Abstract

Dissimilar diffusion bonds of TiAl alloy to AISI 310 stainless steel using Ni/Ti reactive multilayers were studied in this investigation. The Ni and Ti alternating layers were deposited by d.c. magnetron sputtering onto the base materials, with a bilayer thickness of 30 and 60 nm. Joining experiments were performed at 700 and 800 °C for 60 min under pressures of 50 and 10 MPa. The effectiveness of using Ni/Ti multilayers to improve the bonding process was assessed by microstructural characterization of the interface and by mechanical tests. Diffusion bonded joints were characterized by scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS), electron backscatter diffraction (EBSD), transmission electron microscopy (TEM) and selected area electron diffraction (SAED), high resolution TEM (HRTEM) and Fast Fourier transform (FFT). The bonding interfaces are thin (approximately 5 µm thick) with a layered microstructure. For all joints, the interface is mainly composed of equiaxed grains of NiTi and NiTi2. The thickness and number of layers depends on the joining conditions and bilayer thickness of the multilayers. Mechanical characterization of the joints was performed by nanoindentation and shear tests. Young´s modulus distribution maps highlight the phase differences across the joint´s interface. The highest shear strength value is obtained for the joint produced at 800 °C for 60 min under a pressure of 10 MPa using Ni/Ti multilayers with 30 nm of bilayer thickness.

1. Introduction

The development of TiAl intermetallics has attracted the interest of several researchers due to its unique properties, which are suitable for a wide field of applications. However, a limiting factor for the integration of TiAl into structures is the lack of reliable and efficient joining techniques, especially for dissimilar joints. Dissimilar joining of these alloys is very difficult, due to their high reactivity and the tendency to form brittle intermetallic phases [1,2]. The development of joining technologies has become an essential requirement for application of these alloys in replacing traditional metallic alloys in aerospace and automotive applications [3,4,5,6]. However, there are only a few reports regarding the techniques used to join TiAl alloys with other materials [6,7,8,9,10,11,12].

The joining of TiAl and steel is relevant for some applications, in particular for missile and tank engine turbo components. The use of fusion welding techniques to join TiAl to steel promotes the formation of brittle phases, TiC and Ti–Fe intermetallics, and high residual stress produced during solidification, leading to weak joints [4,5].

Diffusion bonding is one of the most promising processes for successfully joining TiAl to steel with high mechanical properties, avoiding the problems associated with fusion welding processes.

Dissimilar joints can be produced by direct diffusion bonding of TiAl to steel at 850–1000 °C for 1 to 60 min under a pressure ranging from 5 to 40 MPa [9]. Close to the TiAl base material, the interfaces are composed of Ti3Al + FeAl + FeAl2 intermetallic compounds. The specimens bonded at low temperature exhibit very low tensile strength (18 MPa); a maximum tensile strength of 170–185 MPa was measured for the optimum bond conditions (930–960 °C for 5–6 min under a pressure of 20–25 MPa). These demanding bonding conditions are not suitable for the industrial implementation of the process and can lead to plastic deformation of the base materials.

Reactive multilayer thin films are an alternative for reducing the temperature and/or the pressure needed for diffusion bonding, since these multilayers can simultaneously improve the diffusivity, due to their nanocrystalline nature and high density of defects, and can also act as a local heat source, as the result of the heat released by the exothermic reaction of the multilayers to form intermetallic compounds [13,14,15,16,17,18,19,20,21,22,23]. Previous studies [23] have shown that Ni/Al multilayers are effective in the diffusion bonding of TiAl to steel. The use of these multilayers in this process allows lower joining conditions. However, these joints present unbonded areas, which impair the shear strength. The process could be rendered more effective by improving the contact of mating surfaces, which can be achieved by the use of different multilayer systems.

In this context, the main objective of this study is the diffusion bonding of TiAl alloy to AISI 310 austenitic stainless steel using Ni/Ti reactive multilayers. Although this multilayer system is less exothermic than others, such as Ni/Al, it has been successfully used in dissimilar joining of NiTi alloy to Ti6Al4V [24]. The present study centers on the microstructural characterization of the interface and on the mechanical characterization of the joints. Interface characterization was performed by scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS), electron backscatter diffraction (EBSD), transmission electron microscopy (TEM) and selected area electron diffraction (SAED), high resolution TEM (HRTEM) and Fast Fourier transform (FFT); mechanical properties were evaluated by nanoindentation and shear strength tests.

2. Materials and Methods

2.1. Materials

The base materials used in this investigation were TiAl (Ti–45Al–5Nb at. %) and AISI 310 austenitic stainless steel (25Cr–20Ni–0.25C wt. %).

Ni/Ti multilayers were used as an interlayer for diffusion bonding between these two base materials. Ni/Ti multilayer thin films with ~2.5 μm total thickness were deposited onto the base materials (substrates) by d.c. magnetron sputtering from titanium (99.99% pure) and nickel (93 wt. %Ni, 7 wt. %V) targets. In the presence of vanadium, the Ni target becomes nonmagnetic, resulting in more stable depositions. Before entering the deposition chamber, the surfaces of the base materials were ground using SiC abrasive papers, followed by polishing down to 1 μm diamond suspension. The final polishing was carried out using colloidal silica. The samples were cleaned in ultrasound bath in acetone and ethanol. After attaining a base pressure of ~5 × 10−4 Pa, the depositions were carried out at an argon pressure of 0.25 Pa. The targets’ power densities were adjusted in order to obtain near equiatomic average chemical composition. To avoid heating during deposition, the base materials were mounted in a thick rotating copper block, which acts as a heat sink. With this procedure the deposition temperature remains close to 100 °C. Multilayer thin films with 30 and 60 nm bilayer thickness (modulation period) were prepared by varying the substrates’ rotation speed with the Ti and Ni targets operating simultaneously. During one rotation the substrates pass once in front of the Ti target and once in front of the Ni target, giving rise to a bilayer (Ti layer + Ni layer). After several rotations a stack of bilayers is obtained multilayered. When the substrates’ rotation speed increases, the time that the substrates are in front of each target decreases, resulting in lower individual layer thicknesses.

