Abstract

Magnesium metal matrix composites (Mg MMCs) possess relatively more favorable mechanical properties than Mg alloys because they add reinforcements, such as small particles, short fibers, or continuous fibers, into the matrix. This study investigated the influence of adding different sizes and percentages of silicon carbide particles (SiCp) for manufacturing AZ61/SiCp Mg alloy composite extrusion plates on the mechanical properties of SiCp. We also examined the impact and discussed the evolution of microstructures, changes of material strength, ductility, formability, and other mechanical properties caused by a subsequent annealing treatment after plate extrusion. The results showed that the mechanical properties of plates can be improved by adding reinforcement particles. The effects of grain refinement were as follows: the smaller the size of the reinforcement particles, the greater the enhancement of mechanical properties. Among them, the AZ61/1 wt % SiCp/50 nm MMC plate had relatively excellent mechanical properties. Specifically, the ultimate tensile strength, yielding strength, ductility, hardness, and grain size of the plate were 331 MPa, 136.4 MPa, 43.1%, 62 HV, and 3.3 μm, respectively. Compared with SiCp-free Mg MMC plates, these properties of the AZ61/1 wt % SiCp/50 nm MMC plate were enhanced (or refined) by 6.4%, 3.4%, 83.4%, 2%, and 13.2%, respectively; by contrast, formability decreased by 9.1%.

1. Introduction

Magnesium (Mg) alloys were widely used in the 1950s and 1960s in the aerospace and automotive industries (e.g., the B-37 airplane and Volkswagen “Beetle”). Since then, Mg alloys have gained more recognition as a structural material for lightweight applications because of their low density, high stiffness-to-weight ratio, favorable castability, shock absorption, and excellent damping. Nevertheless, Mg alloys have not been used for critical applications because of their inferior mechanical properties, high manufacturing cost, and unfavorable formability at room temperature compared with other engineering materials [1,2,3,4]. One of the most frequently used methods for enhancing the mechanical properties of alloys is through strengthening by means of second-phase particles [5,6,7].

Composite materials are vital engineering materials because of their outstanding mechanical properties [8,9]. Metal matrix composite (MMC) materials are some of the most widely known composites, but widespread engineering application of MMC materials has been met with resistance because of their unfavorable machining characteristics, in particular excessive tool wear and inferior surface finish, despite superior physical and mechanical properties [10,11]. Continuous fiber reinforcement was a key research objective for MMCs in the early stage. However, because of the complexity of manufacturing and the relatively high cost of fibrous MMCs, many researchers have instead focused on using discontinuous particles as reinforcement for MMCs [12]. The advantages of discontinuous particle-reinforced MMCs are low cost, being able to fabricate them through secondary processing (e.g., forging or extrusion), more favorable mechanical properties, and homogeneity. Silicon carbide (SiC) is one of the most widely incorporated reinforcing materials for MMC fabrication because of its superior properties and economical production in various forms, such as fibers [13,14], whiskers [15,16], and especially particles (SiCp), which are exceptionally affordable. The mechanical properties of SiCp and aluminum oxide (Al2O3)-reinforced Mg-based MMCs have been extensively studied by researchers [17,18,19,20,21,22,23,24,25,26,27,28,29,30]. Mg alloy sheets fabricated through rolling or extrusion and subsequent annealing can achieve excellent mechanical properties [31,32,33]. Due to global restrictions on CO2 emissions, SiC particulate–reinforced Mg MMCs provide increased specific strength that contribute to weight reduction in the automobile industry. The particulate SiC–reinforced Mg alloy metal matrix composite (Mg/SiCp MMC) has rapidly replaced conventional materials in various industries, particularly in the automotive and aerospace industries, because of its ability to considerably reduce the weight of products. However, few researchers have studied AZ61 Mg MMCs processed through extrusion and subsequent annealing, or the effect of particle size or particle percentage of SiCp on the mechanical properties of such composites.

In this study, the effect of SiC particle size and particle percentage on the mechanical properties of Mg MMCs was investigated. The evolution of the microstructure and changes in material strength, ductility, and other mechanical properties caused by the subsequent annealing treatment of the extruded Mg MMC plates were also examined.

2. Materials and Methods

2.1. Materials

In this study, different sizes (10, 1, and 50 nm) and percentages (0.5, 1, and 2 wt %) of SiCp particles were added to AZ61 alloys to form AZ61/SiCp MMCs through the melt-stirring casting method for plate extrusion. The chemical composition of the AZ61 alloys is shown in Table 1.

Table 1.

Chemical composition of the AZ61 alloys.

2.2. Fabrication of the Ingot and Plate of the Mg MMCs and Their Heat Treatments

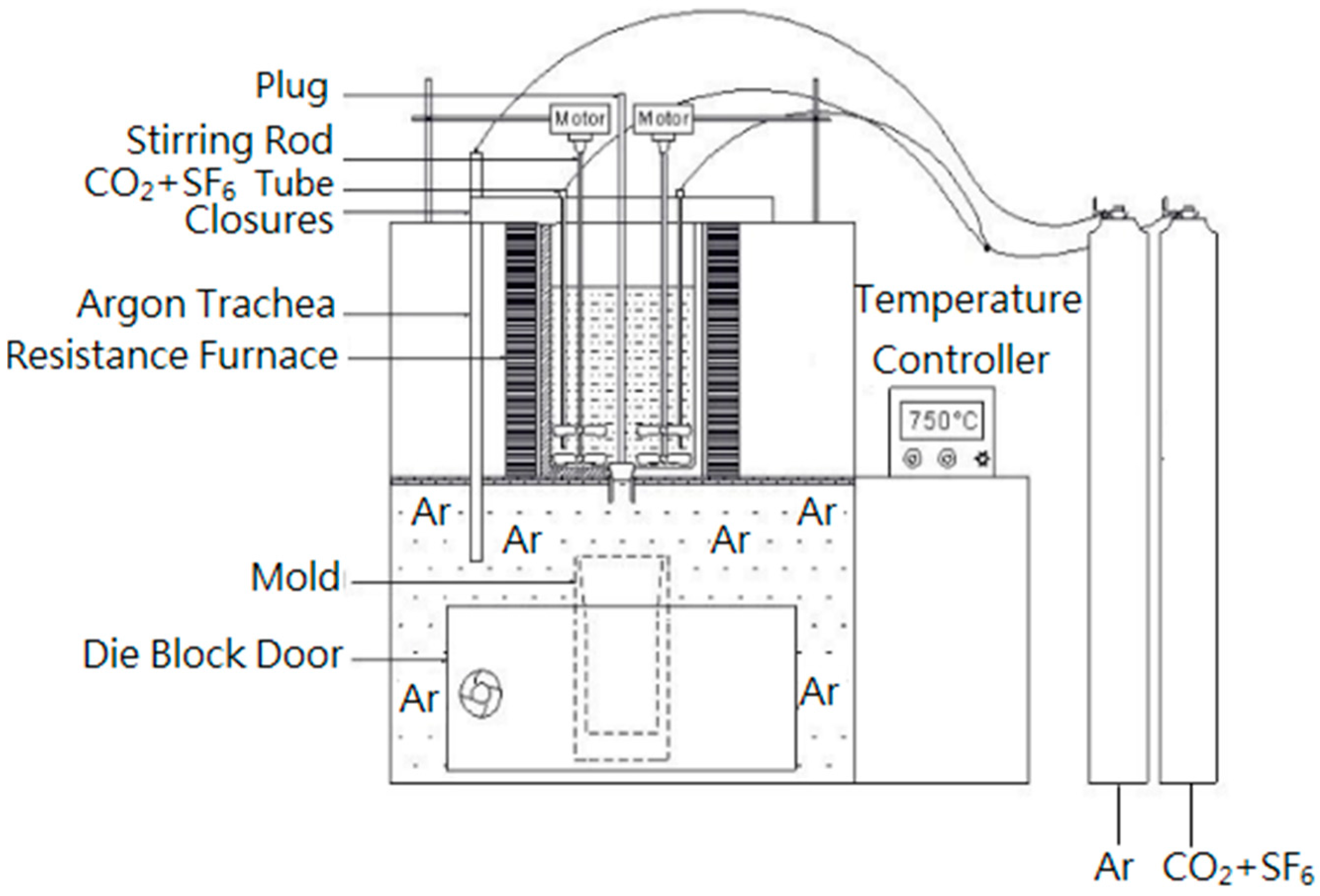

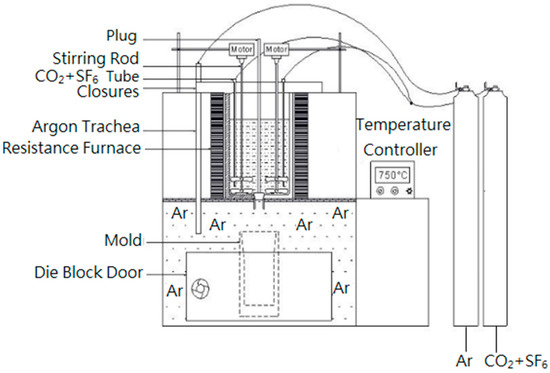

The AZ61/SiCp MMCs were fabricated using the melt-stirring technique, a schematic of which is shown in Figure 1. First, AZ61/SiCp MMCs ingots (diameter = 85 mm, height = 140 mm) were machined to be billets with a diameter of 75 mm and a height of 100 mm. After machining the ingots, but prior to the extrusion process, T4 treatment (homogenization) was performed on the billets for 10 h at 400 °C, which eliminated the β phase caused during casting and improved the strength of the extrusion process of the AZ61/SiCp MMC plates. The T4 treatment was performed using a 500-ton extruder (Gongyi, Taibei, Taiwan) with a single pushing cylinder at an extrusion temperature of 300 °C. An extrusion ratio of 31.56 was used during the extrusion process. Subsequently, T4 annealing treatment was performed on the extruded plates for 1 h at 250 °C, which improved their ductility and formability.

Figure 1.

Schematic of the stir-casting melting furnace.

2.3. Morphological and Mechanical Properties

Microstructure characterization was performed with an optical microscope (OLYMPUS BX51, OLYMPUS, Tokyo, Japan), and the mean grain size was determined using the linear intercept method. For mechanical testing, an MTS Model 458 axial/torsional testing system was used according to standard ASTM B 557M-02a (Standard Test Methods of Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products). With a load of 500 gf, Vickers microhardness was measured using a Matsuzawa (Model MV-1) hardness tester (Akashi MVK-H1, Mitutoyo, Tokyo, Japan). The average hardness of each sample was obtained from nine tests and four specimens of each sample were tested under a strain rate of 1 mm/min. The morphologies were determined using scanning electron microscopy with energy-dispersive X-ray (SEM-EDX) and scanning transmission electron microscopy (SEM; FEG SEM, Hitachi S 3400, Tokyo, Japan).

