An Analysis of Creep Phenomena in the Power Boiler Superheaters

Abstract

:1. Introduction

2. Basic Formulations

3. Analysis of Creep Phenomena

- maximum stresses are limited to allowable values for the initial time.

- maximum stresses are limited to allowable values for the time of 200,000 h under creep conditions (if a design lifetime is not specified), and creep strain should be less than 1% at 100,000 h (if design lifetimes is shorted than 100,000 h).

3.1. Calculation Based on European Standards

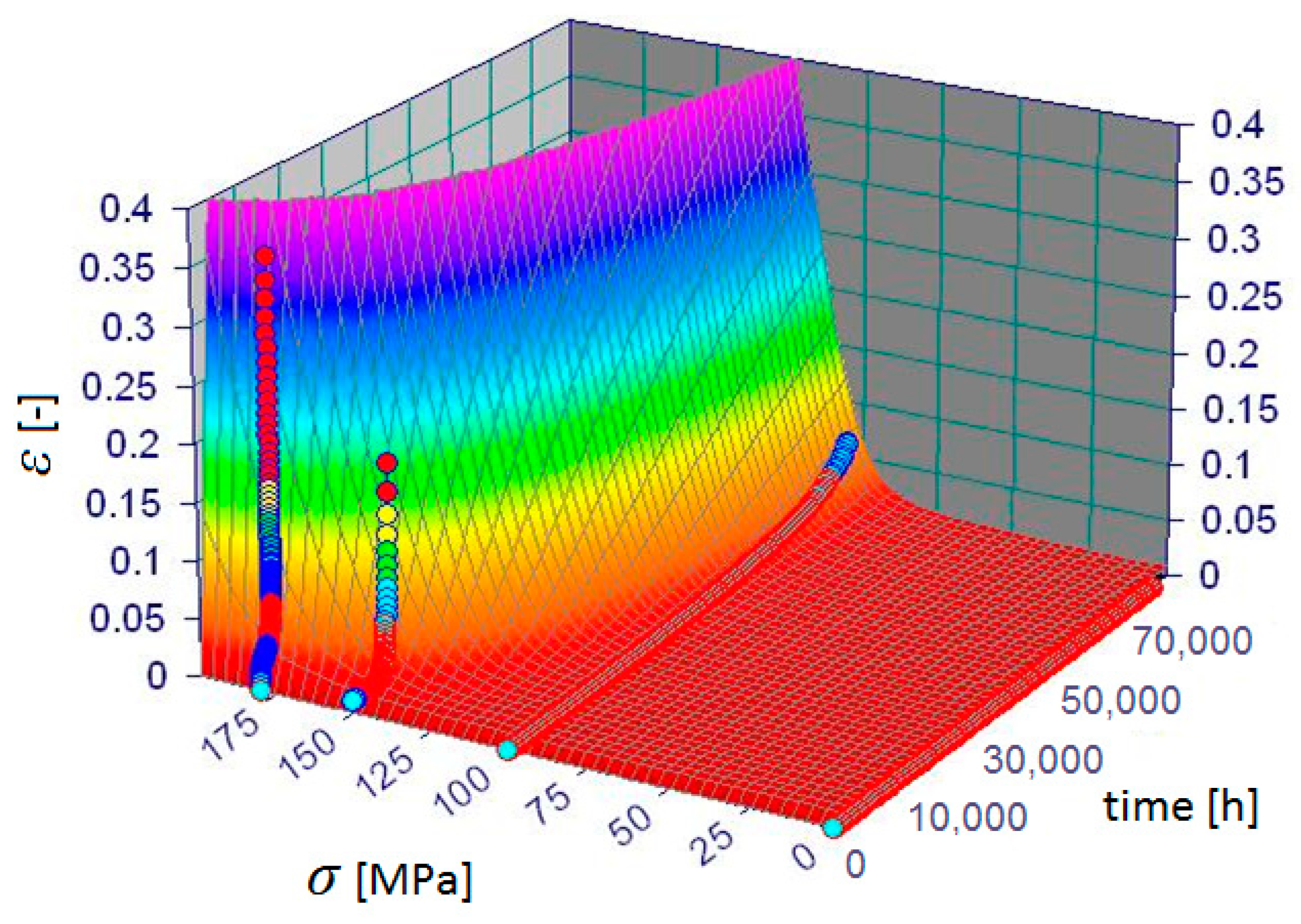

3.2. Verification of Calculated Temperature Values Based on a Detailed Analysis of the Creep Phenomenon

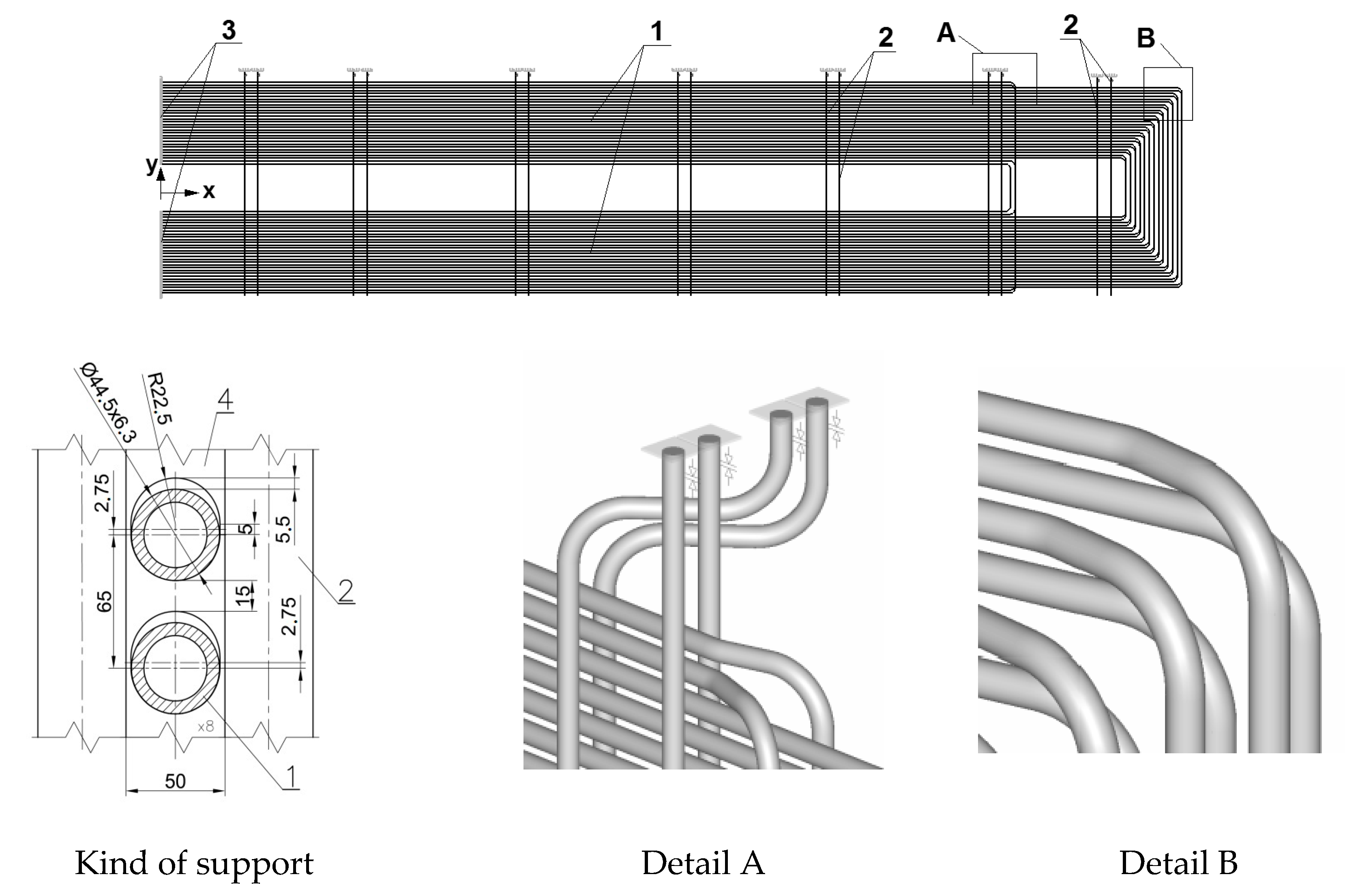