2.2. Diffusion Bonding Experiments

Diffusion bonding of dissimilar (TiAl to steel) joints was produced at 700 and 800 °C under pressures of 10 and 50 MPa with a bonding time of 60 min, in a vertical furnace with a vacuum level better than 10−2 Pa. The diffusion bonding apparatus has been described elsewhere [13,17].

2.3. Joints Characterization

2.3.1. Microstructural Characterization

In order to perform the microstructural and chemical characterization of the interface, cross-sections of the joints were prepared using standard metallographic techniques. The cross-section specimens for TEM were prepared using a focused ion beam (FIB) (FEI FIB200, FEI company, Hillsboro, OR, USA), by means of the lift-out technique, at 5–30 keV. The bond interfaces were characterized by SEM (FEI company, Hillsboro, OR, USA) and analyzed by EDS (Oxford Intruments, Oxfordshire, UK), TEM (JEOL Ltd., Tokyo, Japan) and HRTEM (JEOL Ltd., Tokyo, Japan). A high resolution FEI QUANTA 400 FEG SEM (FEI company, Hillsboro, OR, USA) with EDAX Genesis X4M (Oxford Intruments, Oxfordshire, UK) was used for the SEM and EDS analyses. HRTEM images were obtained in a JEOL 2010F (JEOL Ltd., Tokyo, Japan) and a FEI Tecnai G2 (FEI company, Hillsboto, OR, USA), operating at 200 keV.

The EDS measurements were made at an accelerating voltage of 15 keV by the standardless quantification method. The results obtained by this method provide a fast quantification with an automatic background subtraction, matrix correction and normalization to 100% for all the elements in the peak identification list.

Crystallographic information from the joint interfaces was obtained by EBSD (FEI QUANTA 400 FEG SEM). The diffraction of backscattered electrons forms a Kikuchi pattern characteristic of the underlying crystal phase. For the indexation of the patterns, the ICDD PDF2 (2006) database was used. EBSD is a surface technique, since only the topmost 50 nm of the specimen contributes to the diffraction pattern; for Ti and Ni the minimum lateral spread of the interaction volume ranges from 50 to 100 nm [25], with an accelerating voltage of 15 keV. Seeing that a careful preparation of the surface is the key factor in achieving good quality EBSD patterns, the specimens were submitted to a final chemo-mechanical polishing stage, using colloidal silica, to remove the damage and deformation of the surface of the cross-section specimens.

Selected area electron diffraction (SAED) in TEM and Fast Fourier transform (FFT) in HRTEM were also applied in order to study the crystallographic structure of the phases present at the interface.

