Brittle Fracture Behaviors of Large Die Holders Used in Hot Die Forging

Abstract

:1. Introduction

2. Failure Background of the Die Holder

3. Methods

4. Results

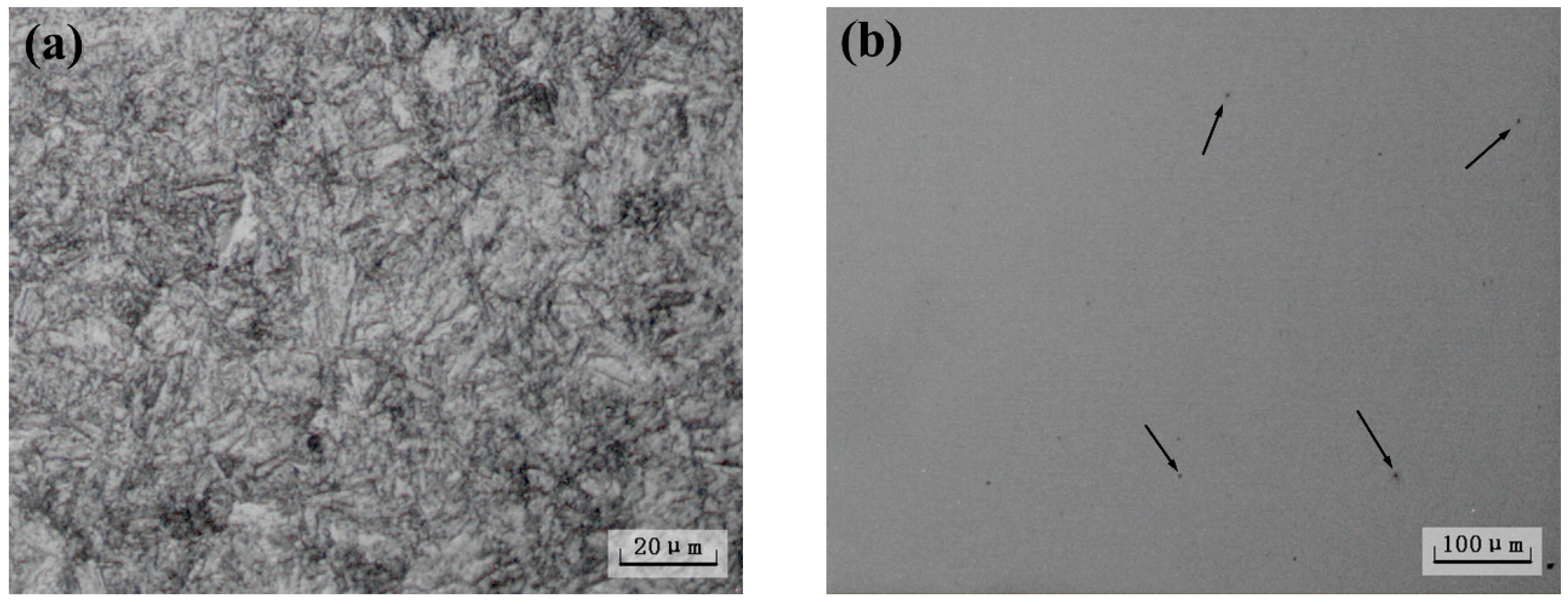

4.1. The Chemical Composition and Metallography

4.2. Hardness Analysis

4.3. Tensile Properties

4.4. Impact Property and Fracture Morphology

4.5. The Tempering and Water-Cooling Effect on Impact Property

4.6. Transmission Electron Microscope Analysis

5. Discussion

6. Conclusions

- The serious material embrittlement and brittle fracture of the die holder are caused by the long-term tempering and water-cooling effect as well as the cyclic mechanical loads. In addition, the operation specification must be emphasized to avoid the die holder being cooled by using water during the working process.

- The tempering and water-cooling treatment at 150 °C to 350 °C could lead to the impact toughness degradation and material embrittlement. The effect of material embrittlement declines with the tempering temperature rising.