3. Results and Discussion

3.1. Mechanical Properties

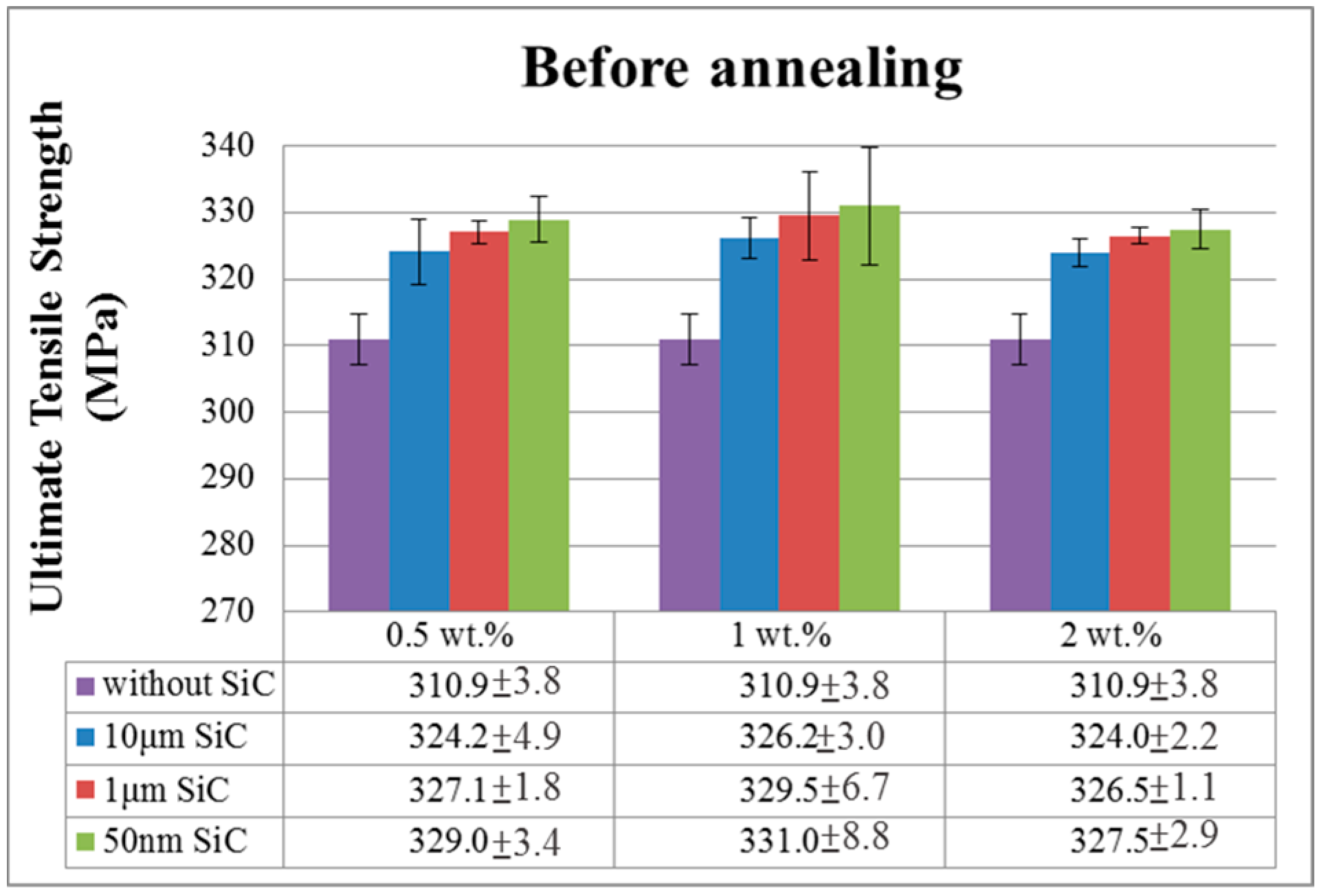

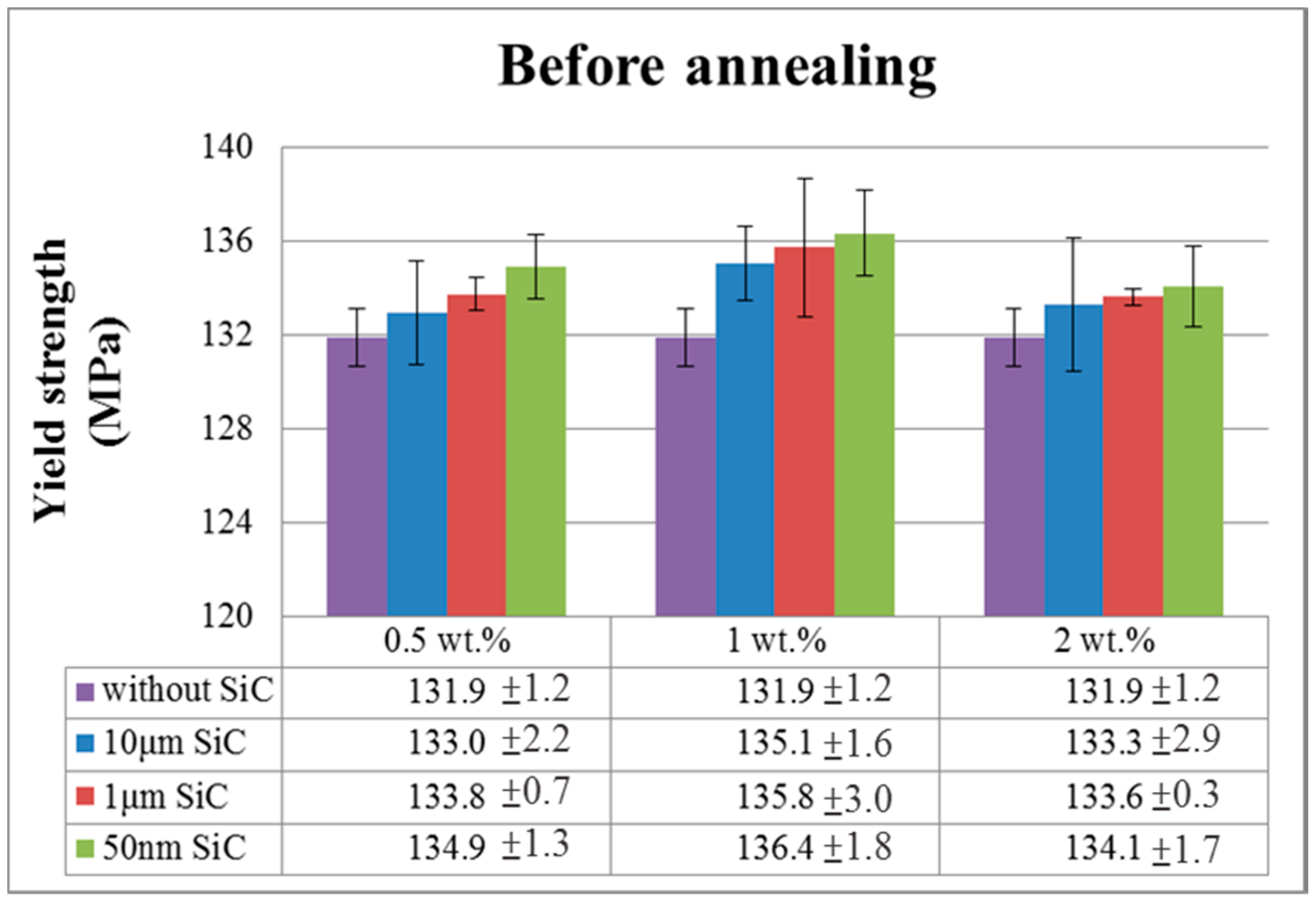

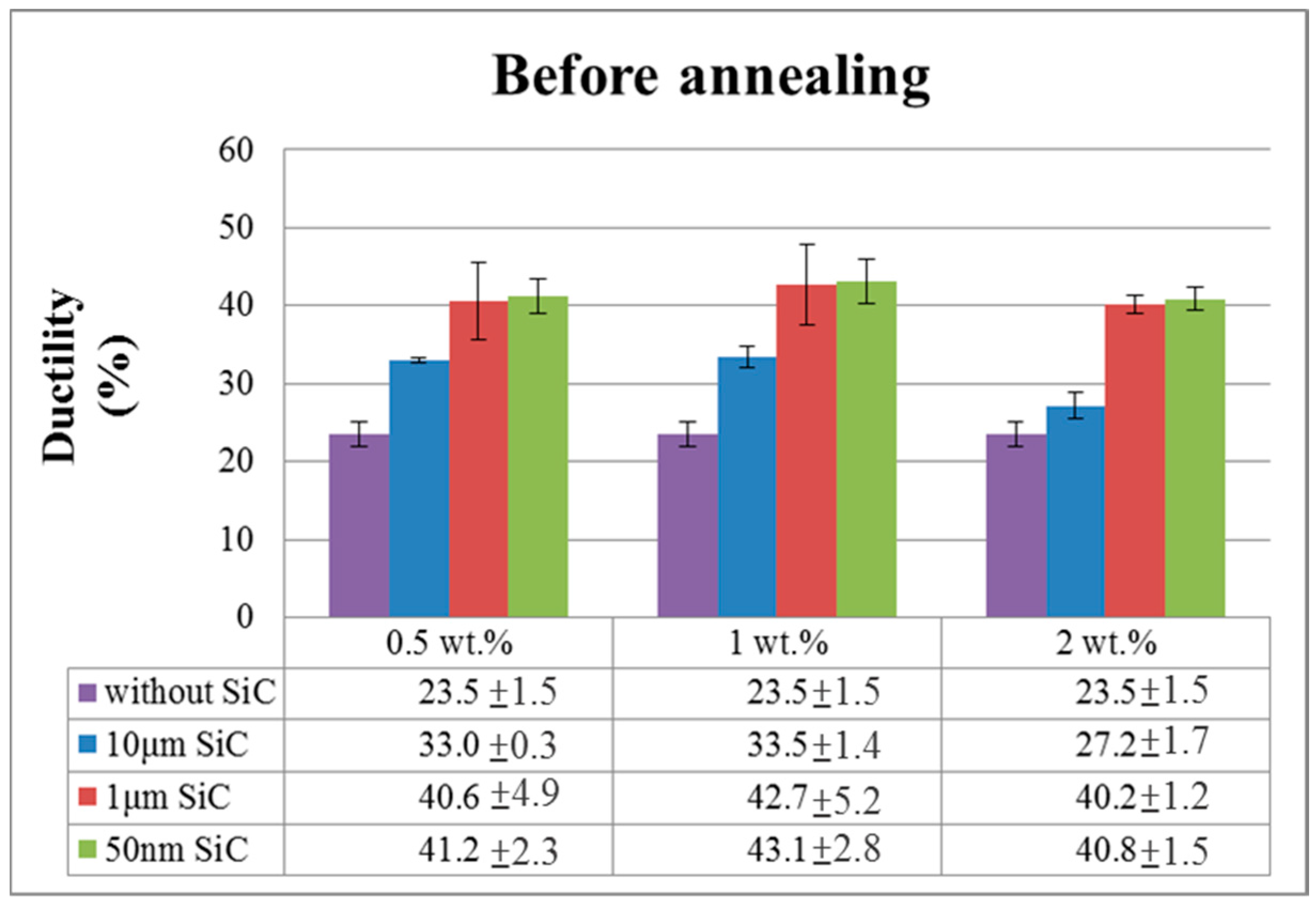

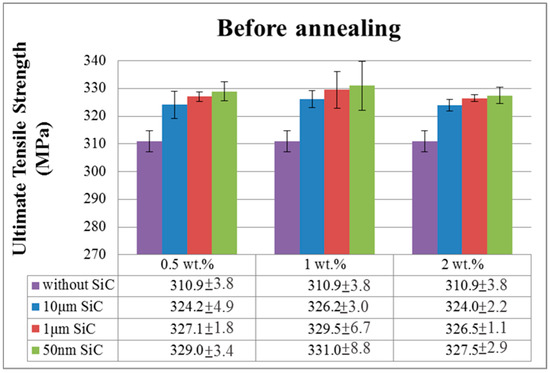

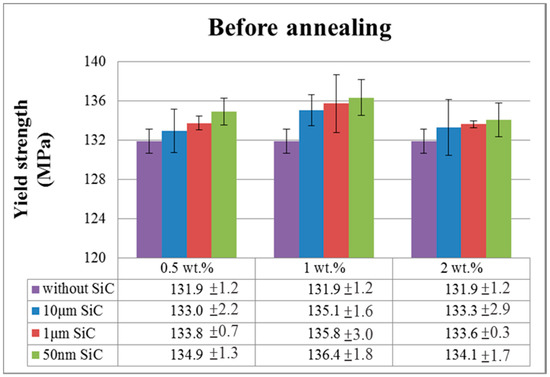

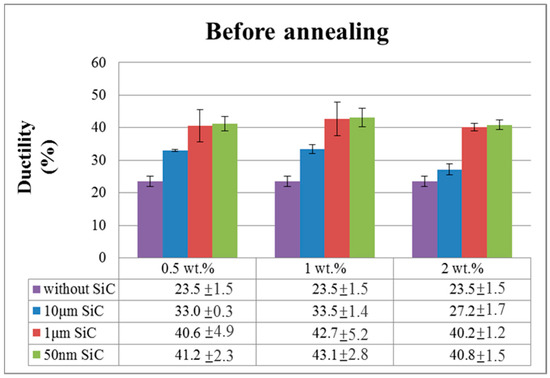

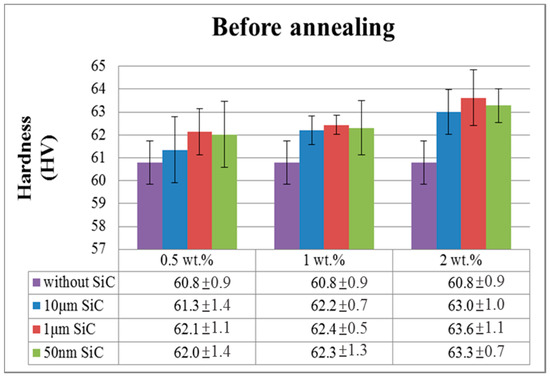

Figure 2, Figure 3, Figure 4 and Figure 5 show the ultimate strength, yield strength, ductility, and hardness, respectively, of the AZ61/SiCp MMC extruded plates before annealing. The results show that the mechanical properties of the unannealed AZ61/SiCp MMC extruded plates increased when the percentage of particles increased; their mechanical properties (all except hardness) all increased when reinforcement particle size decreased, which caused significant grain size refinement. Among all the combinations, Mg MMCs with 1 wt % of SiCp/50 nm possessed the optimal mechanical properties. The ultimate tensile strength, yielding strength, ductility, hardness, and grain size of the AZ61/1 wt % SiCp/50 nm MMC plate were 331 MPa, 136.4 MPa, 43.1%, 62 HV, and 3.3 μm, respectively. Moreover, the ultimate tensile strength, yielding strength, ductility, hardness, and grain size of the AZ61/1 wt % SiCp/50 nm MMC plate increased by 6.4%, 3.4%, 83.4%, 2%, and 13.2%, respectively, compared with the SiCp-free Mg MMC plate (i.e., the AZ61 extruded plate).