2.3.2. Mechanical Characterization

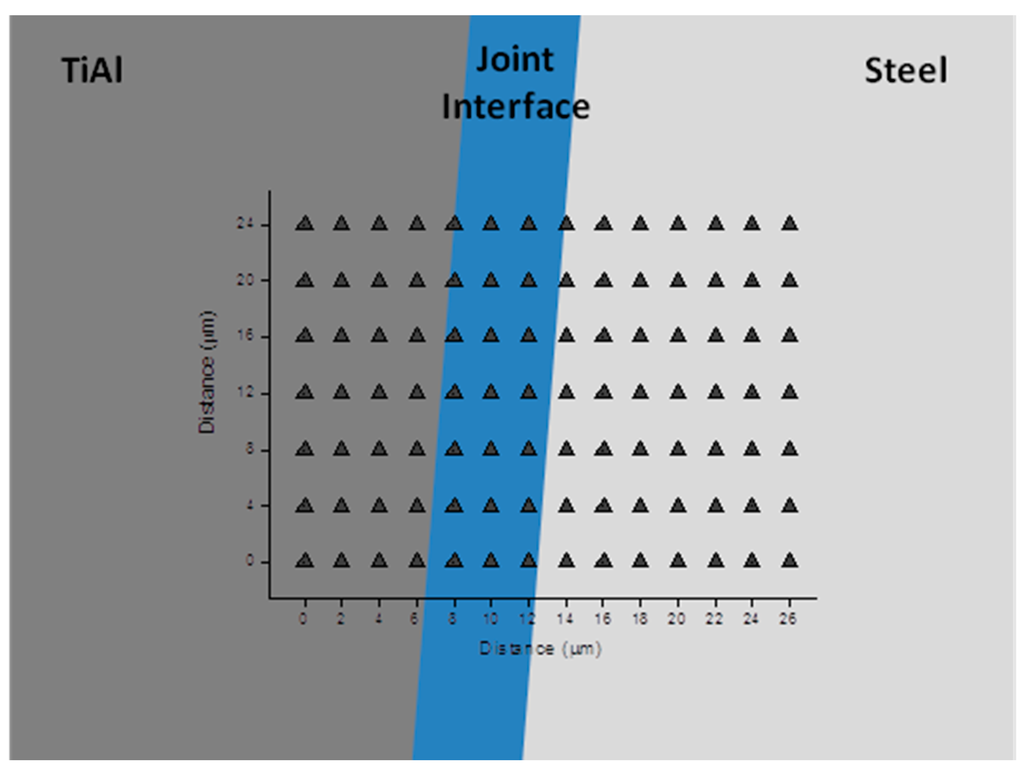

The mechanical behavior was evaluated by nanoindentation using a Micro Materials-Nano hardness apparatus equipped with a Berkovich diamond indenter. Hardness and Young’s modulus were determined by the Oliver and Pharr analysis method [26]. Before the depth-sensing indentation experiments, the tip area function was calibrated using fused silica as a standard. The loading/unloading experiments were run up to a maximum load of 4 mN with a dwell bilayer thickness of 30 s at 0.4 mN during unloading, for thermal drift correction. Indentation matrices with a minimum of 90 measurements were selected in order to test the joint’s interface and both base materials. The scheme of the nanoindentation tests across the joints is represented in Figure 1. Prior to the indentation tests the joints were polished using standard metallographic procedures until a mirror-like surface was achieved.

Figure 1.

Scheme of the nanoindentation tests position (▲) across the joints.

The shear tests were performed at room temperature at a rate of 0.2 mm/min. The apparatus and specimens of the shear tests have been described elsewhere [23]. For each joint, three specimens were tested. SEM combined with EDS was used to identify the phases present at the fracture surfaces of the shear specimens.

3. Results and Discussion

The effectiveness of using Ni/Ti multilayers to improve dissimilar bonds between TiAl and steel was assessed through microstructural and mechanical characterizations. The influence of different processing conditions (700 or 800 °C under a pressure of 10 or 50 MPa) and different bilayer thickness (30 and 60 nm) was evaluated.

3.1. Microstructural Characterization

The microstructural characterization reveals that interfaces with apparent soundness were produced during the solid-state diffusion bonding of TiAl and steel using Ni/Ti multilayers. The bond between these metallic materials using Ni/Ti multilayers with 30 and 60 nm of bilayer thickness was obtained successfully at 700 °C under a pressure of 50 MPa and at 800 °C under a pressure of 10 MPa, for 60 min. However, some unbonded areas are observed at the edge of the samples bonded at 700 °C and at 800 °C using multilayers with 60 nm of bilayer thickness.

