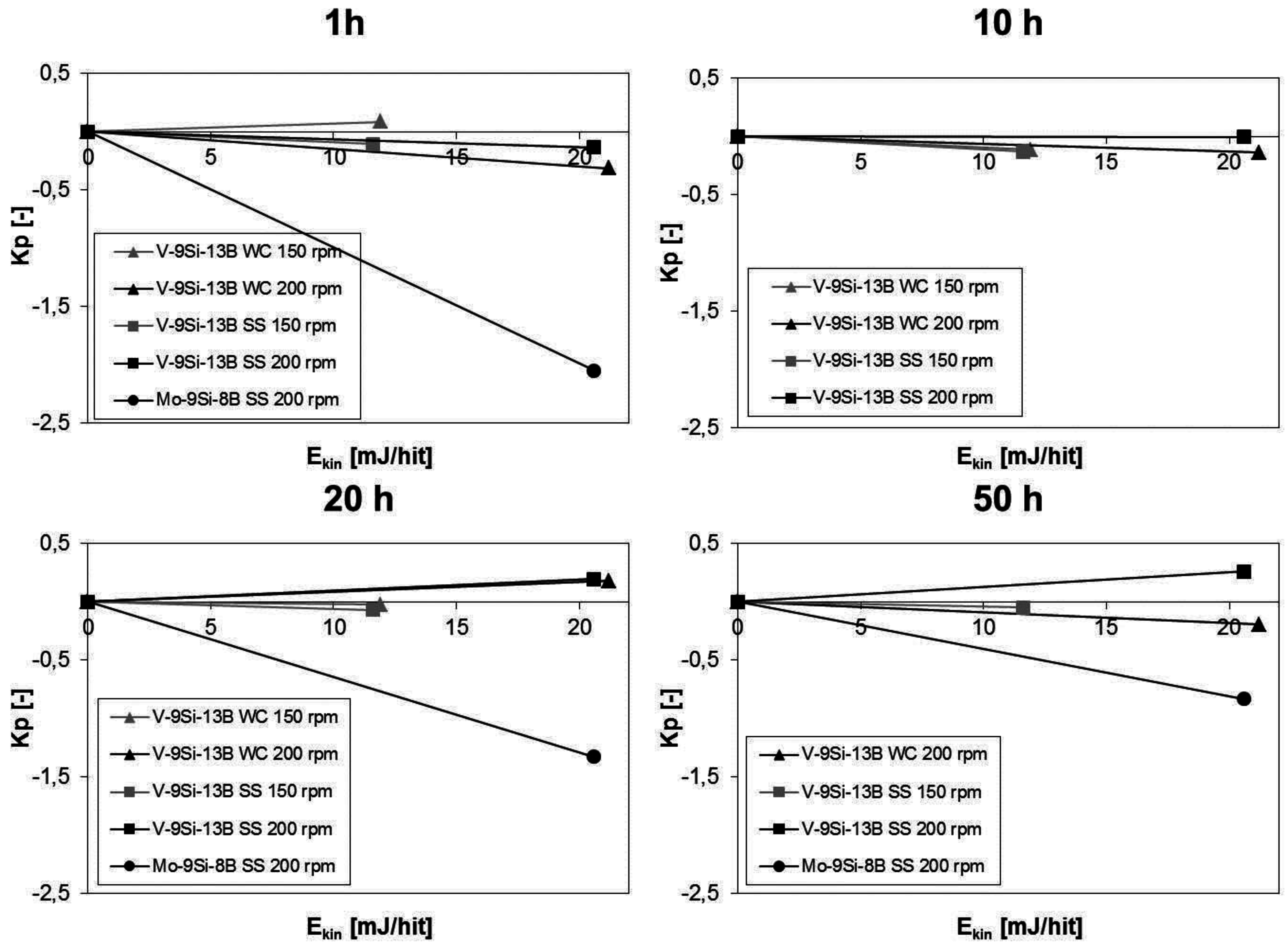

- Fracturing and comminution mechanisms which occur during MA can be described by the comminution rate KP. In both types of alloys the welding processes are more pronounced compared to the comminution processes, which is expressed by mainly negative KP values. During the MA process the slope of the KP-Ekin graphs decreased but did not show significant positive values of KP since the occurring comminution processes did not lead to a particle size reduction smaller than the initial particle size of the elemental powders.

