Modelling of Creep in Alloys Strengthened by Rod-Shaped Particles: Al-Cu-Mg Age-Hardenable Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. The Model

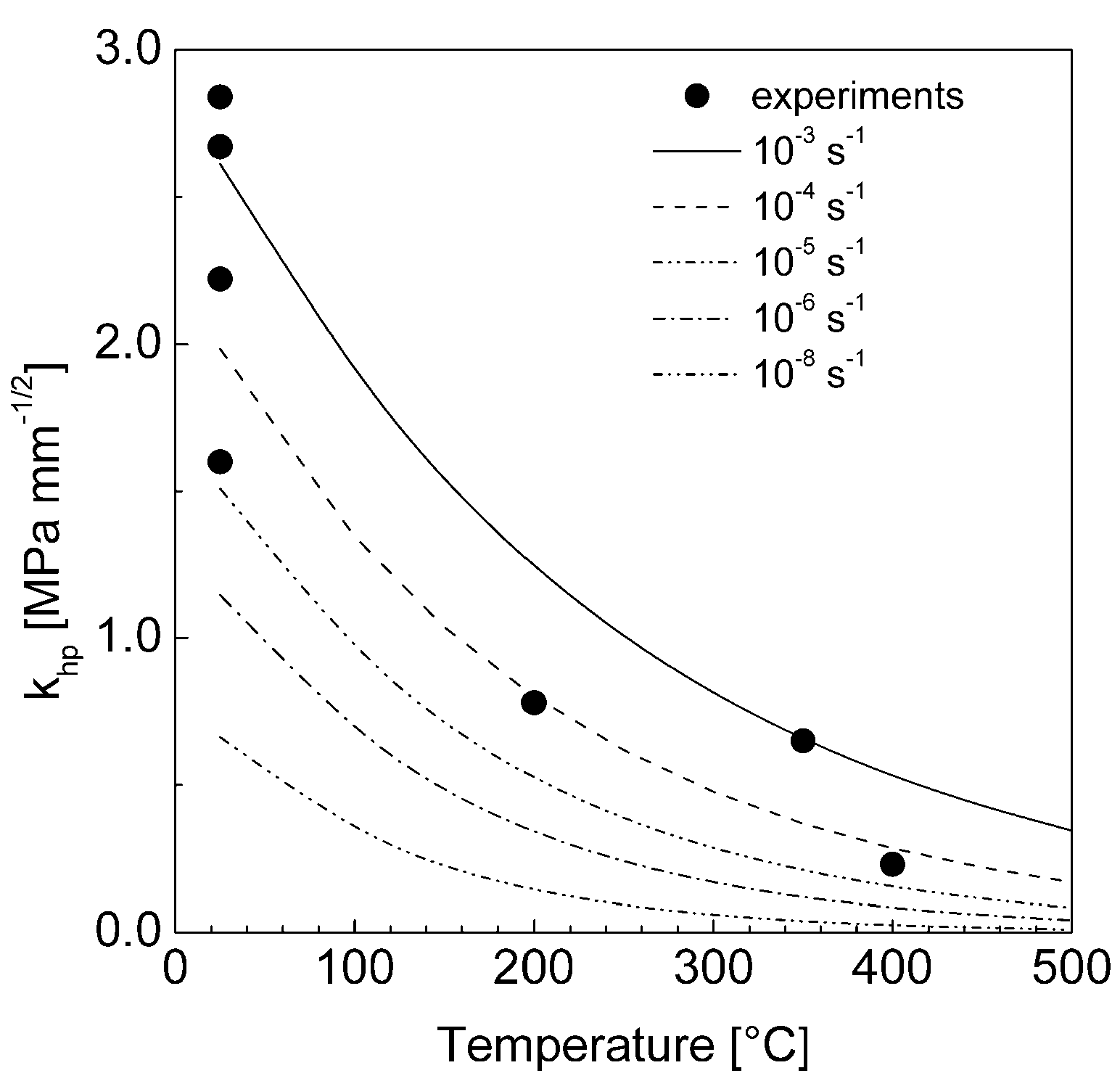

3.1. Equations for Dislocation Creep in Al: Strengthening Terms

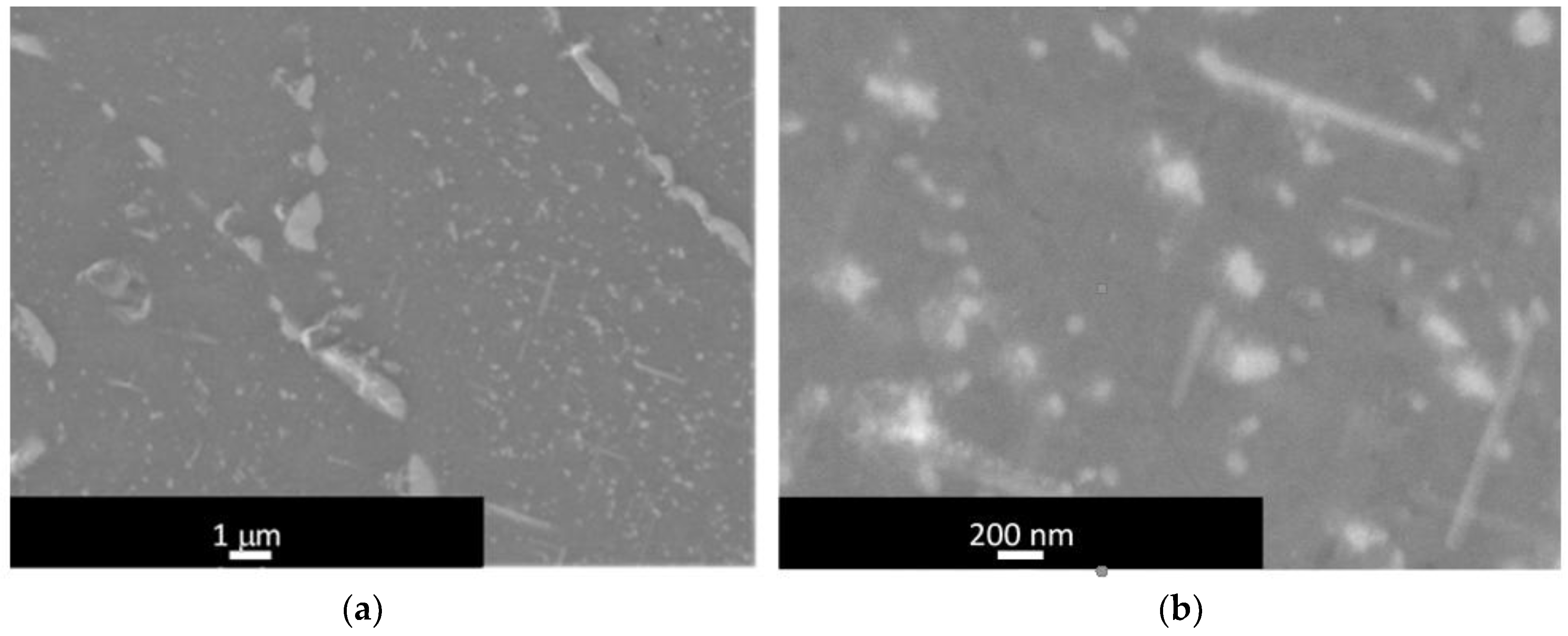

3.2. Nature of Particle Strengthening in 2024 Alloy

3.3. Models for Particle-Dislocation Interaction