Figure 2.

Ultimate strength of the AZ61/SiCp MMC extruded plates before annealing.

Figure 3.

Yield strength of the AZ61/SiCp MMC extruded plates before annealing.

Figure 4.

Ductility of the AZ61/SiCp MMC extruded plates before annealing.

Figure 5.

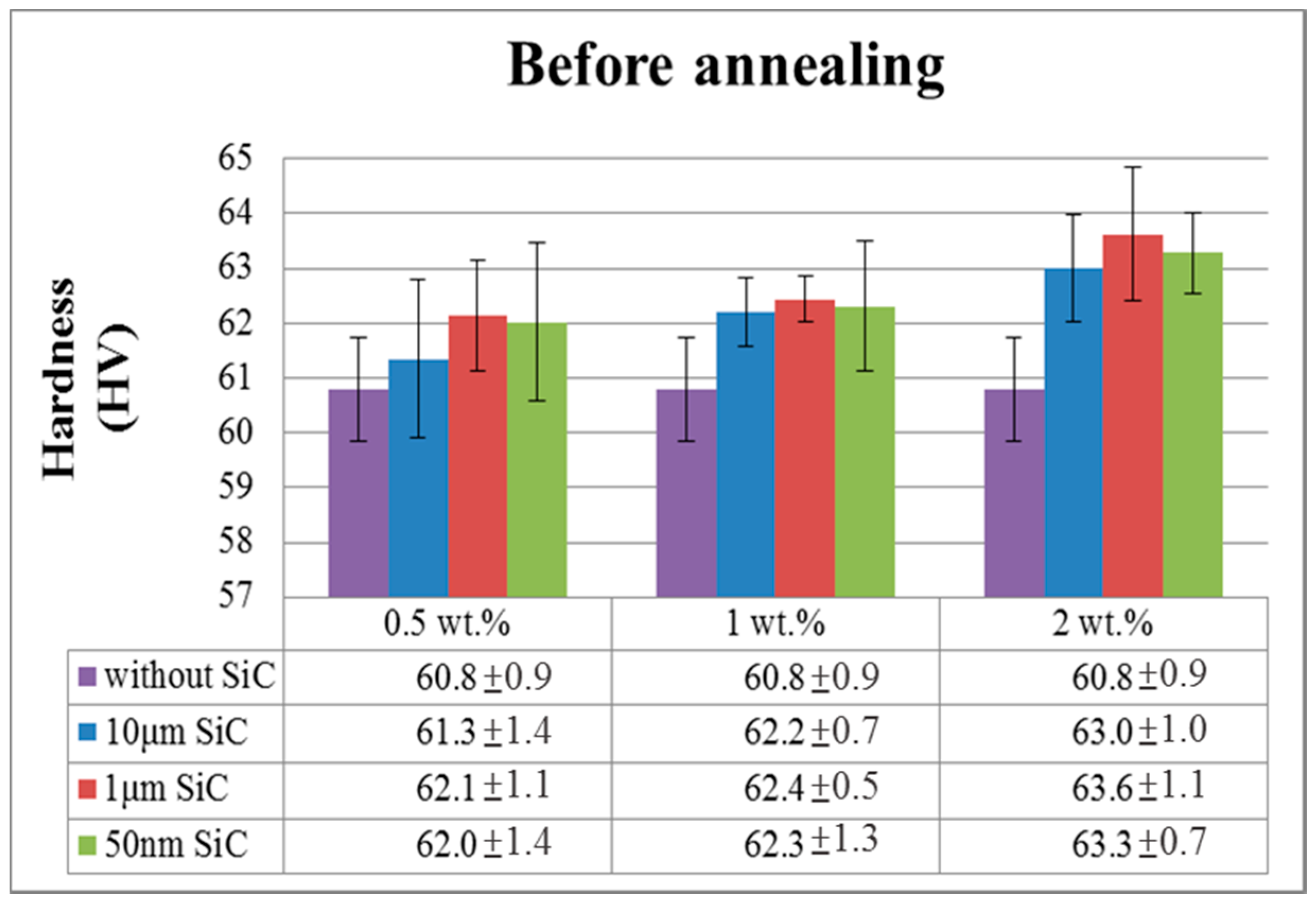

Hardness of the AZ61/SiCp MMC extruded plates before annealing.