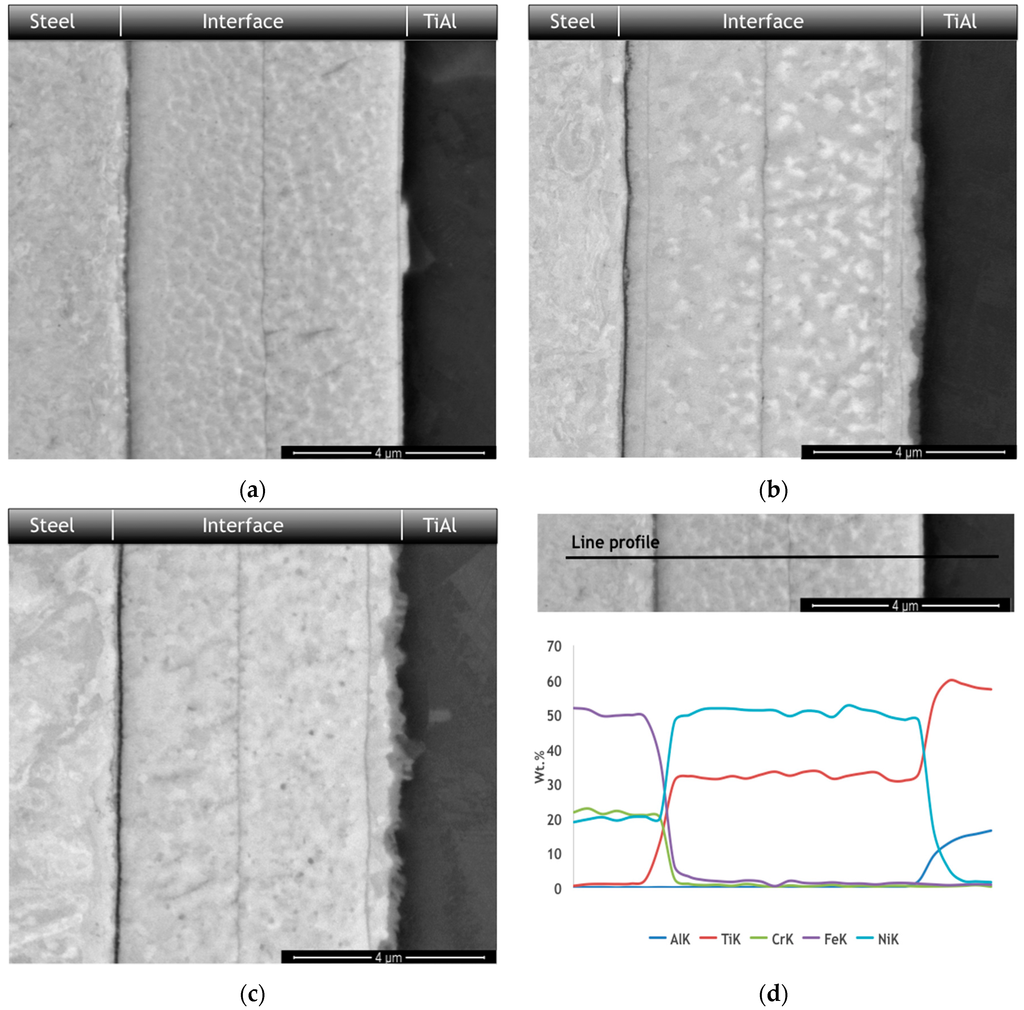

Figure 2 shows SEM images of the interface of the diffusion bonds between TiAl alloys and steel processed with Ni/Ti multilayers. Whatever the bilayer thickness, to achieve a sound joint at 700 °C it was necessary to apply a 50 MPa pressure, while at 800 °C the pressures could be reduced down to 10 MPa. The bond interfaces are thin (thickness close to 5 μm) and exhibit six layers: a thicker layer (4 µm) at the center divided by a very thin dark line and, adjacent to each of the base materials, two diffusion layers with an overall thickness of not more than 1 µm. The thickness of the interface layers, especially those close to the base materials, increase with increasing bonding temperature and multilayer bilayer thickness. These microstructures are different from those obtained using Ni/Al multilayers [23], which exhibited a thick reaction layer near the steel substrate. From the EDS profile of Figure 2d it can be seen that the interfaces mainly consist of Ni and Ti, as expected. The diffusion of elements from the base material to adjacent layers is observed for all bonds. Fe and Cr are detected in zones closest to the stainless steel, while Al is detected in the thin layers closest to TiAl.

Figure 2.

SEM images of the TiAl/steel joints produced at: (a) 700 °C under a pressure of 50 MPa using Ni/Ti multilayers with 30 nm of bilayer thickness; (b) 800 °C under a pressure of 10 MPa using Ni/Ti multilayers with 30 nm of bilayer thickness; (c) 800 °C under a pressure of 10 MPa using Ni/Ti multilayers with 60 nm of bilayer thickness and (d) EDS profile across the interface presented in (a).

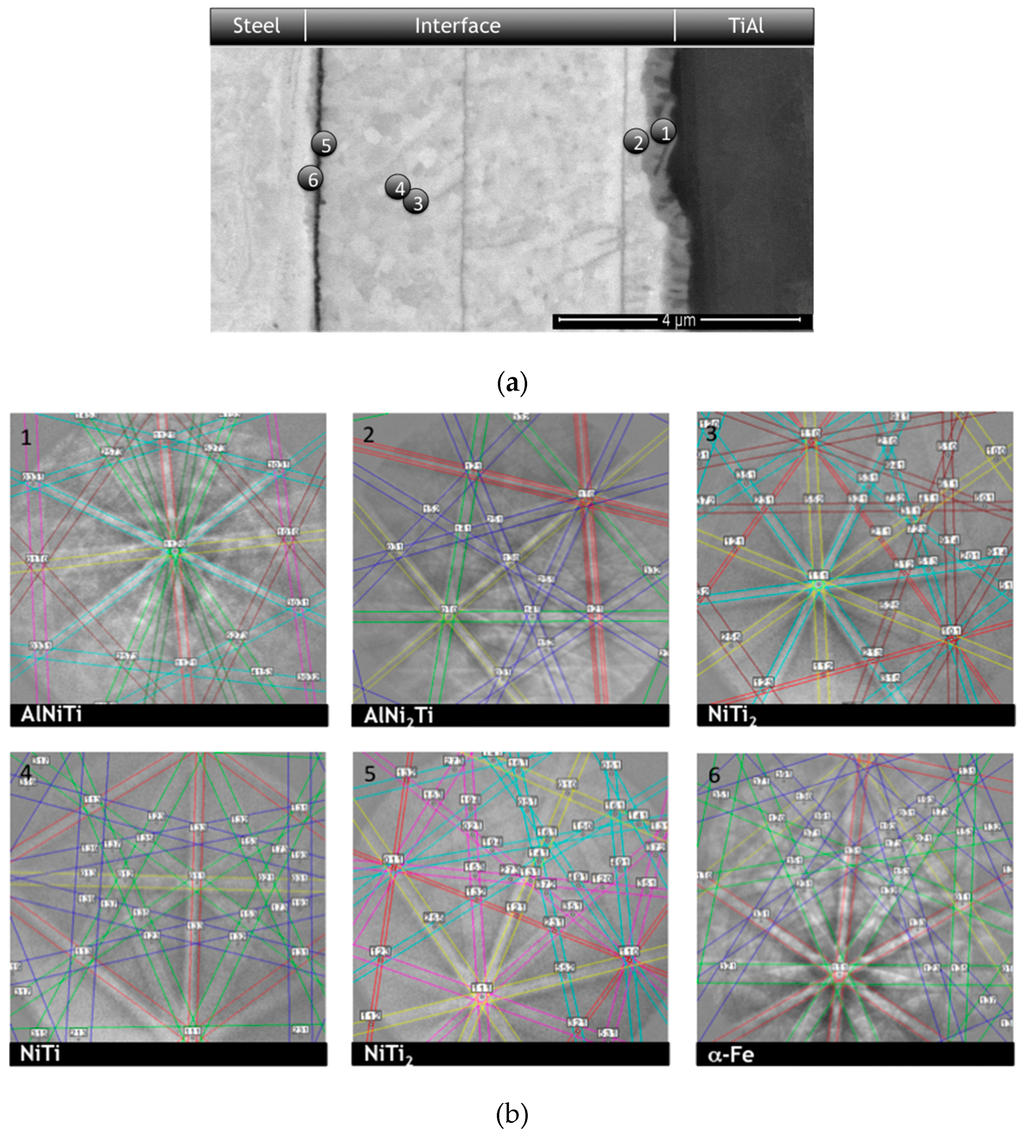

The identification of the phases was carried out through the combination of the EDS, EBSD, SAED and FFT results. Due to the small interaction volume of EBSD analysis, this technique is essential for the crystallographic characterization of the phases of thinner layers and for identifying the formation of nanometric phases at the interface. For phase identification in areas smaller than the EBSD resolution, TEM/SAED and HRTEM/FFT were used.