- The compact V-9Si-13B and Mo-9Si-8B materials show the desired microstructures consisting of a Vss or Moss matrix and dispersed particles of the silicide phases.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Boyce, M.P. Gas Turbine Engineering Handbook 11. In Gas Turbine Engineering Handbook; Elsevier: New York, NY, USA, 2012; pp. 493–514. [Google Scholar]

- Soboyejo, W.O.; Srivatsan, T.S. Introduction to Advanced Materials. In Advanced Structured Materials; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Dimiduk, D.M.; Perepezko, J.H. Mo-Si-B Alloys: Developing a Revolutionary Turbine-Engine Material. MRS Bull. 2003. [Google Scholar] [CrossRef]

- Heilmaier, M.; Krüger, M.; Saage, H.; Rösler, J.; Mukherji, D.; Glatzel, U.; Völkl, R.; Hüttner, R.; Eggeler, G.; Somsen, C.; et al. Metallic Materials for Structural Applications Beyond Nickel-based Superalloys. JOM 2009, 61, 61–67. [Google Scholar] [CrossRef]

- Yao, Z.; Stiglich, J.; Sudarshan, T.S. Molybdenum Silicide Based Materials and Their Properties. J. Mater. Eng. Perform. 1999, 8, 291–304. [Google Scholar] [CrossRef]

- Matsui, H.; Fukumoto, K.; Smith, D.L.; Chung, H.M.; van Witzenburg, W.; Votinov, S.N. Status of vanadium alloys for fusion reactors. J. Nucl. Mater. 1996, 233–237, 92–99. [Google Scholar] [CrossRef]

- Smith, D.L.; Chung, H.M.; Loomis, B.A.; Matsui, H.; Votinov, S.; van Witzenburg, W. Fusion Engineering and Design Development of vanadium-base alloys for fusion first-wall-blanket applications. Fusion Eng. Des. 1995, 29, 399–410. [Google Scholar] [CrossRef]

- Shyrokov, V.V.; Vasyliv, C.B.; Shyrokov, O.V. Ways of improving the high-temperature work service of vanadium and some alloys used in reactors. J. Nucl. Mater. 2009, 394, 114–122. [Google Scholar] [CrossRef]

- Zheng, P.F.; Nagasaka, T.; Muroga, T.; Chen, J.M. Microstructures and mechanical properties of mechanically alloyed V-4Cr-4Ti alloy dispersion strengthened by nano-particles. Fusion Eng. Des. 2014, 89, 1648–1652. [Google Scholar] [CrossRef]

- Northcott, L.; Meyer-Zürich, H.U. Molybdenum, von L Northcott. Reihe: Metallurgy of the rarer Metals, Bd. V, herausgeg. von H.M. Finniston. Butterworths Scientific Publications, London 1956. 1. Aufl. Angew. Chem. 1959, 71, 91–91. [Google Scholar]

- Krüger, M.; Schliephake, D.; Jain, P.; Kumar, K.S.; Schumacher, G.; Heilmaier, M. Effects of Zr additions on the microstructure and the mechanical behavior of PM Mo-Si-B alloys. JOM 2013, 65, 301–306. [Google Scholar] [CrossRef]

- Saage, H.; Krüger, M.; Sturm, D.; Heilmaier, M.; Schneibel, J.; George, E.; Heatherly, L.; Somsen, C.; Eggeler, G.; Yang, Y. Ductilization of Mo-Si solid solutions manufactured by powder metallurgy. Acta Mater. 2009, 57, 3895–3901. [Google Scholar] [CrossRef]

- Sturm, D.; Heilmaier, M.; Schneibel, J.H.; Jéhanno, P.; Skrotzki, B.; Saage, H. The influence of silicon on the strength and fracture toughness of molybdenum. Mater. Sci. Eng. A 2007, 463, 107–114. [Google Scholar] [CrossRef]

- Yu, X.J.; Kumar, K.S. The tensile response of Mo, Mo-Re and Mo-Si solid solutions. Int. J. Refract. Met. Hard Mater. 2013, 41, 329–338. [Google Scholar] [CrossRef]

- Gunter, I.M.; Schneibel, J.H.; Kruzic, J.J. Ductility and fracture toughness of molybdenum with MgAl2O4 additions. Mater. Sci. Eng. A 2007, 458, 275–280. [Google Scholar] [CrossRef]

- Jéhanno, P.; Heilmaier, M.; Saage, H.; Böning, M.; Kestler, H.; Freudenberger, J.; Drawin, S. Assessment of the high temperature deformation behavior of molybdenum silicide alloys. Mater. Sci. Eng. A 2007, 463, 216–223. [Google Scholar] [CrossRef]

