Transparent Conducting Film Fabricated by Metal Mesh Method with Ag and Cu@Ag Mixture Nanoparticle Pastes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ag and Cu@Ag Composite Nanoparticles and Paste

2.2. Metal Mesh Mold and Trench Layer Patterning

2.3. Filling of Ag/Cu@Ag Nanoparticle Paste and Wiping of Residual Paste

2.4. Fabrication of Touch Panel by Using Metal Mesh Films

3. Results

3.1. Ag Nanoparticle Synthesis and Paste Properties

3.2. Cu@Ag Composite Nanoparticles and Paste Properties

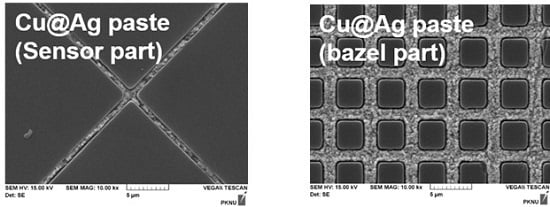

3.3. Inlay Filling of Ag and Cu@Ag Mixture Paste and Performance of Touch Screen Panel

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Park, S.I.; Xiong, Y.; Kim, R.H.; Elvikis, P.; Meitl, M.; Kim, D.H.; Wu, J.; Yoon, J.; Yu, C.J.; Liu, Z.; et al. Printed assemblies of inorganic light-emitting diodes for deformable and semitransparent displays. Science 2009, 325, 977–981. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Niu, X.; Liu, Z.; Pei, Q. Intrinsically Stretchable Polymer Light-Emitting Devices Using Carbon Nanotube-Polymer Composite Electrodes. Adv. Mater. 2011, 23, 3989–3994. [Google Scholar] [CrossRef] [PubMed]

- Sekitani, T.; Nakajima, H.; Maeda, H.; Fukushima, T.; Aida, T.; Hata, K.; Someya, T. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 2009, 8, 494–499. [Google Scholar] [CrossRef] [PubMed]

- Han, T.H.; Jeong, S.H.; Lee, Y.; Seo, H.K.; Kwon, S.J.; Park, M.H.; Lee, T.W. Flexible transparent electrodes for organic light emitting diodes. J. Inf. Disp. 2015, 16, 71–84. [Google Scholar] [CrossRef]

- Choi, Y.M.; Kim, K.W.; Lee, E.; Jo, J.; Lee, T.M. Fabrication of a single layer metal-mesh touchscreen sensor using reverse-offset printing. J. Inf. Disp. 2015, 16, 37–41. [Google Scholar] [CrossRef]

- Ko, S.H.; Park, I.; Pan, H.; Grigoropoulos, C.P.; Pisano, A.P.; Luscombe, C.K.; Fréchet, J.M. Direct nanoimprinting of metal nanoparticles for nanoscale electronics fabrication. Nano Lett. 2007, 7, 1869–1877. [Google Scholar] [CrossRef] [PubMed]

- Park, I.; Ko, S.H.; Pan, H.; Grigoropoulos, C.P.; Pisano, A.P.; Fréchet, J.M.; Lee, E.S.; Jeong, J.H. Nanoscale patterning and electronics on flexible substrate by direct nanoimprinting of metallic nanoparticles. Adv. Mater. 2008, 20, 489–496. [Google Scholar] [CrossRef]

- Suh, Y.D.; Jung, J.; Lee, H.; Yeo, J.; Hong, S.; Lee, P.; Lee, D.; Ko, S.H. Nanowire reinforced nanoparticle nanocomposite for highly flexible transparent electrodes: borrowing ideas from macrocomposites in steel-wire reinforced concrete. J. Mater. Chem. C 2017, 5, 791–798. [Google Scholar] [CrossRef]

- Park, M.; Im, J.; Shin, M.; Min, Y.; Park, J.; Cho, H.; Park, S.; Shim, M.B.; Jeon, S.; Chung, D.Y.; et al. Highly stretchable electric circuits from a composite material of silver nanoparticles and elastomeric fibers. Nat. Nanotechnol. 2012, 7, 803–809. [Google Scholar] [CrossRef] [PubMed]

- BYK Additives & Instruments. Available online: http://BYK.com/kr (accessed on 7 March 2017).

- Mino International Ltd. Available online: http://mino.co.jp (accessed on 7 March 2017).