Figure 3 shows the EBSD patterns obtained for the thin diffusion layers close to the base materials and for the thick central zone. The greatest area of the interface comprises equiaxed grains of NiTi and NiTi2 (Kikuchi patterns 3 and 4 of Figure 3b). The indexation of the EBSD patterns of the layers close to the base materials identified the presence of AlNiTi and AlNi2Ti close to the TiAl (Kikuchi patterns 1 and 2 of Figure 3b) and α-Fe and NiTi2 near the steel (Kikuchi patterns 5 and 6 of Figure 3b). The main differences between the interfaces produced using Ni/Ti and Ni/Al reactive multilayers are the phases that constitute the central area, NiTi + NiTi2 for joints produced with Ni/Ti, and NiAl for those produced with Ni/Al. Phases richer in Ni, such as AlNi2Ti, rather than phases richer in Al, such as Al2NiTi, were also observed. The phases α-Fe and AlNiTi were also identified in the interfaces produced using Ni/Al multilayers [23].

Figure 3.

(a) SEM images of the TiAl/steel joints produced at 800 °C under a pressure of 10 MPa and (b) EBSD Kikuchi pattern indexation of the zones marked in (a).

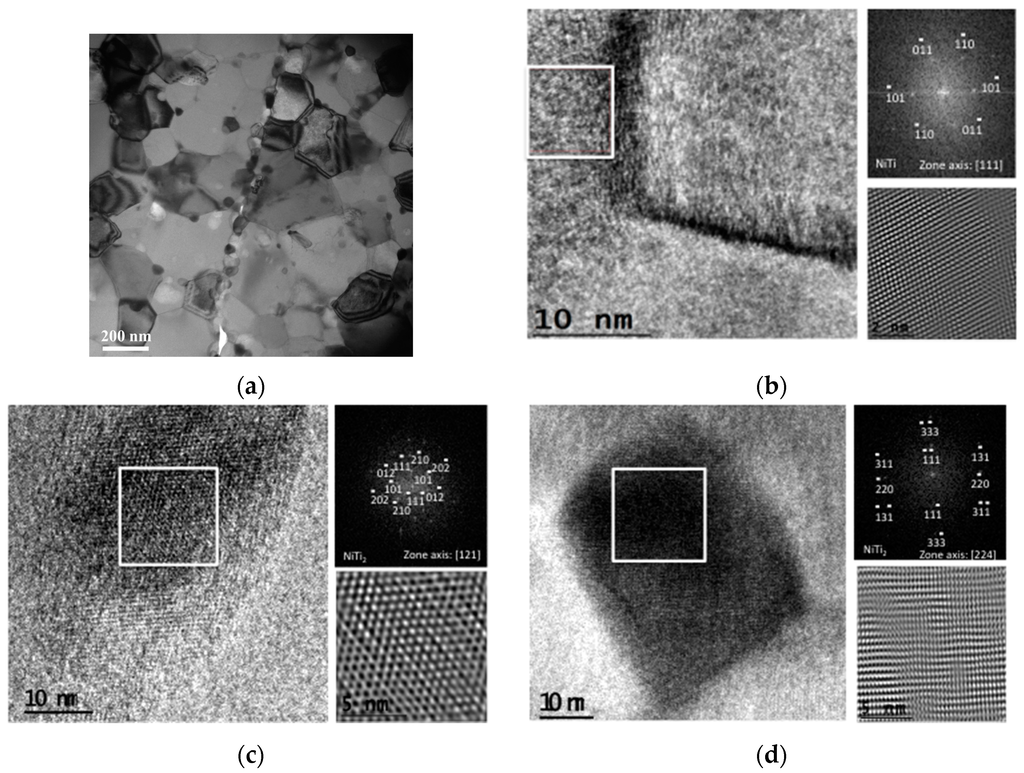

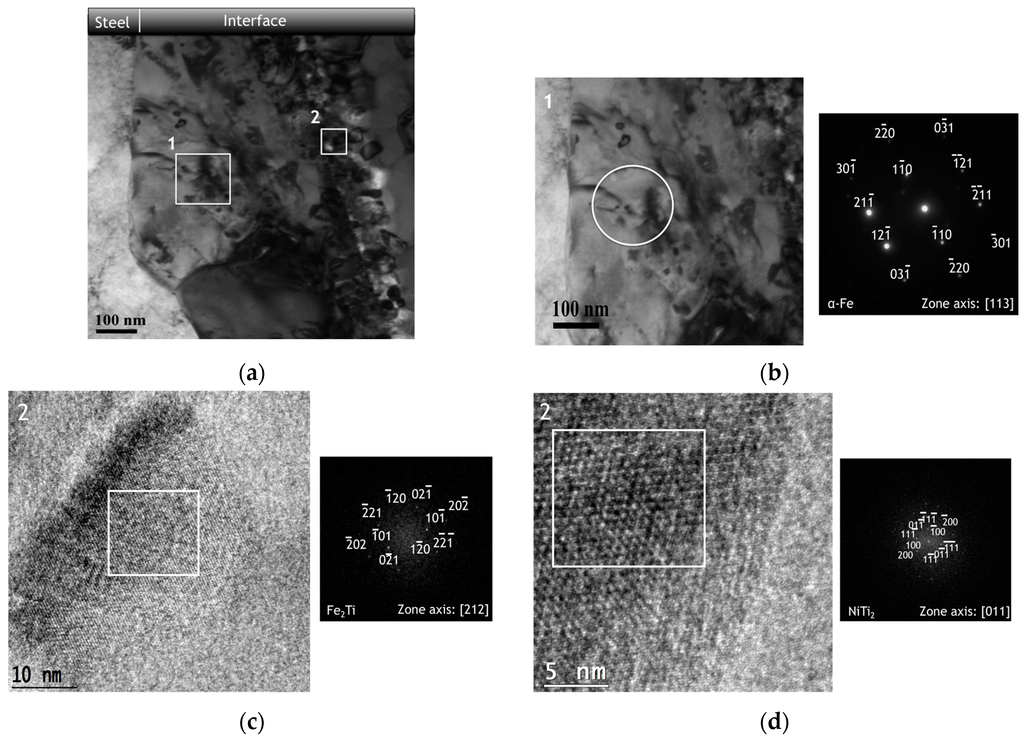

Figure 4 shows the TEM and HRTEM images of the interface central zone. HRTEM images and FFT analysis revealed that this region is composed of a mixture of equiaxed grains of NiTi with nanometric NiTi2 grains divided by a very thin layer with NiTi2 aligned nanograins.

Figure 4.

(a) TEM image of the interface central zone of a TiAl/steel joint produced at 800 °C using Ni/Ti multilayers with 30 nm of bilayer thickness; (b) and (c) HRTEM images and FFT indexation as NiTi and NiTi2 grains at the center of the joint interface; and (d) HRTEM images and FFT indexation as NiTi2 of a nanometric grain at the central line.

The thin layers close to the steel were also characterized by TEM and HRTEM combined with SAED and FFT, respectively, as shown in Figure 5. The TEM image (Figure 5a) of these layers shows large grains adjacent to the steel identified by SAED as α-Fe (Figure 5b) and a line of nanometric grains identified by FFT of HRTEM images as Fe2Ti (Figure 5c) and NiTi2 (Figure 5d).