- Hasemann, G.; Bogomol, I.; Schliephake, D.; Loboda, P.I.; Krüger, M. Microstructure and creep properties of a near-eutectic directionally solidified multiphase Mo-Si-B alloy. Intermetallics 2014, 48, 28–33. [Google Scholar] [CrossRef]

- Alur, A.P.; Chollacoop, N.; Kumar, K.S. Creep effects on crack growth in a Mo-Si-B alloy. Acta Mater. 2007, 55, 961–974. [Google Scholar] [CrossRef]

- Krüger, M.; Franz, S.; Saage, H.; Heilmaier, M.; Schneibel, J.H.; Jéhanno, P.; Böning, M.; Kestler, H. Mechanically alloyed Mo-Si-B alloys with a continuous alpha-Mo matrix and improved mechanical properties. Intermetallics 2008, 16, 933–941. [Google Scholar] [CrossRef]

- Rioult, F.A.; Imhoff, S.D.; Sakidja, R.; Perepezko, J.H. Transient oxidation of Mo-Si-B alloys: Effect of the microstructure size scale. Acta Mater. 2009, 57, 4600–4613. [Google Scholar] [CrossRef]

- Choe, H.; Chen, D.; Schneibel, J.; Ritchie, R. Ambient to high temperature fracture toughness and fatigue-crack propagation behavior in a Mo-12Si-8.5 B (at. %) intermetallic. Intermetallics 2001, 9, 319–329. [Google Scholar] [CrossRef]

- Krüger, M.; Jain, P.; Kumar, K.S.; Heilmaier, M. Correlation between microstructure and properties of fine grained Mo-Mo3Si-Mo5SiB2 alloys. Intermetallics 2014, 48, 10–18. [Google Scholar] [CrossRef]

- Chaia, N.; David, N.; Mathieu, S.; Vilasi, M. Experimental isothermal section at 1200 °C of V-Cr-Si system. Intermetallics 2014, 49, 115–120. [Google Scholar] [CrossRef]

- Chen, J.M.; Chernov, V.M.; Kurtz, R.J.; Muroga, T. Overview of the vanadium alloy researches for fusion reactors. J. Nucl. Mater. 2011, 417, 289–294. [Google Scholar] [CrossRef]

- Sakamoto, T.; Kurishita, H.; Furuno, T.; Nagasaka, T.; Kobayashi, S.; Nakai, K.; Matsuo, S.; Arakawa, H.; Nishimura, A.; Muroga, T. Uniaxial creep behavior of nanostructured, solution and dispersion hardened V-1.4Y-7W-9Mo-0.7TiC with different grain sizes. Mater. Sci. Eng. A 2011, 528, 7843–7850. [Google Scholar] [CrossRef]

- Bei, H.; George, E.P.; Kenik, E.A.; Pharr, G.M. Microstructures and mechanical properties of V-V3Si eutectic composites. Z. Metallkunde 2004, 95, 505–512. [Google Scholar] [CrossRef]

- Nunes, C.A.; de Lima, B.B.; Coelho, G.C.; Suzuki, P.A. Isothermal Section of the V-Si-B System at 1600 °C in the V-VSi2-VB Region. J. Phase Equilib. Diffus. 2009, 30, 345–350. [Google Scholar] [CrossRef]

- Sakidja, R.; Perepezko, J.H.; Kim, S.; Sekido, N. Phase stability and structural defects in high-temperature Mo-Si-B alloys. Acta Mater. 2008, 56, 5223–5244. [Google Scholar] [CrossRef]

- Kruzic, J.J.; Schneibel, J.H.; Ritchie, R.O. Fracture and fatigue resistance of Mo-Si-B alloys for ultrahigh-temperature structural applications. Scr. Mater. 2004, 50, 459–464. [Google Scholar] [CrossRef]

- Schneibel, J.H. High temperature strength of Mo-Mo3Si-Mo5SiB2 molybdenum silicides. Intermetallics 2003, 11, 625–632. [Google Scholar] [CrossRef]

- Krüger, M. High temperature compression strength and oxidation of a V-9Si-13B alloy. Scr. Mater. 2016, 121, 75–78. [Google Scholar] [CrossRef]

- Reis, D.A.P.; Nunes, C.A.; Neto, A.C. Caracterizacao microestrutural e quimica de ligas V-Si-B. Rev. Bras. Apl. Vácuo 2007, 26, 79–82. [Google Scholar]

- Koch, C.C.; Whittenberger, J.D. Mechanical milling/alloying of intermetallics. Intermetallics 1996, 4, 339–355. [Google Scholar] [CrossRef]

