Microstructure Formation and Resistivity Change in CuCr during Rapid Solidification

Abstract

:1. Introduction

2. Material and Methods

3. Results and Discussion

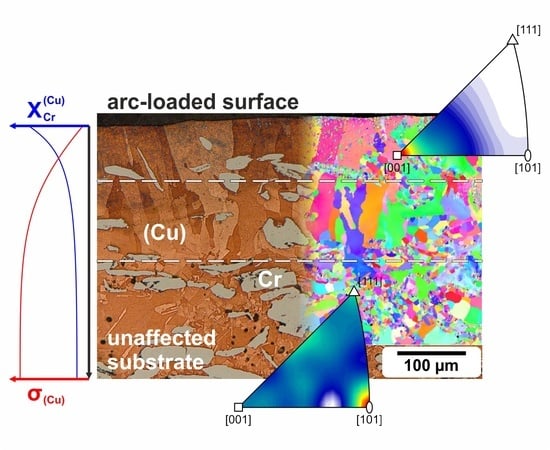

3.1. Microstructure

3.2. Local Texture Analysis

3.3. Global Texture Analysis

3.4. Cr-Content in the Cu Solid Solution

3.5. Propagation of Cr-Content into the Depth

3.6. Influence on Electrical Conductivity

3.7. Heat Distribution

4. Conclusions

- (1)

- The Cu matrix in the initial state already incorporates a small amount of dissolved Cr in the range of 0.1–0.3 at %. This leads to a decreasing electrical conductivity of bulk material down to 21.7 MS/m (CC57) and 31.5 MS/m (CC75). These electrical conductivities can be estimated by applying the according Hashin-Shtrikman formula for Cr-particles incorporated in a Cr-enriched Cu solid solution matrix with reduced electrical conductivity.

- (2)

- Region 1 contains fine Cr-particles and a Cu-Cr solid solution with about 2.25 at % Cr. Hence, the electrical conductivity of the contact material in this region is further reduced to 10 MS/m or lower. R1 also exhibits a common solidification texture with <001> in parallel to the solidification direction. Indicated by microstructure and texture formation, it can be concluded that both phases Cu and Cr being present in the as-manufactured state are considered to be liquid during the switching process. The temperature must be above 1800 °C during arcing and very high cooling rates between 4.5 × 104 K/s and 1.86 × 105 K/s are expected due to the small Cr-particle size of about 450 nm.

- (3)

- Region 2 is characterized by large elongated Cu-grains (up to a length of 200 µm) perpendicularly aligned to the surface. The Cu-grains are still aligned with <001> in parallel to the solidification direction. In this region, only Cu is considered to be completely melted during interruption. The Cr-particles remain virtually unaffected when compared to the initial state. Therefore, it is concluded that the temperature in R2 was between 1175 °C and 1800 °C. This temperature is high enough to melt the Cu and still yields a Cu solid solution supersaturated with Cr.

- (4)

- The total Cr-content of the contact materials showed only negligible influence on microstructure formation and resulting supersaturated Cr in Cu solid solution. However, the texturing during solidification is stronger for CC75, which might be caused by its higher thermal conductivity and therefore higher cooling rates during re-solidification when compared to CC57 material.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zeng, K.; Hämäläinen, M. Thermodynamic analysis of stable and metastable equilibria in the Cu-Cr system. Calphad Comput. Coupling Phase Diagr. Thermochem. 1995, 19, 93–104. [Google Scholar] [CrossRef]

- Villars, P. (Ed.) Inorganic Solid Phases; Springer Materials (Online Database); Springer: Heidelberg, Germany, 2016; Available online: http://materials.springer.com/isp/phase-diagram/docs/c_0905743 (accessed on 18 April 2017).

- Li, D.; Robinson, M.B.; Rathz, T.J. Measurements of liquidus temperatures in the Cu-Nb and Cu-Cr systems. J. Phase Equilib. 2000, 21, 136–140. [Google Scholar] [CrossRef]

- Ivanchenko, V.G.; Filatova, O.N. Methods of study and properties of powder materials calculation of phase equilibria and thermodynamics properties of alloys of the Cr-Cu system. Powder Metall. Met. Ceram. 1996, 35, 167–172. [Google Scholar] [CrossRef]

- Jacob, K.T.; Priya, S.; Waseda, Y. A thermodynamic study of liquid Cu-Cr alloys and metastable liquid immiscibility. Z. Metallkd. 2000, 91, 594–600. [Google Scholar]

- Chakrabarti, D.J.; Laughlin, D.E. The Cr-Cu (chromium-copper) system. Bull. Alloy Phase Diagr. 1984, 5, 59–68. [Google Scholar] [CrossRef]