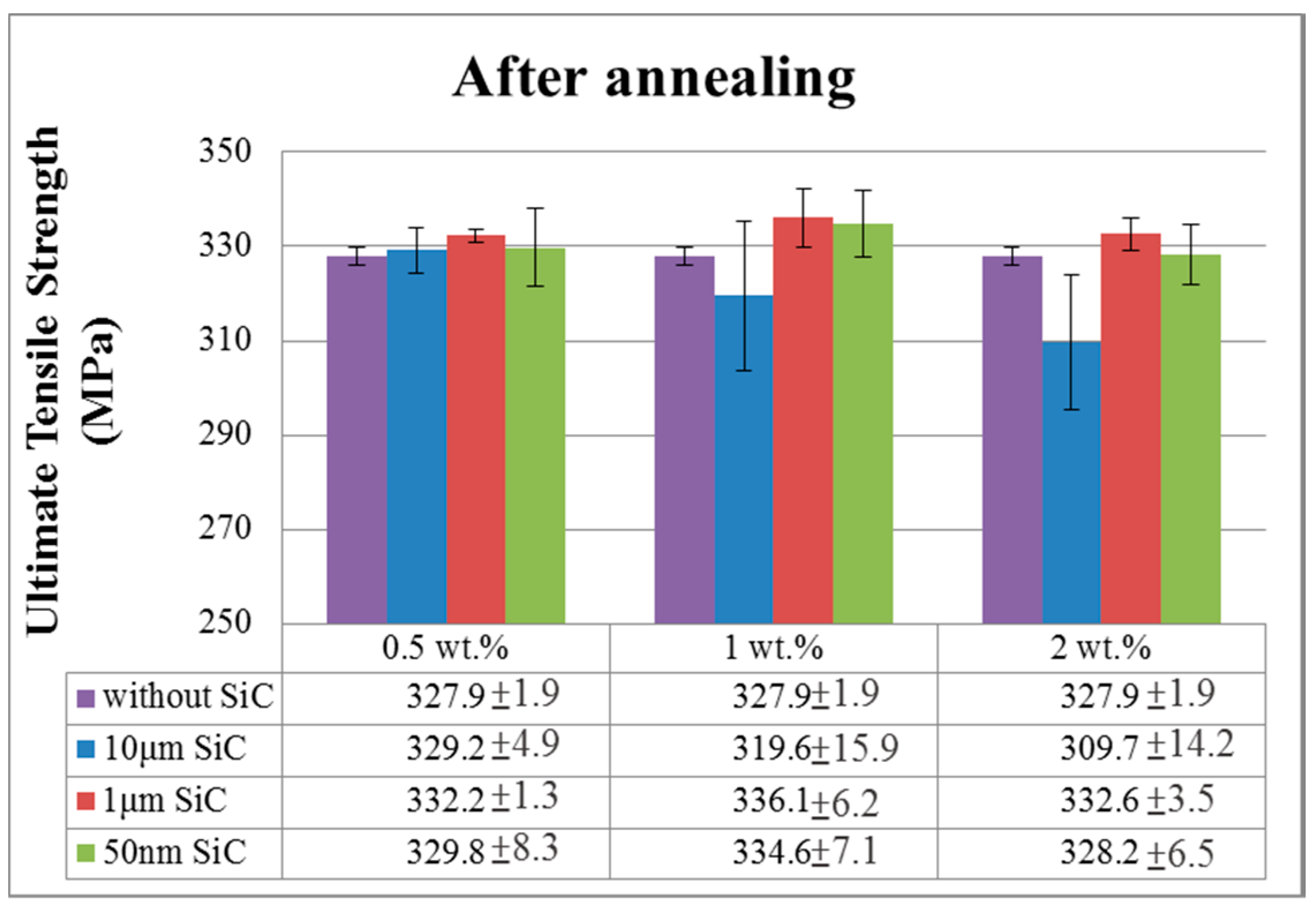

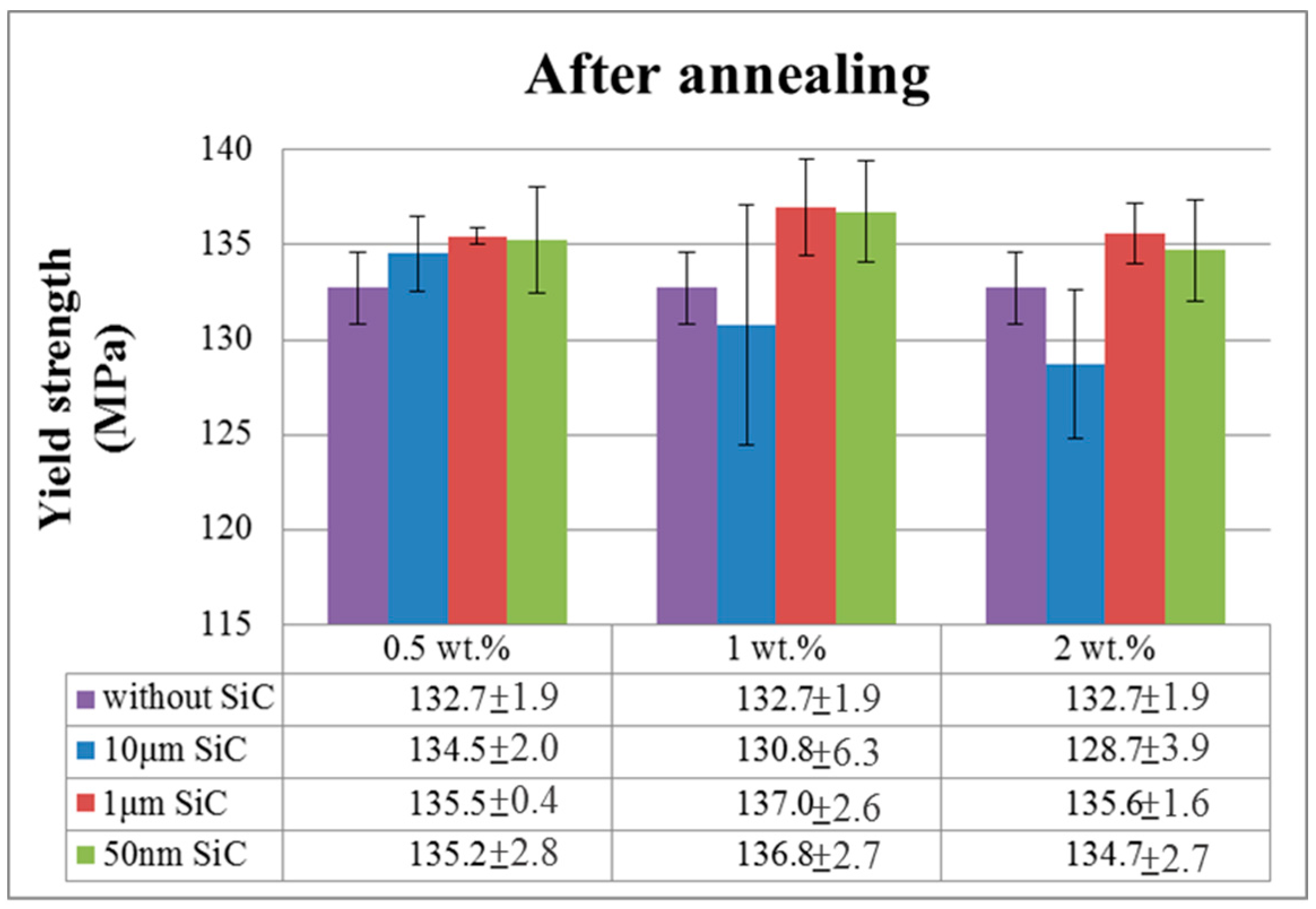

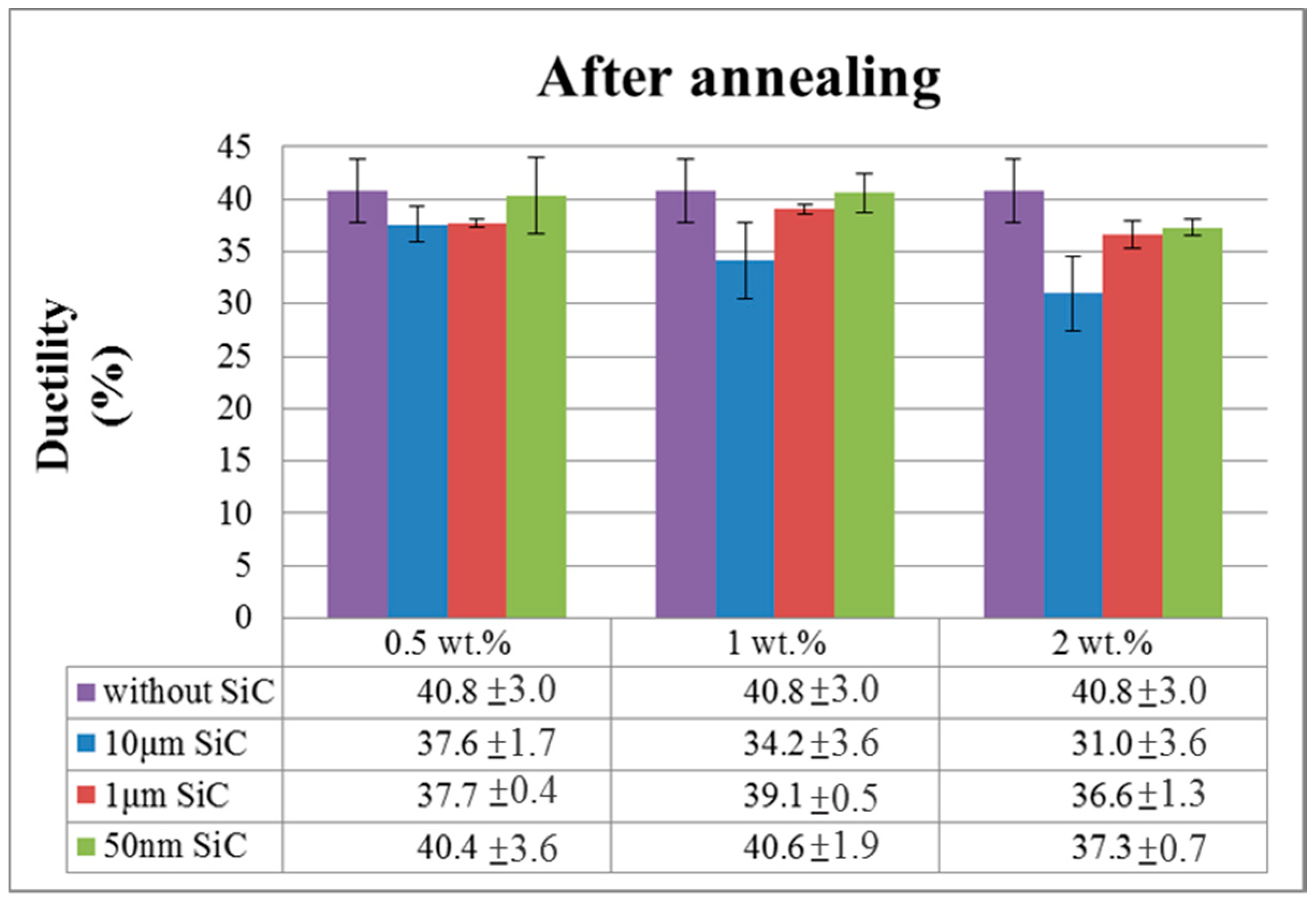

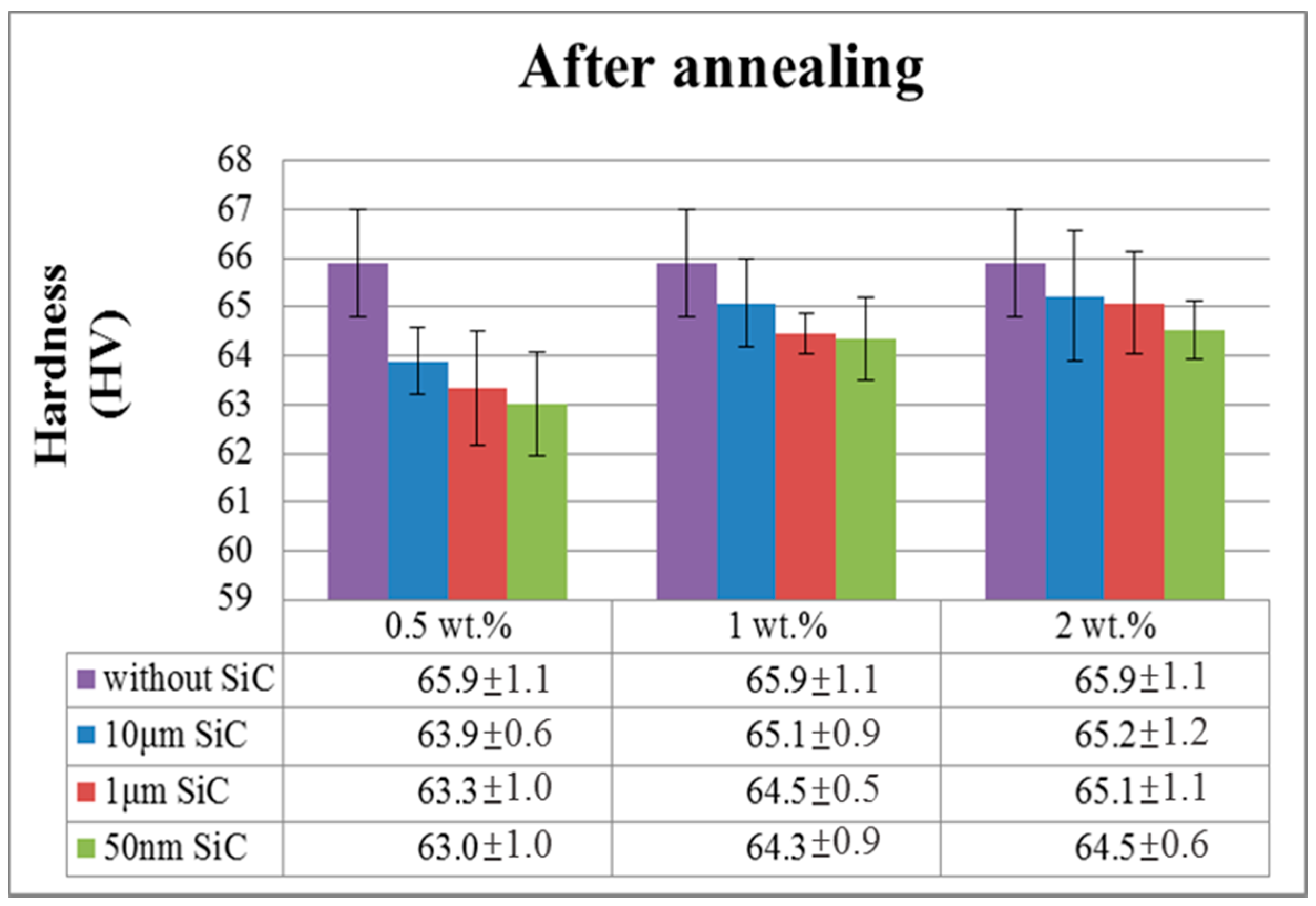

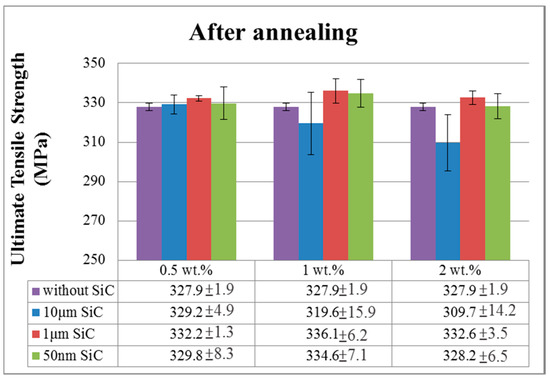

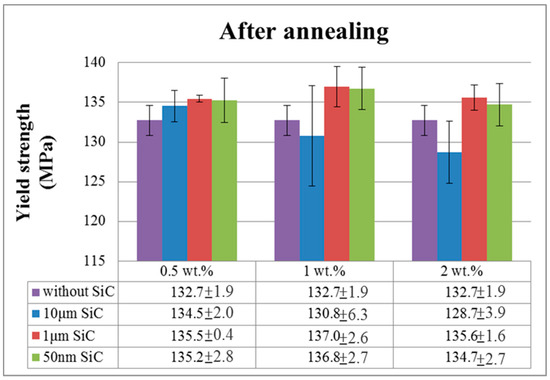

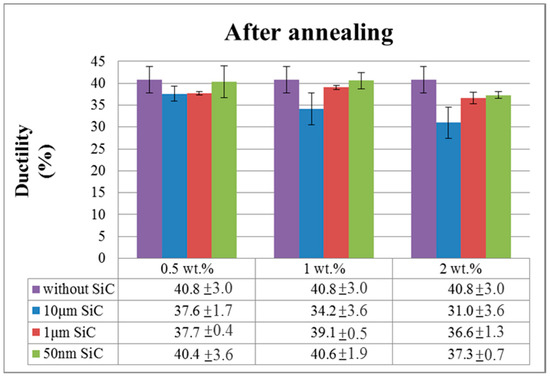

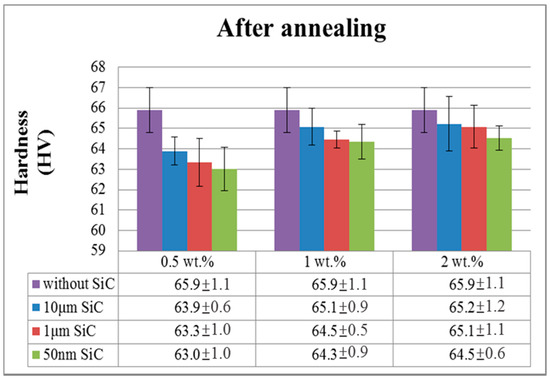

Figure 6, Figure 7, Figure 8 and Figure 9 show the ultimate strength, yield strength, ductility, and hardness, respectively, of the AZ61/SiCp MMC extruded plate after annealing. The results indicate that the ultimate strength and yield strength of the annealed AZ61/SiCp MMC extruded plates (all except the AZ61/SiCp/10 μm MMCs) increased when the percentage of particles increased; furthermore, their hardness decreased when particle sizes decreased, which is caused by significant grain size refinement.

Figure 6.

Ultimate strength of the AZ61/SiCp MMC extruded plates after annealing.

Figure 7.

Yield strength of the AZ61/SiCp MMC extruded plates after annealing.

Figure 8.

Ductility of the AZ61/SiCp MMC extruded plates after annealing.

Figure 9.

Hardness of the AZ61/SiCp MMC extruded plates after annealing.

Figure 5 and Figure 9 reveal the microhardness trends of the plates. According to the Hall–Petch theory, the hardness of the unannealed AZ61/SiCp MMC extruded plate increased when the particle size increased because of the refinement of the grain size (Figures 10 and 11). Similarly, the hardness of the annealed AZ61/SiCp MMC extruded plate increased when the particle size decreased because of the refinement of the grain size (Figures 12 and 13).

The conventional Mg alloy was annealed to improve its ductility and formability. In the case of the SiCp-free AZ61 plates, annealing increased ductility by 73%, compared with that before annealing. However, in the case of the AZ61/SiCp MMC extruded plates, annealing both only increased the ductility of the AZ61/SiCp/10 μm MMC plates and decreased the ductility of the AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates because adding submicron SiCp and nano SiCp reduced the number of effective nucleation sites.

After being subjected to annealing treatment at 250 °C for 1 h, the AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates, irrespective of the quantity of nano or micro particulates, exhibited improvements in hardness and strength; however, ductility slightly decreased because of the precipitation of the β phase (see Section 3.2). Although the AZ61/0.5 wt % SiCp/10 μm MMC annealed plates improved in various properties, the amount of precipitate increased as the percentage of SiCp increased, which led to a drastic decrease in its strength and ductility.

The mechanical properties of the annealed SiCp-free AZ61 alloy plate were better than those of unannealed SiCp-free AZ61 alloy plate. Both annealed and unannealed AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates exhibited higher strength, hardness, and ductility compared with the SiCp-free (i.e., AZ61) Mg alloy plate. However, the annealed AZ61/SiCp/10 μm MMC plate was not in this case because its yield strength did not improve, although its ultimate strength, hardness, and ductility did improve.