- Li, B.; Zhang, G.; Jiang, F.; Ren, S.; Liu, G.; Sun, J. Characterization of Mo-Si-B Nanocomposite Powders Produced Using Mechanical Alloying and Powder Heat Treatment. J. Mater. Sci. Technol. 2015. [Google Scholar] [CrossRef]

- Liu, L.; Cui, K. Mechanical alloying of refractory metal-silicon systems. J. Mater. Process. Technol. 2003, 138, 394–398. [Google Scholar] [CrossRef]

- Koch, C.C. Intermetallic matrix composites prepared by mechanical alloying—A review. Mater. Sci. Eng. A 1998, 244, 39–48. [Google Scholar] [CrossRef]

- Abdellaoui, M.; Gaffet, E. The physics of mechanical alloying in a planetary ball mill: Mathematical treatment. Acta Metall. Mater. 1995, 43, 1087–1098. [Google Scholar] [CrossRef]

- Schmelzer, J.; Baumann, T.; Dieck, S.; Krüger, M. Hardening of V-Si alloys during high energy ball milling. Powder Technol. 2016, 294, 493–497. [Google Scholar] [CrossRef]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. Binary Alloy Phase Diagrams, 2nd ed.; ASM International: Almere, The Netherlands, 1990. [Google Scholar]

- Thermodynamic Properties of Inorganic Materials compiled by SGTE; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2007.

- Sossaman, T.; Sakidja, R.; Perepezko, J.H. Influence of minor Fe addition on the oxidation performance of Mo-Si-B alloys. Scr. Mater. 2012, 67, 891–894. [Google Scholar] [CrossRef]

- Yang, T.; Guo, X.; Luo, Y. Microstructural evolution of mechanically alloyed Mo-Si-B-Zr-Y powders. Int. J. Refract. Met. Hard Mater. 2016, 56, 35–43. [Google Scholar] [CrossRef]

- Zheng, P.F.; Nagasaka, T.; Muroga, T.; Chen, J.M. Investigation on mechanical alloying process for vanadium alloys. J. Nucl. Mater. 2013, 442, S330–S335. [Google Scholar] [CrossRef]

- Koch, C.C. Synthesis of nanostructured materials by mechanical milling: Problems and opportunities. Nanostruct. Mater. 1997, 9, 13–22. [Google Scholar] [CrossRef]

- Rösler, J.; Harders, H.; Bäker, M. Mechanisches Verhalten der Werkstoffe, 4th ed.; Springer: Wiesbaden, Germany, 2012. [Google Scholar]

- Oda, S.; Kurishita, H.; Tsuruoka, Y.; Kobayashi, S.; Nakai, K.; Matsui, H. High temperature strength of fine-grained, particle-dispersed V-(1.7–2.4)wt. %Y alloys with different grain sizes and particle densities. J. Nucl. Mater. 2004, 329–333, 462–466. [Google Scholar] [CrossRef]

- Höffl, K. Zerkleinerungs- und Klassiermaschinen; Springer: Berlin/Heidelberg, Germany, 1986. [Google Scholar]

- Schwister, K.; Leven, V. Verfahrenstechnik für Ingenieure; Carl Hanser Verlag GmbH & Co KG: Munich, Germany, 2014. [Google Scholar]

- Bond, F.C. Crushing and grinding calculations. Br. Chem. Eng. 1961, 6, 378–385. [Google Scholar]

- Stieß, M. Mechanische Verfahrenstechnik 2; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Jankovic, A.; Dundar, H.; Mehta, R. Relationships between comminution energy and product size for a magnetite ore. J. S. Afr. Inst. Min. Metall. 2010, 110, 141–146. [Google Scholar]

- Müller, E.; Oestreich, C. Handling of Highly Dispersed Powders; Shaker Verlag: Aachen, Germany, 2004. [Google Scholar]

- Kano, J.; Mio, H.; Saito, F. Correlation of size reduction rate of inorganic materials with impact energy of balls in planetary ball milling. J. Chem. Eng. Jpn. 1999, 32, 445–448. [Google Scholar] [CrossRef]

- Gupta, A.; Yan, D.S. Mineral Processing Design and Operation; Elsevier: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Mio, H.; Kano, J.; Saito, F. Scale-up method of planetary ball mill. Chem. Eng. Sci. 2004, 59, 5909–5916. [Google Scholar] [CrossRef]

