Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L

Abstract

:1. Introduction

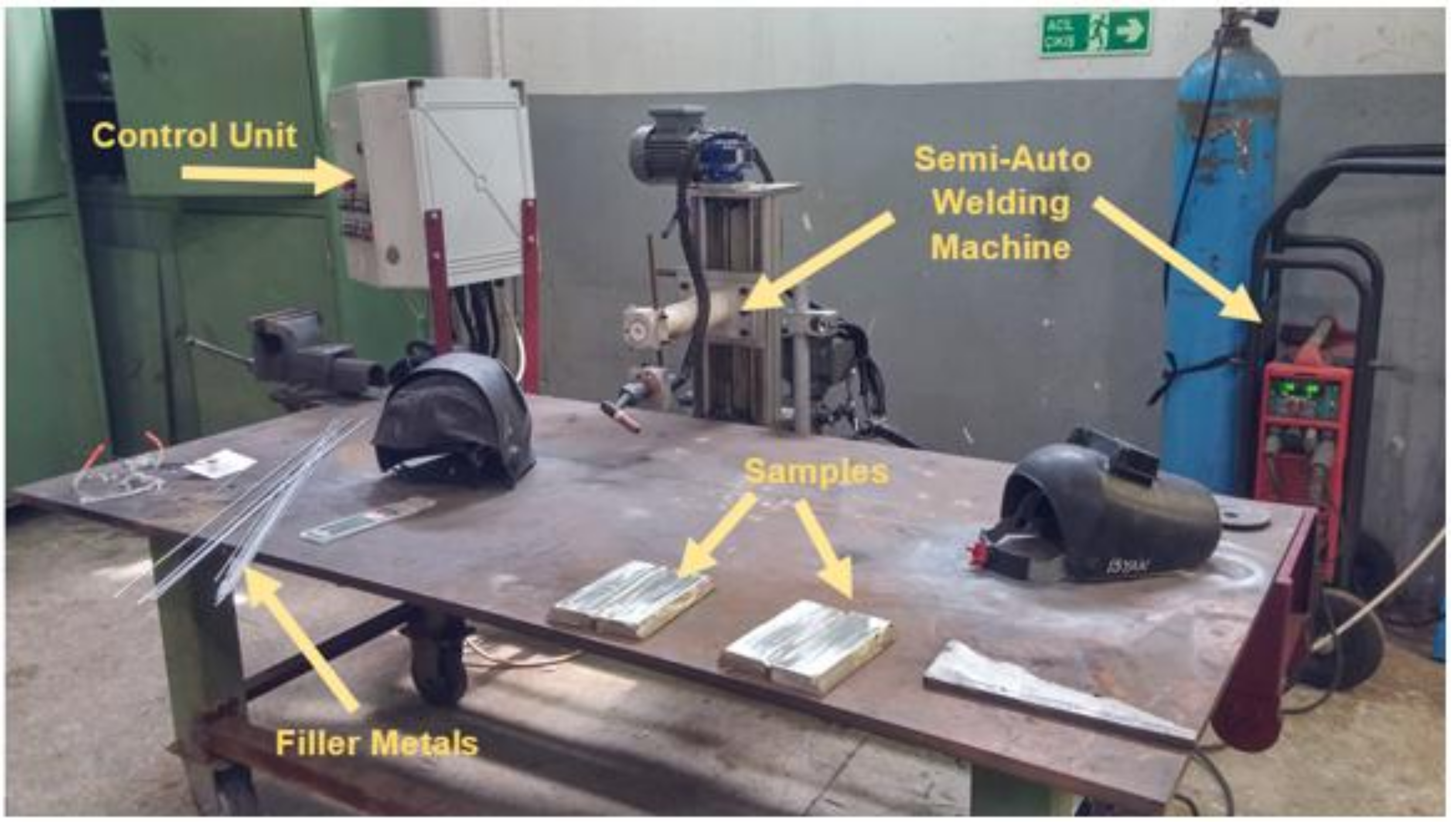

2. Materials and Methods

3. Results

3.1. Macrostructure of the Weldments

3.2. Microstructural Investigation

3.2.1. Microstructure of the CCGTA Welding

3.2.2. Microstructure of the PCGTA Welding

3.2.3. Line Mapping Analysis of the CCGTA Welding

