Improvement of Strength and Impact Toughness for Cold-Worked Austenitic Stainless Steels Using a Surface-Cracking Technique

Abstract

1. Introduction

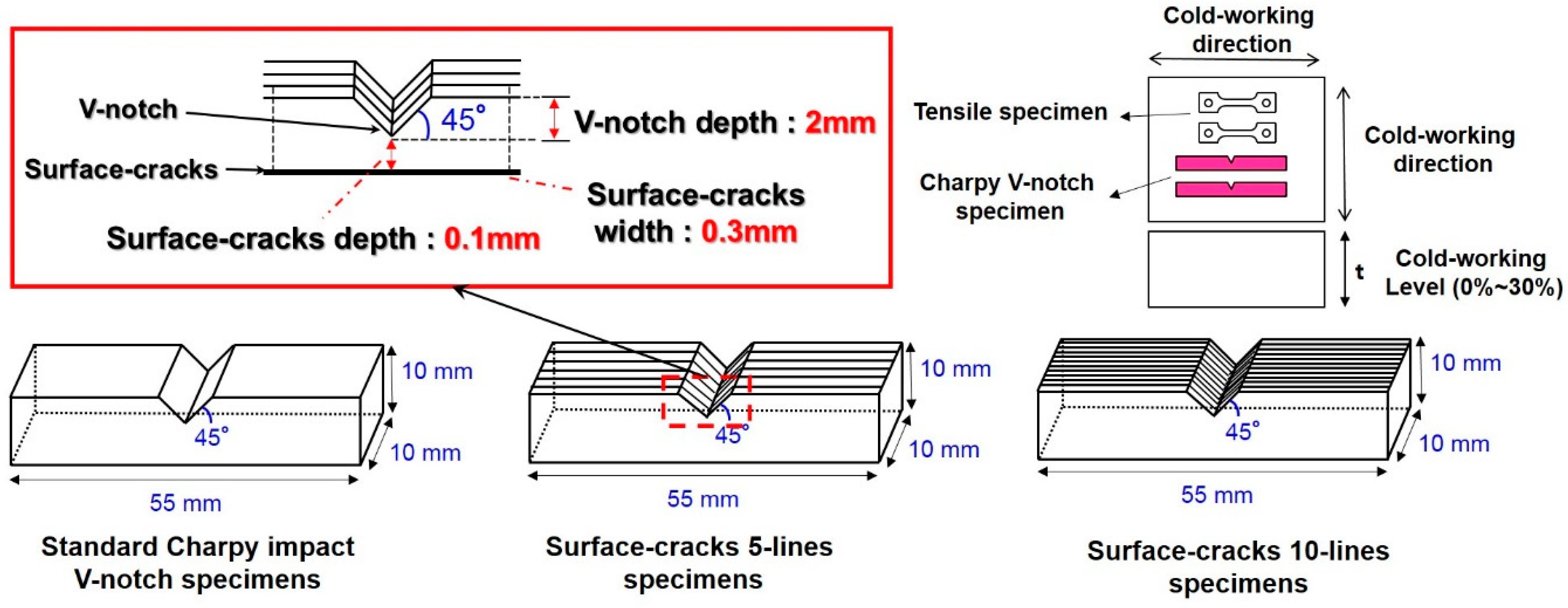

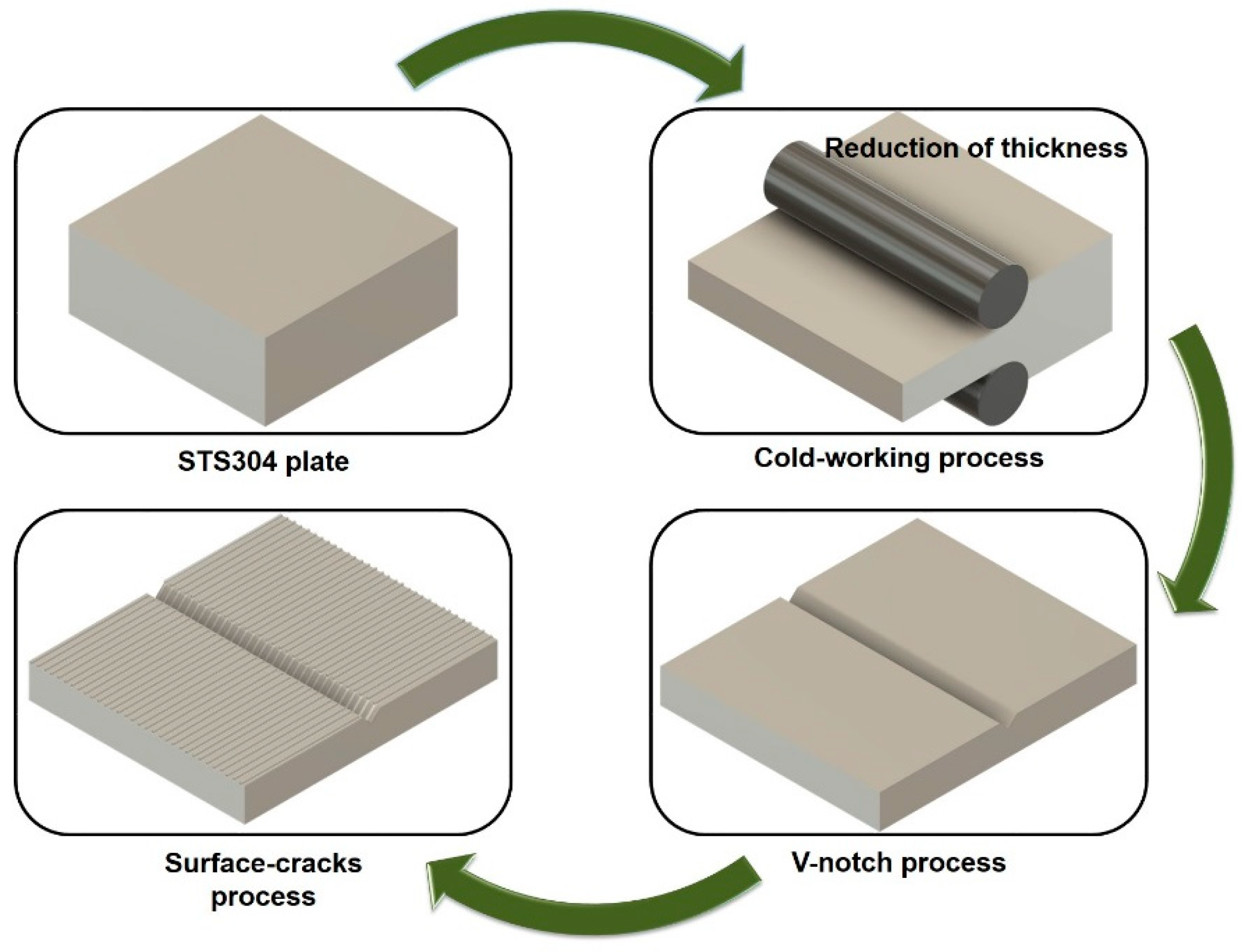

