Microstructure and Properties of Porous Si3N4/Dense Si3N4 Joints Bonded Using RE–Si–Al–O–N (RE = Y or Yb) Glasses

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

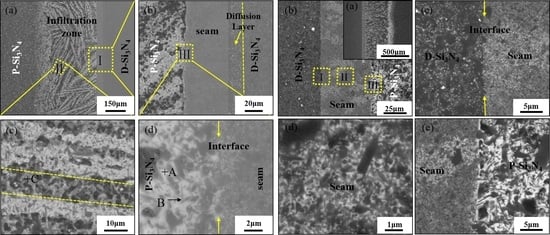

3.1. Characterization of P-Si3N4/RE(Y or Yb)-SiAlON/D-Si3N4 Joints

3.2. Bending Strength of the Joints

3.3. Effect of Bonding Temperatures on Microstructure Evolution of the Joints

4. Conclusions

- (1)

- RE–Si–Al–O–N (RE = Y or Yb) glass solders were successfully used to bond porous Si3N4 to dense Si3N4 ceramics at high temperature. The maximum bending strengths of the joints bonded using Y-SiAlON and Yb-SiAlON glass solders were measured to be 103 MPa and 88 MPa. The bending strength of the joints accounts for 73% and 62% of the bending strength of the porous Si3N4 substrate, respectively.

- (2)

- The microstructure of such joints consisted of a diffusion zone, an infiltration zone, and a seam zone. During the bonding process, an interlocked interface formed on the dense Si3N4 substrate side, and an infiltration zone arose on the porous Si3N4 substrate side. In the seam zone, α-Si3N4 partly transformed into β-SiAlON to form β-SiAlON-glass composite.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Riley, F.L. Silicon nitride and related materials. J. Am. Ceram. Soc. 2000, 83, 245–265. [Google Scholar] [CrossRef]

- Liu, X.J.; Huang, Z.Y.; Ge, Q.M.; Sun, X.W.; Huang, L.P. Microstructure and mechanical properties of silicon nitride ceramics prepared by pressureless sintering with MgO-Al2O3-SiO2 as sintering additive. J. Eur. Ceram. Soc. 2005, 25, 3353–3359. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2011, 47, 535–552. [Google Scholar] [CrossRef]

- Hou, X.; Wang, E.; Li, B.; Chen, J.; Chou, K.-C. Corrosion behavior of porous silicon nitride ceramics in different atmospheres. Ceram. Int. 2017, 43, 4344–4352. [Google Scholar] [CrossRef]

- Kawai, C.; Yamakawa, A. Effect of porosity and microstructure on the strength of Si3N4: Designed microstructure for high strength, high thermal shock resistance, and facile machining. J. Am. Ceram. Soc. 1997, 80, 2705–2708. [Google Scholar] [CrossRef]

- Wang, H.; Yu, J.; Zhang, J.; Zhang, D. Preparation and properties of pressureless-sintered porous Si3N4. J. Mater. Sci. 2010, 45, 3671–3676. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Qiao, R.; Zhang, C.; Chen, L. Fabrication and thermal shock resistance of β-Si3N4-based environmental barrier coating on porous Si3N4 ceramic. Ceram. Int. 2016, 42, 14222–14227. [Google Scholar] [CrossRef]

- Wang, C.; Fan, L.; Fan, J.; Zhang, D.; Wang, H. Effect of spraying power on microstructure and properties of supersonic plasma sprayed Al2O3 coating on porous Si3N4 substrate. J. Alloys Compd. 2013, 559, 152–157. [Google Scholar] [CrossRef]

- Zhuang, Y.L.; Lin, T.S.; Wang, S.J.; He, P.; Sekulic, D.P.; Jia, D.C. Microstructural and mechanical properties of porous Si3N4 carbon coated ceramic brazed with a cobalt-silicon filler. J. Eur. Ceram. Soc. 2017, 37, 3293–3301. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Li, X. Characterization of the Si3N4/Si3N4 joints fabricated using particles modified braze. Mater. Sci. Eng. A 2014, 616, 107–115. [Google Scholar] [CrossRef]

- Wang, T.; Ivas, T.; Lee, W.; Leinenbach, C.; Zhang, J. Relief of the residual stresses in Si3N4/Invar joints by multi-layered braze structure-experiments and simulation. Ceram. Int. 2016, 42, 7080–7087. [Google Scholar] [CrossRef]

- Li, J.; Liu, L.; Wu, Y.; Li, Z.; Zhang, W.; Hu, W. Microstructure of high temperature Ti-based brazing alloys and wettability on SiC ceramic. Mater. Des. 2009, 30, 275–279. [Google Scholar] [CrossRef]

- Lemusruiz, J.; Leonpatino, C.; Aguilarreyes, E. Interface behaviour during the self-joining of Si3N4 using a Nb-foil interlayer. Scr. Mater. 2006, 54, 1339–1343. [Google Scholar] [CrossRef]

