Abstract

Fabrication of Fe3Al–TiB2–Al2O3 composites with a broad range of phase compositions was studied by combustion synthesis involving aluminothermic reduction of oxide precursors. Two reaction systems composed of elemental Fe, amorphous boron, and a thermite mixture of Fe2O3/TiO2/Al were conducted in the mode of self-propagating high-temperature synthesis (SHS). One was to produce the composites of 1.25Fe3Al + xTiB2 + Al2O3 with x = 0.3–1.0. The other was to fabricate the products of yFe3Al + 0.6TiB2 + Al2O3 with y = 1.0–1.6. Reduction of Fe2O3 by Al acted as an initiation step to activate the SHS process. Complete phase conversion from the reactants to Fe3Al–TiB2–Al2O3 composites was achieved. The variation of combustion front velocity with sample stoichiometry was consistent with that of the reaction exothermicity. Based on combustion wave kinetics, the activation energy of Ea = 86.8 kJ/mol was determined for formation of the Fe3Al–TiB2–Al2O3 composite through the thermite-based SHS reaction. In addition, with an increase in TiB2, the fracture toughness of the 1.25Fe3Al + xTiB2 + Al2O3 composite was found to increase from 5.32 to 7.92 MPa·m1/2.

1. Introduction

The iron aluminides Fe3Al and FeAl have been of significant importance for high-temperature structural and coating applications due to their low cost, low density, relatively high melting point, high electrical resistivity, and good oxidation, corrosion, and sulfidation resistance. However, they exhibit low ductility and brittle fracture at ambient temperatures [1,2,3]. Efforts to strengthen iron aluminides showed that the room-temperature strength and wear resistance of Fe3Al were greatly improved by incorporating hard carbide or boride particles (such as TiC, WC, TiB2, and ZrB2) [4,5,6,7]. Also, oxide ceramics are effective in reinforcing iron aluminides. The addition of Al2O3 and ZrO2 particles can enhance the high-temperature strength of Fe3Al without compromising its oxidation resistance [8,9,10,11].

A variety of processing techniques have been employed to fabricate iron aluminide–ceramic composites, including liquid-phase sintering [4], hot pressing [8,9], mechanochemical synthesis [10], solid-state displacement reactions [11], and combustion synthesis in the modes of self-propagating high-temperature synthesis (SHS) [12] and thermal explosion [13]. Among them, the SHS method takes advantage of highly exothermic reactions, and hence has the merits of a low energy requirement, a short reaction time, inexpensive equipment, simplicity of operation, and a structural and functional diversity of final products [14,15,16]. When combined with a thermite reaction using Al as the reducing agent, combustion synthesis represents an in situ fabrication route to prepare Al2O3-reinforced intermetallics and ceramics [12,13,17,18]. Moreover, aluminothermic reduction of metal oxides is thermally beneficial for the SHS process.

Preparation of transition-metal aluminides of the Ni–Al and Ti–Al systems has been studied by the classical SHS method using elemental powder compacts of their corresponding stoichoimetries [19,20,21]. However, direct combustion between Fe and Al powders in a compressed form to produce Fe3Al and FeAl is not feasible because of their low formation enthalpies or high activation energy barrier. As a result, few related studies on combustion synthesis of iron aluminides are available. According to Sharifitabar et al. [12], TiC/Al2O3-added Fe3Al was produced by combustion synthesis in the SHS mode from a 3TiO2 + 4Al + 3C exothermic mixture with an addition of Fe. Liu et al. [13] obtained FeAl/Al2O3 composites from a reactant mixture made up of Fe, Al, and Fe2O3 by thermal explosion of combustion synthesis. The ignition temperatures were between 639 and 648 °C and the products were highly porous [13].