3.4. Rate Equation and Temperature Dependence

3.5. Solid Solution Strengthening Effect on Temperature Dependence of the Strain Rate

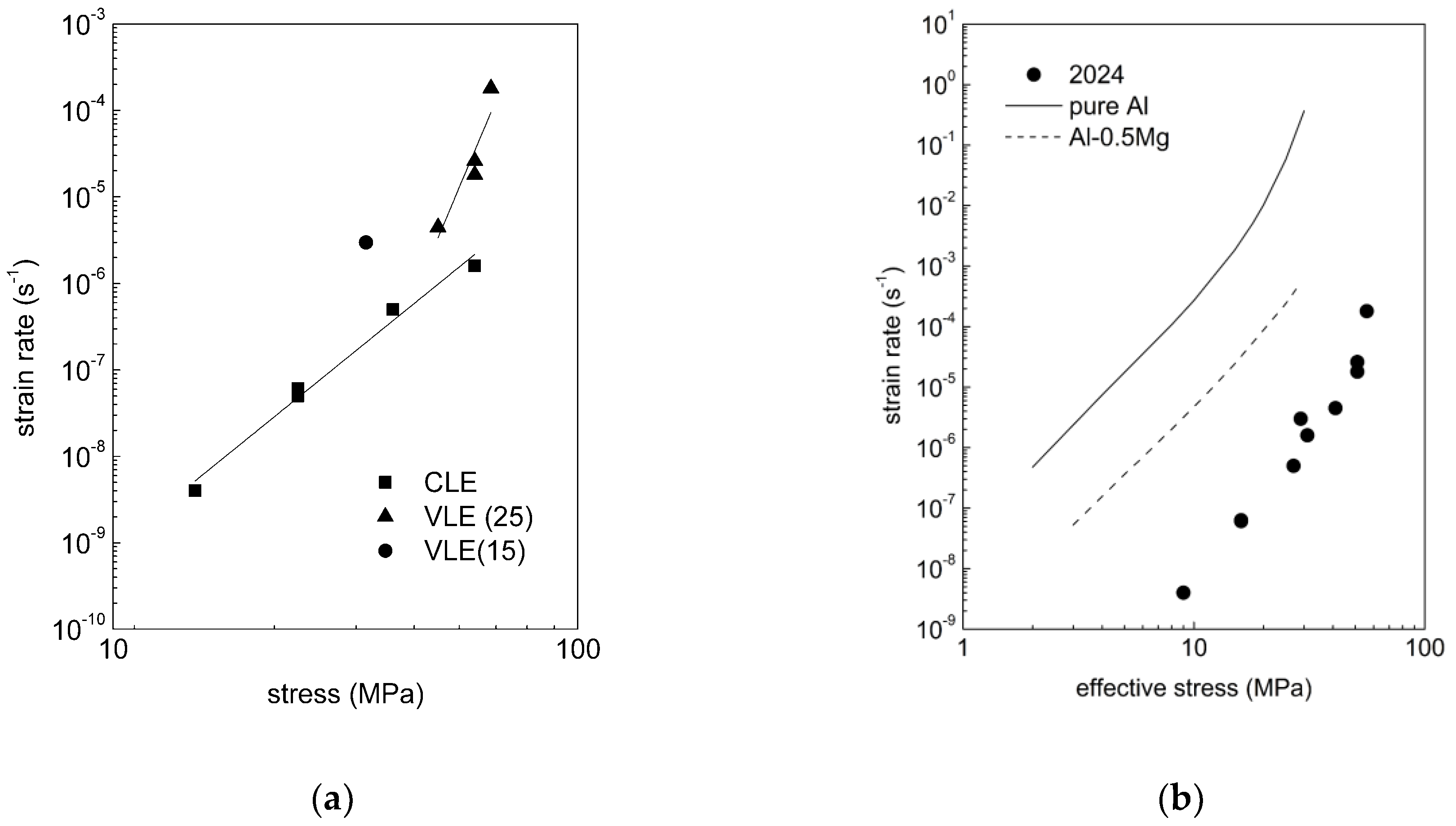

4. Modelling of the Minimum Creep Rate Dependence on Applied Stress in AA2024 T6-T3 Alloy

4.1. The Role of Particle Size and Distribution

4.2. Quantification of Particle Strengthening Effect