- Slade, P.G. The Vacuum Interrupter: Theory, Design and Application; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-0849390913. [Google Scholar]

- Schulman, M.B.; Slade, P.G. Sequential modes of drawn vacuum arcs between butt contacts for currents in the 1 kA to 16 kA range. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1995, 18, 417–422. [Google Scholar] [CrossRef]

- Jüttner, B. Erosion craters and arc cathode spots in vacuum. Akad. Wiss. DDR Zent. Elektronenphys. 1978, 108, 25–48. [Google Scholar] [CrossRef]

- Von Klinski-Wetzel, K.; Kowanda, C.; Rettenmaier, T.; Heilmaier, M.; Müller, F.E.H.; Hinrichsen, V. Correlation between microstructural features of the melt zone and switching behavior in CuCr contact material. In Proceedings of the 27th International Conference on Electrical Contacts, Dresden, Germany, 22–26 June 2014. [Google Scholar]

- Hauf, U.; Feilbach, A.; Böning, M.; Heilmaier, M.; Hinrichsen, V.; Müller, F.E.H. Investigation of the heat affected volume of CuCr contact material for vacuum interrupters. In Proceedings of the 27th International Symposium on Discharges and Electrical Insulation in Vacuum, Suzhou, China, 18–23 September 2016. [Google Scholar]

- Dullni, E.; Gentsch, D.; Shang, W.; Delachaux, T. Resistance increase of vacuum interrupters due to high-current interruptions. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1–7. [Google Scholar] [CrossRef]

- Rieder, W.F.; Schussek, M.; Glätzle, W.; Kny, E. The influence of composition and Cr particle size of Cu/Cr contacts on chopping current, contact resistance, and breakdown voltage in vacuum interrupters. IEEE Trans. Compon. Hybrids Manuf. Technol. 1989, 12, 273–283. [Google Scholar] [CrossRef]

- Li, W.; Thomas, R.L.; Smith, R.K. Effects of Cr content on the interruption ability of CuCr contact materials. IEEE Trans. Plasma Sci. 2001, 29, 744–748. [Google Scholar]

- Xiu, S.; Yang, R.; Xue, J.; Wang, J.X.; Wang, J.Y. Microstructure and properties of CuCr contact materials with different Cr content. Trans. Nonferr. Met. Soc. China 2011, 21, s389–s393. [Google Scholar] [CrossRef]

- NIST-JANAF Thermochemical Tables. Available online: http://kinetics.nist.gov/janaf/ (accessed on 10 January 2017).

- Feilbach, A.; Hauf, U.; Böning, M.; Hinrichsen, V.; Heilmaier, M.; Müller, F.E.H. Investigation of current breaking capacity of vacuum interrupters with focus on contact material properties with the help of a reference model vacuum circuit breaker. In Proceedings of the 27th International Symposium on Discharges and Electrical Insulation in Vacuum, Suzhou, China, 18–23 September 2016. [Google Scholar]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture analysis with MTEX—Free and open source software toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Wang, F.; von Klinski-Wetzel, K.; Mukherjee, R.; Nestler, B.; Heilmaier, M. Experimental and numerical investigation on the phase separation affected by cooling rates and marangoni convection in Cu-Cr alloys. Metall. Mater. Trans. A 2015, 46, 1756–1766. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Y.; Guo, J. Liquid phase separation of Cu-Cr alloys during rapid cooling. Trans. Nonferr. Met. Soc. China 2006, 16, 998–1002. [Google Scholar] [CrossRef]

- Kocks, U.F.; Tomé, C.N.; Wenk, H.R. Texture and Anisotropy; Cambridge University Press: Cambridge, UK, 2000; ISBN 0-521-79420-X. [Google Scholar]

- Winegard, W.C. Fundamentals of the solidification of metals. Metall. Rev. 1961, 21, 57–99. [Google Scholar]

- Suwas, S.; Ray, R.K. Crystallographic Texture of Material; Springer: London, UK, 2014; ISBN 978-1-4471-6313-8. [Google Scholar]

- Ardakani, M.G.; Souza, N.D.; Wagner, A.; Shollock, B.A.; McLean, M. Competitive grain growth and texture evolution during directional solidification of superalloys. In Proceedings of the 9th International Symposium on Superalloys, Seven Springs, PA, USA, 17–21 September 2000; Pollock, T.M., Ed.; TMS: Warrendale, PA, USA, 2000; pp. 219–228. [Google Scholar]

- Tenwick, M.J.; Davies, H.A. Enhanced strength in high conductivity copper alloys. Mater. Sci. Eng. 1988, 98, 543–546. [Google Scholar] [CrossRef]