2. Materials and Methods

3. Results and Discussion

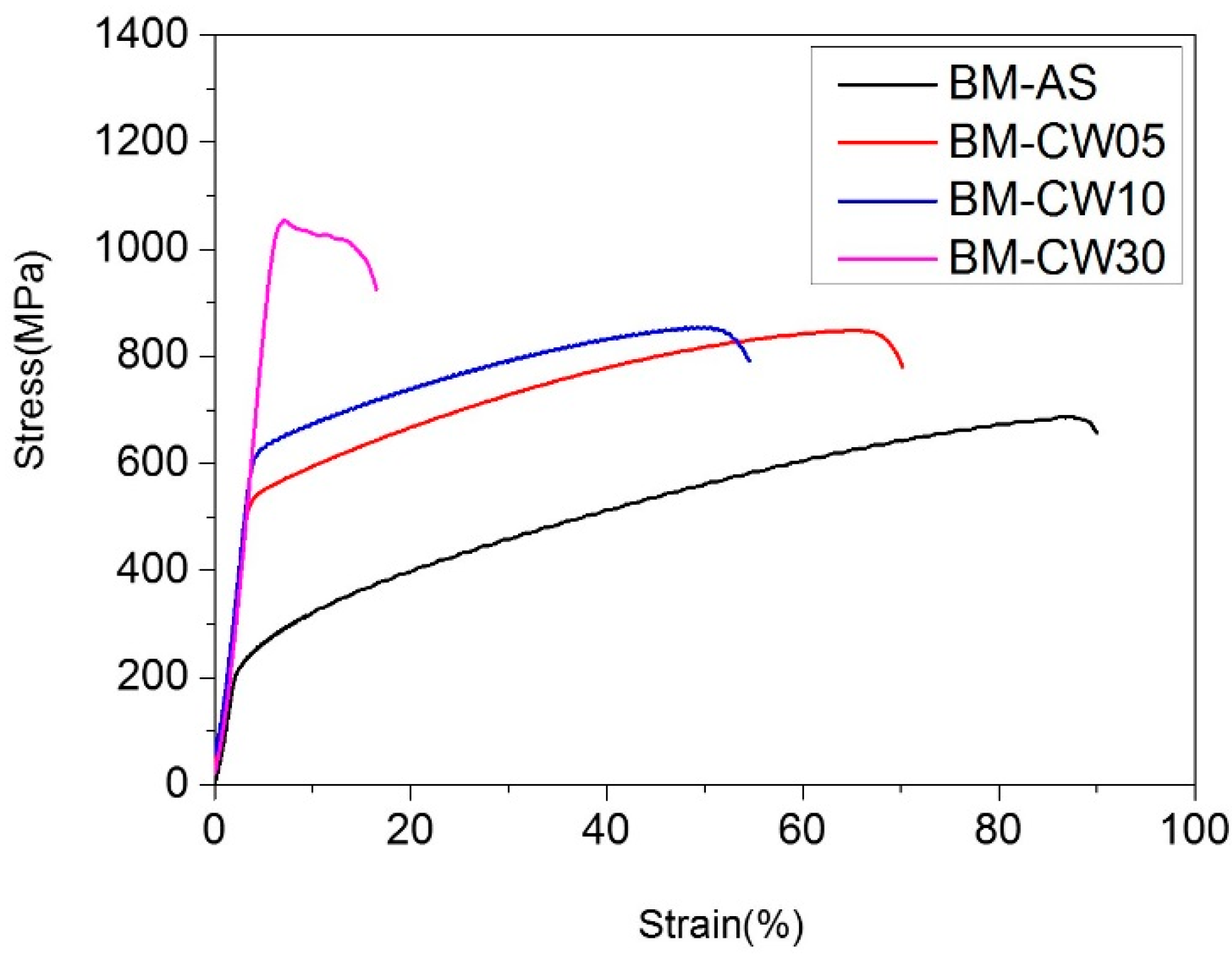

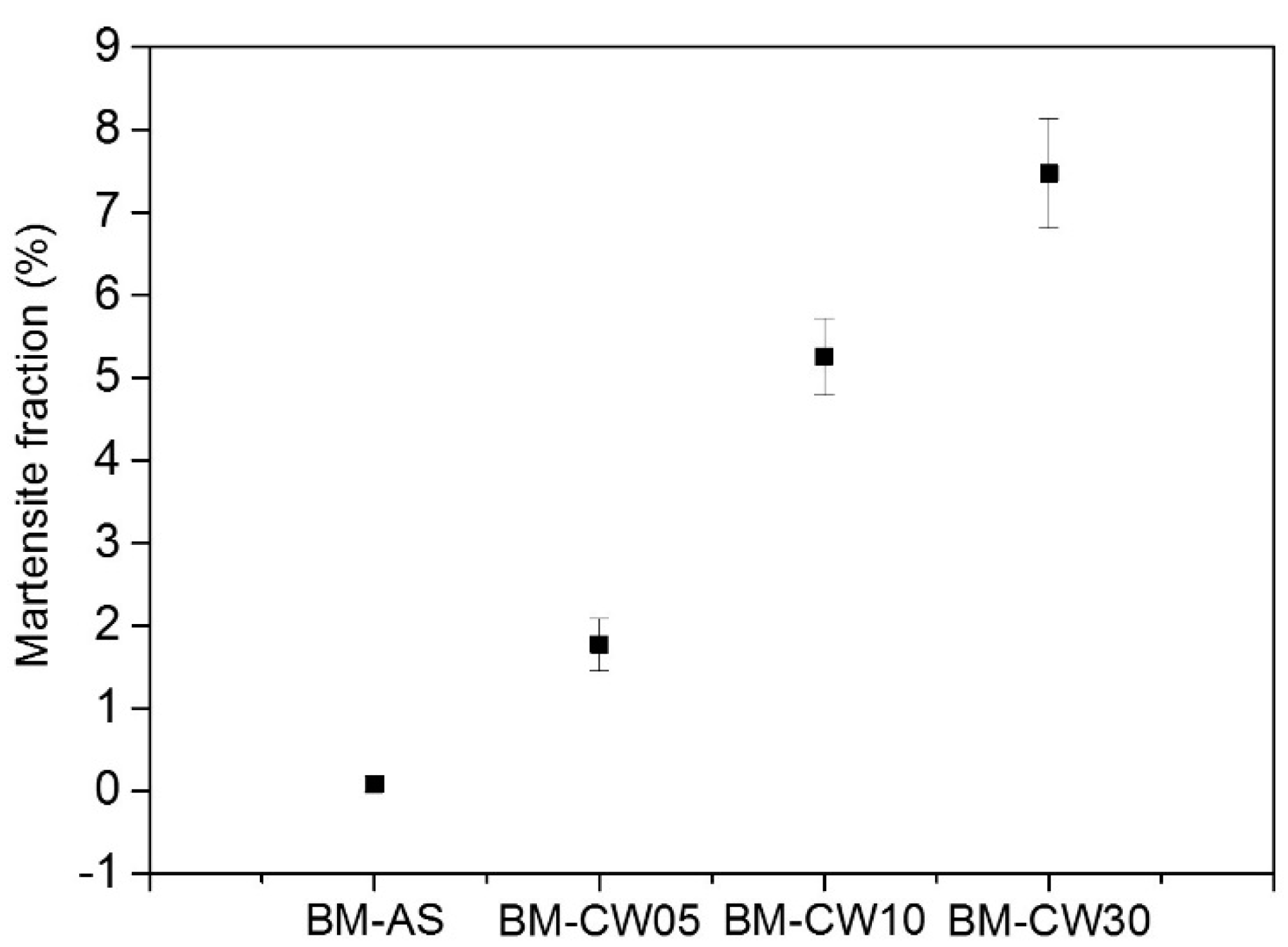

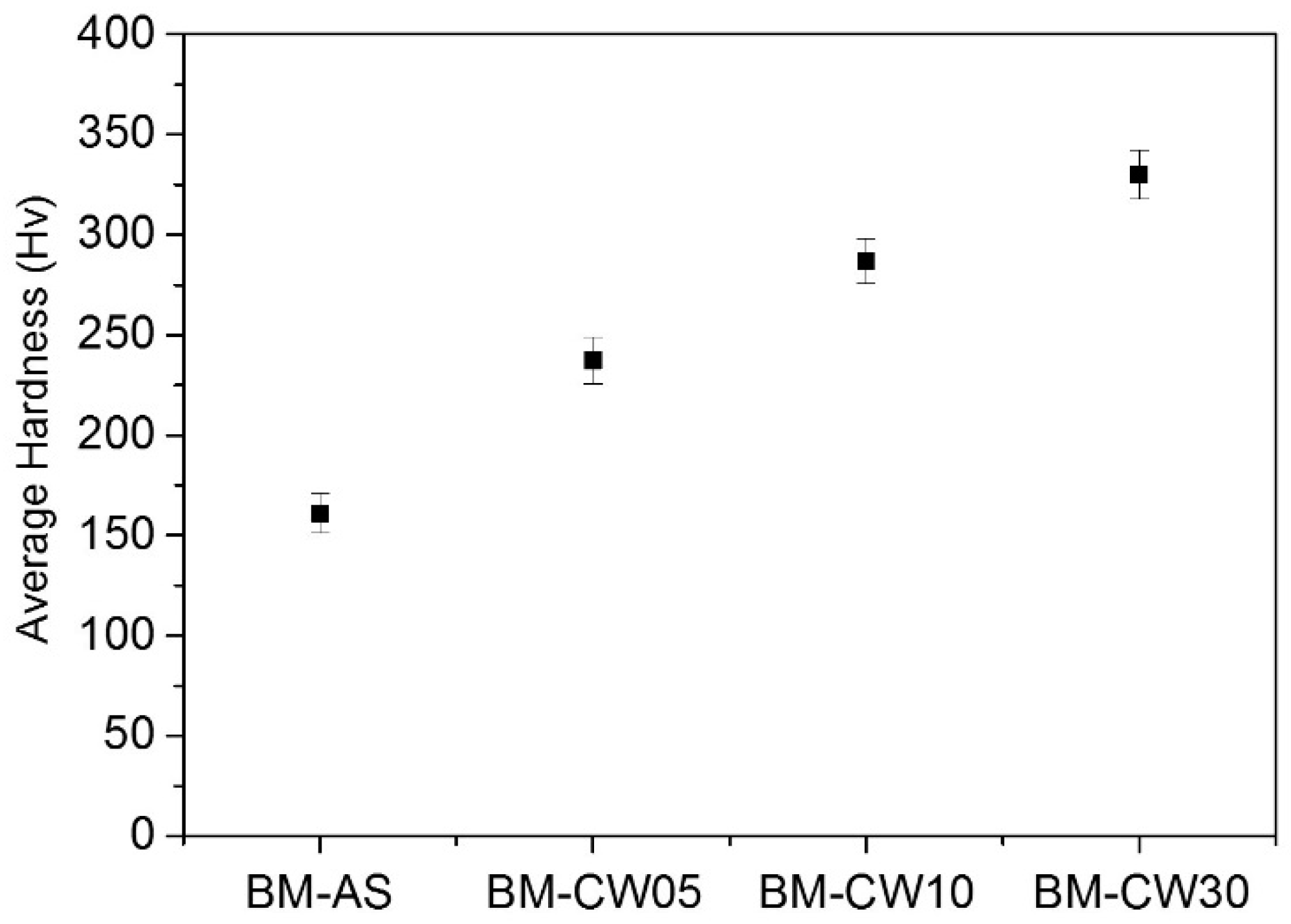

3.1. Strengthening by a Cold-Working Process