- The material embrittlement are related to the large size M23C6 (M: mainly Fe and Cr) and M3C carbides (M: mainly Fe) distributed in the martensitic lath boundaries.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gronostajski, Z.; Kaszuba, M.; Hawryluk, M.; Zwierzchowski, M. A review of the degradation mechanisms of the hot forging tools. Arch. Civ. Mech. Eng. 2014, 14, 528–539. [Google Scholar] [CrossRef]

- Kchaou, M.; Elleuch, R.; Desplanques, Y.; Boidin, X.; Degallaix, G. Failure mechanisms of H13 die on relation to the forging process—A case study of brass gas valves. Eng. Fail. Anal. 2010, 17, 403–415. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Kaszuba, M.; Polak, S.; Zwierzchowski, M.; Niechajowicz, A.; Hawryluk, M. The failure mechanisms of hot forging dies. Mater. Sci. Eng. A 2016, 657, 147–160. [Google Scholar] [CrossRef]

- Okazaki, Y. Comparison of fatigue properties and fatigue crack growth rates of various implantable metals. Materials 2012, 5, 2981–3005. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, B.M.; Choi, J.C. Prediction of die wear in the wire-drawing process. J. Mater. Process. Technol. 1997, 65, 11–17. [Google Scholar] [CrossRef]

- Alimi, A.; Fajoui, J.; Kchaou, M.; Branchu, S.; Elleuch, R.; Jacquemin, F. Multi-scale hot working tool damage (X40CrMoV5-1) analysis in relation to the forging process. Eng. Fail. Anal. 2016, 62, 142–155. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.P.; Jain, N.K. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Chen, C.; Wang, Y.; Ou, H.; He, Y.; Tang, X. A review on remanufacture of dies and moulds. J. Clean. Prod. 2014, 64, 13–23. [Google Scholar] [CrossRef]

- Brnic, J.; Turkalj, G.; Lanc, D.; Canadija, M.; Brcic, M.; Vukelic, G. Comparison of material properties: Steel 20MnCr5 and similar steels. J. Constr. Steel. Res. 2014, 95, 81–89. [Google Scholar] [CrossRef]

- Li, J.; Huang, Q.; Ren, X. Dynamic initiation and propagation of multiple cracks in brittle materials. Materials 2013, 6, 3241–3253. [Google Scholar] [CrossRef]

- Zhang, Z.; Delagnes, D.; Bernhart, G. Microstructure evolution of hot-work tool steels during tempering and definition of a kinetic law based on hardness measurements. Mater. Sci. Eng. A 2004, 380, 222–230. [Google Scholar] [CrossRef]

- Zhang, Z.; Qi, Y.; Delagnes, D.; Bernhart, G. Microstructure variation and hardness diminution during low cycle fatigue of 55NiCrMoV7 steel. J. Iron Steel Res. Int. 2007, 14, 68–73. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, P.; Zhang, W.; Zhang, Y.; Song, T. Failure analysis of large press die holder. Eng. Fail. Anal. 2015, 64, 13–25. [Google Scholar] [CrossRef]

- Roberti, R.; Faccoli, M. On the step cooling treatment for the assessment of temper embrittlement susceptibility of heavy forgings in superclean steels. Metals 2016, 6, 239. [Google Scholar] [CrossRef]

- Song, Y.Y.; Ping, D.H.; Yin, F.X.; Li, X.Y.; Li, Y.Y. Microstructural evolution and low temperature impact toughness of a Fe-13%Cr-4%Ni-Mo martensitic stainless steel. Mater. Sci. Eng. A 2010, 527, 614–618. [Google Scholar] [CrossRef]

- Ning, A.; Mao, W.; Chen, X.; Guo, H.; Guo, J. Precipitation behavior of carbides in H13 hot work die steel and its strengthening during tempering. Metals 2017, 7, 70. [Google Scholar] [CrossRef]

- Flora, M.G.D.; Pellizzari, M. Behavior at elevated temperature of 55NiCrMoV7 tool steel. Mater. Manuf. Process. 2009, 24, 791–795. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, N.; Li, D.; Zhang, J.; Luo, Y.; Zhang, R. Effect of microstructure evolution on strength and impact toughness of G18CrMo2-6 heat-resistant steel during tempering. Mater. Sci. Eng. A 2014, 604, 103–110. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Morales-Rivas, L.; Caballero, F.G.; Milbourn, D.; Sourmail, T. Vanadium effect on a medium carbon forging steel. Metals 2016, 6, 130. [Google Scholar] [CrossRef]

