Microstructural, Mechanical, Texture and Residual Stress Characterizations of X52 Pipeline Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Microstructural Analysis

2.2.1. Optical Analysis

2.2.2. Electron Back-Scatter Diffraction (EBSD) Measurements

2.2.3. Hardness Measurements

2.2.4. Residual Stress Measurements

2.2.5. Texture Measurements

3. Results

3.1. Microstructural Analysis

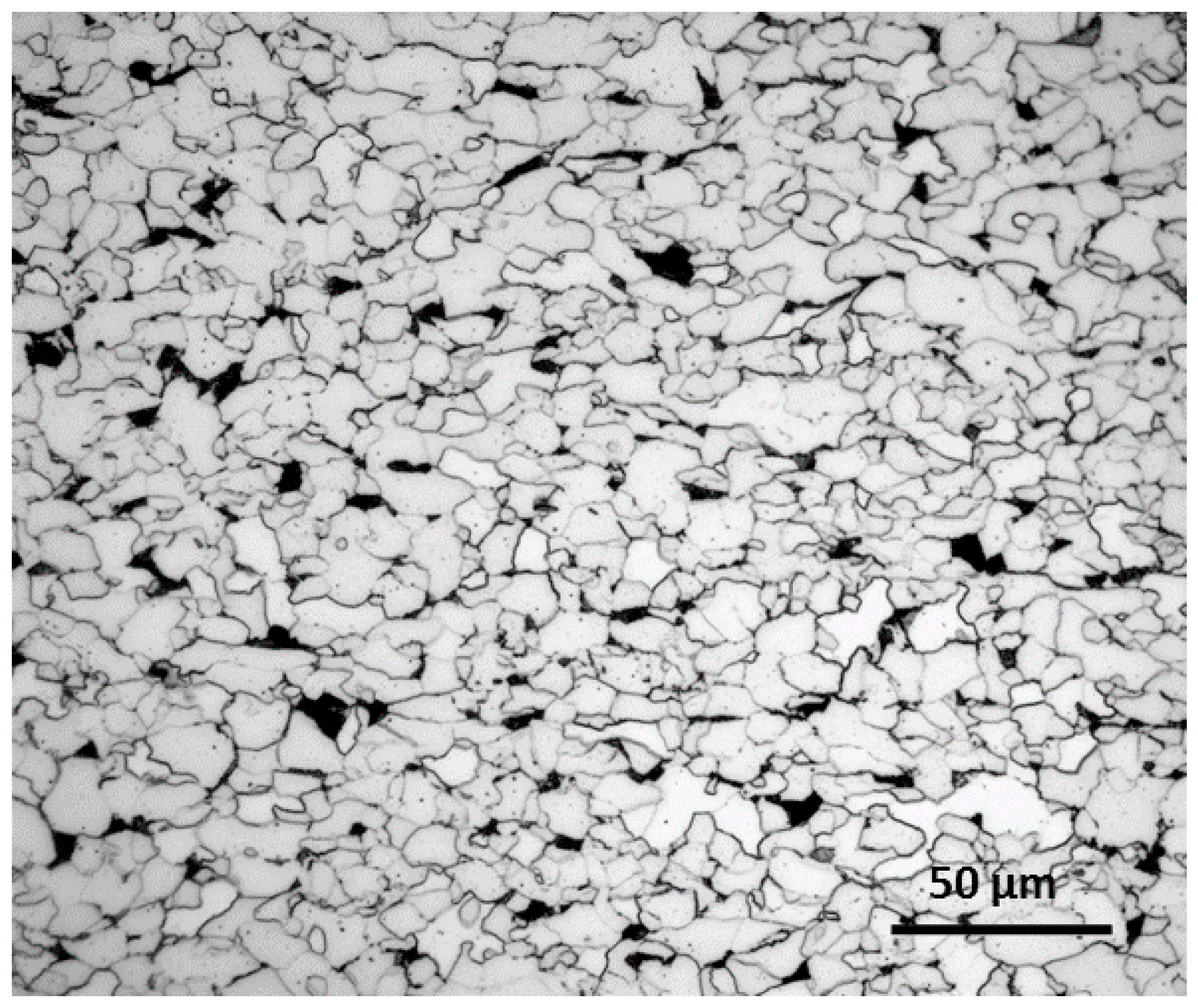

3.1.1. Optical Analysis

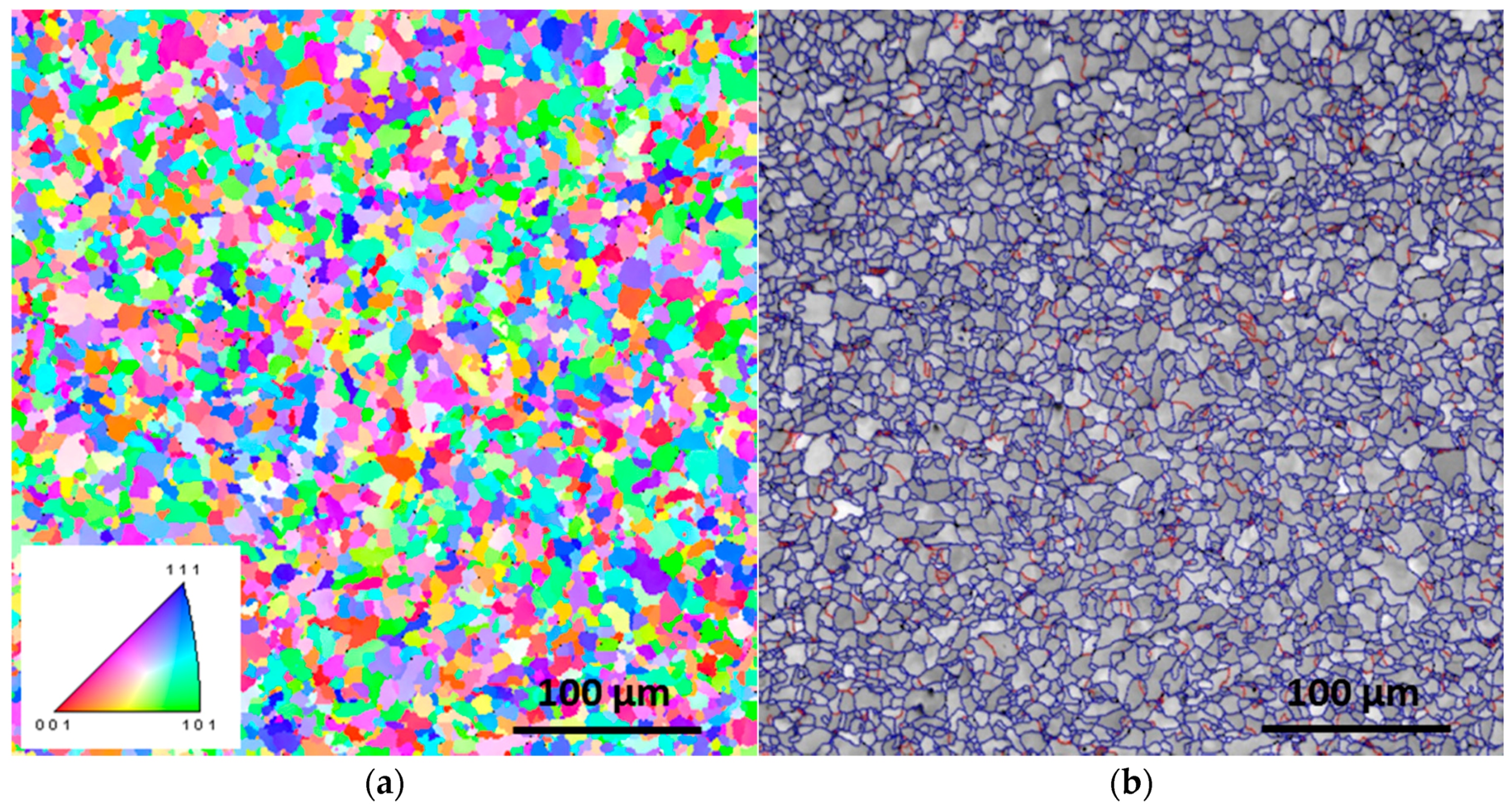

3.1.2. EBSD Measurements

3.2. Mechanical Properties

3.2.1. Tensile Test Results

3.2.2. Hardness Measurements and Determination of Dislocation Density

3.3. Neutron Diffraction Measurements