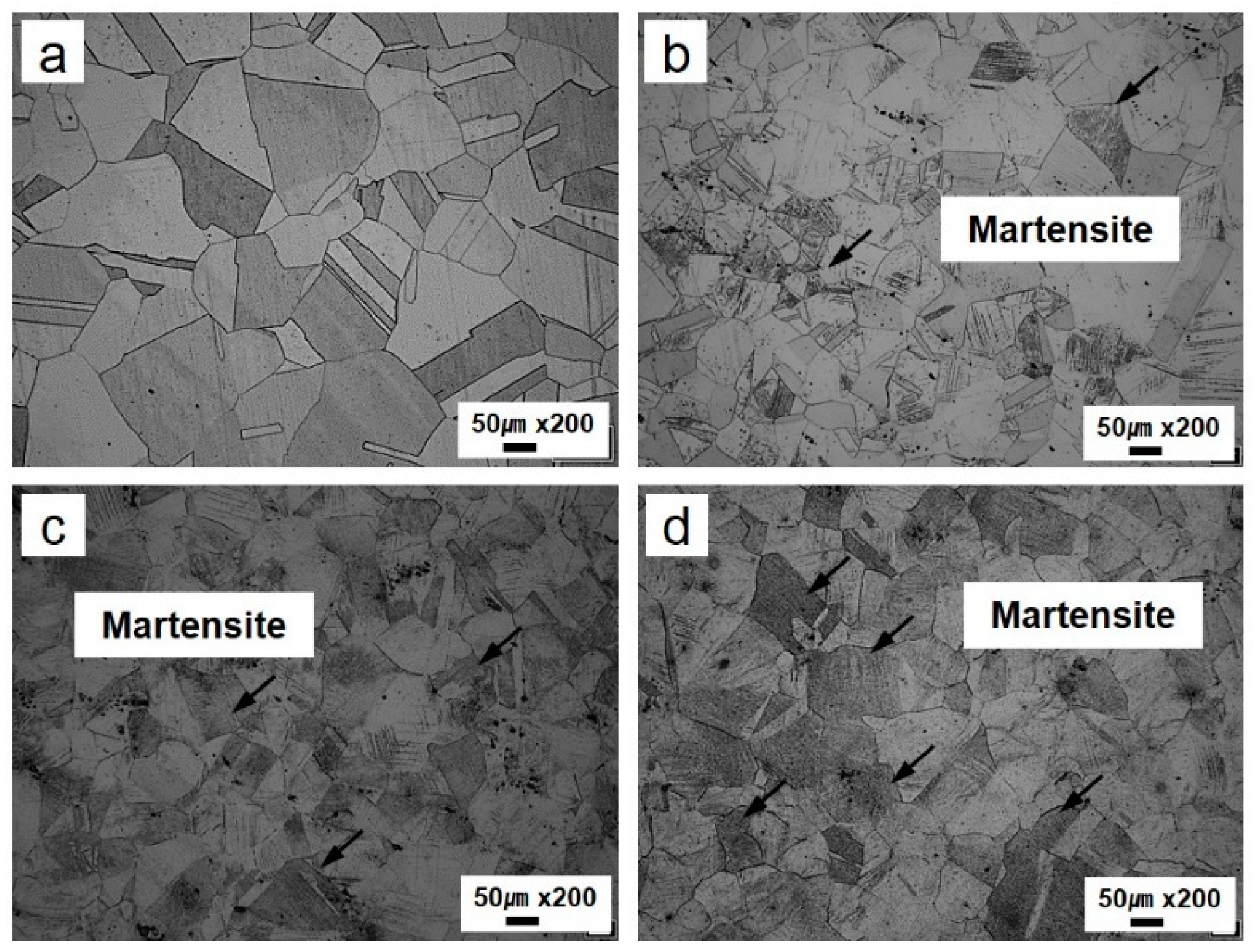

3.2. Mechanism of Strengthening of a Cold-Working Process

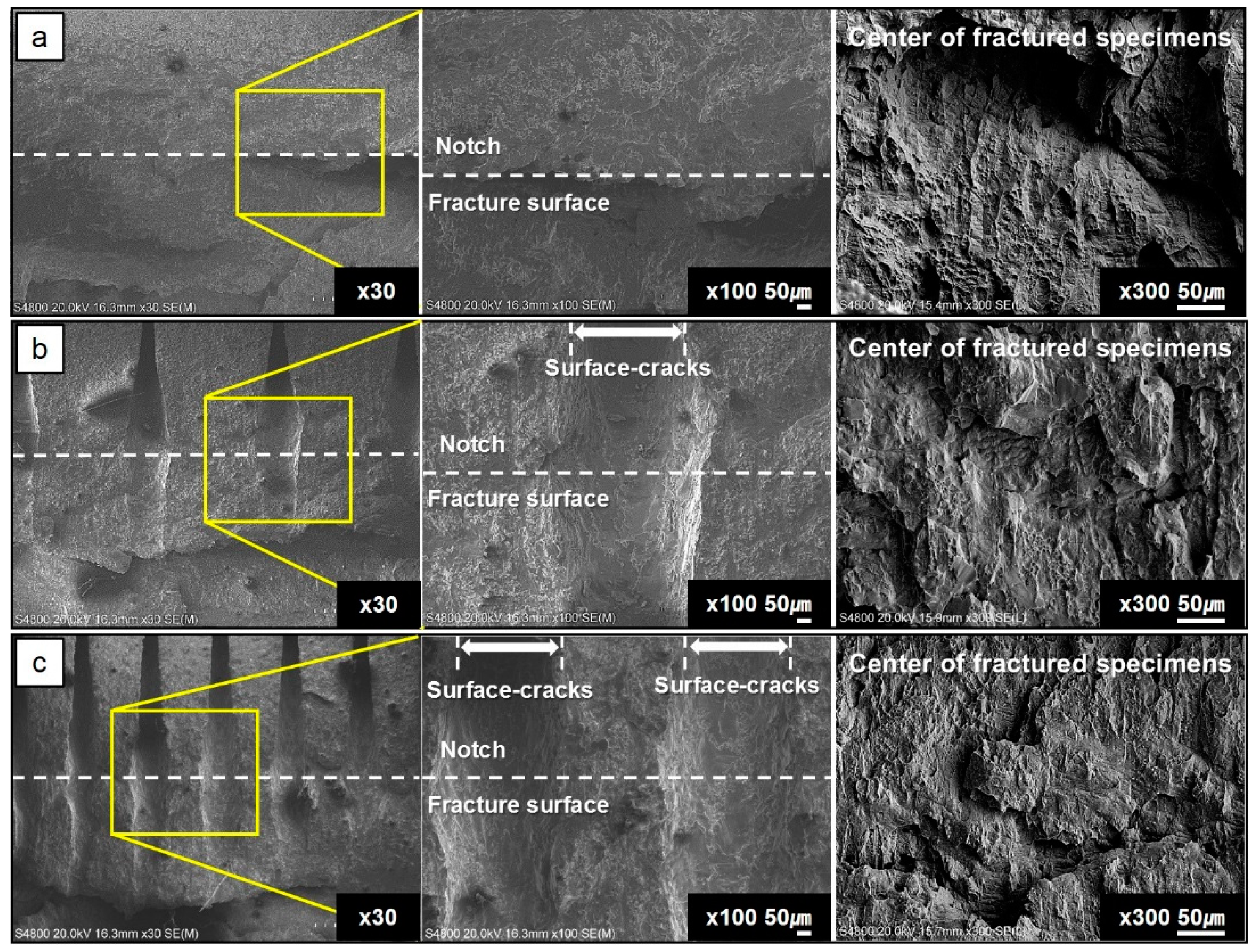

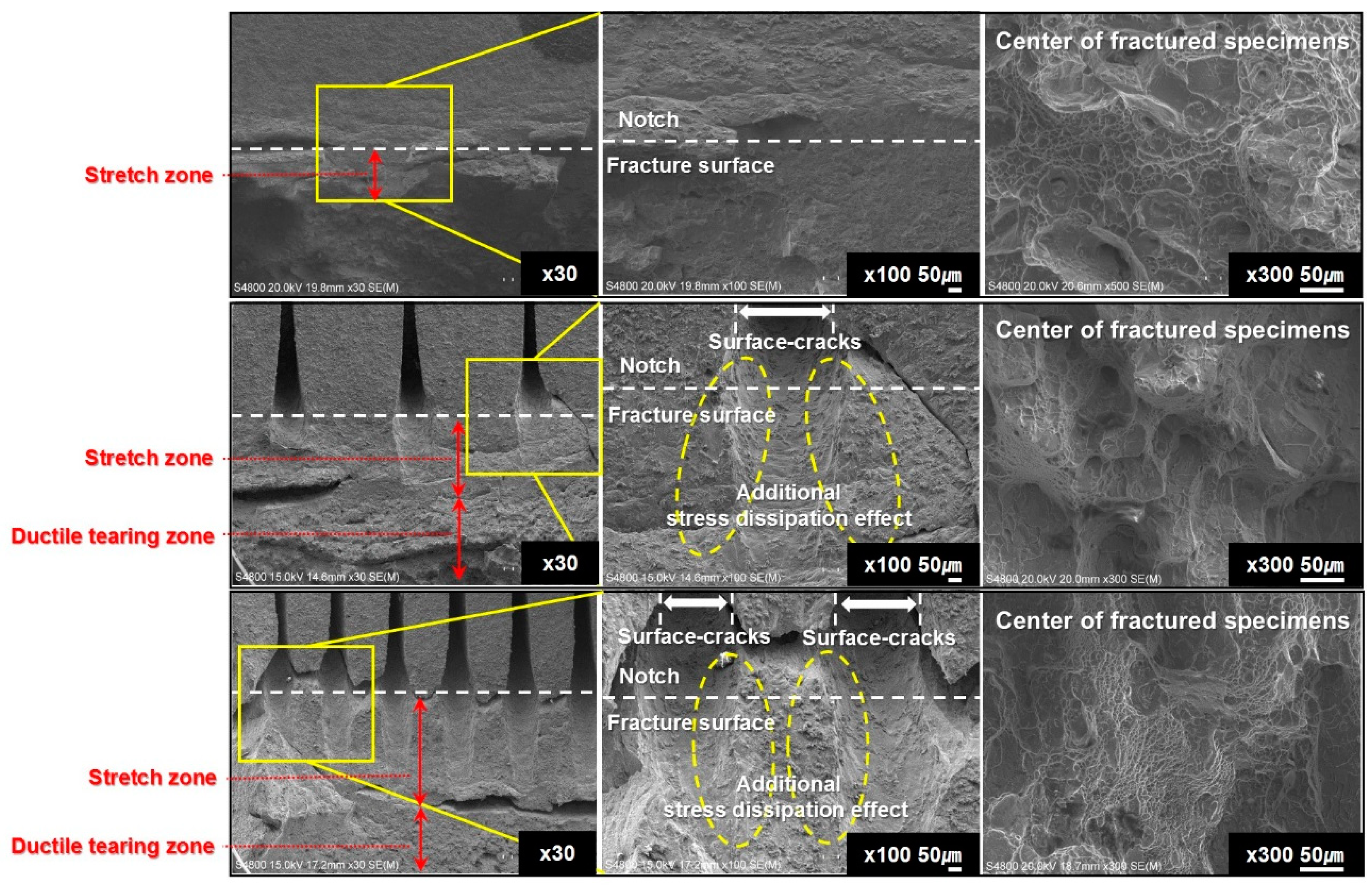

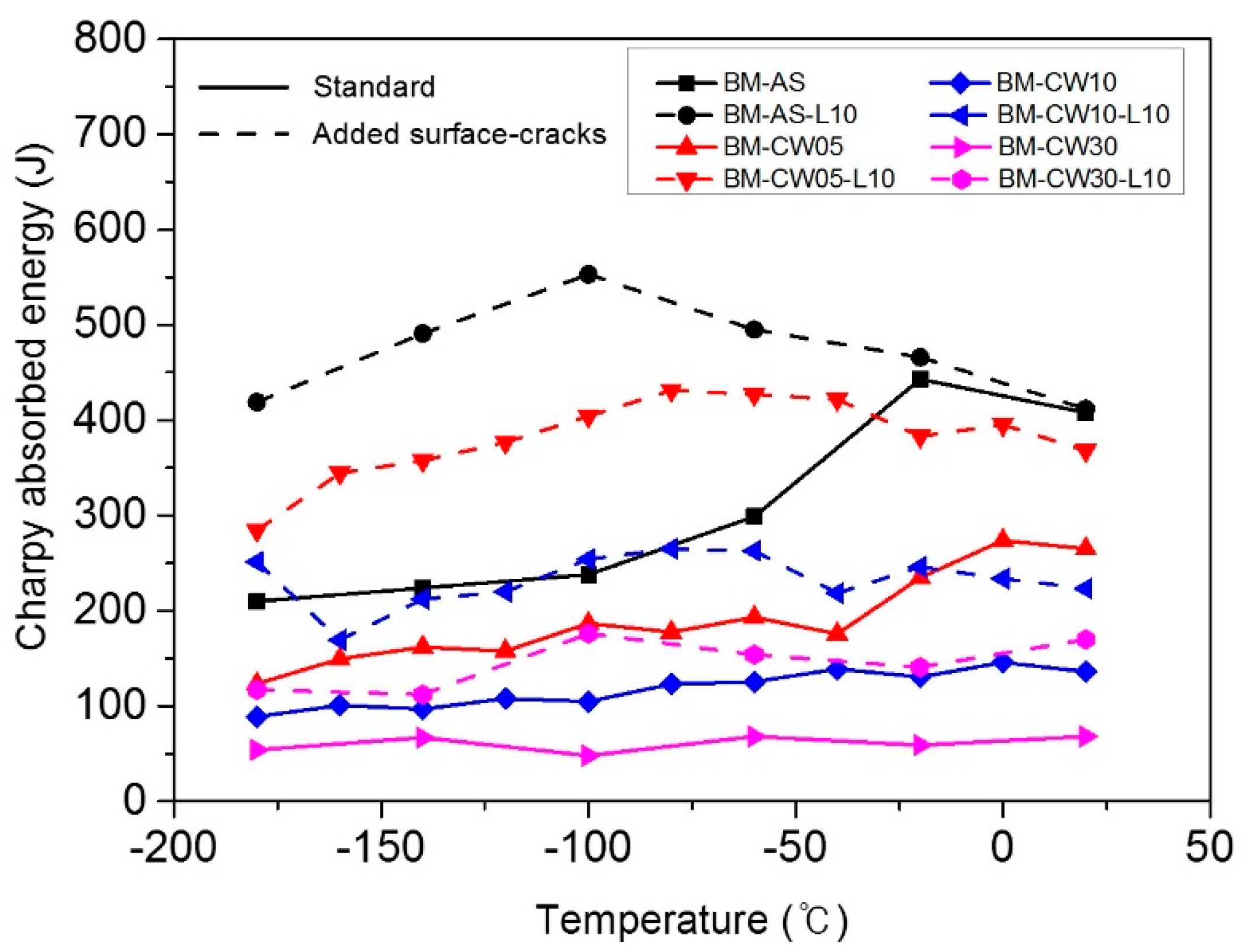

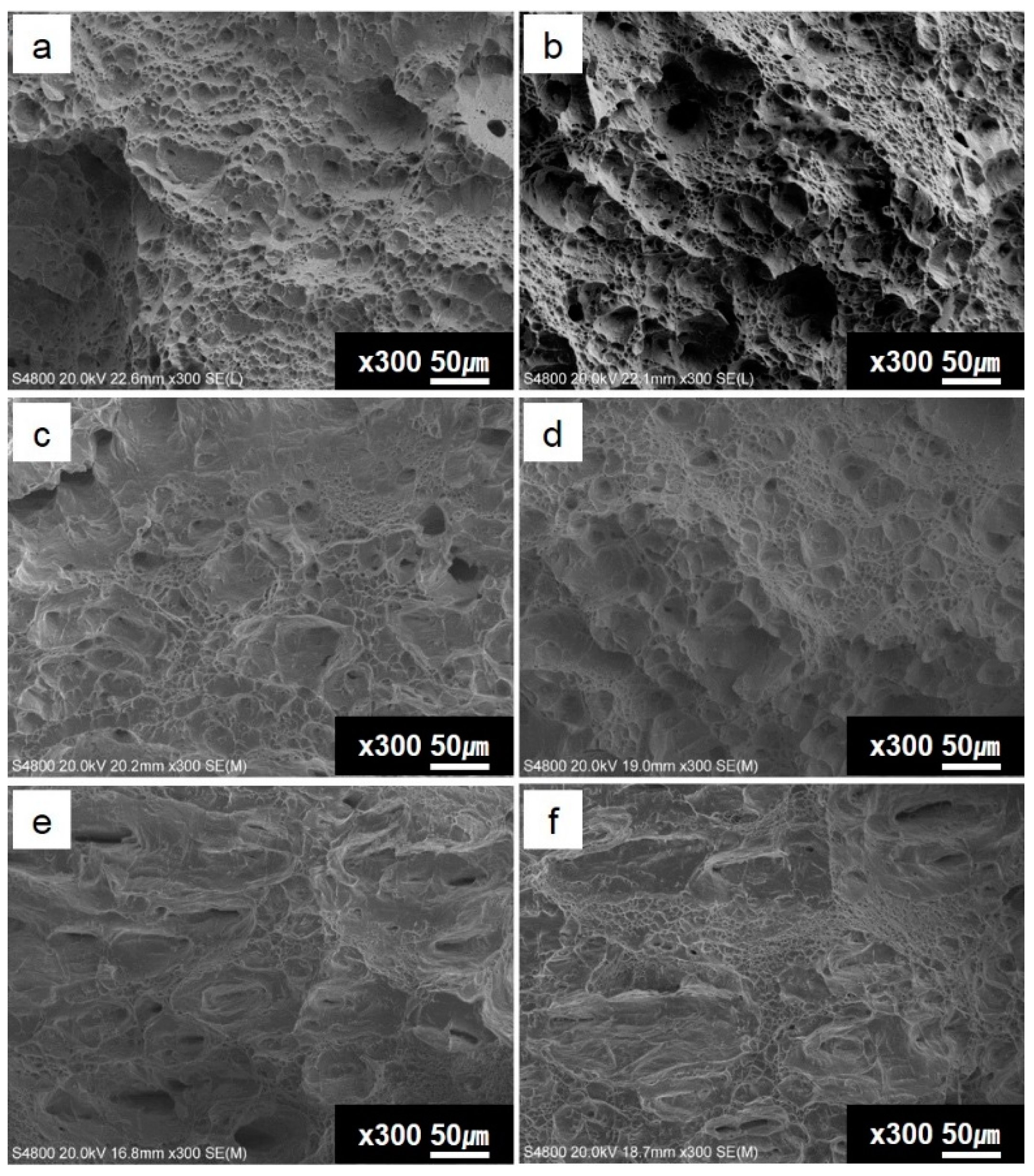