In short, adding submicron SiCp and nano SiCp particles to AZ61 MCC plates during processing results in excellent advantages, including strengthening the mechanical properties and increasing ductility of the plates. Annealing can further improve the ductility and formability of the Mg alloy and Mg MMCs with micron SiCp and reduce those of Mg MMCs with submicron SiCp and nano SiCp.

3.2. Morphology and SEM Observation

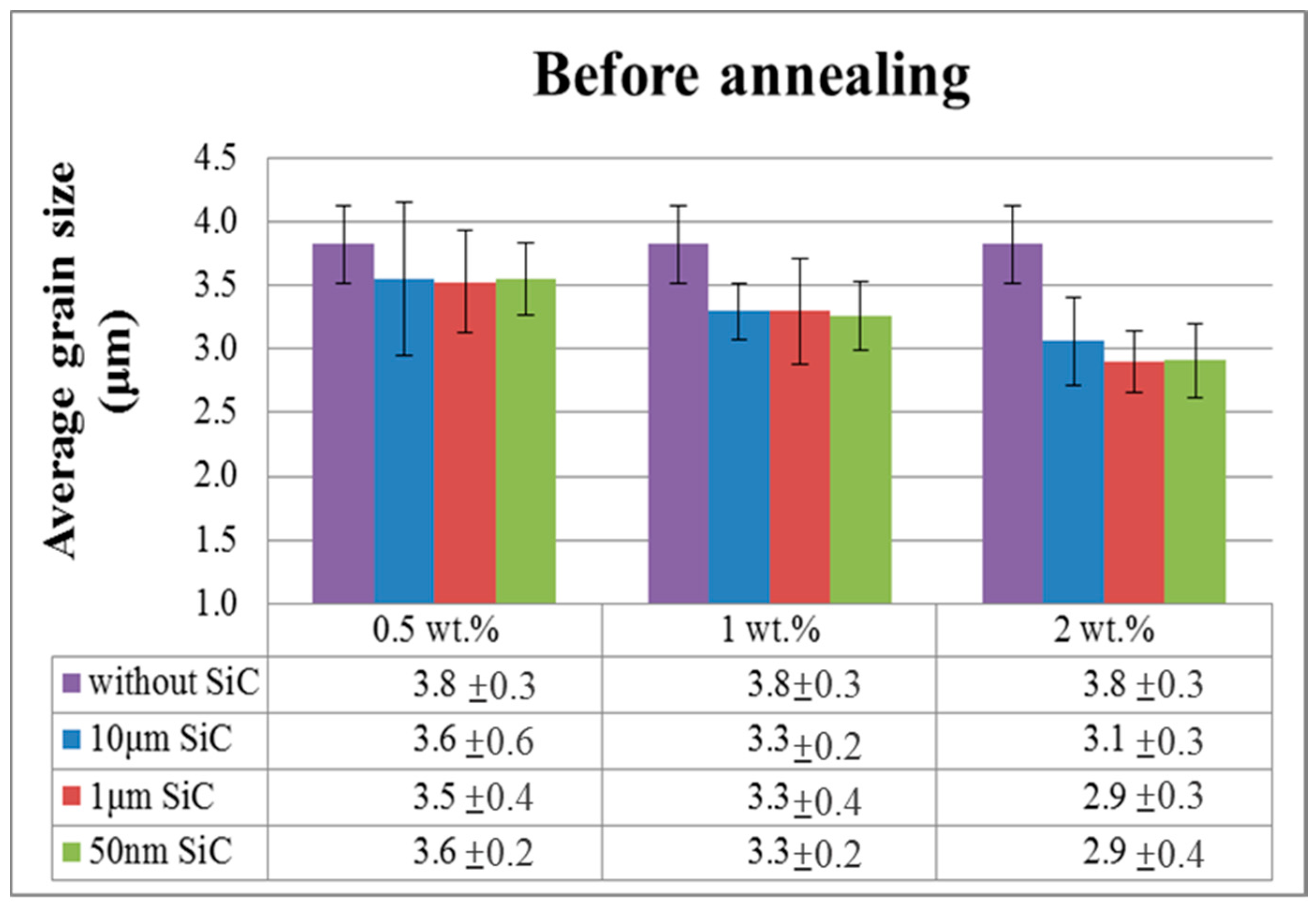

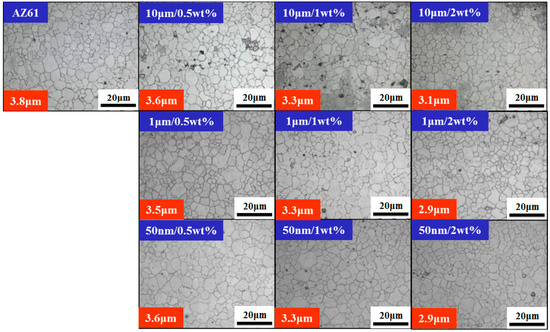

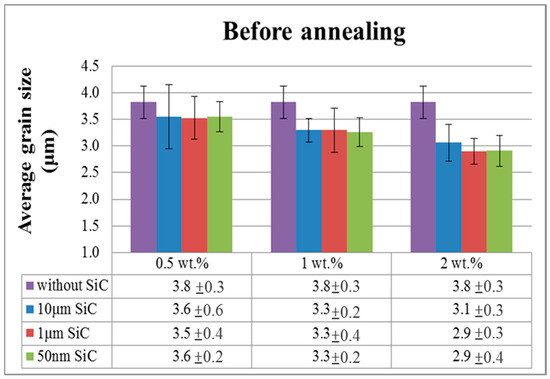

Figure 10 presents the metallography of the AZ61/SiCp MMC extruded plates before annealing with the addition of different SiCp particle percentages and sizes. The average grain size was calculated through the linear intercept method (Figure 11). Compared with the average grain size of cast AZ61/SiCp MMCs, which is approximately 30–80 μm, the average grain size of the AZ61/SiCp MMC extruded plates was approximately 3–4 μm, which is substantially smaller. Overall, the average grain size decreased as the addition of SiCp particles increased and as the size of the SiCp particles decreased. The minimum average grain size obtained for the AZ61/SiCp MMC extruded plates was 2.9 μm, which diminished 24% compared with the raw AZ61 extruded plate. The results indicate that adding SiCp restricts grain growth during the extrusion process.

Figure 10.

Metallography of the AZ61/SiCp MMCs extruded plates before annealing.

Figure 11.

Average grain size of the AZ61/SiCp MMC extruded plates before annealing.

