Effects of Warm Laser Peening on Thermal Stability and High Temperature Mechanical Properties of A356 Alloy

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Warm Laser Peening Experiments

2.3. Characterization

3. Results and Discussion

3.1. Residual Stress

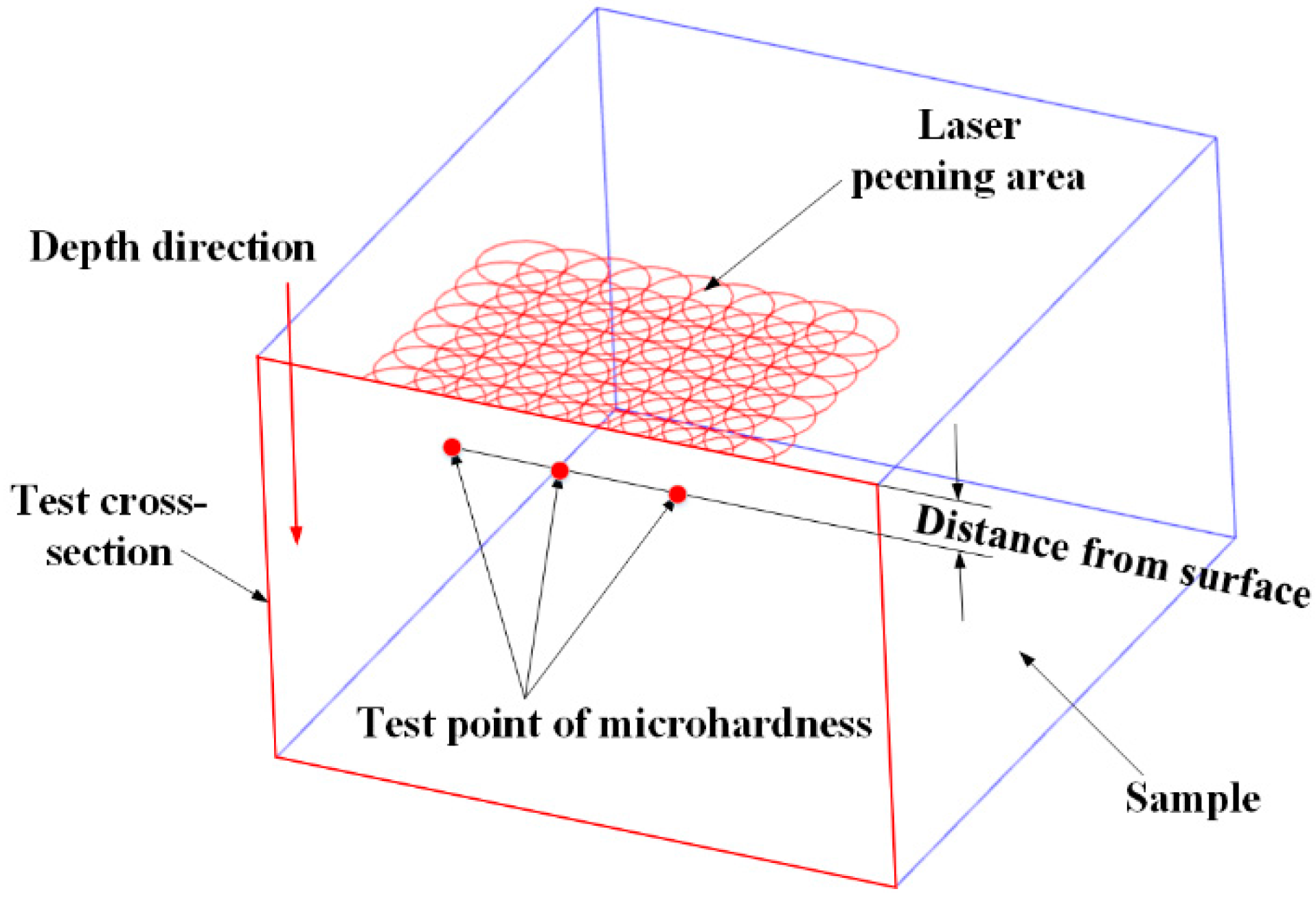

3.2. Micro-Hardness

3.3. Microstructure Analysis

3.4. Thermal Stability Test

3.4.1. Residual Stress

3.4.2. Micro-Hardness

3.4.3. Microstructure

4. Conclusions

- (1)

- The surface residual compressive stress induced by WLP decreases with the increase of temperature. The micro-hardness increases initially, and then decreases with the increasing temperature. The depth of the hardening layer increases with the increasing temperature.