3.2.4. Line Mapping Analysis of the PCGTA Welding

3.2.5. SEM/EDAX Analysis of CCGTA Welding

3.2.6. SEM/EDAX Analysis of PCGTA Welding

3.3. Mechanical Investigation

3.3.1. Hardness Tests

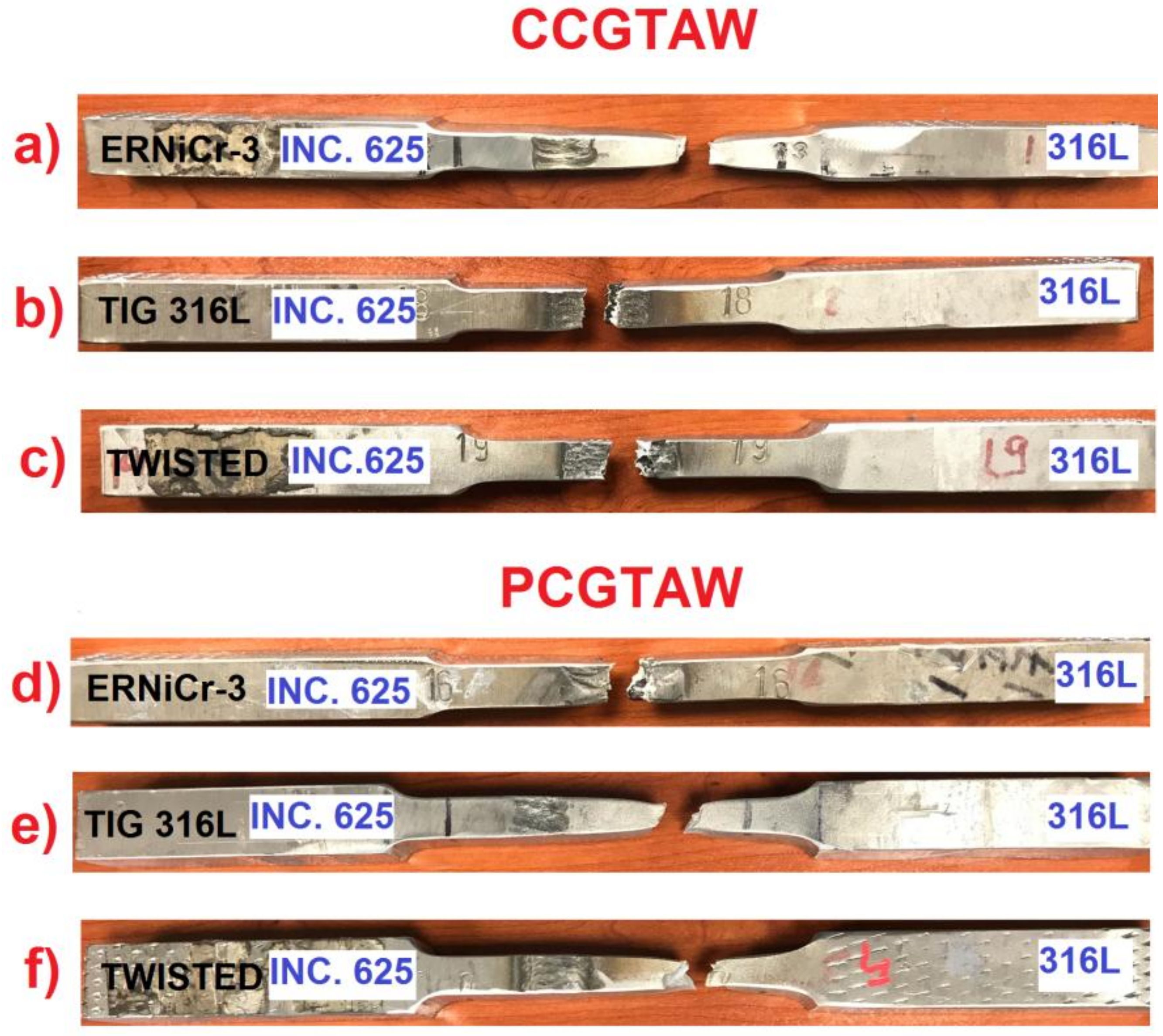

3.3.2. Tensile Test

4. Discussion

5. Conclusions

- Successful weldments obtained for all specimens in terms of macrostructure, without any lack of penetration, crack, spatter, etc.