This study aims to investigate in situ formation of TiB2/Al2O3-reinforced Fe3Al composites by the SHS method involving aluminothermic reduction of Fe2O3 and TiO2. In addition to the thermite reagents, the starting materials included elemental iron and amorphous boron powders. Effects of TiB2 and Fe3Al contents on combustion characteristics were studied. The activation energy of the Fe2O3–TiO2–Al–Fe–B combustion system was deduced from the measured combustion wave velocity and temperature. Moreover, the strengthening effect of TiB2/Al2O3 on Fe3Al was examined.

2. Materials and Methods

The starting materials of this study included Fe2O3 (Alfa Aesar Co., <45 µm, 99.5%, Ward Hill, MA, USA), TiO2 (Alfa Aesar Co., 1–2 µm, 99.5%), Al (Showa Chemical Co., <45 µm, 99.9%, Tokyo, Japan), Fe (Alfa Aesar Co., <45 µm, 99.5%), and amorphous boron (Noah Technologies Corp., <1 µm, 92%, San Antonio, TX, USA). Two combustion systems adopting TiO2, Fe2O3, and Al as the thermite reagents were prepared. Reaction (1) has a variable molar ratio of TiO2 to Fe2O3 and is to produce Fe3Al–TiB2–Al2O3 composites with different contents of TiB2. On the other hand, the molar proportion between the two oxide precursors is fixed and equal to unity in Reaction (2) and the resulting composites contain different amounts of Fe3Al.

where the stoichiometric coefficients, x and y, signify the molar contents of TiB2 and Fe3Al formed in Fe3Al/TiB2/Al2O3 composites based upon Reactions (1) and (2), respectively. Reactant mixtures were formulated with 0.3 ≤ x ≤ 1.0 in Reaction (1) and 1.0 ≤ y ≤ 1.6 in Reaction (2) to attain stable and self-sustaining combustion.

The reactant powders were well-mixed and compressed into cylindrical samples that were 7 mm in diameter, 12 mm in length, and had a relative density of 60%. The SHS reaction was conducted in a windowed stainless-steel chamber under high purity argon (99.99%) of 0.15 MPa. The combustion wave velocity (Vf) was deduced from the time sequence of recorded images. The combustion temperature (Tc) was measured by a fine-wire (125 µm) Pt/Pt-13%Rh thermocouple attached on the sample surface. Phase constituents of the final product were identified by carrying out phase analyses based on the measured powder X-ray diffraction patterns (Bruker D2) using CuKα radiation with λ = 1.5406 Å. The measured XRD patterns were corrected against an external silicon standard. FullProf software (FullProf, Saclay, France) was used for the processing of the data and analyses of the X-ray diffraction patterns. The FullProf program has been mainly developed for the Rietveld analysis of neutron (constant wavelength, time of flight, and nuclear and magnetic scattering) or X-ray powder diffraction data collected at a constant or variable step in scattering angle 2θ [22,23]. The program can be used as a profile matching (or pattern decomposition using the Le Bail method) tool without knowledge of the structure. Single crystal refinement can also be performed alone or in combination with powder data [23]. The microstructure of the synthesized product was examined under a scanning electron microscope (SEM) (Hitachi, S3000H, Tokyo, Japan) and elemental analysis was performed by energy dispersive spectroscopy (EDS) (Hitachi, S3000H, Tokyo, Japan). The fracture toughness (KIC) of the SHS-derived composite was determined by the indentation method [24]. Details of the experimental methods were previously reported [25].