4. Numerical Example

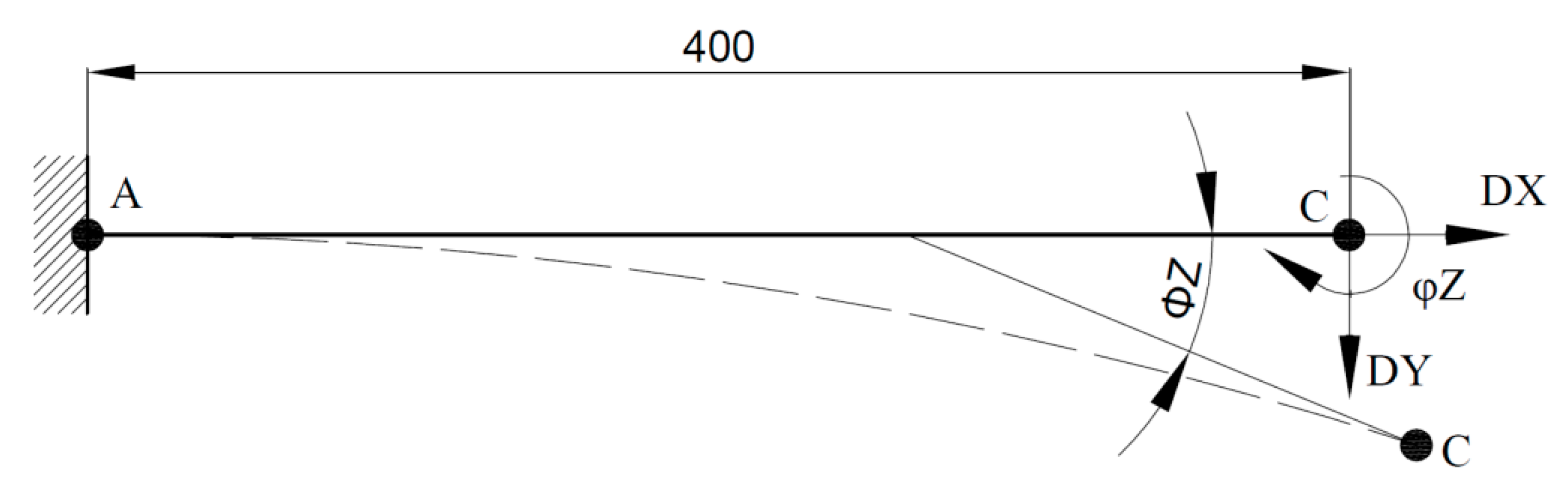

4.1. Calculation Based on European Standards

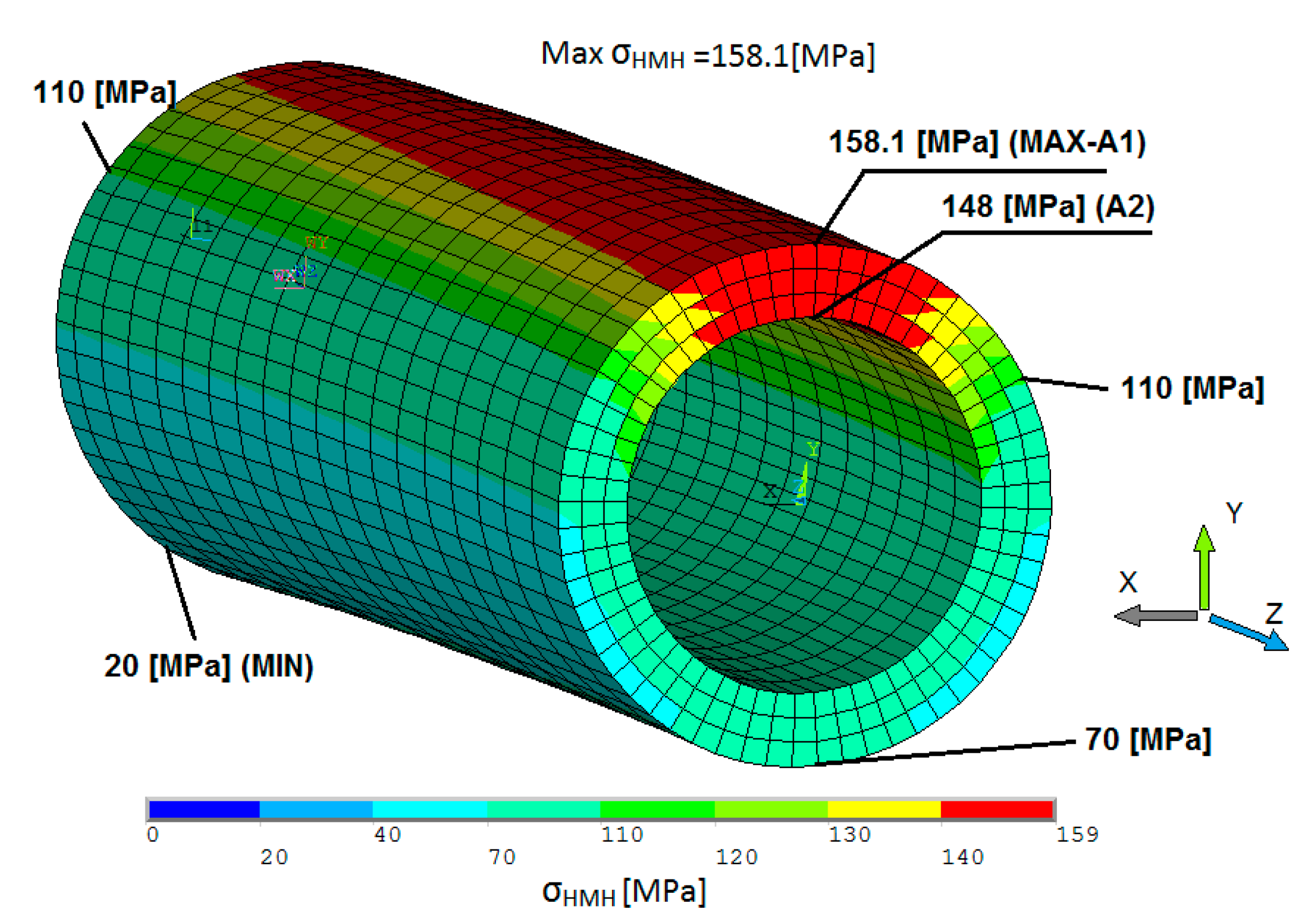

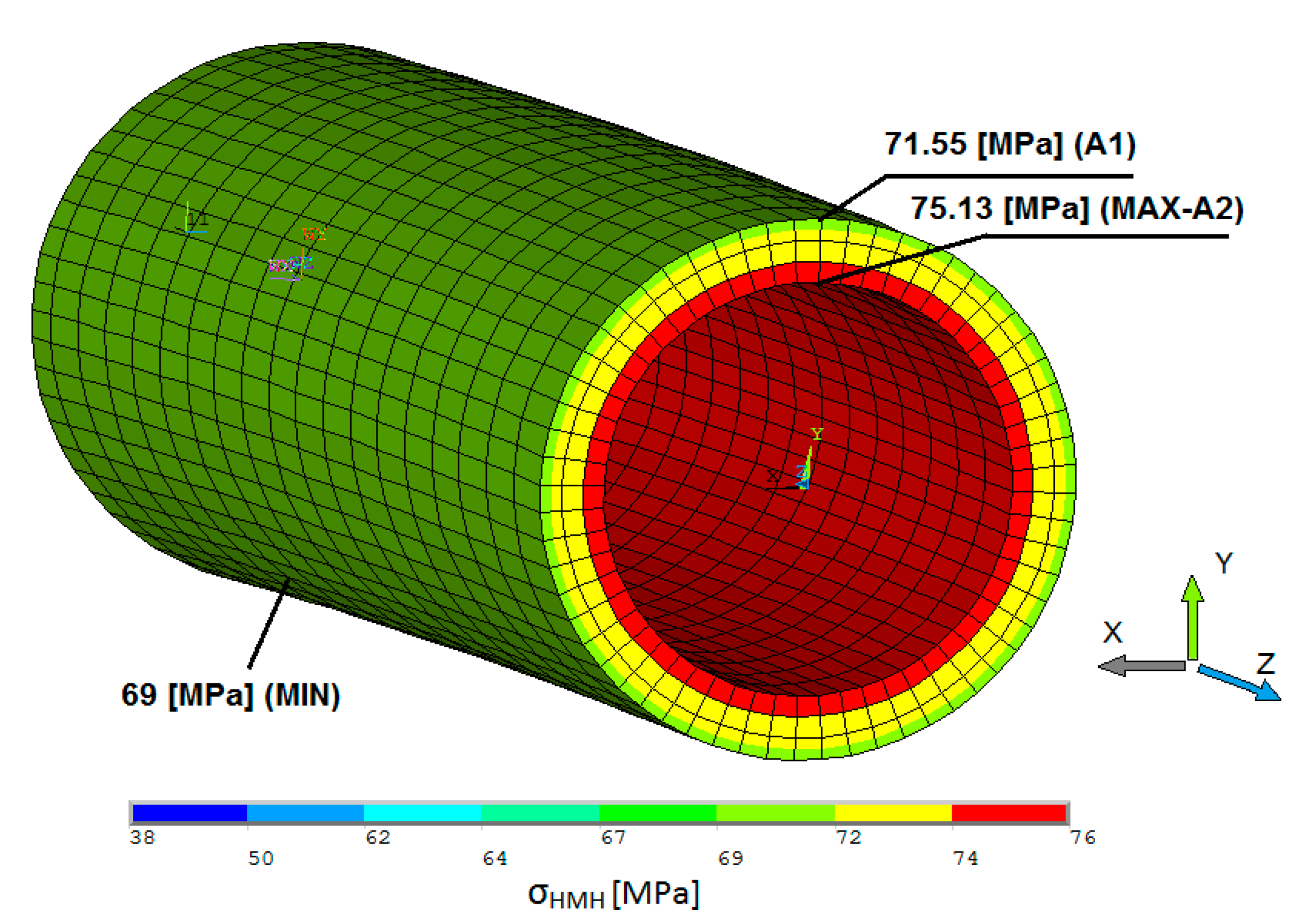

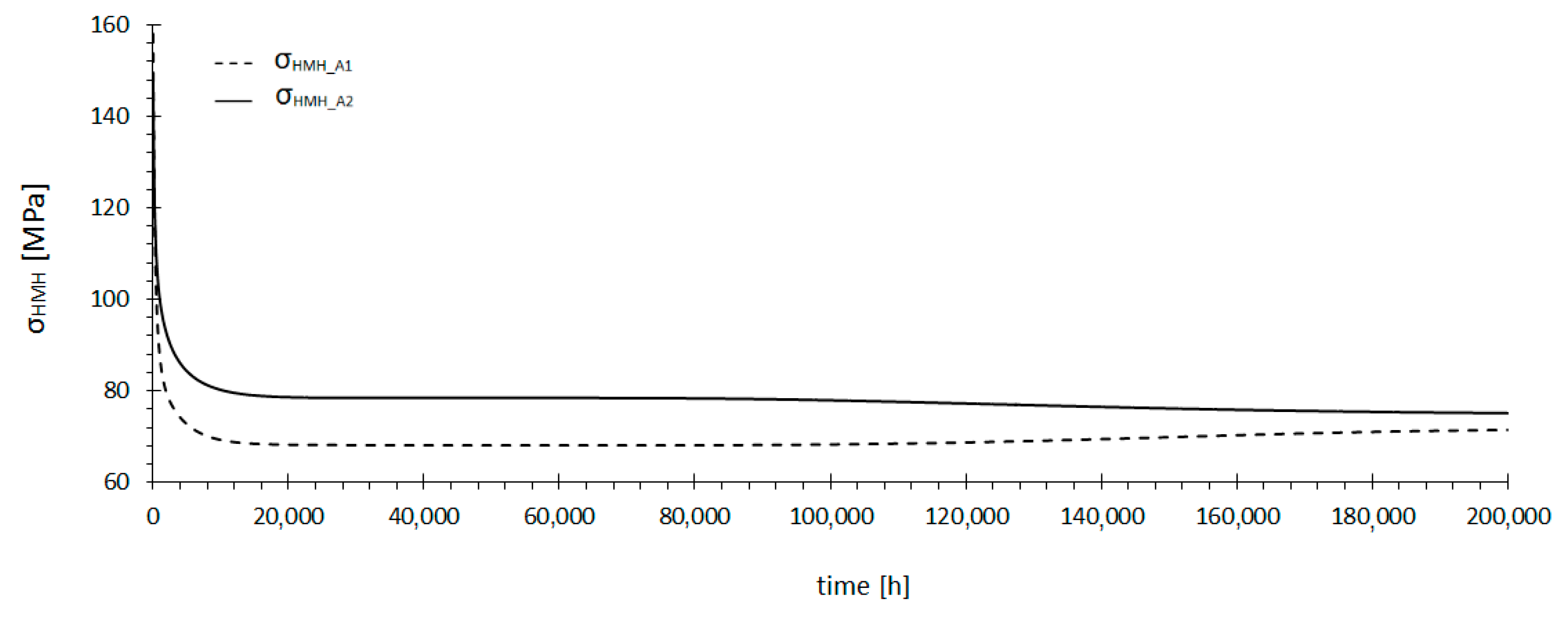

4.2. Verification of the Final Solution Based on a Detailed Analysis of the Creep Phenomenon

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | the highest creep strain at the end of the first stage of creep, - |