- Bell, A.; Davies, H.A. Solid solubility extension in Cu-V and Cu-Cr alloys produced by chill block melt-spinning. Mater. Sci. Eng. A 1997, 226–288, 1039–1041. [Google Scholar] [CrossRef]

- Straumanis, M.E.; Yu, L.S. Lattice parameters, densities, expansion coefficients and perfection of structure of Cu and of Cu-In α phase. Acta Crystallogr. Sect. A 1969, 25, 676–682. [Google Scholar] [CrossRef]

- Haynes, W.M. (Ed.) Handbook of Chemistry and Physics, 96th ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the effective magnetic permeability of multiphase materials. J. Appl. Phys. 1962, 33, 3125–3131. [Google Scholar] [CrossRef]

- Von Klinski-Wetzel, K.; Kowanda, C.; Heilmaier, M.; Müller, F.E.H. The influence of microstructural features on the electrical conductivity of solid phase sintered CuCr composites. J. Alloy. Compd. 2015, 631, 237–247. [Google Scholar] [CrossRef]

- Villars, P. (Ed.) Inorganic Solid Phases; Springer Materials (Online Database); Springer: Heidelberg, Germany, 2016; Available online: http://materials.springer.com/isp/phase-diagram/docs/c_0908235 (accessed on 26 May 2017).

- Methling, R.; Franke, St.; Gortschakow, S.; Abplanalp, M.; Sütterlin, R.P.; Delachaux, T.; Menzel, K.O. Comparison of methods of electrode temperature determination in high-current vacuum arcs. In Proceedings of the 27th International Symposium on Discharges and Electrical Insulation in Vacuum, Suzhou, China, 18–23 September 2016. [Google Scholar]

- Pieniak, T.; Kurrat, M.; Gentsch, D. Surface temperature measurement of transversal magnetic field contacts using a thermography camera. In Proceedings of the 27th International Symposium on Discharges and Electrical Insulation in Vacuum, Suzhou, China, 18–23 September 2016. [Google Scholar]

| Alloy | Nominal Cr-Content in wt % | Nominal Cr-Content in at % | Nominal Cr-Content in vol % | Exp. Cr-Content in vol % | Ip in kA | tarc in ms | Q in As |

|---|---|---|---|---|---|---|---|

| CC75 | 25 | 28.95 | 29.5 | 33 ± 2 | 6.25 | 10.4 | 43.6 |

| CC57 | 43 | 47.97 | 48.5 | 53 ± 3 | 6.7 | 9.5 | 43.7 |

| CuCr0.72 | 0.72 ± 0.01 | 0.89 ± 0.01 | reference sample | ||||

| Alloy | Depth of R1/µm | Depth of R1 + R2/µm |

|---|---|---|

| CC75 | 101 ± 9 | 170 ± 12 |

| CC57 | 81 ± 9 | 219 ± 22 |

| Sample | /MS/m | /MS/m |

|---|---|---|

| CC57 | ||

| CC75 | ||

| CuCr0.72 | - |

| Sample | /MS/m | /MS/m | Penetration Depth at 960 kHz/µm |

|---|---|---|---|

| CC57 | 21.7 ± 0.4 | 7.3 ± 0.1 | 190 |

| CC75 | 31.5 ± 0.2 | 10.6 ± 0.1 | 158 |

| CuCr0.72 | 20.87 ± 0.01 | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hauf, U.; Kauffmann, A.; Kauffmann-Weiss, S.; Feilbach, A.; Boening, M.; Mueller, F.E.H.; Hinrichsen, V.; Heilmaier, M. Microstructure Formation and Resistivity Change in CuCr during Rapid Solidification. Metals 2017, 7, 478. https://doi.org/10.3390/met7110478

Hauf U, Kauffmann A, Kauffmann-Weiss S, Feilbach A, Boening M, Mueller FEH, Hinrichsen V, Heilmaier M. Microstructure Formation and Resistivity Change in CuCr during Rapid Solidification. Metals. 2017; 7(11):478. https://doi.org/10.3390/met7110478

Chicago/Turabian StyleHauf, Ulla, Alexander Kauffmann, Sandra Kauffmann-Weiss, Alexander Feilbach, Mike Boening, Frank E. H. Mueller, Volker Hinrichsen, and Martin Heilmaier. 2017. "Microstructure Formation and Resistivity Change in CuCr during Rapid Solidification" Metals 7, no. 11: 478. https://doi.org/10.3390/met7110478

APA StyleHauf, U., Kauffmann, A., Kauffmann-Weiss, S., Feilbach, A., Boening, M., Mueller, F. E. H., Hinrichsen, V., & Heilmaier, M. (2017). Microstructure Formation and Resistivity Change in CuCr during Rapid Solidification. Metals, 7(11), 478. https://doi.org/10.3390/met7110478