- Microstructural investigations illustrated that in CCGTA welding with TIG 316L and twisted fillers, PMZs were obtained, which may cause cracking. TIG 316L filler metal weldments showed grain coarsening and twisted fillers could produce a laxer chemical composition with CCGTA welding process. However, CCGTA welding with ERNiCr-3 demonstrated almost regular boundaries on both sides. PCGTA welding with twisted fillers showed PMZ on the AISI 316L side and caused UZ to disappear on the Inconel 625 side. PCGTA welding reduced PMZ and UZ employing twisted fillers and minor grain coarsening.

- WZ microstructural analysis exhibited the existence of multi-directional grain growth in all specimens on the AISI 316L side. Grain growth was less on the Inconel 625 side and almost disappeared on the Inconel 625 side in PCGTA welding with twisted fillers.

- It was observed that the formation of Ni-, Ti-, Nb-, Mo-, Mn- and Cr-rich secondary precipitates appeared in all specimens. However, in PCGTA welding with twisted fillers, a meager amount of precipitates occurred. Moreover, these are particular precipitates that are represented by black dots in images, whereas others are tiny white secondary phases.

- Hardness and tensile test results show that PCGTA welding improve mechanical properties. Twisted fillers exhibit the best mechanical properties for bimetallic joint for Inconel 625 and AISI 316L.

- According to the study results, for the dissimilar metal welding of Inconel 625 and AISI 316L, the best process is PCGTA with twisted fillers (ERNiCr-3 and TIG 316L).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moosavy, H.N.; Aboutalebi, M.R.; Seyedein, S.H.; Mapelli, C. A Solidification Model for Prediction of Castability in the Precipitation-strengthened Nickel-based Superalloy. J. Mater. Process. Technol. 2013, 213, 1875–1884. [Google Scholar] [CrossRef]

- Korrapati, P.K.; Avasarala, V.K.; Bhushan, M.; Ramkumar, K.D.; Arivazhagan, N. Narayanan, S. Assessment of Mechanical Properties of PCGTA Weldments of Inconel 625. Procedia Eng. 2014, 75, 9–13. [Google Scholar] [CrossRef]

- Shankar, V.; Sankara, K.B.; Mannan, S.L. Microstructural and Mechanical Properties of Inconel 625 Superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Mithilesh, P.; Varun, D.; Reddy, A.R.G.; Arivazhagan, N.; Narayanan, S.; Kumar, K.G. Characterization of Microstructure and Mechanical Properties of Inconel 625 and AISI 304 Dissimilar Weldments. J. Int. Ste. Inst. Jap. 2014, 54, 900–908. [Google Scholar] [CrossRef] [Green Version]

- American Welding Society. Available online: https://app.aws.org/wj/2002/06/feature2/ (accessed on 23 September 2018).

- Dreshfield, R.L.; Moore, T.J.; Bartolotta, P.A. Post-Test Examination of a Pool Boiler Receiver. DOE/NASA/33408-6; U.S Department of Energy Conservation and Renewable Energy Office of Solar Heat Technologies: Washington, WA, USA, 1992; pp. 1–4. [Google Scholar]

- Mitilesh, P.; Varun, D.; Reddy, A.R.G.; Ramkumar, K.D.; Arivazhagan, N.; Narayanan, S. Investigations on Dissimilar Weldments of Inconel 625 and AISI 304. Procedia Eng. 2014, 75, 66–70. [Google Scholar] [CrossRef]

- Dev, S.; Ramkumar, K.D.; Arivazhagan, N.; Rajendran, R. Investigations on the Microstructure and Mechanical Properties of Dissimilar Welds of Inconel 718 and Sulphur Rich Martensitic Stainless Steel AISI 416. J. Manuf. Process. 2018, 32, 685–689. [Google Scholar] [CrossRef]

- Mortezaie, A.; Shamanian, M. An Assessment of Microstructure, Mechanical Properties and Corrosion Resistance of Dissimilar Welds between Inconel 718 and 310S Austenitic Stainless Steel. Int. J. Press. Vessel. Pip. 2014, 116, 37–46. [Google Scholar] [CrossRef]