3.3. Toughening by a Surface-Cracking Process

3.4. Toughening by a Surface-Cracking Process

3.5. High Strength and Toughness Steels by a Surface-Cracking Technique

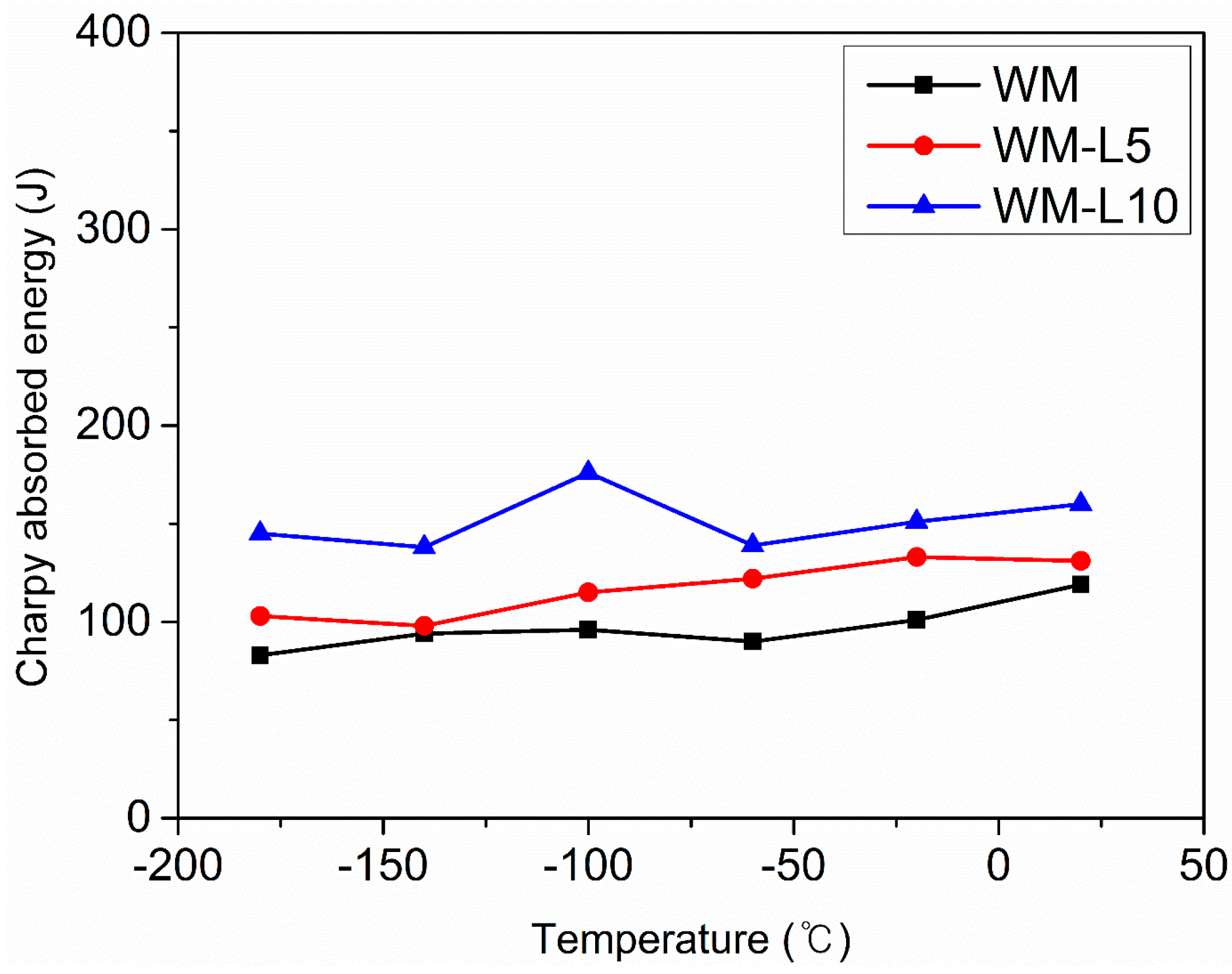

3.6. Application of a Surface-Cracking Technique in Weld Metal

4. Conclusions

- After a cold-working process, the microstructure was changed from austenite single phase to dual phases which consisted of austenite and martensite. The tensile strength and hardness increased with an increase in the cold-working level. The phase transformation from austenite to martensite and the increase in dislocations by plastic deformation led to the strengthening of cold-worked STS304 steels.