| cp | specific heat capacity, J/(kg·K) |

| c1 | experimental constant, ln(h) |

| c2 | experimental constant, ln(h)/ln(MPa2) |

| c3 | directional factor for the second stage of creep, (ln(1/h))/MPa |

| c4 | coordinate of the t-intercept for the second stage of creep, ln(1/h) |

| do | pipe outer diameter, mm |

| en | pipe thickness, mm |

| fR, fCR | allowable stresses, MPa |

| G | Lame constant, MPa |

| i | stress intensification factor, - |

| k | thermal conductivity, W/(m·K) |

| K, M | coefficients describing the destruction process intensity, - |

| MA | moment caused by weight and other sustained loads, Nm |

| MC | moment caused by thermal expansion, Nm |

| P | pressure, MPa |

| t | time, h |

| tII | time marking the beginning of the second stage of creep, h |

| T | temperature, °C |

| Tm | the material melting point, °C |

| u | displacement vector, m |

| x,y,z | Cartesian coordinates, m |

| Z | the pipe section modulus, mm3 |

| β | thermal expansion coefficient, 1/K |

| εc(t) | actual normal creep strain, - |

| ε | strain tensor, - |

| λ | Lame constant, MPa |

| ν | Poisson’s ratio, - |

| ρ | density, kg/m3 |

| σ | normal stress, MPa |

| σ | stress tensor, MPa |

| n | time step (subscripts) |

References

- Stoppato, A.; Mirandola, A.; Meneghetti, G.; Lo Casto, E. On the operation strategy of steam power plants working at variable load Technical and economic issues. Energy 2012, 37, 228–236. [Google Scholar] [CrossRef]

- Rusin, A.; Wojaczek, A. Influence of thermal loads variation on the probability of waterwall tubes corrosion failure in low-emission combustion. Rynek Energii 2009, 6, 129–133. [Google Scholar]

- Tognoli, M.; Najafi, B.; Rinaldi, F. Dynamic modelling and optimal sizing of industrial fire-tube boilers for various demand profiles. Appl. Therm. Eng. 2018, 132, 341–351. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Fernandez, A.; Celaya, A.; Lamikiz, A.; Lopez de Lacalle, L.N. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Lasers Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

- Duda, P.; Felkowski, Ł.; Dobrzański, J. An analysis of an incident during the renovation work of a power boiler superheater. Eng. Fail. Anal. 2015, 57, 248–253. [Google Scholar] [CrossRef]

- Duda, P.; Felkowski, Ł.; Dobrzański, J.; Purzyńska, H. Modelling the strain and stress state under creep conditions in P91 steel. Mater. High Temp. 2016, 33, 85–93. [Google Scholar] [CrossRef]

- RAFAKO, SA. Superheater Coils SH3 Documentation; RAFAKO SA: Racibórz, Poland, 2012. [Google Scholar]

- Bentley Systems. Bentley Auto Pipe V8i Select Series 5 Edition (Version 09.05.00.21); Workbook: Exton, PA, USA, 2013. [Google Scholar]

- ANSYS. Revision 15.0 A. In User’s Manual, Revision 15.0, Version 14; ANSYS: Canonsburg, PA, USA, 2014. [Google Scholar]

- The Pressure Equipment Directive (PED). Directive 2014/68/EU; L189/165-166; European Parliament: Brussels, Belgium, 2014; pp. 211–212. [Google Scholar]

- EN 12952-3. Design and calculation of pressure parts. In Water-Tube Boilers and Auxiliary Installations; NSAI: Dublin, Ireland, 2011. [Google Scholar]

- EN 13480-3. Design and calculation. In Metallic Industrial Piping; NSAI: Dublin, Ireland, 2011. [Google Scholar]