- Vorontsov, V.A.; Barnard, J.S.; Rahman, K.M.; Yan, H.Y.; Midgley, P.A.; Dye, D. Coarsening behaviour and interfacial structure of g precipitates in Co-Al-W based superalloys. Acta Mater. 2016, 120, 14–23. [Google Scholar] [CrossRef]

- Zenk, C.H.; Neumeier, S.; Engl, N.M.; Fries, S.G.; Dolotko, O.; Weiser, M.; Virtanen, S.; Göken, M. Intermediate Co/Ni-base model superalloys—Thermophysical properties, creep and oxidation. Scr. Mater. 2016, 112, 83–86. [Google Scholar] [CrossRef]

- Reed, R.C.; Tao, T.; Warnken, N. Alloys-By-Design: Application to nickel-based single crystal superalloys. Acta Mater. 2009, 57, 5898–5913. [Google Scholar] [CrossRef]

| Alloy Composition (at. %) | V-9Si-13B | Mo-9Si-8B | |||||

|---|---|---|---|---|---|---|---|

| Grinding Material | Steel (SS) | Tungsten Carbide (WC) | Steel | Tungsten Carbide | |||

| speed ball mill (rpm) | 150 | 200 | 150 | 200 | 150 | 200 | 200 |

| Ekin collision (mJ/hit) | 11.6 | 20.6 | 11.9 | 21.2 | 11.6 | 20.6 | 21.2 |

| milling time to achieve homogenization (h) | 20 | 10–20 | 20 | 10 | 50 | 20 | 20 |

| Fe impurities in the homogenized particles (at. %) | <2 | <2 | <2 | <2 | |||

| WC particles in the homogenized particles (%) | 0.2 | 0.45 | 0.8 | ||||

| Fe impurities after 50 h of milling (at. %) | <2 | <2 | <2 | 6.7 | |||

| WC particles after 50 h of milling (%) | 0.75 | 1.75 | 1.7 | ||||

| Grinding Material | Steel | Tungsten Carbide | ||

|---|---|---|---|---|

| ball mill speed (rpm) | 150 | 200 | 150 | 200 |

| mb (kg) | 0.004 | 0.006 | ||

| ωe (s−1) | 15.71 | 20.93 | 15.71 | 20.93 |

| ωr (s−1) | 39.25 | 52.35 | 39.25 | 52.35 |

| rm (m) | 0.150 | 0.150 | ||

| r* (m) | 0.033 | 0.034 | ||

| α | 14.87 | 14.91 | 14.94 | 15.10 |

| Duration of Milling (h) | V-9Si-13B | Mo-9Si-8B | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WC; 150 rpm | WC; 200 rpm | SS; 150 rpm | SS; 200 rpm | SS; 200 rpm | ||||||

| k (hit/mJ) | KP (-) | k (hit/mJ) | KP (-) | k (hit/mJ) | KP (-) | k (hit/mJ) | KP (-) | k (hit/mJ) | KP (-) | |

| 1 | 0.007 | 0.084 | −0.015 | −0.312 | −0.009 | −0.107 | −0.007 | −0.136 | −0.099 | −2.047 |

| 10 | −0.010 | −0.115 | −0.007 | −0.138 | −0.011 | −0.131 | −0.001 | −0.006 | - | - |

| 20 | −0.002 | −0.025 | 0.008 | 0.179 | −0.006 | −0.070 | 0.009 | 0.194 | −0.065 | −1.329 |

| 50 | - | - | −0.009 | −0.193 | −0.004 | −0.050 | 0.013 | 0.262 | −0.040 | −0.832 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krüger, M.; Schmelzer, J.; Helmecke, M. Similarities and Differences in Mechanical Alloying Processes of V-Si-B and Mo-Si-B Powders. Metals 2016, 6, 241. https://doi.org/10.3390/met6100241

Krüger M, Schmelzer J, Helmecke M. Similarities and Differences in Mechanical Alloying Processes of V-Si-B and Mo-Si-B Powders. Metals. 2016; 6(10):241. https://doi.org/10.3390/met6100241

Chicago/Turabian StyleKrüger, Manja, Janett Schmelzer, and Maria Helmecke. 2016. "Similarities and Differences in Mechanical Alloying Processes of V-Si-B and Mo-Si-B Powders" Metals 6, no. 10: 241. https://doi.org/10.3390/met6100241

APA StyleKrüger, M., Schmelzer, J., & Helmecke, M. (2016). Similarities and Differences in Mechanical Alloying Processes of V-Si-B and Mo-Si-B Powders. Metals, 6(10), 241. https://doi.org/10.3390/met6100241