3. Results and Discussion

3.1. Self-Propagating Combustion Characteristics and Kinetics

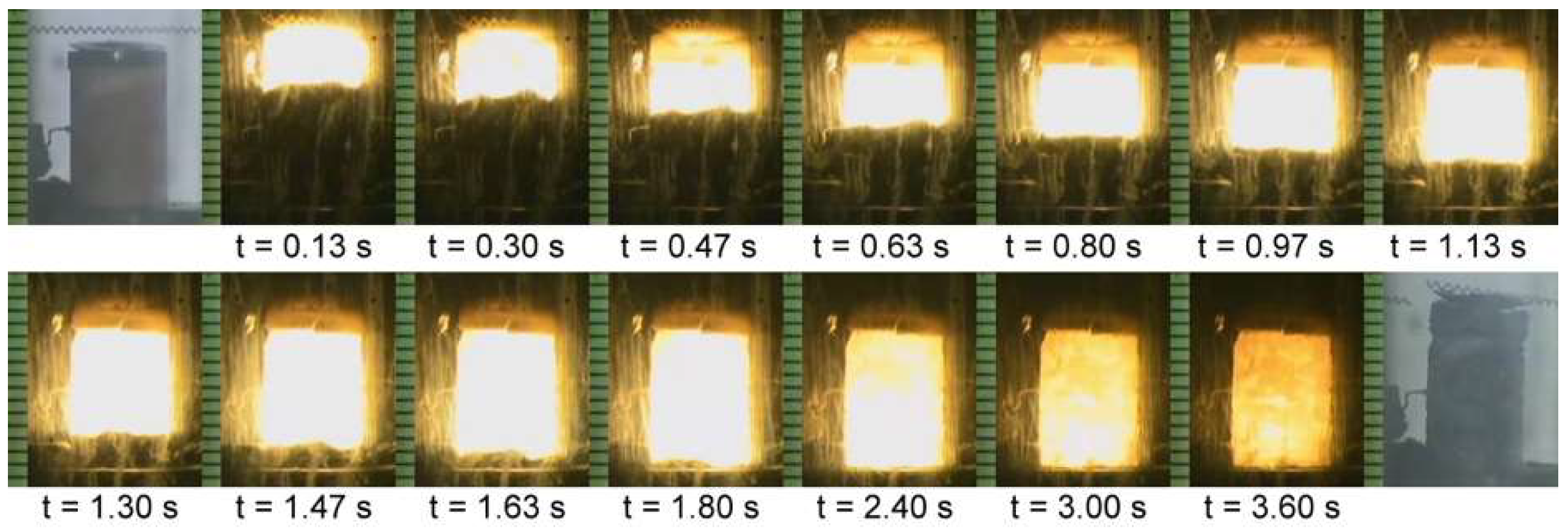

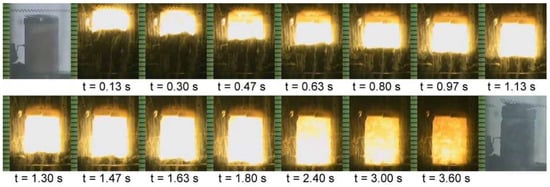

Figure 1 presents a typical combustion sequence recorded from the sample of Reaction (1) with x = 0.5. It is evident that upon ignition a distinct combustion wave forms and propagates over the starting reactant compact in a self-sustaining manner. Namely, the synthesis reaction proceeds in a form of combustion wave and yields the final product progressively without requiring additional heat. It took about t = 1.8 s for the combustion wave to arrive at the bottom of the sample. With an optically superimposed scale on the left-hand side of each image, the flame-front propagation velocity was determined.

Figure 1.

A time sequence of self-propagating combustion images recorded from a powder compact of Reaction (1) with x = 0.5.

It is useful to note that the thermite reaction of Fe2O3 + 2Al (∆H = –852.3 kJ and Tad = 3622 K) is much more exothermic than that of 1.5TiO2 + 2Al (∆H = –258.7 kJ and Tad = 1799 K) [26,27]. Therefore, the reaction exothermicity of overall aluminothermic reduction decreases with the increase of x in Reaction (1). It was found in this study that due most likely to insufficient reaction exothermicity, combustion ceased to proceed in Reaction (1) with x > 1.0. On the contrary, violent combustion accompanying massive melting of the sample occurred in Reaction (1) with x < 0.3, which made both experimental measurement and product recovery difficult.

In Reaction (2), the increase of Fe and Al (i.e., the coefficient y) for the production of more Fe3Al imposes a dilution effect on combustion, because the formation enthalpy of Fe3Al (∆Hf = –67 kJ/mol) is much lower than those of TiB2 (∆Hf = –315.9 kJ/mol) and Al2O3 (∆Hf = –1675.7 kJ/mol) [1,27]. The combustibility limit of Reaction (2) was found at y = 1.6, beyond which no combustion can be triggered.