- Xie, L.-J.; Ren, X.; Shen, M.-X.; Tu, L.-Q. Parameter correlation of high-temperature creep constitutive equation for RPV metallic materials. J. Nucl. Mater. 2015, 465, 196–203. [Google Scholar] [CrossRef]

- Naumenko, K.; Altenbach, H. Modelling of Creep for Structural Analysis; Springer: Berlin, Germany, 2007; pp. 1–15. [Google Scholar]

- Osocha, P. Determination of the Extent of Damage to the Boiler Thick-Walled High-Pressure Elements. Ph.D. Thesis, Institute of Thermal Power Engineering-Cracow University of Technology, Cracow, Poland, 2009. [Google Scholar]

- Sroka, M.; Zieliński, A.; Mikuła, J. The service life of the repair welded joint of Cr-Mo/Cr-Mo-V. Arch. Metall. Mater. 2016, 61, 969–974. [Google Scholar] [CrossRef]

- Zieliński, A.; Sroka, M.; Miczka, M.; Śliwa, A. Forecasting the particle diameter size distribution in P92 (X10CRWMOVNB9-2) steel after long-term ageing at 600 and 650 °C. Arch. Metall. Mater. 2016, 61, 753–760. [Google Scholar] [CrossRef]

- Sroka, M.; Zieliński, A.; Hernas, A.; Kania, Z.; Rozmus, R.; Tański, T.; Śliwa, A. The effect of long-term impact of elevated temperature on changes in the microstructure of Inconel 740H alloy. Metalurgija 2017, 56, 333–336. [Google Scholar]

- Zieliński, A.; Sroka, M.; Hernas, A.; Kremzer, M. The effect of long-term impact of elevated temperature on changes in microstructure and mechanical properties of HR3C steel. Arch. Metall. Mater. 2016, 61, 761–766. [Google Scholar] [CrossRef]

- Felkowski, Ł.; Duda, P.; Węglowski, B. Analysis of Power Systems; Węglowski, B., Duda, P., Eds.; Cracow University of Technology Press: Kraków, Poland, 2013; pp. 387–401. [Google Scholar]

- ASME Case 2328-2. Cases of ASME Boiler and Pressure Vessel Code; ASME: New York, NY, USA, 2010. [Google Scholar]

- Miroshnik, R.; Shaked, Y.; Elmakis, D. Life Assessment Evaluation of piping branch connection under creep & fatigue. Int. J. Press. Vessels Pip. 1997, 8, 147–154. [Google Scholar]

| Chemical Composition (%)—ASME Code Case 2328-1 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cu | Cr | Ni | Nb | B | N | Al |

| 0.07–0.13 | Max 0.30 | Max 1.00 | Max 0.0040 | Max 0.0010 | 2.50 3.50 | 17.0 19.0 | 7.5 10.5 | 0.30 0.60 | 0.0001 0.0010 | 0.05 0.12 | 0.0003 0.0030 |

| Temperature (°C) | Stress σ (MPa) | Stress σC (MPa) | Yield Strength (MPa) | Allowable Stress (MPa) (See Section 3.1) | ||

|---|---|---|---|---|---|---|

| fR | fCR | σC/fCR | ||||

| 650 | 158 | 90 | 172 | 319.0 | 105.3 | 0.85 |

| 700 | 167 | 92 | 160 | 252.5 | 58.3 | 1.58 |

| 665 | 160 | 90 | 160 | 296.5 | 91.2 | 0.99 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duda, P.; Felkowski, Ł.; Duda, A. An Analysis of Creep Phenomena in the Power Boiler Superheaters. Metals 2018, 8, 892. https://doi.org/10.3390/met8110892

Duda P, Felkowski Ł, Duda A. An Analysis of Creep Phenomena in the Power Boiler Superheaters. Metals. 2018; 8(11):892. https://doi.org/10.3390/met8110892

Chicago/Turabian StyleDuda, Piotr, Łukasz Felkowski, and Andrzej Duda. 2018. "An Analysis of Creep Phenomena in the Power Boiler Superheaters" Metals 8, no. 11: 892. https://doi.org/10.3390/met8110892

APA StyleDuda, P., Felkowski, Ł., & Duda, A. (2018). An Analysis of Creep Phenomena in the Power Boiler Superheaters. Metals, 8(11), 892. https://doi.org/10.3390/met8110892