| Sample | UV Oligomer | UV Monomer | Photoinitiator | |

|---|---|---|---|---|

| F-130 (g) | EEEA (g) | HDDA (g) | PI-TPO 25 wt % in EEEA (g) | |

| UVT-1-1 | 7.0 | 1.0 | 1.8 | 0.2 |

| UVT-2-1 | 6.0 | 2.0 | 1.8 | 0.2 |

| UVT-3-1 | 5.0 | 3.0 | 1.8 | 0.2 |

| UVT-3-2 | 5.0 | 3.0 | 1.8 | 0.4 |

| UVT-4-1 | 4.0 | 4.0 | 1.8 | 0.2 |

| UVT-4-2 | 4.0 | 4.0 | 1.8 | 0.4 |

| UVT-5-1 | 3.0 | 5.0 | 1.8 | 0.2 |

| UVT-5-2 | 3.0 | 5.0 | 1.8 | 0.4 |

| Ag Paste | Ag Powder Synthetic Condition | Ag Powder | Binder Polymer | Solvent | Additive |

|---|---|---|---|---|---|

| 88 wt % | 4 wt % | 7 wt % | 1 wt % | ||

| Ag Paste (1) | Acid value: 100 / Injection rate: 10 mL/min (40 min) | Ag powder (1) | Bisphenol-A Epoxy acrylate | ECA | BYK-754 |

| Ag Paste (2) | Acid value: 100 / Injection rate: 40 mL/min (10 min) | Ag powder (2) | Bisphenol-A Epoxy acrylate | ECA | BYK-754 |

| Ag Paste (3) | Acid value: 50 / Injection rate: 40 mL/min (10 min) | Ag powder (3) | Bisphenol-A Epoxy acrylate | ECA | BYK-754 |

| Ag Paste | Thermal curing condition and conductivity | ||||

| 100 °C, 20 min | 130 °C, 20 min | 180 °C, 20 min | |||

| Ag Paste (1) | - | 13–18 mΩ | 3–4 mΩ | ||

| Ag Paste (2) | - | 11–13 mΩ | 4–6 mΩ | ||

| Ag Paste (3) | - | 8–10 mΩ | 4–5 mΩ | ||

| Cu@Ag Pastes | Cu@Ag Powder | Cu@Ag Paste Formulation (wt %) | ||||

|---|---|---|---|---|---|---|

| Cu@Ag Powder | Binder Polymer | Solvent | Additive | Sheet Resistance (4 Point, Ω/cm2) | ||

| Bisphenol-A Epoxy Acrylate | ECA | BYK-9076 | ||||

| Cu@Ag paste (1) | Cu@Ag (Ag: 20 wt %) | 88 | 4 | 7 | 1 | 500–600 |

| Cu@Ag paste (2) | Cu@Ag (Ag: 30 wt %) | 88 | 4 | 7 | 1 | 380–480 |

| Cu@Ag paste (3) | Cu@Ag (Ag: 40 wt %) | 88 | 4 | 7 | 1 | 200–300 |

| Cu@Ag paste (4) | Cu@Ag (Ag: 20 wt %) | 88 | 2 | 9 | 1 | 450–500 |

| Cu@Ag paste (5) | Cu@Ag (Ag: 30 wt %) | 88 | 2 | 9 | 1 | 250–300 |

| Cu@Ag paste (6) | Cu@Ag (Ag: 40 wt %) | 88 | 2 | 9 | 1 | 150–200 |

| Cu@Ag Pastes | Ag and Cu@Ag Paste Mixture Formulation (wt %) | |||||

|---|---|---|---|---|---|---|

| Cu@Ag Powder | Ag Powder | Binder Polymer | Solvent | Additive | Sheet Resistance (4 Point, Ω/cm2) | |

| Bisphenol Epoxy Acrylate | ECA | BYK-9706 | ||||

| Paste (1) | Cu@Ag 70.4 wt % | Ag 17.6 wt % | 2 | 9 | 1 | 55–80 |

| Paste (2) | Cu@Ag 44.0 wt % | Ag 44.0 wt % | 2 | 9 | 1 | 30–45 |

| Paste (3) | Cu@Ag 17.6 wt % | Ag 70.4 wt % | 2 | 9 | 1 | 13–15 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nam, H.M.; Seo, D.M.; Yun, H.D.; Thangavel, G.; Park, L.S.; Nam, S.Y. Transparent Conducting Film Fabricated by Metal Mesh Method with Ag and Cu@Ag Mixture Nanoparticle Pastes. Metals 2017, 7, 176. https://doi.org/10.3390/met7050176

Nam HM, Seo DM, Yun HD, Thangavel G, Park LS, Nam SY. Transparent Conducting Film Fabricated by Metal Mesh Method with Ag and Cu@Ag Mixture Nanoparticle Pastes. Metals. 2017; 7(5):176. https://doi.org/10.3390/met7050176

Chicago/Turabian StyleNam, Hyun Min, Duck Min Seo, Hyung Duk Yun, Gurunathan Thangavel, Lee Soon Park, and Su Yong Nam. 2017. "Transparent Conducting Film Fabricated by Metal Mesh Method with Ag and Cu@Ag Mixture Nanoparticle Pastes" Metals 7, no. 5: 176. https://doi.org/10.3390/met7050176

APA StyleNam, H. M., Seo, D. M., Yun, H. D., Thangavel, G., Park, L. S., & Nam, S. Y. (2017). Transparent Conducting Film Fabricated by Metal Mesh Method with Ag and Cu@Ag Mixture Nanoparticle Pastes. Metals, 7(5), 176. https://doi.org/10.3390/met7050176