- Ramkumar, T.; Selvakumar, M.; Narayanasamy, P.; Begam, A.A.; Mathavan, P.; Raj, A.A. Studies on the Structural Property, Mechanical Relationships and Corrosion Behaviour of Inconel 718 and SS 316L Dissimilar Joints by TIG welding without Using Activated Flux. J. Manuf. Process. 2017, 30, 290–298. [Google Scholar] [CrossRef]

- Ahmad, H.W.; Hwang, J.H.; Lee, J.H.; Bae, D.H. An Assessment of the Mechanical Properties and Microstructural Analysis of Dissimilar Material Welded Joint between Alloy 617 and 12Cr Steel. Metals 2016, 6, 242. [Google Scholar] [CrossRef]

- Kim, J.S.; Park, Y.I.; Lee, H.W. Effects of Heat Input on the Pitting Resistance of Inconel 625 Welds by Overlay Welding. Met. Mater. Int. 2015, 21, 350–355. [Google Scholar] [CrossRef]

- Knapp, S. Mechanical Properties of an Inconel Dissimilar Metal Weld. Master’s Thesis, University of Ottowa, Ottawa, ON, Canada, 2013. [Google Scholar]

- Kulekci, M.K.; Esme, U.; Kahraman, F.; Ocalir, S. An examination of the mechanical properties of dissimilar steel welds. Mater. Test. 2016, 58, 362–370. [Google Scholar] [CrossRef]

- Badiger, R.I.; Narendranath, S.; Srinath, M.S. Microstructure and Mechanical Properties of Inconel-625 Welded Joint Developed Through Microwave Hybrid Heating. J. Eng. Manuf. 2017. [Google Scholar] [CrossRef]

- DuPont, J.N.; Lippold, J.C.; Kiser, S.D. Welding Metallugy and Weldability of Nickel-Base Alloys; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 82–100. [Google Scholar]

- Manikandan, S.G.K.; Sivakumar, D.; Rao, K.P.; Kamaraj, M. Microstructural Characterization of Liquid Nitrogen Cooled Alloy 718 fusion zone. J. Mater. Process. Technol. 2014, 214, 3141–3149. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Kumar, P.S.G.; Krishna, V.R.; Chandrasekhar, A.; Dev, S.; Abraham, W.S.; Prabhakaran, S.; Kalainathan, S.; Sridhar, R. Influence of Laser Peening on the Tensile Strength and Impact Toughness of Dissimilar Welds of Inconel 625 and UNSS32205. Mater. Sci. Eng. A 2016, 676, 88–99. [Google Scholar] [CrossRef]

- Olden, V.; Kvaale, P.E.; Simensen, P.A.; Aaldstedt, S.; Solberg, J.K. The Effect of PWHT on the Material Properties and Microstructure in Inconel 625 and Inconel 725 Buttered Joints. In Proceedings of the 22nd International Conference on Offshore Mechanics and Artic Engineering, Cancun, Mexico, 8–13 June 2003. [Google Scholar]

- Soares, B.A.; Schvartzman, M.M.A.M.; Campos, W.R.C. Characterization of Dissimilar Metal Welding—Austenitic Stainless Steel with Filler Metal of the Nickel Alloy. In Proceedings of the International Nuclear Atlantic Conference, Sao Paolo, Brazil, 30 September–5 October 2007. [Google Scholar]

- Prabu, S.S.; Ramkumar, K.D.; Arivazhagan, N. Microstructural Evolution and Precipitation Behavior in Heat Affected Zone of Inconel 625 and AISI 904L Dissimilar Welds. Mater. Sci. Eng. 2017, 263, 062073. [Google Scholar] [CrossRef]

- Naffakh, N.; Shamanian, M.; Ashrafizadeh, F. Microstructural evolutions in dissimilar welds between AISI 310 austenitic stainless steel and Inconel 657. J. Mater. Sci. 2010, 45, 2564–2573. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Patel, S.D.; Praveen, S.S.; Choudhury, D.J.; Prabaharan, P.; Arivazhagan, N.; Xavior, M.A. Influence of Filler Metals and Welding Techniques the Structure—Property Relationships of Inconel 718 and AISI 316L Dissimilar Weldments. Mater. Des. 2014, 62, 175–188. [Google Scholar] [CrossRef]