For both combustion systems, formation of the Fe3Al–TiB2–Al2O3 composite proceeds in three consecutive stages [26]. Reduction of Fe2O3 by Al to produce Fe and Al2O3 is believed to be the initiation step, which is followed by aluminothermic reduction of TiO2. Then, the interactions of Fe with Al and Ti with B respectively yield Fe3Al and TiB2.

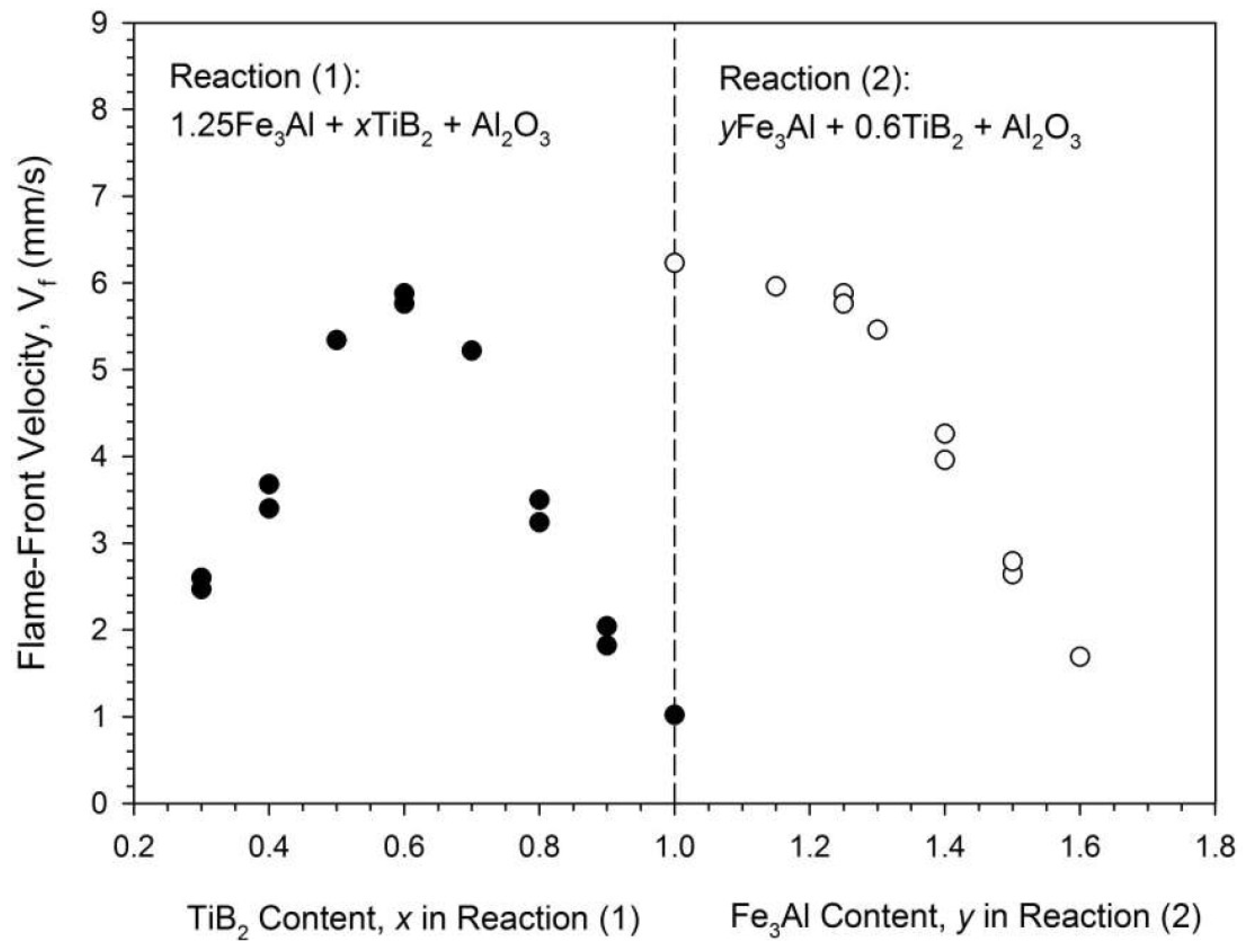

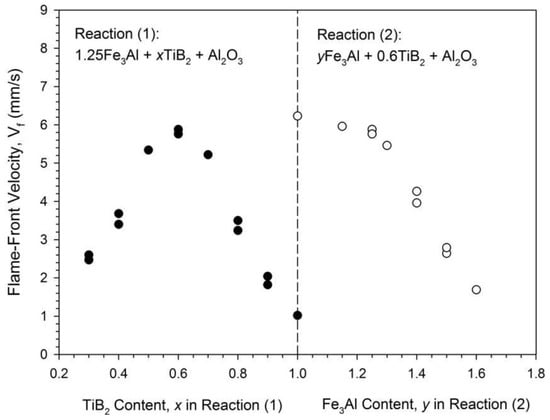

Variations of the flame-front velocity of Reactions (1) and (2) are shown in Figure 2 with respect to their corresponding stoichiometric coefficients x and y. As revealed in Figure 2, the combustion front velocity of Reaction (1) first increases with x, approaches to a maximum of about 5.88 mm/s at x = 0.6, and then decreases with a further increase in x. This is because the influence of the sample stoichiometry of Reaction (1) on combustion velocity is attributed to two competing factors. With the increase of x, the amount of TiO2 increases but that of Fe2O3 deceases in the starting mixture, thus resulting in a decline in reaction exothermicity of the overall aluminothermic reduction. On the other hand, the content of TiB2 formed in the product increases as the coefficient x rises and TiB2 is a highly exothermic phase with ∆Hf = –315.9 kJ/mol [27]. The observation in Figure 2 for Reaction (1) implies that the latter concern governs when the sample stoichiometry varies from x = 0.3 to 0.6, beyond which the former factor becomes dominant. As a result, the flame-front velocity dropped to around 1.02 mm/s at x = 1.0.

Figure 2.

Effects of stoichiometric coefficients (x and y) on flame-front velocities of Reactions (1) and (2) for combustion synthesis of Fe3Al–TiB2–Al2O3 composites.

Figure 2 also points out that the combustion wave speed of Reaction (2) decreases with increasing y value. The increase of y in Reaction (2) is to enlarge the content of Fe3Al formed from metallic Fe and Al without varying the composition of thermite reagents and the amount of TiB2. As mentioned above, the formation enthalpy of Fe3Al is relatively low in comparison to that of TiB2 and the heat released from the reduction of Fe2O3 and TiO2 by Al. Therefore, the increase of y from 1.0 to 1.6 reduced the overall combustion exothermicity of Reaction (2) and led to deceleration of the combustion wave from 6.23 to 1.69 mm/s.