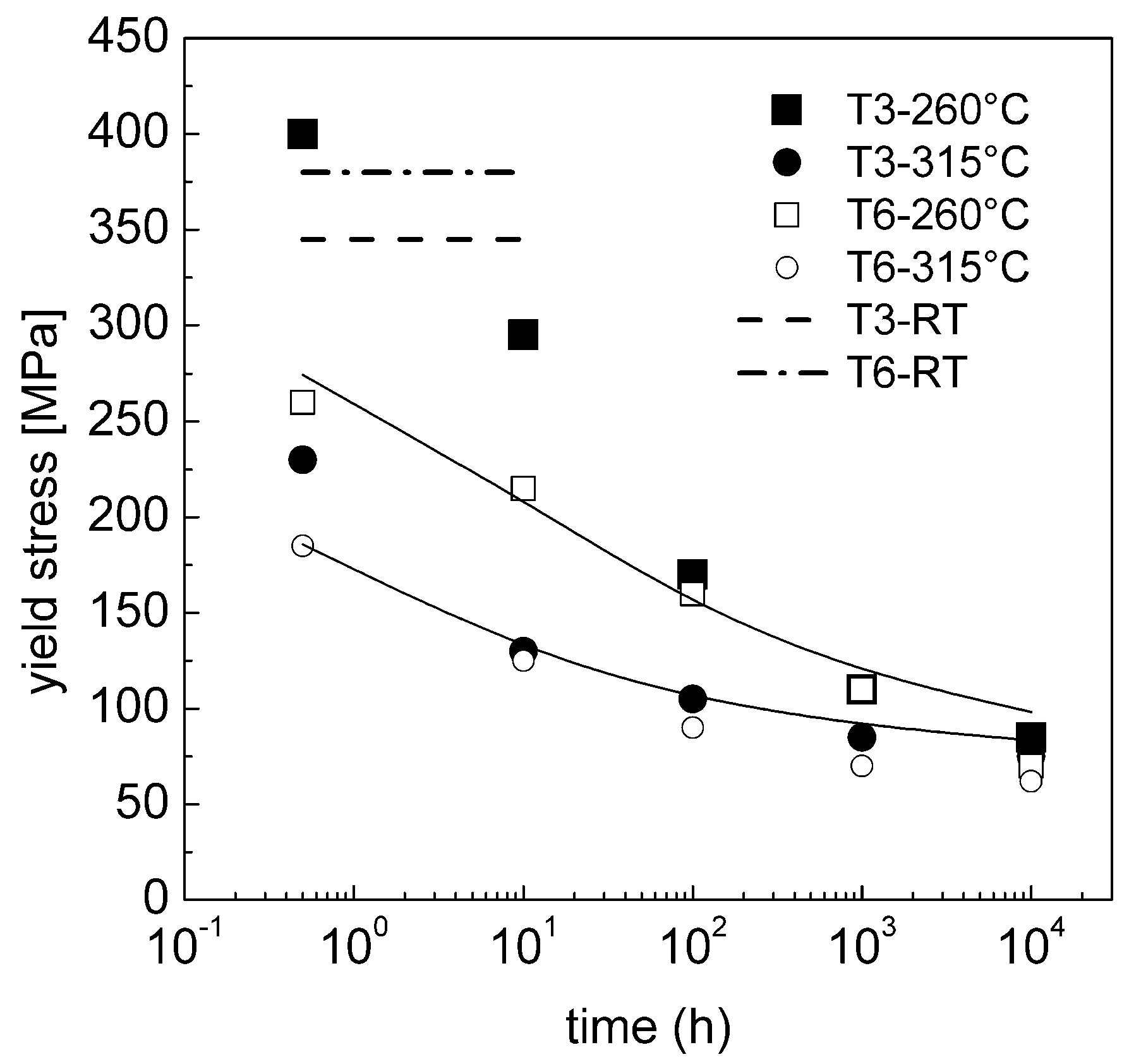

4.3. Effect of Stress on Particle Evolution

4.4. Description of the AA2024 T3 Constant and Variable Load Experiments

- The model does not require any fitting of the experimental creep data (none of the creep data were used to fit the equations, once the model was properly tuned by other microstructural results and tensile testing, required to provide an estimate of αp).

- The model is self-consistent, since it easily explains the lower creep rate observed when comparing the alloy tested under a given effective stress and the pure metal under an equivalent applied stress.

- Although the model considers only rod-shaped particles, the observed presence of equiaxed precipitates does not seem to significantly affect the accuracy of the description.