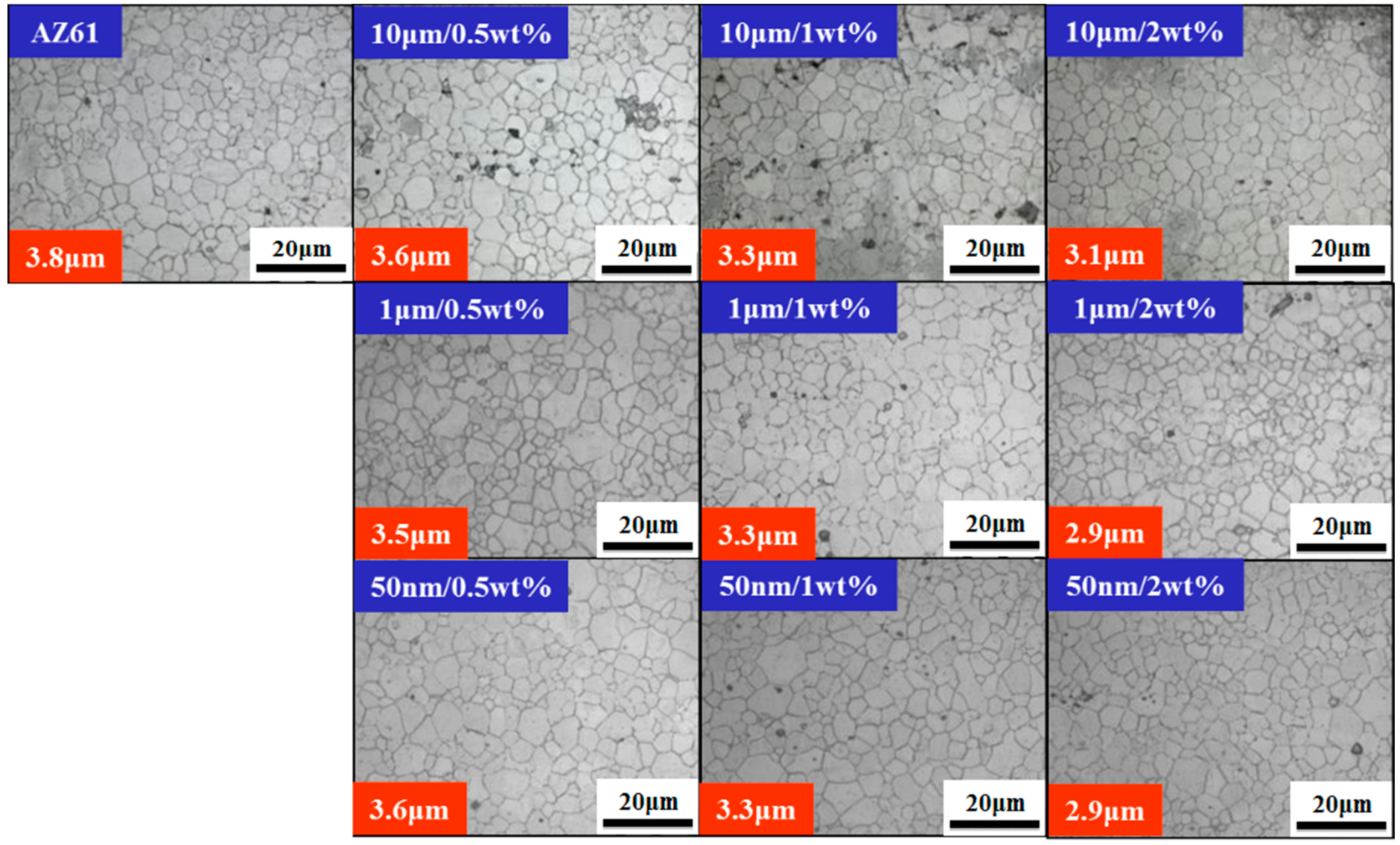

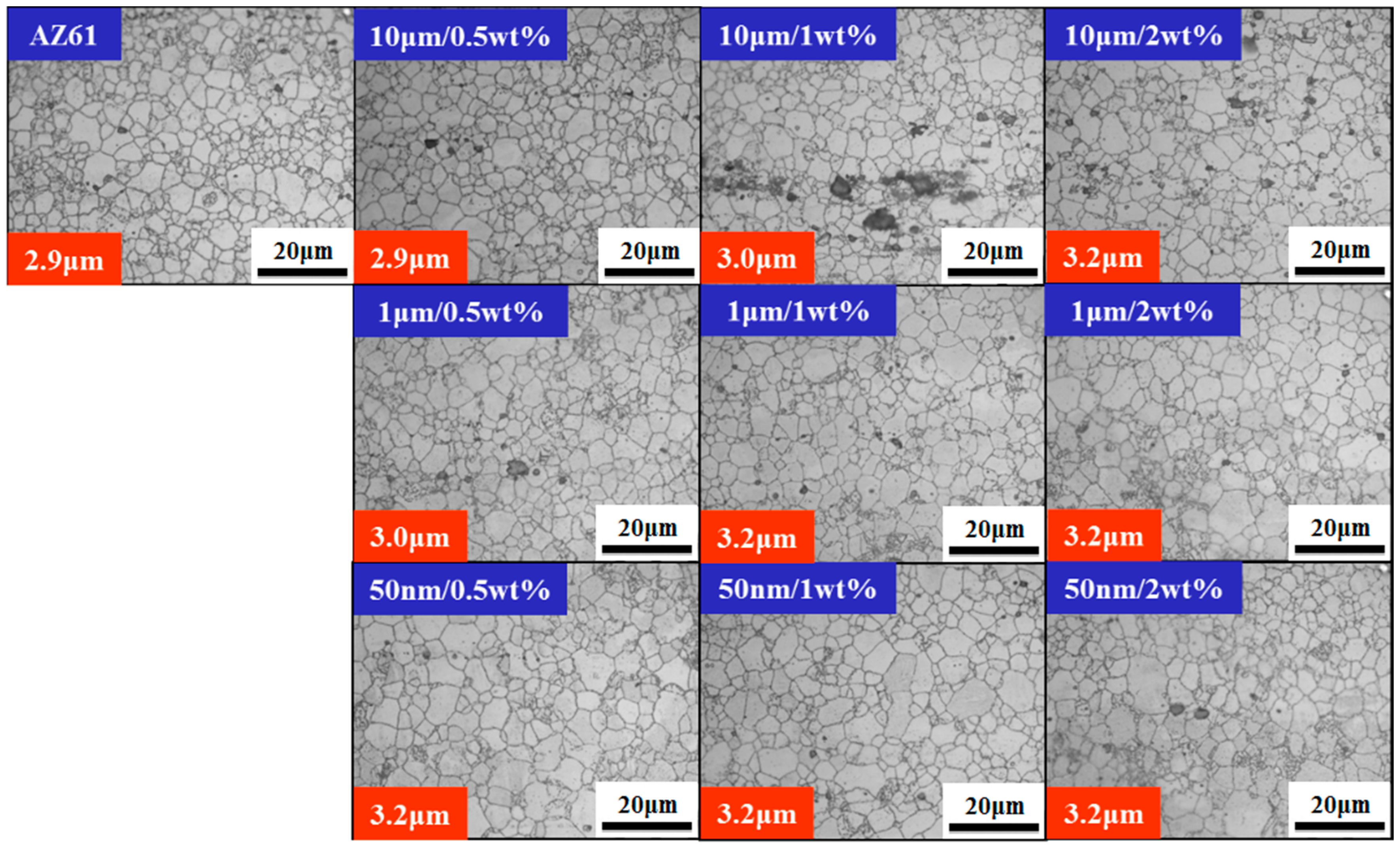

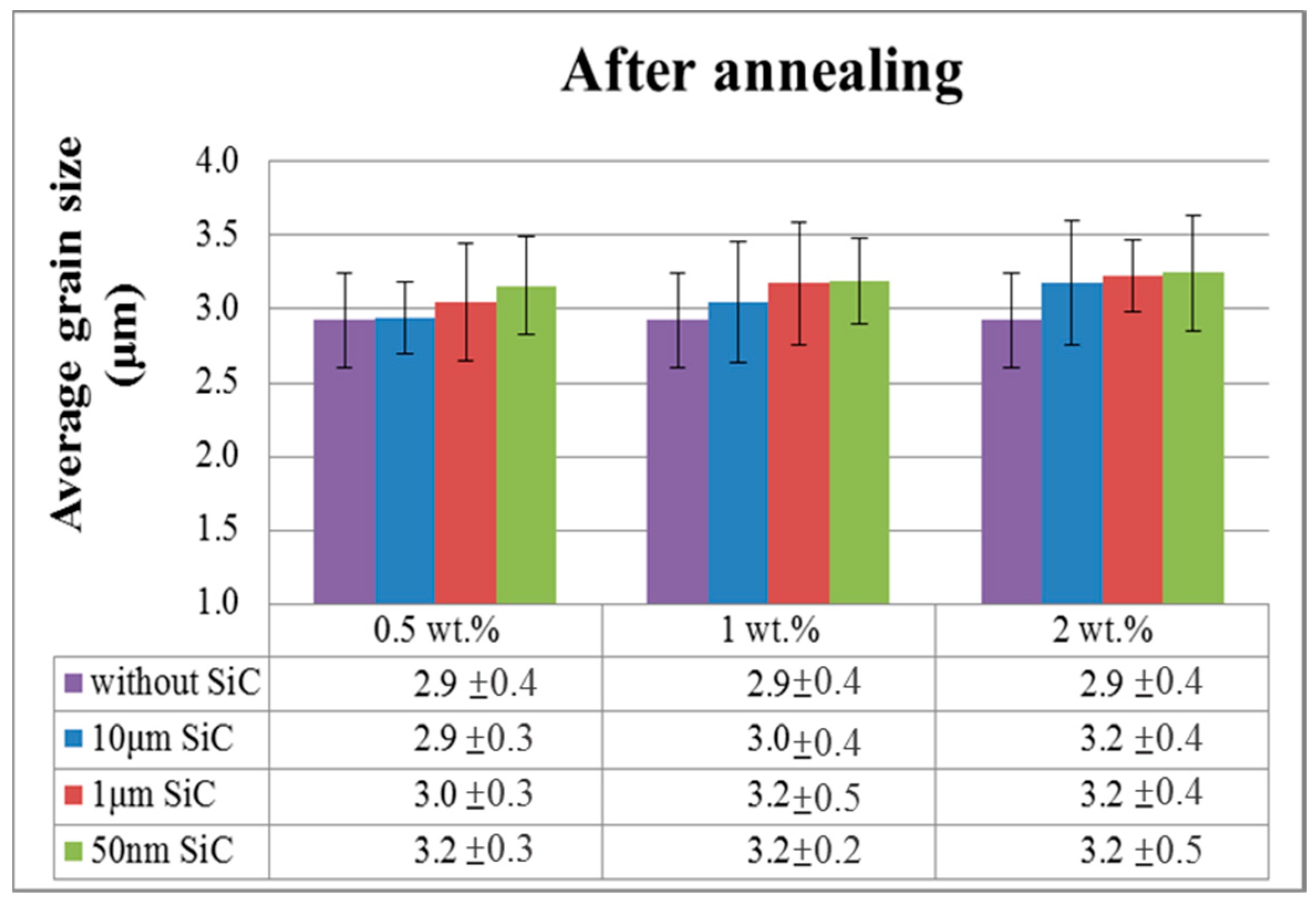

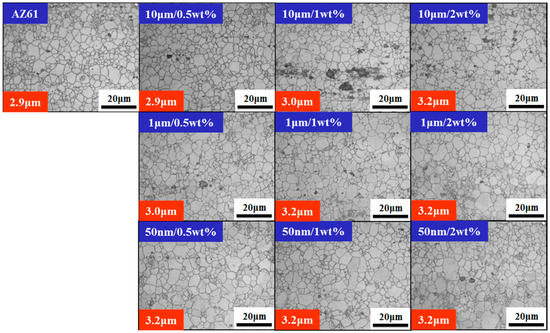

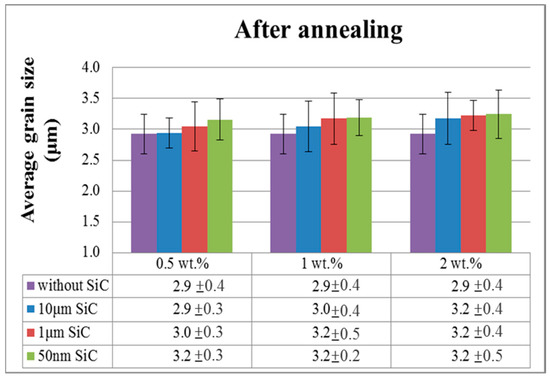

Figure 12 and Figure 13 present the metallography and average grain size of the AZ61/SiCp MMC extruded plates after annealing with different percentages and sizes of SiCp particles, respectively. Prior to annealing, the average grain size of the AZ61/SiCp MMC extruded plates decreased as the percentage of added SiCp particles increased. Using reinforcement particles larger than 1 µm can initiate particle-stimulated dynamic recrystallization (particle-stimulated nucleation, PSN), and adding particles smaller than 1 µm mainly provides a grain boundary pinning mechanism that contributes to matrix grain refinement. The average grain size of the AZ61/SiCp MMC extruded plates after annealing was approximately 2.9–3.2 μm, which suggests that adding SiCp particles has no obvious effect on average grain size. Compared with the average grain size of the AZ61/SiCp MMCs before annealing, the average grain size of all samples after annealing decreased, except for the MMC with the addition of 2 wt % of SiCp. This occurred because the energy supplied by the annealing process could make the high strain zone grain results the static recrystallization. The situation is different for the average grain size of the AZ61/SiCp MMCs after annealing, where the average grain size increased as SiCp particles were added because the SiCp particles could not be the nucleation site in the annealing process. SiCp addition can restrict grain growth, but SiCp particles cannot be used directly as the nucleation site of an α-Mg alloy; thus, adding a strengthening phase reduces the effective nucleation site.

Figure 12.

Metallography of the AZ61/SiCp MMC extruded plates after annealing.

Figure 13.

Average grain size of the AZ61/SiCp MMC extruded plates after annealing.