- Hejripour, F.; Aidun, D.K. Consumable Selection for Arc Welding between Stainless Steel 410 and Inconel 718. J. Mater. Process. Technol. 2017, 245, 287–299. [Google Scholar] [CrossRef]

- Kumar, K.G.; Ramkumar, K.D.; Arivazhagan, N. Characterization of Metallurgical and Mechanical Properties of the multi-pass welding of Inconel 625 and AISI 316L. J. Mech. Sci. Tech. 2015, 29, 1039–1047. [Google Scholar] [CrossRef]

- Kourdani, A.; Haghighi, R.D. Evaluating the Properties of Dissimilar Metal Welding Between Inconel 625 and 316L Stainless Steel by Applying Different Welding Methods and Consumables. Metall. Mater. Trans. A 2018, 49A, 1231–1243. [Google Scholar] [CrossRef]

- Xie, M.X.; Shang, X.T.; Zhang, L.J.; Bai, Q.L.; Xu, T.T. Interface Characteristic of Explosive-Welded and Hot-Rolled TA1/X65 Bimetallic Plate. Metals 2018, 8, 1–14. [Google Scholar] [CrossRef]

- Topolski, T.; Szulc, Z.; Garbacz, H. Microstructure and Properties of the Ti6Al4V/Inconel 625 Bimetal Obtained by Explosive Joining. J. Mat. Eng. Perf 2016. [Google Scholar] [CrossRef]

- Mohommed, G.H.; Ishak, M.; Ahmad, S.N.A.S.; Abdulhadi, H.A. Fiber Laser Welding of Dissimilar 2205/304 Stainless Steel Plates. Metals 2017, 7, 1–19. [Google Scholar] [CrossRef]

- Shakil, M.; Ahmad, M.; Tariq, N.H.; Hasan, B.A.; Akhter, J.I.; Ahmed, E.; Mehmood, M.; Choudhry, M.A.; Iqbal, M. Microstructure and hardness studies of electron beam welded Inconel 625 and stainless steel 304L. Vacuum 2014, 110, 121–126. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2003; p. 151. ISBN 978-0-471-43491-7. [Google Scholar]

- Ramkumar, K.D.; Abraham, W.S.; Viyash, V.; Arivazhagan, N.; Rabel, A.M. Investigations on the Microstructure, Tensile Strength and High Temperature Corrosion Behaviour of Inconel 625 and Inconel 718 Dissimilar Joints. J. Manuf. Process. 2017, 25, 306–322. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Sai, R.J.; Reddy, V.S.; Gundla, S.; Mohan, T.H.; Saxena, V.; Arivazhagan, N. Effect of Filler Wires and Direct Ageing on the Microstructure and Mechanical Properties in the Multi-Pass Welding of Inconel 718. J. Manuf. Process. 2015, 18, 23–45. [Google Scholar] [CrossRef]

| Base/Filler | C | Cr | Si | Ni | P | Mn | Nb + Ta | Mo | Fe | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.04 | 22.12 | 0.15 | Rem. | 0.012 | 0.09 | 3.38 | 8.32 | 4.48 | Cu—0.05 Al—0.11 Ti—0.21 Co—0.3 |

| AISI 316L | 0.02 | 17.25 | 0.04 | 10.38 | 0.039 | 1.78 | - | 2.15 | Rem. | S—0.004 |

| ERNiCr-3 | 0.04 | 20.0 | 0.09 | 73.00 | 0.003 | 2.8 | 2.4 | - | 1.5 | Ti—0.40 S—0.002 Cu—0.03 Other < 0.5 |

| TIG316L | 0.02 | 18 | 0.45 | 12 | 0.04 | 1.70 | - | 2.3 | Rem. | Cu—0.75 S—0.03 |

| Welding | Filler | Pass | Current (A) | Voltage (V) | Duty Cycle | Frequency (Hz) | Welding Speed (mm/s) | |