- (2)

- The WLP process can further refine the grain size compared to the LP process due to the dynamic strain aging effect. The Si particles are significantly refined and balled in SEM morphologies for both LP- and WLP-treated samples.

- (3)

- After aging for 100 min at 220 °C, the residual compressive stress and micro-hardness induced by WLP reveal an excellent thermal stability, only decreasing by 23.31% and 19.70%, respectively.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhu, M.; Jian, Z. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2009, 36, 243–249. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A. Predictive equations of the tensile properties based on alloy hardness and microstructure for an A356 gravity die cast cylinder head. Mater. Des. 2011, 32, 1367–1375. [Google Scholar] [CrossRef]

- Baradarani, B.; Raiszadeh, R. Precipitation hardening of cast Zr-containing A356 aluminum alloy. Mater. Des. 2011, 32, 935–940. [Google Scholar] [CrossRef]

- Dobrzanski, L.A.; Borek, W.; Maniara, R. Influence of the crystallization condition on Al-Si-Cu casting alloys structure. Mater. Manuf. Eng. 2006, 18, 211–214. [Google Scholar]

- Hirsch, J.; Al-Samman, T. Superior light metals by texture Engineering: Optimized aluminum and magnesium alloys for Automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Molina, R.; Leghissa, M.; Mastrogiacomo, L. New developments in high performance cylinder heads: Application of LHIP and split cylinder head concept. Metall. Sci. Technol. 2004, 22, 1–8. [Google Scholar]

- Feicus, F.J. Optimization of Al-Si cast alloys for cylinder head applications. AFS Trans. 1998, 106, 225–231. [Google Scholar]

- Wang, F.; Zhang, J.S.; Xiong, B.Q. Effect of Fe and Mn additions on microstructure and mechanical properties of spray-deposited Al-20Si-3Cu-1Mg alloy. Mater. Charact. 2009, 60, 384–388. [Google Scholar] [CrossRef]

- Wang, Q.G. Plastic deformation behavior of aluminum casting alloys A356/357. Metall. Mater. Trans. A 2004, 35A, 2707–2718. [Google Scholar] [CrossRef]

- Haghshenas, M.; Zarei-Hanzaki, A.; Fatemi-Varzaneh, S.M. The effects of thermo-mechanical parameters on the microstructure of Thixocast A356 aluminum alloy. Mater. Sci. Eng. A 2008, 480, 68–74. [Google Scholar] [CrossRef]

- Hwang, J.Y.; Doty, H.W.; Kaufman, M.J. The effects of Mn additions on the microstructure and mechanical properties of Al-Si-Cu casting alloys. Mater. Sci. Eng. A 2008, 488, 496–504. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; DeSmet, P.; Haszler, A.; Vieregge, A. Recent development in aluminum alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Cho, K.T.; Yoo, S.; Lim, K.M.; Kim, H.S.; Lee, W.B. Effect of Si content on surface hardening of Al-Si alloy by shot peening treatment. J. Alloys Compd. 2011, 509, S265–S270. [Google Scholar] [CrossRef]

- Chang, H.-W.; Kelly, P.M.; Shi, Y.-N.; Zhang, M.-X. Effect of eutectic Si on surface nanocrystallization of Al-Si alloys by surface mechanical attrition treatment. Mater. Sci. Eng. A 2011, 530, 304–314. [Google Scholar] [CrossRef]

- Chang, H.-W.; Kelly, P.M.; Shi, Y.-N.; Zhang, M.-X. Thermal stability of nanocrystallized surface produced by surface mechanical attrition treatment in aluminum alloys. Surf. Coat. Technol. 2012, 206, 3970–3980. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Karimzadeh, F.; Enayati, M.H. A novel technique for development of A356/Al2O3 surface nano-composite by friction stir processing. J. Mater. Process. Technol. 2011, 211, 1614–1619. [Google Scholar] [CrossRef]

