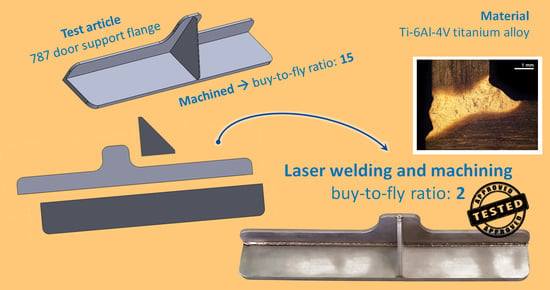

Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction

Abstract

Share and Cite

Caiazzo, F.; Alfieri, V.; Corrado, G.; Argenio, P.; Barbieri, G.; Acerra, F.; Innaro, V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals 2017, 7, 183. https://doi.org/10.3390/met7050183

Caiazzo F, Alfieri V, Corrado G, Argenio P, Barbieri G, Acerra F, Innaro V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals. 2017; 7(5):183. https://doi.org/10.3390/met7050183

Chicago/Turabian StyleCaiazzo, Fabrizia, Vittorio Alfieri, Gaetano Corrado, Paolo Argenio, Giuseppe Barbieri, Francesco Acerra, and Vincenzo Innaro. 2017. "Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction" Metals 7, no. 5: 183. https://doi.org/10.3390/met7050183

APA StyleCaiazzo, F., Alfieri, V., Corrado, G., Argenio, P., Barbieri, G., Acerra, F., & Innaro, V. (2017). Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals, 7(5), 183. https://doi.org/10.3390/met7050183