- Paul, V.T.; Saroja, S.; Vijayalakshmi, M. Microstructural stability of modified 9Cr-1Mo steel during long term exposures at elevated temperatures. J. Nucl. Mater. 2008, 378, 273–281. [Google Scholar] [CrossRef]

- Lee, T.-H.; Lee, Y.-J.; Joo, S.-H.; Nersisyan, H.H.; Park, K.-T.; Lee, J.-H. Intergranular M23C6 carbide precipitation behavior and its effect on mechanical properties of Inconel 690 tubes. Metall. Mater. Trans. A 2015, 46, 4020–4026. [Google Scholar] [CrossRef]

| Element | C | Cr | Mo | Ni | V | Si | Mn | P | S |

|---|---|---|---|---|---|---|---|---|---|

| Standard | 0.5–0.6 | 1.0–1.2 | 0.45–0.55 | 1.5–1.8 | 0.07–0.1 | 0.1–0.4 | 0.65–0.95 | ≤0.02 | ≤0.02 |

| Tested | 0.56 | 1.07 | 0.52 | 1.61 | 0.096 | 0.26 | 0.79 | 0.007 | 0.003 |

| Number | HRC | HRC | HRC | HRC | HRC | Average |

|---|---|---|---|---|---|---|

| Region 4-1 | 32.9 | 32.9 | 32.8 | 32.9 | 32.9 | 32.9 |

| Region 4-2 | 32.9 | 33.0 | 33.0 | 33.2 | 33.2 | 33.1 |

| Region 4-3 | 33.1 | 33.3 | 32.6 | 32.9 | 32.9 | 33.0 |

| Region 6 | 37.7 | 37.2 | 37.3 | 36.6 | 37.4 | 37.2 |

| Standard | - | - | - | - | - | HRC 36–40 |

| Sample Locations | Rm (MPa) | Rp0.2 (MPa) | A (%) | Z (%) |

|---|---|---|---|---|

| Region 4-1 (the upper region) | 1017 | 819 | 13.0 | 39 |

| Region 4-2 (the middle region) | 1018 | 821 | 14.0 | 47 |

| Region 4-3 (the lower region) | 1033 | 833 | 16.5 | 50 |

| Region 6 | 1046 | 850 | 16.5 | 51 |

| Standard | 1000–1250 | ≥650 | ≥15.0 | – |

| Sample Locations | (J/cm2) | Average | ||

|---|---|---|---|---|

| Region 4-1 | 7.0 | 11.3 | 11.1 | 9.8 |

| Region 4-2 | 8.2 | 7.3 | 12.8 | 9.4 |

| Region 4-3 | 6.4 | 11.1 | 9.4 | 9.0 |

| Region 6 | 43.6 | 42.4 | 34.0 | 40.0 |

| Standard | - | - | - | ≥25 |

| Precipitate Elements | NiK | FeK | MnK | CrK | MoK | VK |

|---|---|---|---|---|---|---|

| Polyhedron precipitate | 0.59 | 77.46 | - | 13.80 | 7.58 | 0.57 |

| Elongated precipitate | 0.88 | 93.41 | 4.31 | 1.40 | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wang, H.; Zhang, J.; Dai, W.; Huang, Y. Brittle Fracture Behaviors of Large Die Holders Used in Hot Die Forging. Metals 2017, 7, 198. https://doi.org/10.3390/met7060198

Zhang W, Wang H, Zhang J, Dai W, Huang Y. Brittle Fracture Behaviors of Large Die Holders Used in Hot Die Forging. Metals. 2017; 7(6):198. https://doi.org/10.3390/met7060198

Chicago/Turabian StyleZhang, Weifang, Hongxun Wang, Jingyu Zhang, Wei Dai, and Yuanxing Huang. 2017. "Brittle Fracture Behaviors of Large Die Holders Used in Hot Die Forging" Metals 7, no. 6: 198. https://doi.org/10.3390/met7060198

APA StyleZhang, W., Wang, H., Zhang, J., Dai, W., & Huang, Y. (2017). Brittle Fracture Behaviors of Large Die Holders Used in Hot Die Forging. Metals, 7(6), 198. https://doi.org/10.3390/met7060198