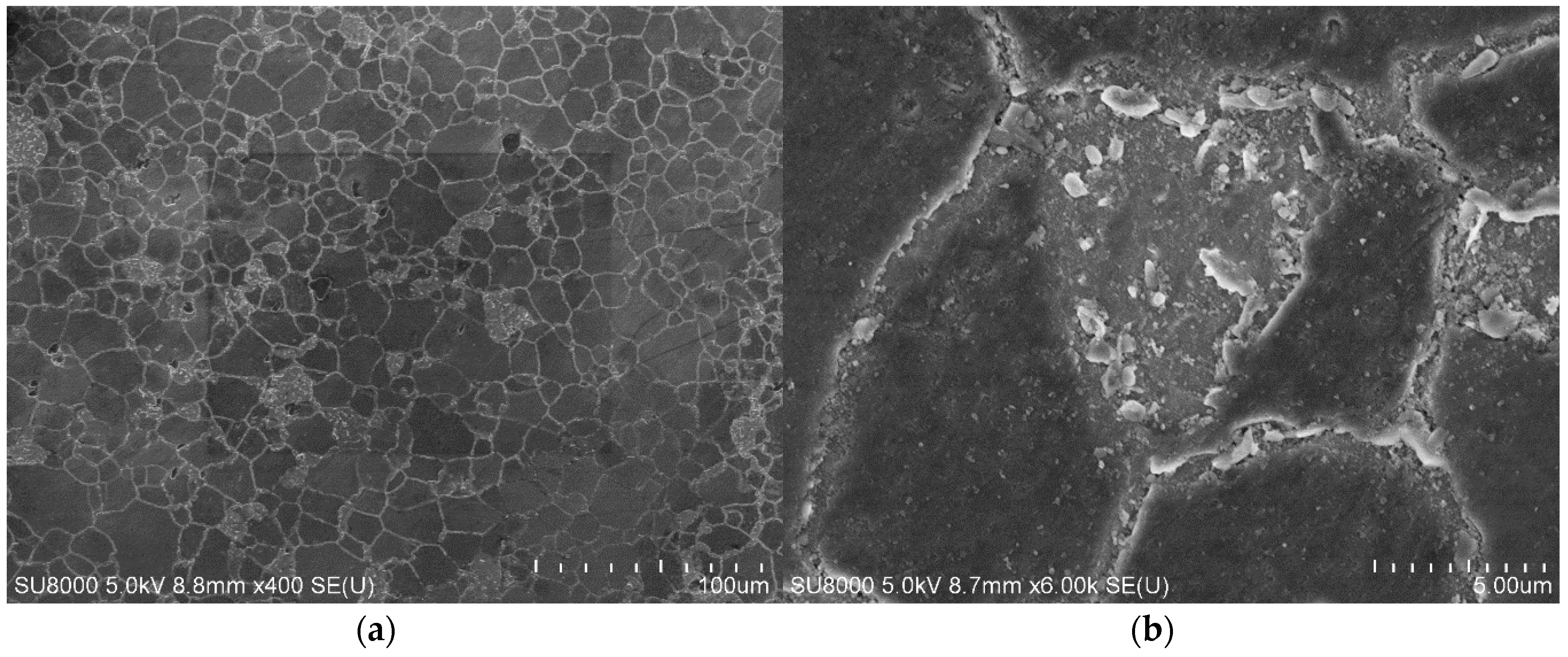

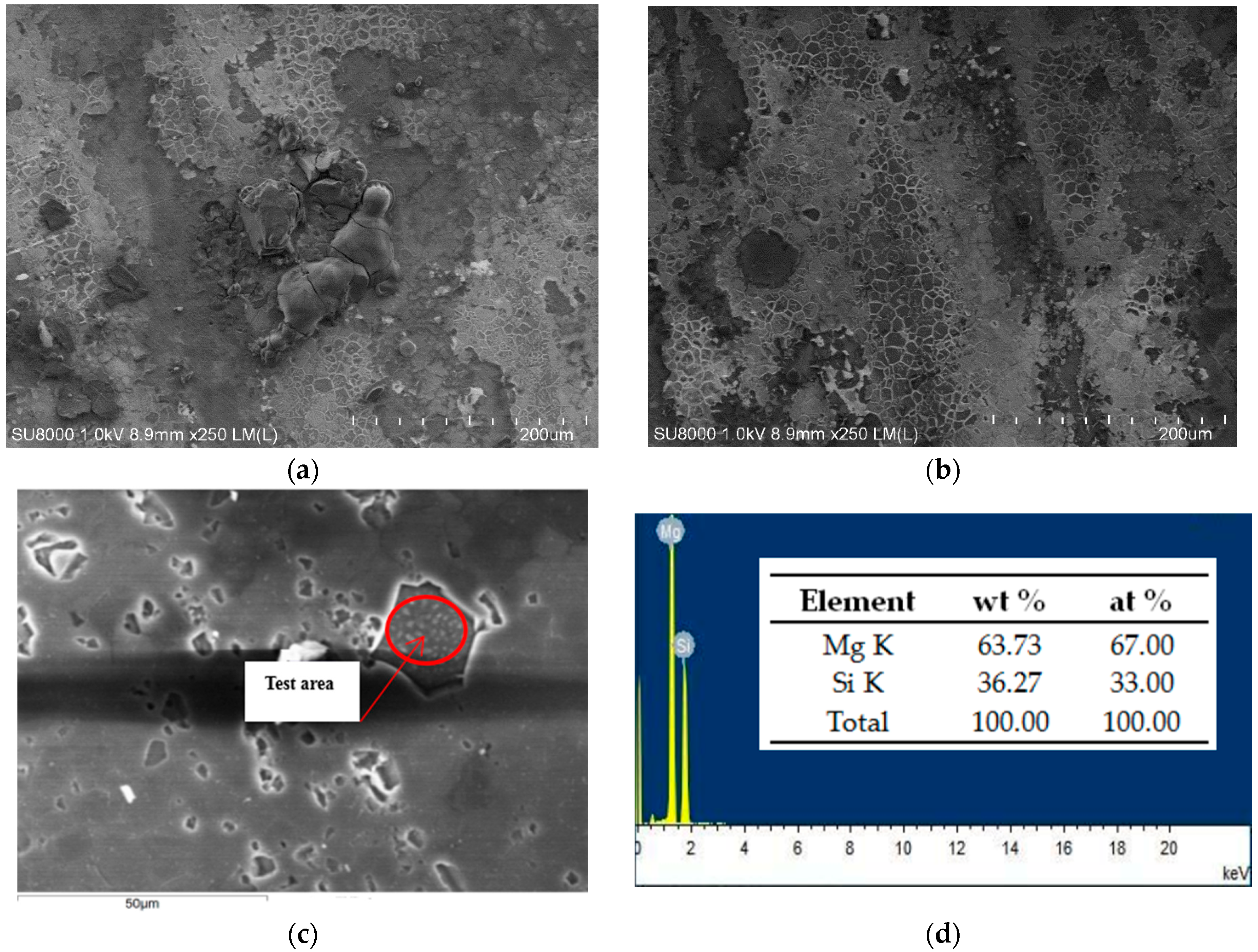

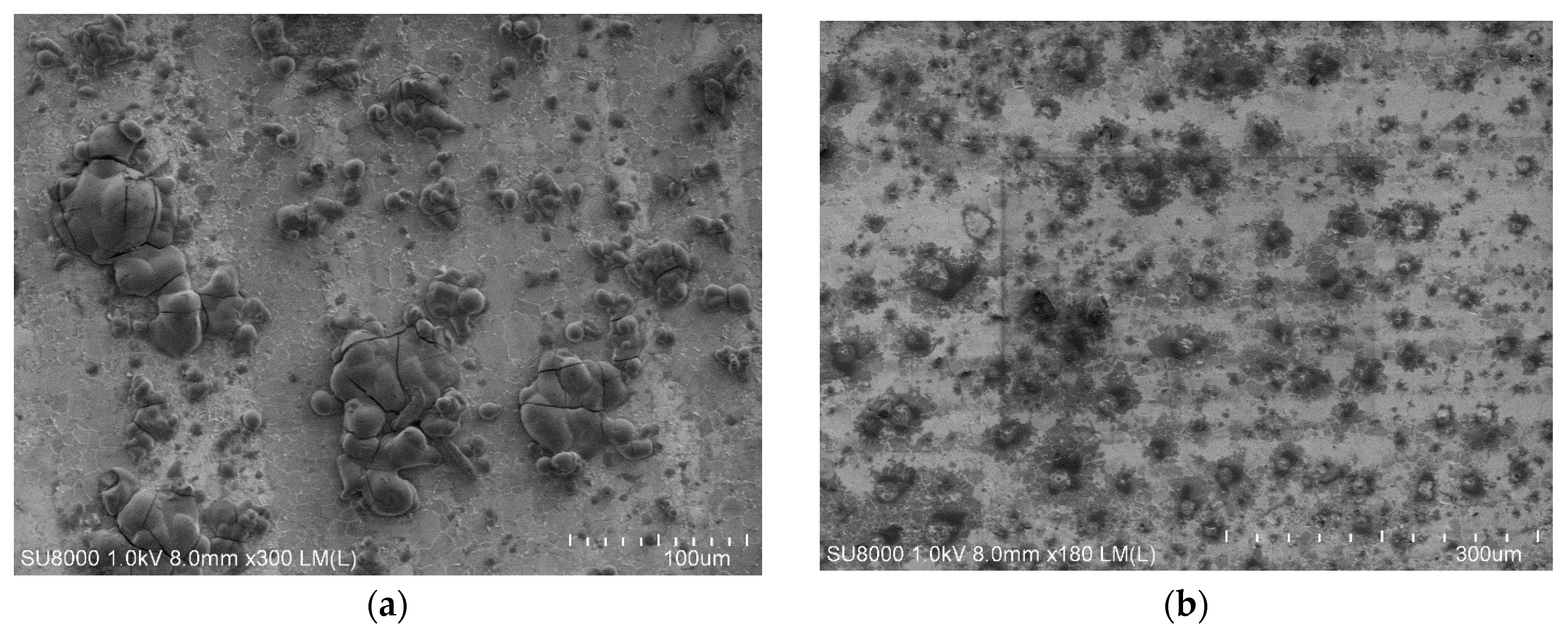

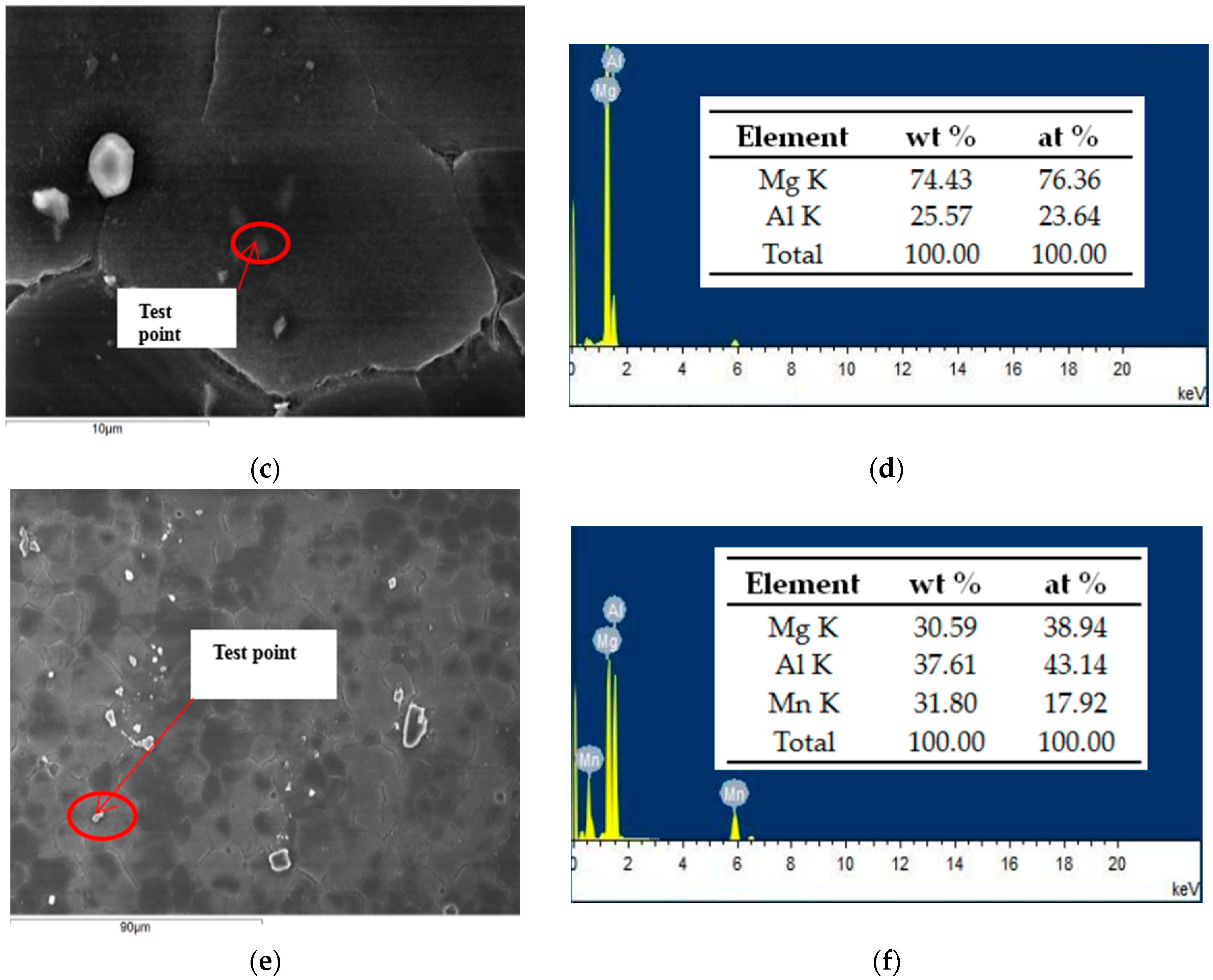

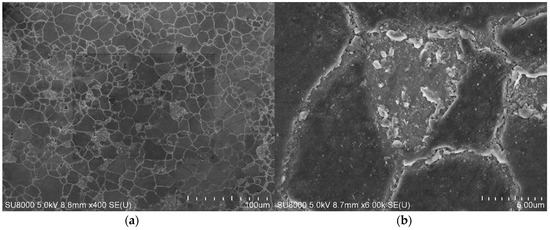

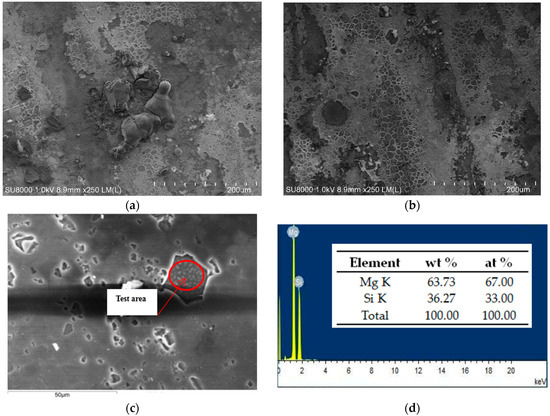

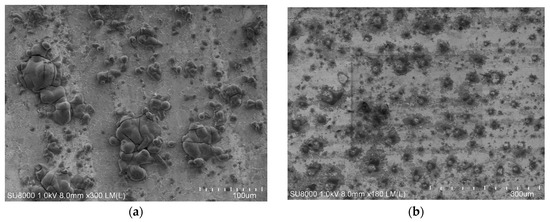

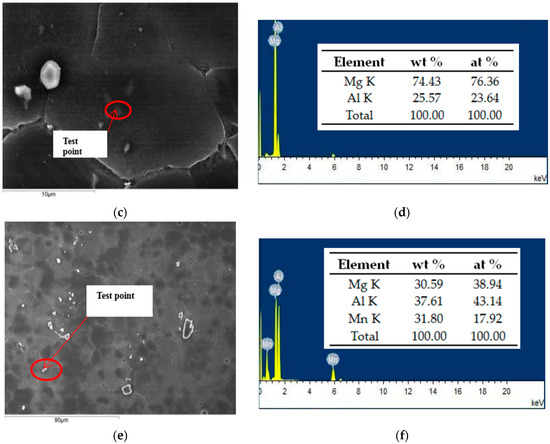

Figure 14 shows the images of the as-cast AZ61 Mg alloy; it mainly contains Mg17Al12 and α-Mg. The particles of SiCp were added to prepare the AZ61/SiCp MMC extruded plate before annealing (Figure 15). The existence of the SiCp particles was confirmed through EDX analysis, which revealed that the distribution was nonuniform. Compared with the as-cast AZ61 Mg alloy, SiC had a higher density and surface tension, which can cause the sinking and floating of SiC. Moreover, harder Mg2Si produced through extrusion was observed in the matrix of the AZ61/SiCp MMCs prior to annealing, which can increase the hardness and strength of the MMCs compared with the as-cast AZ61 Mg alloy. Figure 16 presents the SEM images and EDX results of the AZ61/SiCp MMC extruded plates after annealing. These results reveal that the existence of the precipitation of Al-Mn and β phase Mg17Al12 is the principal reason why the mechanical properties changed (the yield strength and ultimate strength slightly decreased as SiCp addition increased after annealing, but their ductility declined).