- The main drawback of the model here presented, is that the quantification of the particle-strengthening term still needed to be evaluated from experimental data (the yield stress). Thus, the determination of the threshold stress originated by particle-dislocation interaction remains phenomenological in nature.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Nakai, M.; Eto, T. New aspects of development of high strength aluminum alloys for aerospace applications. Mater. Sci. Eng. A. 2000, 258, 62–68. [Google Scholar] [CrossRef]

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Lumley, R.N.; Morton, A.J.; Polmear, I.J. Enhanced creep performance in an Al-Cu-Mg-Ag alloy through underageing. Acta Mater. 2002, 50, 3597–3608. [Google Scholar]

- Lumley, R.N.; Polmear, I.J. The effect of long term creep exposure on the microstructure and properties of an underaged Al-Cu-Mg-Ag alloy. Scr. Mater. 2004, 50, 1227–1231. [Google Scholar] [CrossRef]

- Heimerl, G.J.; Farquhar, J. Compressive and Tensile Creep of 7075-T6 and 2024-T3 Aluminium Alloy Sheet; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 1 December 1959.

- Kloc, L.; Cerri, E.; Spigarelli, S.; Evangelista, E.; Langdon, T.G. Significance of continuous precipitation during creep of a powder metallurgy aluminum alloy. Mater. Sci. Eng. A 1996, 216, 161–168. [Google Scholar] [CrossRef]

- Kloc, L.; Spigarelli, S.; Cerri, E.; Evangelista, E.; Langdon, T.G. Creep behavior of an aluminum 2024 alloy produced by powder metallurgy. Acta Mater. 1997, 45, 529–540. [Google Scholar]

- Spigarelli, S.; Cabibbo, M.; Evangelista, E.; Langdon, T.G. Creep properties of an Al-2024 composite reinforced with SiC particulates. Mater. Sci. Eng. A 2002, 328, 39–47. [Google Scholar]

- Lin, Y.C.; Xia, Y.C.; Jiang, Y.Q.; Li, L.T. Precipitation in Al-Cu-Mg alloy during creep exposure. Mater. Sci. Eng. A. 2012, 556, 796–800. [Google Scholar]

- Lin, Y.C.; Xia, Y.C.; Jiang, Y.Q.; Zhou, H.M.; Li, L.T. Precipitation hardening of 2024-T3 aluminum alloy during creep aging. Mater. Sci. Eng. A 2013, 565, 420–429. [Google Scholar]

- Härtel, M.; Frint, P.; Abstoss, K.G.; Wagner, M.F.-X. Effect of creep ad aging on the precipitation kinetics of an Al-Cu alloy after one pass of ECAP. Adv. Eng. Mater. 2018, 20, 1700307. [Google Scholar] [CrossRef]

- Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Ichkova, M.D. Modeling of strain hardening and creep behaviour of 2024T3 aluminium alloy at room and high temperatures. Comput. Mater. Sci. 2014, 83, 381–393. [Google Scholar] [CrossRef]

- Regev, M.; Rashkovsky, T.; Cabibbo, M.; Spigarelli, S. Microstructure stability during creep of friction stir welded AA2024-T3 alloy. J. Mater. Eng. Perform. 2018, 1–10. [Google Scholar] [CrossRef]

- Buchheit, R.G.; Grant, R.P.; Hiava, P.F.; Mckenzie, B.; Zender, G. Local dissolution phenomena associated with S phase (Al2CuMg) particles in aluminum alloy 2024-13. J. Electrochem. Soc. 1997, 144, 2621–2628. [Google Scholar] [CrossRef]

- Boag, A.; Hughes, A.E.; Wilson, N.C.; Torpy, A.; MacRae, C.M.; Glenn, A.M.; Muster, T.H. How complex is the microstructure of AA2024-T3? Corros. Sci. 2009, 51, 1565–1568. [Google Scholar] [CrossRef]

- Shih, H.C.; Ho, N.J.; Huang, J.C. Precipitation behaviors in Al-Cu-Mg and 2024 aluminum alloys. Metall. Mater. Trans. A 1996, 27, 2479–2494. [Google Scholar] [CrossRef]