Figure 5.

(a) TEM image of the zone close to the steel; (b) TEM images and SAED indexation as α-Fe of a grain at the region marked as 1 in (a); and (c) HRTEM images and FFT indexation as Fe2Ti of a grain at the region marked as 2 in (a).

In summary, the interface is composed mainly of NiTi and NiTi2 phases, formed during the multilayer reaction. In addition, thin layers of α-Fe and Fe2Ti + NiTi2 were identified close to the steel while AlNiTi and AlNi2Ti were detected close to the TiAl base material, resulting from the interdiffusion of multilayer and base materials.

3.2. Mechanical Characterization

The mechanical characterization of the diffusion bonds was performed by nanoindentation and shear tests.

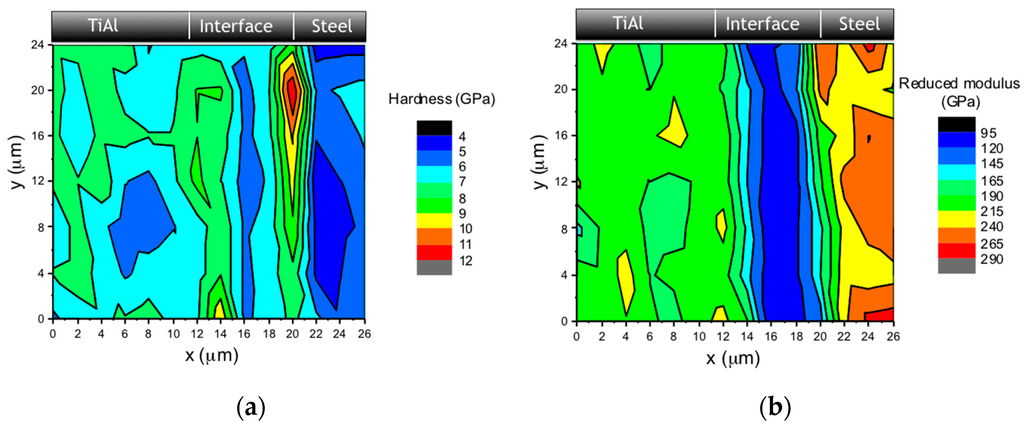

Figure 6 shows the hardness and reduced Young´s modulus (Er) distribution maps for the joints produced at 800 °C using the multilayers with 30 nm bilayer thickness. The interface of the joints shows hardness values similar to those of the base materials with the exception of the thin layers close to the base materials, which are harder, in particular on the steel side. These layers exhibit a high hardness value of about 10–12 GPa. These values may be associated with the formation of AlNiTi, AlNi2Ti and Fe2Ti intermetallics together with nanometric microstructures. In the diffusion bonding of these materials with Ni/Al multilayers, similar results were observed. The reduced Young´s modulus maps clearly reproduce the phase variations across the base materials and diffusion bond, with the joint interface and the diffusion layers perfectly identifiable. According to the nanoindentation results the interface has a lower Young’s modulus (Er ≈ 85–120 GPa) in comparison with the base materials (ErTiAl ≈ 185–210 GPa and Ersteel ≈ 210–260 GPa), which was expected due to the different phases that compose the interface. The variation of the Er values obtained by nanoindentation is in accordance with the Young’s modulus values found in the available literature (Estainless steel > ETiAl > ENiTi > ENiTi2) [27,28].