- The specimen with surface-cracks had a higher absorbed energy compared to the as-received specimen without surface-cracks at low temperature regions (below −60 °C). The dissipation of the crack propagation energy with surface-cracks enhanced the impact toughness, showing a ductile fracture mode even in the cryogenic temperature region.

- The absorbed energy of cold-worked steels decreased with a cold-working level. Comparing the surface-cracking effect of specimens with the same cold-working level, the absorbed energy of specimens with surface-cracks was two times higher than that of the specimen without surface-cracks. In particular, the strength and toughness were simultaneously increased at 5% cold-worked specimens with surface-cracks. The absorbed energy of the welded specimen had a relatively lower value compared to the as-received specimen. After a surface-cracking process, the absorbed energy was increased by effect of a surface-cracking process. Similar to the result of the cold-worked specimen, toughening by a surface-cracking process in the welded specimen happened in all temperature regions.

Author Contributions

Funding

Conflicts of Interest

References

- Pacio, J.C.; Dorao, C.A. A review on heat exchanger thermal hydraulic models for cryogenic applications. Cryogenics 2011, 51, 366–379. [Google Scholar] [CrossRef]

- Raab, J.; Tward, E. Northrop Grumman aerospace systems cryocooler overview. Cryogenics 2010, 50, 572–581. [Google Scholar] [CrossRef]

- Haberbusch, M.S.; Nguyen, C.T.; Stochl, R.J.; Hui, T.Y. Development of No-Vent™ liquid hydrogen storage system for space applications. Cryogenics 2010, 50, 541–548. [Google Scholar] [CrossRef]

- Chen, Q.-S.; Wegrzyn, J.; Prasad, V. Analysis of temperature and pressure changes in liquefied natural gas (LNG) cryogenic tanks. Cryogenics 2004, 44, 701–709. [Google Scholar] [CrossRef]

- Honda, A.; Okano, F.; Ooshima, K.; Akino, N.; Kikuchi, K.; Tanai, Y.; Takenouchi, T.; Numazawa, S.; Ikeda, Y. Application of PLC to dynamic control system for liquid He cryogenic pumping facility on JT-60U NBI system. Fusion Eng. Des. 2008, 83, 276–279. [Google Scholar] [CrossRef]

- Kim, S.B.; Takano, R.; Nakano, T.; Imai, M.; Hahn, S.Y. Characteristics of the magnetic field distribution on compact NMR magnets using cryocooled HTS bulks. Phys. C Supercond. 2009, 469, 1811–1815. [Google Scholar] [CrossRef]

- Qiu, L.L.; Zhuang, M.; Hu, L.B.; Xu, G.F.; Yuan, C.Y. Operational performance of EAST cryogenic system and analysis of it’s upgrading. Fusion Eng. Des. 2011, 86, 2821–2826. [Google Scholar] [CrossRef]

- Lee, K.J.; Chun, M.S.; Kim, M.H.; Lee, J.M. A new constitutive model of austenitic stainless steel for cryogenic applications. Comput. Mater. Sci. 2009, 46, 1152–1162. [Google Scholar] [CrossRef]

- Marshall, P. Austenitic Stainless Steels: Microstructure and Mechanical Properties; Springer Science & Business Media: Dordrecht, The Netherlands, 1984. [Google Scholar]

- Kim, Y.G.; Han, J.M.; Lee, J.S. Composition and temperature dependence of tensile properties of austenitic Fe–Mn–Al–C alloys. Mater. Sci. Eng. A 1989, 114, 51–59. [Google Scholar] [CrossRef]

- Nakanishi, D.; Kawabata, T.; Aihara, S. Effect of dispersed retained γ-Fe on brittle crack arrest toughness in 9% Ni steel in cryogenic temperatures. Mater. Sci. Eng. A 2018, 723, 238–246. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantas, K.; Pekbey, Y. Effect of cryogenic and aging treatments on low-energy impact behaviour of Ti–6Al–4V alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 514–526. [Google Scholar] [CrossRef]

- Barucci, M.; Ligi, C.; Lolli, L.; Marini, A.; Martelli, V.; Risegari, L.; Ventura, G. Very low temperature specific heat of Al 5056. Phys. B Condens. Matter 2010, 405, 1452–1454. [Google Scholar] [CrossRef]

- Dai, Q.; Yuan, Z.; Chen, X.; Chen, K. High-cycle fatigue behavior of high-nitrogen austenitic stainless steel. Mater. Sci. Eng. A 2009, 517, 257–260. [Google Scholar] [CrossRef]

- Abe, A.; Nakamura, M.; Sato, I.; Uetani, H.; Fujitani, T. Studies of the large-scale sea transportation of liquid hydrogen. Int. J. Hydrogen Energy 1998, 23, 115–121. [Google Scholar] [CrossRef]

- Nam, T.-H.; An, E.; Kim, B.J.; Shin, S.; Ko, W.-S.; Park, N.; Kang, N.; Jeon, J.B. Effect of post weld heat treatment on the microstructure and mechanical properties of a submerged-arc-welded 304 stainless steel. Metals 2018, 8, 26. [Google Scholar] [CrossRef]

- Markandeya, R.; Nagarjuna, S.; Sarma, D.S. Effect of prior cold work on age hardening of Cu–3Ti–1Cr alloy. Mater. Charact. 2006, 57, 348–357. [Google Scholar] [CrossRef]

- Karlsen, W.; Van Dyck, S. The effect of prior cold-work on the deformation behaviour of neutron irradiated AISI 304 austenitic stainless steel. J. Nuclear Mater. 2010, 406, 127–137. [Google Scholar] [CrossRef]

- Karjalainen, L.P.; Taulavuori, T.; Sellman, M.; Kyröläinen, A. Some strengthening methods for austenitic stainless steels. Steel Res. Int. 2008, 79, 404–412. [Google Scholar] [CrossRef]

- Shintani, T.; Murata, Y. Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater. 2011, 59, 4314–4322. [Google Scholar] [CrossRef]

- Milad, M.; Zreiba, N.; Elhalouani, F.; Baradai, C. The effect of cold work on structure and properties of AISI 304 stainless steel. J. Mater. Process. Technol. 2008, 203, 80–85. [Google Scholar] [CrossRef]

- Shen, Y.; Li, X.; Sun, X.; Wang, Y.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng. A. 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Xu, D.; Wan, X.; Yu, J.; Xu, G.; Li, G. Effect of cold deformation on microstructures and mechanical properties of austenitic stainless steel. Metals 2018, 8, 522. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Karjalainen, L.P. Reversed microstructures and tensile properties after various cold rolling reductions in AISI 301LN steel. Metals 2018, 8, 109. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Wu, W. Effect of α′ martensite content induced by tensile plastic prestrain on hydrogen transport and hydrogen embrittlement of 304L austenitic stainless steel. Metals 2018, 8, 660. [Google Scholar] [CrossRef]