- Spigarelli, S.; Sandström, R. Basic creep modelling of aluminium. Mater. Sci. Eng. A. 2018, 711, 343–349. [Google Scholar] [CrossRef]

- Spigarelli, S.; Paoletti, C. A unified physical model for creep and hot working of Al-Mg solid solution alloys. Metals 2018, 8, 9. [Google Scholar] [CrossRef]

- Kassner, M.E.; Pérez-Prado, M.-T. Five-power-law creep in single phase metals and alloys. Prog. Mater. Sci. 2000, 45, 1–102. [Google Scholar] [CrossRef]

- Morishige, T.; Hirata, T.; Uesugi, T.; Takigawa, Y.; Tsujikawa, M.; Higashi, K. Effect of Mg content on the minimum grain size of Al-Mg alloys obtained by friction stir processing. Scr. Mater. 2011, 64, 355–358. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, S.H.; Park, J.H.; Kim, H.W.; Lee, J.C. Role of Mg in simultaneously improving the strength and ductility of Al-Mg alloys. Mater. Sci. Eng. A 2016, 657, 115–122. [Google Scholar] [CrossRef]

- Zhao, D.; Løvvik, O.M.; Marthinsen, K.; Li, Y. Impurity effect of Mg on the generalized planar fault energy of Al. J. Mater. Sci. 2016, 51, 6552–6568. [Google Scholar] [CrossRef] [Green Version]

- Sandström, R.; Andersson, H.C.M. Creep in phosphorus alloyed copper during power-law breakdown. J. Nucl. Mater. 2008, 372, 76–88. [Google Scholar] [CrossRef]

- Sandström, R. Basic model for primary and secondary creep in copper. Acta Mater. 2012, 60, 314–322. [Google Scholar] [CrossRef]

- Sandström, R. Influence of phosphorus on the tensile stress strain curves in copper. J. Nucl. Mater. 2016, 470, 290–296. [Google Scholar] [CrossRef]

- Sandström, R. The role of cell structure during creep of cold worked copper. Mater. Sci. Eng. A 2016, 674, 318–327. [Google Scholar] [CrossRef]

- Korzhavyi, P.A.; Sandström, R. First-principles evaluation of the effect of alloying elements on the lattice parameter of a 23Cr25NiWCuCo austenitic stainless steel to model solid solution hardening contribution to the creep strength. Mater. Sci. Eng. A 2015, 626, 213–219. [Google Scholar] [CrossRef]

- Khan, I.N.; Starink, M.J.; Yan, J.L. A model for precipitation kinetics and strengthening in Al-Cu-Mg alloys. Mater. Sci. Eng. A 2008, 472, 66–74. [Google Scholar] [CrossRef]

- Blum, W.; Reppich, B. Creep of particle-strengthened alloys. Creep Behav. Cryst. Solids. 1985, 83–135. [Google Scholar]

- Heilmaier, M.; Reppich, B. Particle Threshold Stresses in High Temperature Yielding and Creep: A Critical Review. In Proceedings of the Creep Behavior of Advanced Materials for the 21st Century, San Diego, CA, USA, 28 February–4 March 1999. [Google Scholar]

- Lagneborg, R.; Bergman, B. The stress/creep rate behaviour of precipitation-hardened alloys. Met. Sci. 1976, 10, 20–28. [Google Scholar] [CrossRef]

- Rösler, J. Back-stress calculation for dislocation climb past non-interacting particles. Mater. Sci. Eng. A 2003, 339, 334–339. [Google Scholar] [CrossRef]

- Rösler, J.; Arzt, E. A new model-based creep equation for dispersion strengthened materials. Acta Metall. Mater. 1990, 38, 671–683. [Google Scholar] [CrossRef]

- Rösler, J.; Joos, R.; Arzt, E. Microstructure and creep properties of dispersion-strengthened aluminum alloys. Metall. Trans. A 1992, 23, 1393–1521. [Google Scholar] [CrossRef]

- Kaufman, J.G. Properties of Aluminium Alloys: Tensile, Creep, and Fatigue Data at High and Low Temperatures; ASM international: Materials Park, OH, USA, 1999. [Google Scholar]