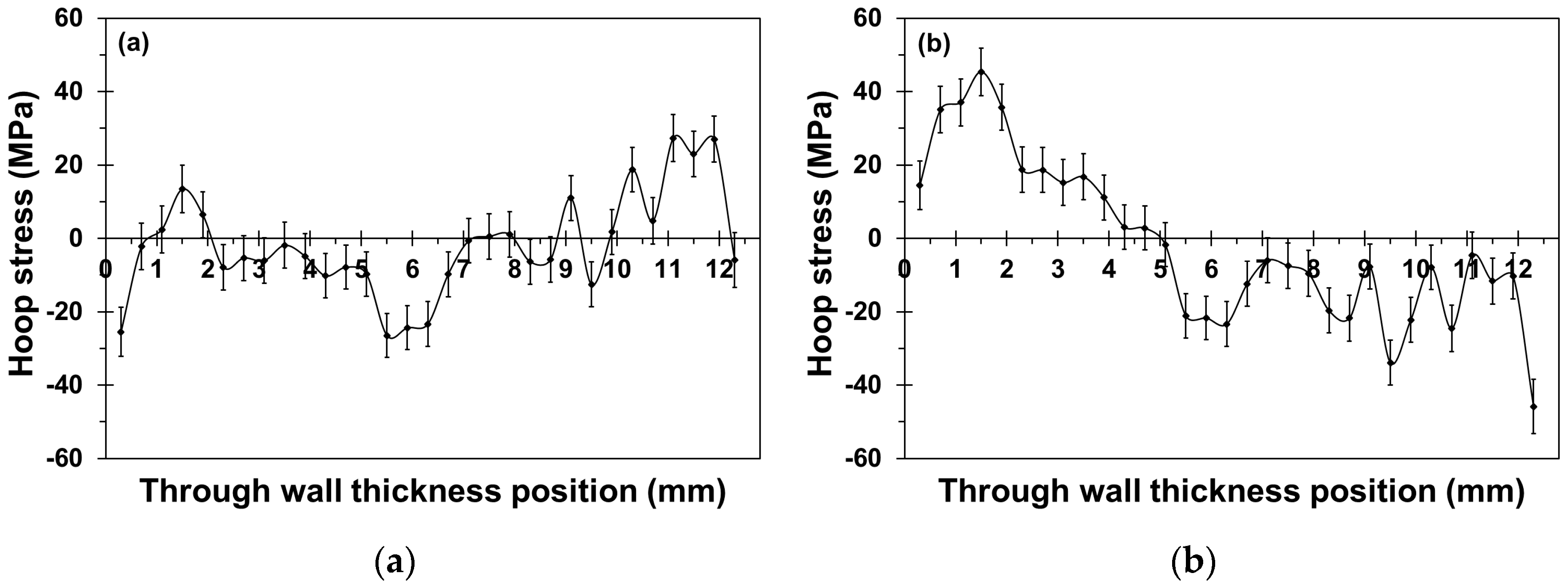

3.3.1. Residual Stress Measurements

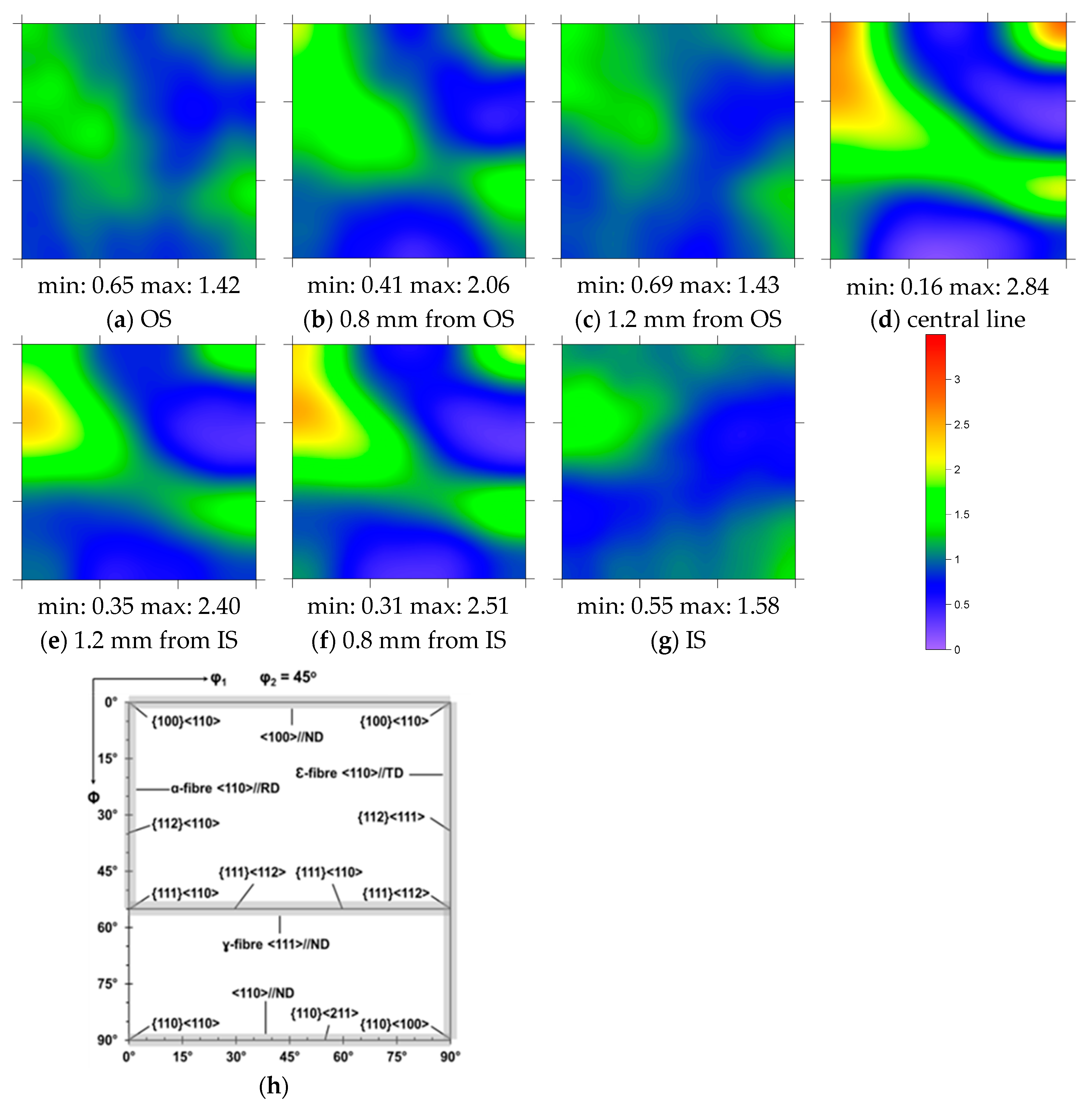

3.3.2. Texture Measurements

4. Discussion

4.1. Strengthening Mechanisms

4.1.1. Solid Solution Strengthening

4.1.2. Grain Size Strengthening

4.1.3. Dislocation Strengthening

4.1.4. Precipitation Strengthening

4.2. Microstructure and Stresses Implications in Stress Corrosion Cracking Susceptibility

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Costin, W.L.; Lavigne, O.; Kotousov, A. A study on the relationship between microstructure and mechanical properties of acicular ferrite and upper bainite. Mater. Sci. Eng. A 2016, 663, 193–203. [Google Scholar] [CrossRef]