- Xie, R.; Huang, L.; Fu, X. Bond strength and microstructural investigation on Si3N4/Si3N4 joint bonded with glass-ceramic. J. Mater. Sci. Lett. 1998, 17, 761–763. [Google Scholar] [CrossRef]

- Xie, R.; Huang, L.; Fu, X.; Chen, Y. Effects of adhesive composition on bond strength of joined silicon nitride ceramics. J. Eur. Ceram. Soc. 1998, 18, 901–905. [Google Scholar] [CrossRef]

- Xie, R.; Huang, L.; Chen, Y.; Fu, X. Effects of chemical compositions of adhesive and joining processes on bond strength of Si3N4/Si3N4 joints. Ceram. Int. 1999, 25, 101–105. [Google Scholar] [CrossRef]

- Gopal, M.; Sixta, M.; De Jonghe, L.; Thomas, G. Seamless joining of silicon nitride ceramics. J. Am. Ceram. Soc. 2001, 84, 708–712. [Google Scholar] [CrossRef]

- Gopal, M.; De Jonghe, L.C.; Thomas, G. Silicon nitride joining using rare-earth reaction sintering. Scr. Mater. 1997, 36, 455–460. [Google Scholar] [CrossRef]

- Iwamoto, N.; Umesaki, N.; Haibara, Y. Silicon nitride joining with glass solder in the system CaO-SiO2-TiO2. Int. J. High Technol. Ceram. 1987, 3, 176. [Google Scholar] [CrossRef]

- Johnson, S.M.; Rowcliffe, D.J. Mechanical properties of joined silicon nitride. J. Am. Ceram. Soc. 1985, 68, 468–472. [Google Scholar] [CrossRef]

- Walls, P.A.; Ueki, M. Mechanical properties of β-sialon ceramics joined using composite β-sialon-glass adhesives. J. Am. Ceram. Soc. 1995, 78, 999–1005. [Google Scholar] [CrossRef]

- Walls, P.A.; Ueki, M. Joining sialon ceramics using composite β-sialon-glass adhesives. J. Am. Ceram. Soc. 1992, 75, 2491–2497. [Google Scholar] [CrossRef]

- Weldon, L.M.; Hampshire, S.; Pomeroy, M.J. Joining of ceramics using oxide and oxynitride glasses in the Y-Sialon system. J. Eur. Ceram. Soc. 1997, 17, 1941–1947. [Google Scholar] [CrossRef]

- Saito, N.; Kai, K.; Furusho, S.; Nakashima, K.; Mori, K.; Shimizu, F. Properties of nitrogen-containing yttria-Alumina-Silica melts and glasses. J. Am. Ceram. Soc. 2003, 86, 711–716. [Google Scholar] [CrossRef]

| Glass Solders | Y2O3 | Yb2O3 | Al2O3 | SiO2 | α-Si3N4 |

|---|---|---|---|---|---|

| Y-SiAlON | 44.5 | - | 10.5 | 10.3 | 34.7 |

| Yb-SiAlON | - | 58.3 | 7.9 | 7.7 | 26.1 |

| Spots | Y | Al | Si | N | O | Possible Phases |

|---|---|---|---|---|---|---|

| A | 8.41 | 2.67 | 27.70 | 41.18 | 20.03 | Y–Si–Al–O–N phase |

| B | 1.80 | 3.16 | 44.47 | 45.25 | 5.32 | β-Sialon |

| C | 4.77 | 0.97 | 48.26 | 46.00 | - | β-Si3N4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Sun, L.; Liu, C.; Wang, X.; Wang, X.; Zhang, J. Microstructure and Properties of Porous Si3N4/Dense Si3N4 Joints Bonded Using RE–Si–Al–O–N (RE = Y or Yb) Glasses. Metals 2017, 7, 500. https://doi.org/10.3390/met7110500

Li L, Sun L, Liu C, Wang X, Wang X, Zhang J. Microstructure and Properties of Porous Si3N4/Dense Si3N4 Joints Bonded Using RE–Si–Al–O–N (RE = Y or Yb) Glasses. Metals. 2017; 7(11):500. https://doi.org/10.3390/met7110500

Chicago/Turabian StyleLi, Ling, Liangbo Sun, Chunfeng Liu, Xinhua Wang, Xuanzhi Wang, and Jie Zhang. 2017. "Microstructure and Properties of Porous Si3N4/Dense Si3N4 Joints Bonded Using RE–Si–Al–O–N (RE = Y or Yb) Glasses" Metals 7, no. 11: 500. https://doi.org/10.3390/met7110500

APA StyleLi, L., Sun, L., Liu, C., Wang, X., Wang, X., & Zhang, J. (2017). Microstructure and Properties of Porous Si3N4/Dense Si3N4 Joints Bonded Using RE–Si–Al–O–N (RE = Y or Yb) Glasses. Metals, 7(11), 500. https://doi.org/10.3390/met7110500