- Zhang, F.; Levine, L.E.; Allen, A.J.; Campbell, C.E.; Creuziger, A.A.; Kazantseva, N.; Ilavsky, J. In situ structural characterization of ageing kinetics in aluminum alloy 2024 across angstrom-to-micrometer length scales. Acta Mater. 2016, 111, 385–398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rockenhäuser, C.; Schriever, S.; von Hartrott, P.; Piesker, B.; Skrotzki, B. Comparison of long-term radii evolution of the S-phase in aluminum alloy 2618A during ageing and creep. Mater. Sci. Eng. A 2018, 716, 78–86. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids. 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wagner, C. Theorie der Alterung von Niederschlägen durch Umlösen (Ostwald-Reifung). Zeitschrift Für Elektrochemie, Berichte Der Bunsengesellschaft Für physikalische Chemie 1961, 65, 581–591. [Google Scholar]

- Liu, D.; Zhang, L.; Du, Y.; Xu, H.; Liu, S.; Liu, L. Assessment of atomic mobilities of Al and Cu in fcc Al–Cu alloys. Calphad 2009, 33, 761–768. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six decades of the Hall–Petch effect—A survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Kassner, M.E.; Li, X. The effect of grain size on the elevated temperature yield strength of polycrystalline aluminum. Scr. Metall. Mater. 1991, 25, 2833–2838. [Google Scholar] [CrossRef]

- Panin, V.E.; Armstrong, R.W. Hall-Petch analysis for temperature and strain rate dependent deformation of polycrystalline lead. Phys. Mesomech. 2016, 19, 35–40. [Google Scholar] [CrossRef]

- Al-haidary, J.T.; Petch, N.J.; de los Rios, E.R. The plastic deformation of polycrystals I. Aluminium between room temperature and 400 °C. Philos. Mag. A 1983, 47, 869–890. [Google Scholar] [CrossRef]

| CLE | |||||

| T (°C) | σ (MPa) | tm (h) | (s−1) | ||

| 250 | 60 | 200 | 9.4 × 10−9 | ||

| 100 | 10 | 7.5 × 10−8 | |||

| 120 | 7 | 3.3 × 10−7 | |||

| 155 | 1 | 6.0 × 10−7 | |||

| 175 | 0.35 | 1.5 × 10−6 | |||

| 200 | 0.05 | 5.0 × 10−6 | |||

| 315 | 15* | 337 | 4.0 × 10−9 | ||

| 25 | 50 | 5.0 × 10−8 | |||

| 40 | 8 | 5.0 × 10−7 | |||

| 60 | 0.6 | 1.6 × 10−6 | |||

| VLE | |||||

| T (°C) | σ (First Loading) (MPa) | σ (Final Loading) (MPa) | t Under First Load (h) | tm Second Load (h) | |

| 315 | 25 | 50 | 15 | 1 | |

| 25 | 60 | 15 | 0.08 | ||

| 25 | 65 | 15 | 0.03 | ||

| 15* | 35 | 337 | 1 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paoletti, C.; Regev, M.; Spigarelli, S. Modelling of Creep in Alloys Strengthened by Rod-Shaped Particles: Al-Cu-Mg Age-Hardenable Alloys. Metals 2018, 8, 930. https://doi.org/10.3390/met8110930

Paoletti C, Regev M, Spigarelli S. Modelling of Creep in Alloys Strengthened by Rod-Shaped Particles: Al-Cu-Mg Age-Hardenable Alloys. Metals. 2018; 8(11):930. https://doi.org/10.3390/met8110930

Chicago/Turabian StylePaoletti, Chiara, Michael Regev, and Stefano Spigarelli. 2018. "Modelling of Creep in Alloys Strengthened by Rod-Shaped Particles: Al-Cu-Mg Age-Hardenable Alloys" Metals 8, no. 11: 930. https://doi.org/10.3390/met8110930

APA StylePaoletti, C., Regev, M., & Spigarelli, S. (2018). Modelling of Creep in Alloys Strengthened by Rod-Shaped Particles: Al-Cu-Mg Age-Hardenable Alloys. Metals, 8(11), 930. https://doi.org/10.3390/met8110930