Figure 6.

(a) Hardness and (b) reduced Young’s modulus distribution maps of the joint produced at 800 °C using a Ni/Ti multilayer with 30 nm of bilayer thickness.

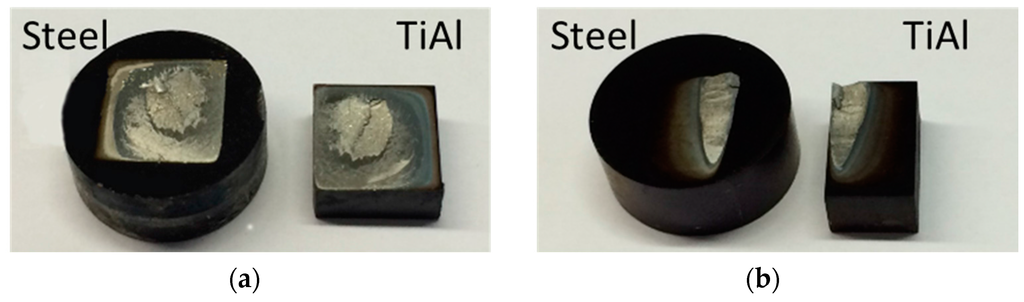

The mechanical characterization of the diffusion bonds was also performed by shear tests. Table 1 shows the values of shear strength of the bonds produced. The macroscopic images of the fracture surfaces are present in Figure 7. These images show that the fracture always begins at the interface.

Table 1.

Shear strength values of TiAl/steel joints produced using Ni/Ti multilayers.

Figure 7.

Macroscopic images of fracture surfaces of shear test specimens of the joints produced at 800 °C using Ni/Ti multilayers with: (a) 30 nm and (b) 60 nm of bilayer thickness.

The highest shear strength value of 225 MPa was obtained for the diffusion bonding of TiAl and steel using Ni/Ti multilayers with 30 nm of bilayer thickness at 800 °C for 60 min under a pressure of 10 MPa.

The microstructural features and hardness distribution across the interfaces are similar for all tested conditions and cannot explain the lower strength of the joints produced at 700 and 800 °C using multilayers with 60 nm of bilayer thickness. The higher shear strength of the joints produced at 800 °C with 30 nm bilayer thickness may be explained by a smaller unbonded region, which is clearly observed in Figure 7.

From the shear strength results it can be concluded that the use of Ni/Ti multilayers with 30 nm of bilayer thickness provides advantages in solid-state diffusion bonding of steel to TiAl in comparison with the more reactive Ni/Al multilayers that present an average shear strength of 144 MPa [23]. This may be associated with the mechanical properties of the phases formed at the interface; with the use of Ni/Al multilayers, the interface comprises essentially NiAl, which is harder and has a higher elastic modulus than the NiTi and NiTi2 that form when the Ni/Ti multilayers are used.

Diffusion bonding of TiAl to steel using Ni/Ti multilayers can be performed under lower temperature and produces joints with higher shear strength values than the ones without the interlayer and with Ni/Al multilayers.

4. Conclusions

Diffusion bonding of TiAl alloys to stainless steel can be enhanced by the use of Ni/Ti multilayers as interlayers. The use of these multilayers enables the production of sound joints at 800 °C for 60 min under a pressure of 10 MPa and multilayers with 30 nm of bilayer thickness with an average shear strength of 225 MPa. The joints are produced at a lower temperature than those required to diffusion bond TiAl to steel without multilayers and have higher strength than those obtained with Ni/Al multilayers. The interfaces are mainly composed of NiTi and NiTi2 grains showing thin layers of α-Fe and Fe2Ti + NiTi2 close to the steel and AlNiTi and AlNi2Ti close to the TiAl alloy.

Acknowledgments

This study was supported by the Portuguese Foundation for Science and Technology through the SFRH/BDP/109788/2015 grant and UID/EMS/00285/2013 project. The authors are grateful to CEMUP-Centro de Materiais da Universidade do Porto for expert assistance with SEM.

Author Contributions

S. Simões implemented and conducted the diffusion bonding experiments and the shear tests; A.S. Ramos and M.T. Vieira produced and characterized the multilayers and performed the nanoindentation tests; S. Simões, F. Viana and M.F. Vieira characterized the interfaces and analyzed and discussed the results; all the authors participated in the design of the experiments and cooperated in writing this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shiue, R.K.; Wu, S.K.; Chem, S.Y. Infrared brazing of TiAl using Al-based braze alloys. Intermetallics 2003, 11, 616–671. [Google Scholar] [CrossRef]

- Çam, G.; Ípekoglu, G.; Bohm, K.H.; Koçak, M. Investigation into the microstructure and mechanical properties of diffusion bonded TiAl alloys. J. Mater. Sci. 2006, 41, 5273–5282. [Google Scholar] [CrossRef]

- Kim, Y.W. Ordered intermetallic alloys, Part III: Gamma-titanium aluminides. JOM 1994, 46, 30–39. [Google Scholar] [CrossRef]