|---|---|---|---|---|---|---|---|---|

| Peak | Back | |||||||

| CCGTAW | ERNiCr3 | Root 1 | 110 | - | 14 | - | - | 0.56 |

| Pass 1 | 110 | - | 17 | - | - | 0.71 | ||

| Cap 1 | 110 | - | 18 | - | - | 0.95 | ||

| Root 2 | 110 | - | 15 | - | - | 0.65 | ||

| Pass 2 | 110 | - | 17 | - | - | 0.82 | ||

| Cap 2 | 110 | - | 20 | - | - | 1.09 | ||

| TIG 316L | Root 1 | 110 | - | 15 | - | - | 0.62 | |

| Pass 1 | 110 | - | 17 | - | - | 0.79 | ||

| Cap 1 | 110 | - | 19 | - | - | 1.02 | ||

| Root 2 | 110 | - | 13 | - | - | 0.78 | ||

| Pass 2 | 110 | - | 16 | - | - | 0.92 | ||

| Cap 2 | 110 | - | 18 | - | - | 1.18 | ||

| TWISTED | Root 1 | 120 | - | 16 | - | - | 0.81 | |

| Pass 1 | 120 | - | 19 | - | - | 1.02 | ||

| Cap 1 | 120 | - | 20 | - | - | 1.15 | ||

| Root 2 | 120 | - | 14 | - | - | 0.95 | ||

| Pass 2 | 120 | - | 16 | - | - | 1.13 | ||

| Cap 2 | 120 | - | 18 | - | - | 1.29 | ||

| PCGTAW | ERNiCr3 | Root 1 | 170 | 100 | 12 | 50% | 6 | 0.56 |

| Pass 1 | 170 | 100 | 15 | 50% | 6 | 0.71 | ||

| Cap 1 | 170 | 100 | 16 | 50% | 6 | 0.95 | ||

| Root 2 | 160 | 90 | 13 | 50% | 6 | 0.65 | ||

| Pass 2 | 150 | 85 | 14 | 50% | 6 | 0.82 | ||

| Cap 2 | 150 | 85 | 16 | 50% | 6 | 1.09 | ||

| TIG 316L | Root 1 | 170 | 100 | 11 | 50% | 6 | 0.62 | |

| Pass 1 | 170 | 100 | 15 | 50% | 6 | 0.79 | ||

| Cap 1 | 170 | 100 | 17 | 50% | 6 | 1.02 | ||

| Root 2 | 160 | 90 | 10 | 50% | 6 | 0.78 | ||

| Pass 2 | 150 | 85 | 14 | 50% | 6 | 0.92 | ||

| Cap 2 | 140 | 80 | 16 | 50% | 6 | 1.18 | ||

| TWISTED | Root 1 | 180 | 110 | 13 | 50% | 6 | 0.81 | |

| Pass 1 | 170 | 100 | 15 | 50% | 6 | 1.02 | ||

| Cap 1 | 170 | 100 | 17 | 50% | 6 | 1.15 | ||

| Root 2 | 170 | 100 | 12 | 50% | 6 | 0.95 | ||

| Pass 2 | 160 | 90 | 14 | 50% | 6 | 1.13 | ||

| Cap 2 | 150 | 85 | 15 | 50% | 6 | 1.29 | ||

| Weldment | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Fracture Zone |

|---|---|---|---|---|

| CCGTAW emp. ERNiCr-3 | 442 | 674 | 34 | AISI 316L |

| CCGTAW emp. TIG 316L | 389 | 529 | 13 | WZ |

| CCGTAW emp. Twisted | 437 | 567 | 19 | WZ |

| PCGTAW emp. ERNiCr-3 | 401 | 532 | 17 | WZ |

| PCGTAW emp. TIG 316L | 446 | 661 | 32 | AISI 316L |

| PCGTAW emp. Twisted | 451 | 687 | 36 | AISI 316L |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dokme, F.; Kulekci, M.K.; Esme, U. Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L. Metals 2018, 8, 797. https://doi.org/10.3390/met8100797

Dokme F, Kulekci MK, Esme U. Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L. Metals. 2018; 8(10):797. https://doi.org/10.3390/met8100797

Chicago/Turabian StyleDokme, Fatih, Mustafa Kemal Kulekci, and Ugur Esme. 2018. "Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L" Metals 8, no. 10: 797. https://doi.org/10.3390/met8100797

APA StyleDokme, F., Kulekci, M. K., & Esme, U. (2018). Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L. Metals, 8(10), 797. https://doi.org/10.3390/met8100797