- Kim, T.K.; Kim, S.H. Study on the cold working process for FM steel cladding tubes. J. Nuclear Mater. 2011, 411, 208–212. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Sivaprasad, K.; Narayanasamy, R. Microstructure, cold workability and strain hardening behavior of trimodaled AA 6061–TiO2 nanocomposite prepared by mechanical alloying. Mater. Sci. Eng. A. 2011, 528, 6776–6787. [Google Scholar] [CrossRef]

- Mallick, P.; Tewary, N.K.; Ghosh, S.K.; Chattopadhyay, P.P. Microstructure-tensile property correlation in 304 stainless steel after cold deformation and austenite reversion. Mater. Sci. Eng. A 2017, 707, 488–500. [Google Scholar] [CrossRef]

- Panwar, S.; Goel, D.B.; Pandey, O.P. Effect of cold work and aging on mechanical properties of a copper bearing microalloyed HSLA-100 (GPT) steel. Bull. Mater. Sci. 2007, 30, 73–79. [Google Scholar] [CrossRef]

- Tsuji, N.; Okuno, S.; Koizumi, Y.; Minamino, Y. Toughness of ultrafine grained ferritic steels fabricated by ARB and annealing process. Mater. Trans. 2004, 45, 2272–2281. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse temperature dependence of toughness in an ultrafine grain-structure steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed]

- Takaki, S.; Kawasaki, K.; Kimura, Y. Mechanical properties of ultra fine grained steels. J. Mater. Process. Technol. 2001, 117, 359–363. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Valiev, R.Z.; Zhu, Y.T. Enhanced low-temperature impact toughness of nanostructured Ti. Appl. Phys. Lett. 2006, 88, 041905. [Google Scholar] [CrossRef]

- Rao, K.T.V.; Ritchie, R.O. Fatigue of aluminium—Lithium alloys. Int. Mater. Rev. 1992, 37, 153–186. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Comp. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

- Guo, W.; Dong, H.; Lu, M.; Zhao, X. The coupled effects of thickness and delamination on cracking resistance of X70 pipeline steel. Int. J. Pres. Vessel. Pip. 2002, 79, 403–412. [Google Scholar] [CrossRef]

- Morris, J.W. Stronger, tougher steels. Science 2008, 320, 1022–1023. [Google Scholar] [CrossRef] [PubMed]

- Jafari, M.; Kimura, Y.; Tsuzaki, K. Enhanced upper shelf energy by ultrafine elongated grain structures in 1100 MPa high strength steel. Mater. Sci. Eng. A 2012, 532, 420–429. [Google Scholar] [CrossRef]

- Lu, K. The future of metals. Science 2010, 328, 319–320. [Google Scholar] [CrossRef] [PubMed]

- Launey, M.E.; Ritchie, R.O. On the fracture toughness of advanced materials. Adv. Mater. 2009, 21, 2103–2110. [Google Scholar] [CrossRef]

- Ritchie, R.O. The quest for stronger, tougher materials. Science 2008, 320, 448. [Google Scholar] [CrossRef] [PubMed]

- Rajasekhara, S.; Ferreira, P.J.; Karjalainen, L.P.; Kyröläinen, A. Hall–Petch behavior in ultra-fine-grained AISI 301LN stainless steel. Metall. Mater. Trans. A 2007, 38, 1202–1210. [Google Scholar] [CrossRef]

- Dumont, D.; Deschamps, A.; Brechet, Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy. Mater. Sci. Eng. A 2003, 356, 326–336. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, G.; Wang, R.; Zhang, G.-J.; Pu, X.; Sun, J.; Chen, K.-H. Effect of precipitate morphology evolution on the strength-toughness relationship in Al–Mg–Si alloys. Scr. Mater. 2009, 60, 1109–1112. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (Filadelfia). Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; ASTM: West Conshohocken, PA, USA, 2002. [Google Scholar]

| Alloys | C | Mn | Si | Cr | Ni | Mo | Al | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Base Metal (STS304) | 0.046 | 1.19 | 0.42 | 18.23 | 8.02 | 0.149 | 0.003 | 0.223 | Bal. |

| Weld Metal (STS308L) | 0.02 | 1.98 | 0.41 | 19.71 | 10.79 | 0.03 | - | 0.13 | Bal. |

| Specimen ID | Region | Cold-Working Level | Number of Added Surface-Cracks |

|---|---|---|---|

| BM-AS | Base metal | - | - |

| BM-AS-L5 | Base metal | - | 5 lines |

| BM-AS-L10 | Base metal | - | 10 lines |

| BM-CW05 | Base metal | 5% | - |

| BM-CW05-L10 | Base metal | 5% | 10 lines |

| BM-CW10 | Base metal | 10% | - |

| BM-CW10-L10 | Base metal | 10% | 10 lines |

| BM-CW30 | Base metal | 30% | - |

| BM-CW30-L10 | Base metal | 30% | 10 lines |

| WM | Weld metal | - | - |

| WM-L5 | Weld metal | - | 5 lines |

| WM-L10 | Weld metal | - | 10 lines |

| Specimen ID | Yield Strength, σy (MPa) | Tensile Strength, σt (MPa) | Elongation, (%) | Average Vickers Hardness (HV) |

|---|---|---|---|---|

| BM-AS | 212 | 689 | 91 | 161 |

| BM-CW05 | 548 | 848 | 70 | 237 |

| BM-CW10 | 611 | 854 | 56 | 286 |

| BM-CW30 | 1002 | 1053 | 17 | 330 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Park, M.; Jang, J.; Kim, H.C.; Moon, H.-S.; Lim, D.-H.; Jeon, J.B.; Kwon, S.-H.; Kim, H.; Kim, B.J. Improvement of Strength and Impact Toughness for Cold-Worked Austenitic Stainless Steels Using a Surface-Cracking Technique. Metals 2018, 8, 932. https://doi.org/10.3390/met8110932

Kim K, Park M, Jang J, Kim HC, Moon H-S, Lim D-H, Jeon JB, Kwon S-H, Kim H, Kim BJ. Improvement of Strength and Impact Toughness for Cold-Worked Austenitic Stainless Steels Using a Surface-Cracking Technique. Metals. 2018; 8(11):932. https://doi.org/10.3390/met8110932

Chicago/Turabian StyleKim, Kwangyoon, Minha Park, Jaeho Jang, Hyoung Chan Kim, Hyoung-Seok Moon, Dong-Ha Lim, Jong Bae Jeon, Se-Hun Kwon, Hyunmyung Kim, and Byung Jun Kim. 2018. "Improvement of Strength and Impact Toughness for Cold-Worked Austenitic Stainless Steels Using a Surface-Cracking Technique" Metals 8, no. 11: 932. https://doi.org/10.3390/met8110932

APA StyleKim, K., Park, M., Jang, J., Kim, H. C., Moon, H.-S., Lim, D.-H., Jeon, J. B., Kwon, S.-H., Kim, H., & Kim, B. J. (2018). Improvement of Strength and Impact Toughness for Cold-Worked Austenitic Stainless Steels Using a Surface-Cracking Technique. Metals, 8(11), 932. https://doi.org/10.3390/met8110932