Figure 14.

SEM images (a,b) of the dendrites on the edge of the as-cast AZ61 magnesium alloy with different magnifications, respectively.

Figure 15.

(a,b) SEM images of the AZ61/SiCp MMCs extruded plates before annealing (10 μm SiC with 5 wt %) with different magnifications; (c) Test area for EDX analysis of the AZ61/SiCp MMCs extruded plates before annealing (10 μm SiC with 5 wt %); (d) Element results from EDX analysis of the AZ61/SiCp MMCs extruded plates before annealing (10 μm SiC with 5 wt %).

Figure 16.

(a,b) SEM images of the AZ61/SiCp MMC extruded plates after annealing (10 μm SiC with 5 wt %) with different magnifications; (c,e) Test point for EDX analysis of the AZ61/SiCp MMC extruded plates after annealing (10 μm SiC with 5 wt %); (d,f) Element results from EDX analysis of the AZ61/SiCp MMC extruded plates after annealing (10 μm SiC with 5 wt %).

3.3. Comparison of the Mechanical Measurements of Mg MMCs

The mechanical properties of the present composites and other composites are listed in Table 2. The present study’s AZ61 MMCs with submicron SiCp and nano SiCp had higher ultimate tensile strength, but a reduced hardness compared with those of our previous work [34]. Additionally, the SiC/AZ61 MMCs in the present study had a similar hardness compared with that of Hong et al. [35] but exhibited lower hardness compared with that of Zulkoffli et al. [36] because of their sintering process. Casted AZ61 with 3, 6, and 18 vol % 10 μm SiCp AZ61 MMCs studied by Hu et al. [37] exhibited a strong yield strength of 168–186 MPa, but considerably smaller elongation of 1.7–4.5%, than did those of the present study. Casted AZ61 with 3, 6, and 9 vol % 10 μm SiCp AZ61 MMCs studied by Yan et al. [38] were very hard (79–115 HV) but had no other enhanced mechanical properties. Consequently, the SiC/AZ61 MMCs in the present study exhibited more complete mechanical property results than did those of other studies.

Table 2.

Mechanical properties of the synthesized composites in the present study compared with those in other studies.

4. Conclusions

The effect of reinforcement size and quantity (wt %) of SiCp on the AZ61 alloy synthesized through the stir-casting melting method followed by hot extrusion and annealing was investigated in this study. Our conclusions are as follows:

- The mechanical properties of the annealed SiCp-free AZ61 alloy plate are better than those of the unannealed SiCp-free AZ61 alloy plate.

- Both the annealed and unannealed AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates exhibited greater strength, hardness, and ductility that did the SiCp-free (i.e., AZ61) MMC Mg alloy plate.

- The annealed AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates exhibited improvements in hardness and strength, but ductility slightly decreased because of the precipitation of the β phase.

- Adding submicron SiCp and nano SiCp particles to AZ61 during processing resulted in the advantages of strengthening the mechanical properties and increasing ductility.

- Annealing can improve the ductility and formability of Mg alloys and Mg MMCs with micron SiCp, but it weakens those properties in Mg MMCs with submicron SiCp and nano SiCp.

- The SiC/AZ61 MMCs in the present study exhibited more complete mechanical property results compared with other studies.

Acknowledgments

The present study was supported by the National Natural Science Foundation of China (31300488) and Fujian Agriculture and Forestry University Fund for Distinguished Young Scholars (xjq201420). This manuscript was edited by Wallace Academic Editing.

Author Contributions

Song-Jeng Huang and Weigang Zhao conceived and designed the experiments; Yi-Jhang Wu and Cheng-Wei Kang performed the experiments; Song-Jeng Huang, Weigang Zhao, Yi-Jhang Wu, and Cheng-Wei Kang analyzed the data; Song-Jeng Huang and Weigang Zhao contributed reagents/materials/analysis tools; and Song-Jeng Huang and Weigang Zhao wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Rokhlin, L.L. The 7th International conference Magnesium alloys and their applications. Metalloved. I Term. Obrab. Met. 2008, 3, 22–23. [Google Scholar]

- Schindler, S.; Mergheim, J.; Zimmermann, M.; Aurich, J.C.; Steinmann, P. Numerical homogenization of elastic and thermal material properties for metal matrix composites (mmc). Contin. Mech. Thermodyn. 2017, 29, 1–25. [Google Scholar] [CrossRef]

- Abbott, T.B.; Rienass, G.; Zhen, Z.S. Property assessment of magnesium alloys for powertrain applications. VDI Ber. 2012, 2158, 321–332. [Google Scholar]

- Wang, M.; Xiao, D.H.; Liu, W.S. Effect of Si addition on microstructure and properties of magnesium alloys with high Al and Zn contents. Vacuum 2017, 141, 144–151. [Google Scholar] [CrossRef]

- Venkatachalam, G.; Kumaravel, A. Mechanical Behaviour of Aluminium Alloy Reinforced With SiC/Fly Ash/Basalt Composite for Brake Rotor. Polym. Polym. Compos. 2017, 25, 203–208. [Google Scholar]

- Dai, J.H.; Jiang, B.; Peng, C.; Pan, F.S. Effect of mn additions on diffusion behavior of Fe in molten magnesium alloys by solid-liquid diffusion couples. J. Alloys Compd. 2017, 710, 260–266. [Google Scholar] [CrossRef]

- Cui, S.; Wu, X.; Liu, R.; Teng, X.; Leng, J.; Geng, H. Effects of Te addition on microstructure and mechanical properties of AZ91 magnesium alloy. Mater. Res. Express 2017, 4, 016503. [Google Scholar] [CrossRef]

- Volkova, E.F. Modern magnesium-base deformable alloys and composite materials (a review). Met. Sci. Heat Treat. 2006, 48, 473–478. [Google Scholar] [CrossRef]

- Fridlyander, I.N. Modern aluminum and magnesium alloys and composite materials based on them. Met. Sci. Heat. Treat. 2002, 44, 292–296. [Google Scholar] [CrossRef]

- Si, C.; Tang, X.; Zhang, X.; Wang, J.; Wu, W. Microstructure and mechanical properties of particle reinforced metal matrix composites prepared by gas-solid two-phase atomization and deposition technology. Mater. Lett. 2017, 201, 78–81. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Grishina, O.I.; Serpova, V.M. Aspects of mechanical properties of metal matrix composites reinforced with continuous unidirectional fibers (review). Trudy VIAM 2017. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Akbari, M.K.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part A Appl. Sci. Manuf. 2016, 92, 70–96. [Google Scholar] [CrossRef]

- Yong, H.P.; Bang, J.; Oak, J.J.; Lee, Y.C.; Jung, K.H. The effect of the addition of Ti metal fiber and Al-Mg alloy binder on the mechanical properties of Al-Si/SiCp metal matrix composites fabricated by powder metallurgy. J. Korean Inst. Met. Mater. 2016, 54, 400–408. [Google Scholar] [CrossRef]

- Iqbal, A.A.; Arai, Y.; Araki, W. Fatigue crack growth mechanism in cast hybrid metal matrix composite reinforced with SiC particles and Al2O3 whiskers. Trans. Nonferrous Met. Soc. China 2014, 241, S1–S13. [Google Scholar] [CrossRef]

- Li, A.B.; Geng, L.; Meng, Q.Y.; Zhang, J. Simulation of the large compressive deformation of metal matrix composites with misaligned whiskers. Mater. Sci. Eng. A 2003, 358, 324–333. [Google Scholar] [CrossRef]

- Huang, C.C. Effect of Reinforcement Size on the Mechanical Properties of as Cast and Extruded AZ61/SiCp Magnesium Matrix Composites. Master’s Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 2013. [Google Scholar]

- Chen, T.J.; Jiang, X.D.; Ma, Y.; Li, Y.D.; Hao, Y. Grain refinement of AZ91D magnesium alloy by SiC. J. Alloys Compd. 2010, 496, 218–225. [Google Scholar] [CrossRef]

- Chua, B.W.; Lu, L.; Lai, M.O. Influence of SiC particles on mechanical properties of Mg based composite. Compos. Struct. 1999, 47, 595–601. [Google Scholar] [CrossRef]

- Zhang, B.H.; Zhang, Z.M. Influence of homogenizing on mechanical properties of as-cast AZ31 magnesium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 439–443. [Google Scholar] [CrossRef]

- Li, J.Y.; Xie, J.X.; Jin, J.B.; Wang, Z.X. Microstructural evolution of AZ91 magnesium alloy during extrusion and heat treatment. Trans. Nonferrous Met. Soc. China 2012, 22, 1028–1034. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Z.; Shu, D.; Zhao, Z. Microstructure and mechanical properties of AZ91D magnesium alloy prepared by compound extrusion. Mater. Sci. Eng. A 2011, 528, 3930–3934. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Effect of length scale of Al2O3 particulates on microstructural and tensile properties of elemental Mg. Mater. Sci. Eng. A 2006, 425, 22–27. [Google Scholar] [CrossRef]

- Agrawal, P.; Sun, C.T. Fracture in metal—Ceramic composites. Compos. Sci. Technol. 2004, 64, 1167–1178. [Google Scholar] [CrossRef]

- Psakhie, S.; Ovcharenko, V.; Yu, B.; Shilko, E.; Astafurov, S.; Ivanov, Y.; Byeli, A.; Mokhovikov, A. Influence of Features of Interphase Boundaries on Mechanical Properties and Fracture Pattern in Metal-Ceramic Composites. J. Mater. Sci. Technol. 2013, 29, 1025–1034. [Google Scholar] [CrossRef]

- Ma, G.; Han, G.; Liu, X. Grain refining efficiency of a new Al-1B-0.6C master alloy on AZ63 magnesium alloy. J. Alloys Compd. 2010, 491, 165–169. [Google Scholar]

- Habibnejad-Korayem, M.; Mahmudia, R.; Pooleb, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Huang, S.J.; Lin, P.C. Grain refinement of AM60/Al2O3p Megnesium Metal-matrix Composites Processed by ECAE. Kov. Mater. Met. Mater. 2013, 51, 357–366. [Google Scholar]

- Hassan, S.F.; Gupta, M. Development of high performance magnesium nanocomposites using solidification processing route. Mater. Sci. Technol. 2004, 20, 1383–1388. [Google Scholar] [CrossRef]

- Besterci, M.; Huang, S.-J.; Sülleiová, K.; Balloková, B.; Velgosová, O. Fracture analysis of AZ61-F magnesium composite materials at quasi-superplastic state. Kov. Mater. 2017, 55, 217–221. [Google Scholar]

- Wu, X.; Yang, X.; Ma, J.; Huo, Q.; Wang, J.; Sun, H. Enhanced stretch formability and mechanical properties of a magnesium alloy processed by cold forging and subsequent annealing. Mater. Des. 2013, 43, 206–212. [Google Scholar] [CrossRef]

- Miao, Q.; Hu, L.; Wang, G.; Wang, E. Fabrication of excellent mechanical properties AZ31 magnesium alloy sheets by conventional rolling and subsequent annealing. Mater. Sci. Eng. A 2011, 528, 6694–6701. [Google Scholar] [CrossRef]

- Sun, H.F.; Li, C.J.; Yang, X.; Fang, W.B. Microstructures and mechanical properties of pure magnesium bars by high ratio extrusion and its subsequent annealing treatment. Trans. Nonferrous Met. Soc. China 2012, 22, 445–449. [Google Scholar] [CrossRef]

- Huang, S.J.; Hwang, Y.M.; Huang, Y.S. Grain Refinement of AZ61/SiCp Magnesium Matrix Composites for Tubes Extruded by Hot Extrusion Processes. Key Eng. Mater. 2013, 528, 135–143. [Google Scholar] [CrossRef]

- Hong, Y.; Xiaowu, H.; Qiao, N.; Lei, C. Aging behavior of nano-SiCp reinforced AZ61 magnesium matrix composites. Res. Dev. 2011, 8, 269–273. [Google Scholar]

- Zulkoffli, Z.; Syarif, J.; Sajuri, Z. Fabrication of AZ61/SIC composites by powder metallurgy process. Int. J. Mech. Mater. Eng. 1970, 4, 156–159. [Google Scholar]

- Hu, Q.; Jie, X.P.; Yan, H.; Zhang, F.Y.; Chen, G.X. Mechanical properties and damping capacity of AZ61 magnesium alloy matrix composites with SiC particulates. Forg. Stamp. Technol. 2008, 33, 106–109. [Google Scholar]

- Yan, H.; Fu, M.F.; Zhang, F.Y.; Chen, G.X. Research on properties of SiCp/AZ61 magnesium matrix composites in fabrication processes. Mater. Sci. Forum 2007, 561, 945–948. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).