- Lee, J.-M.; Kang, S.-B.; Han, J. Dry sliding wear of MAO-coated A356/20 vol. % SiCp composites in the temperature range 25–180 °C. Wear 2008, 264, 75–85. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Kim, B.-J.; Suslov, S.; Stach, E.A.; Cheng, G.J. Nucleation of highly dense nano-scale precipitates based on warm laser shock Peening. J. Appl. Phys. 2010, 108, 063518. [Google Scholar] [CrossRef]

- Ye, C.; Liao, Y.; Cheng, G.J. Warm Laser shock Peening Driven Nanostructures and Their Effects on Fatigue Performance in Al Alloy 6061. Adv. Eng. Mater. 2010, 12, 291–297. [Google Scholar]

- Cottrell, A.H. LXXXVI. A note on the Portevin-Le Chatelier effect. Philos. Mag. 1953, 44, 829. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Kim, B.J.; Stach, E.A.; Cheng, G.J. Fatigue performance improvement in AISI 4140 steel by dynamic strain aging and dynamic precipitation during warm laser shock peening. Acta Mater. 2011, 59, 1014–1025. [Google Scholar] [CrossRef]

- Ye, C.; Cheng, G.J. Effects of temperature on laser shock induced plastic deformation: The case of cooper. J. Manuf. Sci. Eng. 2010, 132, 061009. [Google Scholar] [CrossRef]

- Liao, Y.; Suslov, S.; Ye, C.; Cheng, G.J. The mechanisms of thermal engineered laser shock peening for enhanced fatigue performance. Acta Meter. 2012, 60, 4997–5009. [Google Scholar] [CrossRef]

- Xu, Z.; Fan, Z. A phenomenological Experimental of the Variation of Elastic Modulus with Temperature. J. Southwest Jiaotong Univ. 1993, 3, 88–92. [Google Scholar]

- Matlock, D.K.; Richards, M.D.; Speer, J.G.; Alogab, K.A. Surface Modification to enhance Fatigue of Steel: Applications of Deep Rolling. Mater. Sci. Forum 2010, 638–642, 142–147. [Google Scholar] [CrossRef]

- Li, H.Q.; Xing, D.M.; Tong, J.W.; Wang, S.B.; Yue, C. Relationship between yield stress and microcosmic structure of nanostructured material. J. Tianjin Univ. 2000, 33, 671–674. [Google Scholar]

- Estrin, Y.; Tóth, L.S.; Molinari, A.; Bréchet, Y. A dislocation-based model for all hardening stages in large strain deformation. Acta Mater. 1998, 46, 5509–5522. [Google Scholar] [CrossRef]

| Elements | Si | Cu | Fe | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| (wt. %) | 6.5~7.5 | 0.2 | 0.2 | 0.1 | 0.25~0.45 | 0.1 | 0.08~0.2 | balance |

| Mechanical Properties | Value |

|---|---|

| Tensile strength (MPa) | 197 |

| Yield strength (MPa) | 168 |

| Elongation (d, %) | 6.1 |

| Brinell hardness (HV) | 80 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Zhou, J.; Sheng, J.; Meng, X.; Huang, S.; Xie, X. Effects of Warm Laser Peening on Thermal Stability and High Temperature Mechanical Properties of A356 Alloy. Metals 2016, 6, 126. https://doi.org/10.3390/met6060126

Chen H, Zhou J, Sheng J, Meng X, Huang S, Xie X. Effects of Warm Laser Peening on Thermal Stability and High Temperature Mechanical Properties of A356 Alloy. Metals. 2016; 6(6):126. https://doi.org/10.3390/met6060126

Chicago/Turabian StyleChen, Hansong, Jianzhong Zhou, Jie Sheng, Xiankai Meng, Shu Huang, and Xiaojiang Xie. 2016. "Effects of Warm Laser Peening on Thermal Stability and High Temperature Mechanical Properties of A356 Alloy" Metals 6, no. 6: 126. https://doi.org/10.3390/met6060126

APA StyleChen, H., Zhou, J., Sheng, J., Meng, X., Huang, S., & Xie, X. (2016). Effects of Warm Laser Peening on Thermal Stability and High Temperature Mechanical Properties of A356 Alloy. Metals, 6(6), 126. https://doi.org/10.3390/met6060126