- Costin, W.L.; Lavigne, O.; Kotousov, A.; Ghomashchi, R.; Linton, V. Investigation of hydrogen assisted cracking in acicular ferrite using site-specific micro-fracture tests. Mater. Sci. Eng. A 2016, 651, 859–868. [Google Scholar] [CrossRef]

- Fernandes, T.R.C.; Chen, F.; Da Graça Carvalho, M. “HySociety” in support of European hydrogen projects and EC policy. Int. J. Hydrog. Energy 2005, 30, 239–245. [Google Scholar] [CrossRef]

- Mulder, G.; Hetland, J.; Lenaers, G. Towards a sustainable hydrogen economy: Hydrogen pathways and infrastructure. Int. J. Hydrogen Energy 2007, 32, 1324–1331. [Google Scholar] [CrossRef]

- Lavigne, O.; Gamboa, E.; Costin, W.; Law, M.; Luzin, V.; Linton, V. Microstructural and mechanical factors influencing high pH stress corrosion cracking susceptibility of low carbon line pipe steel. Eng. Fail. Anal. 2014, 45, 283–291. [Google Scholar] [CrossRef]

- Carretero Olalla, V.; Bliznuk, V.; Sanchez, N.; Thibaux, P.; Kestens, L.A.I.; Petrov, R.H. Analysis of the strengthening mechanisms in pipeline steels as a function of the hot rolling parameters. Mater. Sci. Eng. A 2014, 604, 46–56. [Google Scholar] [CrossRef]

- Faraji, G.; Mashhadi, M.M.; Bushroa, A.R.; Babaei, A. TEM analysis and determination of dislocation densities in nanostructured copper tube produced via parallel tubular channel angular pressing process. Mater. Sci. Eng. A 2013, 563, 193–198. [Google Scholar] [CrossRef]

- Graça, S.; Colaço, R.; Carvalho, P.A.; Vilar, R. Determination of dislocation density from hardness measurements in metals. Mater. Lett. 2008, 62, 3812–3814. [Google Scholar] [CrossRef]

- Alipooramirabad, H.; Paradowska, A.M.; Ghomashchi, R.; Kotousov, A.; Hoye, N. Prediction of welding stresses in WIC test and its application in pipelines. Mater. Sci. Technol. 2016, 32, 1462–1470. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Arafin, M.A.; Szpunar, J.A. A new understanding of intergranular stress corrosion cracking resistance of pipeline steel through grain boundary character and crystallographic texture studies. Corros. Sci. 2009, 51, 119–128. [Google Scholar] [CrossRef]

- Kamikawa, N.; Sato, K.; Miyamoto, G.; Murayama, M.; Sekido, N.; Tsuzaki, K.; Furuhara, T. Stress-strain behavior of ferrite and bainite with nano-precipitation in low carbon steels. Acta Mater. 2015, 83, 383–396. [Google Scholar] [CrossRef]

- Liu, G. Designing with Carbon-, Low-, and Medium-alloy Steels. In Handbook of Mechanical Alloy Design; Totten, G.E., Xie, L., Funatani, K., Eds.; Taylor & Francis Inc., Marcel Dekker Inc.: New York, NY, USA, 2004; pp. 73–89. [Google Scholar]

- Pickering, F.B. Physical Metallurgy and the Design of Steels; Applied Science Publishers: London, UK, 1978; p. 63. [Google Scholar]

- Bhadeshia, H.K.D.H. Models for the Elementary Mechanical Properties of Steel Welds; Institute of Materials: London, UK, 1997; pp. 229–284. [Google Scholar]

- Altuna, M.A.; Iza-Mendia, A.; Gutierrez, I. Precipitation strengthening produced by the formation in ferrite of Nb carbides. In Proceedings of the 3rd International Conference on Thermomechanical Processing of Steels, Padova, Italia, 10–12 September 2008. [Google Scholar]