- Dimiduk, D.M. Gamma titanium aluminide alloys—An assessment within the competition of aerospace structural materials. Mater. Sci. Eng. A 1999, 263, 281–288. [Google Scholar] [CrossRef]

- Loria, E.A. Quo vadis gamma titanium aluminide. Intermetallics 2001, 9, 997–1001. [Google Scholar] [CrossRef]

- Cao, J.; Qi, J.; Song, X.; Feng, J. Welding and joining of titanium aluminides. Materials 2014, 7, 4930–4962. [Google Scholar] [CrossRef]

- Noda, T.; Shimizu, T.; Okabe, M.; Iikubo, T. Joining of TiAl and steels by induction brazing. Mater. Sci. Eng. A 1997, 239–240, 613–618. [Google Scholar] [CrossRef]

- Dong, H.; Yang, Z.; Yang, G.; Dong, C. Vacuum brazing of TiAl alloy to 40Cr steel with Ti60Ni22Cu10Zr8 alloy foil as filler metal. Mater. Sci. Eng. A 2013, 561, 252–258. [Google Scholar] [CrossRef]

- He, P.; Feng, J.C.; Zhang, B.G.; Qian, Y.Y. Microstructure and strength of diffusion-bonded joints of TiAl base alloy to steel. Mater. Charact. 2002, 48, 401–406. [Google Scholar] [CrossRef]

- He, P.; Feng, J.C.; Zhang, B.G.; Qian, Y.Y. A new technology for diffusion bonding intermetallic TiAl to steel with composite barrier layers. Mater. Charact. 2003, 50, 87–92. [Google Scholar] [CrossRef]

- Han, W.; Zhang, J. Diffusion bonding between TiAl based alloys and steels. J. Mater. Sci. Technol. 2001, 17, 191–192. [Google Scholar]

- He, P.; Yue, X.; Zhang, J.H. Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mater. Sci. Eng. A 2008, 486, 171–176. [Google Scholar] [CrossRef]

- Duckham, A.; Spey, S.J.; Wang, J.; Reiss, M.E.; Weihs, T.P.; Besnoin, E.; Knio, O.M. Reactive nanostructured foil used as a heat source for joining titanium. J. Appl. Phys. 2004, 96, 2336–2342. [Google Scholar] [CrossRef]

- Ramos, A.S.; Vieira, M.T.; Duarte, L.; Vieira, M.F.; Viana, F.; Calinas, R. Nanometric multilayers: A new approach for joining TiAl. Intermetallics 2006, 14, 1157–1162. [Google Scholar] [CrossRef]

- Duarte, L.I.; Ramos, A.S.; Vieira, M.F.; Viana, F.; Vieira, M.T.; Koçak, M. Solid-state diffusion bonding of gamma-TiAl alloys using Ti/Al thin films as interlayers. Intermetallics 2006, 14, 1151–1156. [Google Scholar] [CrossRef]

- Ramos, A.S.; Vieira, M.T.; Simões, S.; Viana, F.; Vieira, M.F. Joining of superalloys to intermetallics using nanolayers. Adv. Mater. Res. 2009, 59, 225–229. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ventzke, V.; Koçak, M.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Diffusion bonding of TiAl using Ni/Al multilayers. J. Mater. Sci. 2010, 45, 4351–4357. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Koçak, M.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Diffusion bonding of TiAl using reactive Ni/Al nanolayers and Ti and Ni foils. Mater. Chem. Phys. 2011, 128, 202–207. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Koçak, M.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Microstructure of reaction zone formed during diffusion bonding of TiAl with Ni/Al multilayer. J. Mater. Eng. Perform. 2012, 21, 678–682. [Google Scholar] [CrossRef]

- Namazu, T.; Takemoto, H.; Fujita, H.; Nagai, Y.; Inoue, S. Self-propagating explosive reactions in nanostructured Al/Ni multilayer films as a localized heat process technique for MEMS. In Proceedings of 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22--26 January 2006; pp. 286–289.

- Zhang, J.; Wu, F.S.; Zou, J.; An, B.; Liu, H. Al/Ni multilayer used as a local heat source for mounting microelectronic components. In Proceedings of the International Conference on Electronic Packaging Technology & High Density Packaging,ICEPT-HDP 09, Beijing, China, 10--13 August 2009; pp. 838–842.

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Anisothermal solid-state reaction of Ni/Al nanometric multilayer. Intermetallics 2011, 19, 350–356. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Reaction-assisted diffusion bonding of TiAl alloy to steel. Mater. Chem. Phys. 2016, 161, 73–82. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Reaction Zone Formed during Diffusion Bonding of TiNi to Ti6Al4V using Ni/Ti Nanolayers. J. Mater. Sci. 2013, 48, 7718–7727. [Google Scholar]

- Kim, J.S.; LaGrange, T.; Reed, B.W.; Taheri, M.L.; Armstrong, M.R.; King, W.E.; Browning, N.D.; Campbell, G.H. Imaging of transient structures using nanosecond in situ TEM. Science 2008, 321, 1472–1475. [Google Scholar] [CrossRef] [PubMed]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacements sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Kipp, D.O. Material Data Sheets. MatWeb, LLC. 2010. Online version. Available online: http://www.matweb.com (accessed on 25 April 2016).

- Toprek, D.; Belosevic-Cavor, J.; Koteski, V. Ab initio studies of the structural, elastic, electronic and thermal properties of NiTi2 intermetallic. J. Phys. Chem. Solids 2015, 85, 197–205. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).