- Gladshtein, L.I.; Larionova, N.P.; Belyaev, B.F. Effect of ferrite-pearlite microstructure on structural steel properties. Metallurgist 2012, 56, 579–590. [Google Scholar] [CrossRef]

- Yang, J.R.; Bhadeshia, H.K.D.H. The dislocation density of acicular ferrite in steel welds. Weld. Res. Suppl. 1990, 69, 305s–307s. [Google Scholar]

- Zhao, M.C.; Hanamura, T.; Qiu, H.; Nagai, K.; Yang, K. Grain growth and Hall-Petch relation in dual-sized ferrite/cementite steel with nano-sized cementite particles in a heterogeneous and dense distribution. Scr. Mater. 2006, 54, 1193–1197. [Google Scholar] [CrossRef]

- Hashemi, S.H. Strength–hardness statistical correlation in API X65 steel. Mater. Sci. Eng. A 2011, 528, 1648–1655. [Google Scholar] [CrossRef]

- Saleem, B.; Ahmed, F.; Rafiq, M.A.; Ajmal, M.; Ali, L. Stress corrosion failure of an X52 grade gas pipeline. Eng. Fail. Anal. 2014, 46, 157–165. [Google Scholar] [CrossRef]

- Zheng, W.; Elboujdaini, M.; Revie, R.W. Stress corrosion cracking in pipelines. In Stress Corrosion Cracking; Raja, V.S., Shoji, T., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2011; pp. 749–771. [Google Scholar]

- Standard Practice. Stress Corrosion Cracking (SCC) Direct Assessment Methodology; NACE International: Houston, TX, USA, 2008; ISBN 1-57590-191-9. [Google Scholar]

- Fessler, R.R. Combination of conditions causes stress-corrosion cracking. Oil Gas J. 1976, 74, 81–83. [Google Scholar]

- Wells, D.B. SCC threshold stress in line pipe steels. In Proceedings of the 8th Symposium on Line Pipe Research, Houston, TX, USA, 26–29 September 1993. [Google Scholar]

| Element | C | P | Mn | S | Cu | Ni | Cr | Mo | Al | Ti | V | Si | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | 0.075 | 0.014 | 0.95 | 0.003 | 0.01 | 0.01 | 0.015 | Tr. | 0.021 | 0.014 | 0.0015 | 0.226 | 0.013 | Bal. |

| Orientation | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Longitudinal | 400 | 500 | 32 |

| Transverse | 395 | 490 | 42 |

| Solute and Precipitate | Bmax (MPa/wt %) | Bave (MPa/wt %) | Solute Concentration (wt %) |

|---|---|---|---|

| V as V4C3 | 1000 | 500 | 0–0.15 |

| V as VN | 3000 | 1500 | 0–0.06 |

| Nb as Nb(CN) | 3000 | 1500 | 0–0.05 |

| Ti as TiC | 3000 | 1500 | 0.03–0.18 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lavigne, O.; Kotousov, A.; Luzin, V. Microstructural, Mechanical, Texture and Residual Stress Characterizations of X52 Pipeline Steel. Metals 2017, 7, 306. https://doi.org/10.3390/met7080306

Lavigne O, Kotousov A, Luzin V. Microstructural, Mechanical, Texture and Residual Stress Characterizations of X52 Pipeline Steel. Metals. 2017; 7(8):306. https://doi.org/10.3390/met7080306

Chicago/Turabian StyleLavigne, Olivier, Andrei Kotousov, and Vladimir Luzin. 2017. "Microstructural, Mechanical, Texture and Residual Stress Characterizations of X52 Pipeline Steel" Metals 7, no. 8: 306. https://doi.org/10.3390/met7080306

APA StyleLavigne, O., Kotousov, A., & Luzin, V. (2017). Microstructural, Mechanical, Texture and Residual Stress Characterizations of X52 Pipeline Steel. Metals, 7(8), 306. https://doi.org/10.3390/met7080306