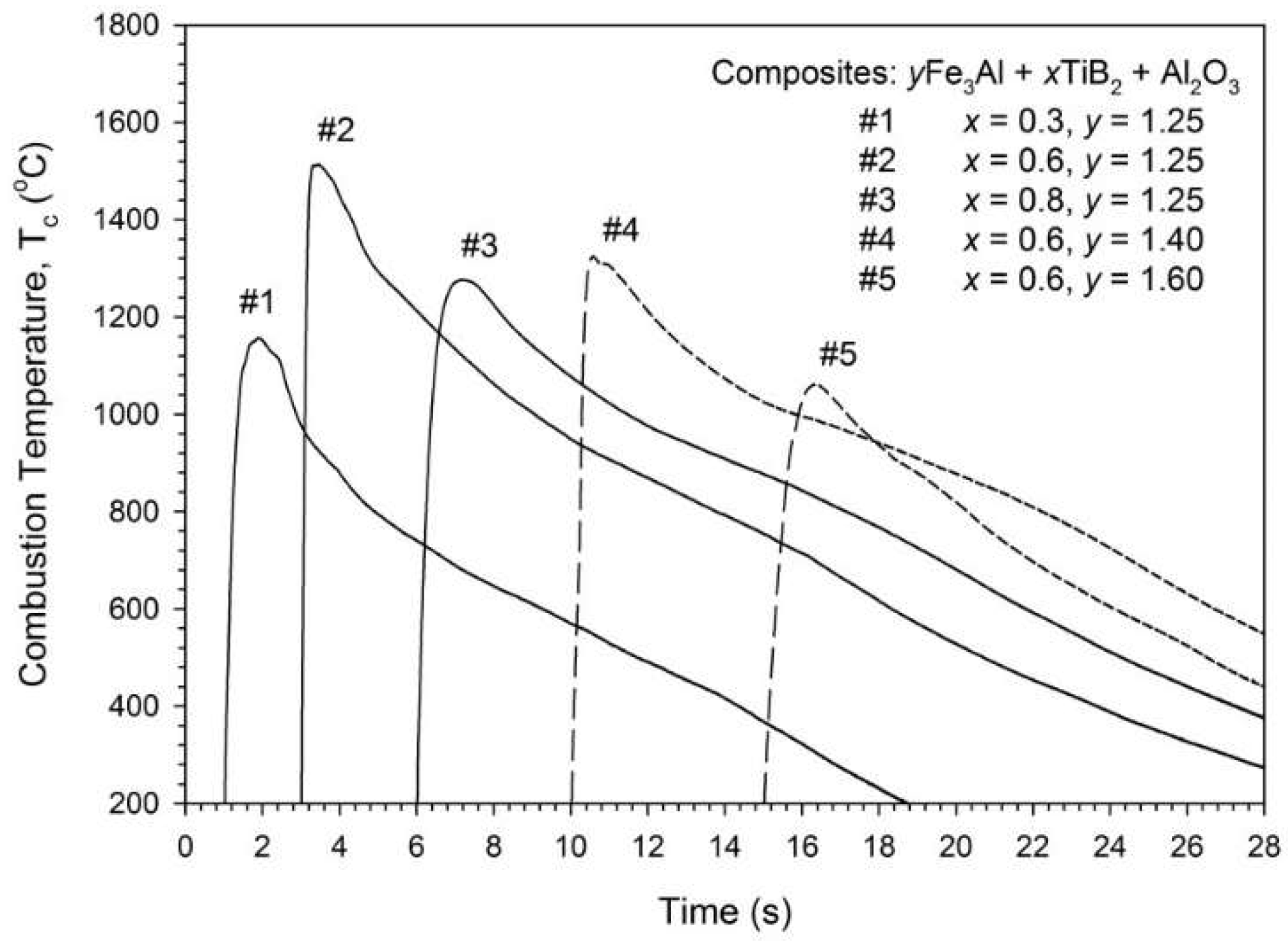

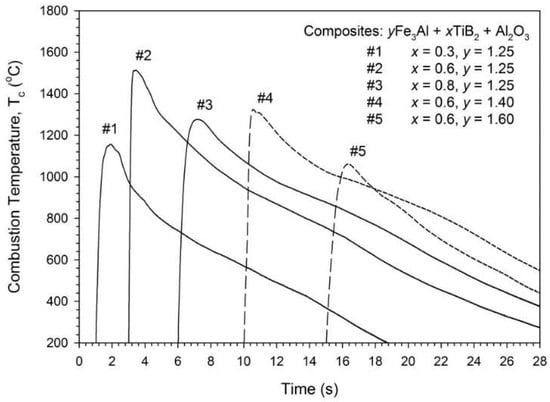

Typical combustion temperature profiles recorded from the powder compacts of Reactions (1) and (2) with different stoichiometries are depicted in Figure 3. The abrupt rise in temperature signifies a rapid arrival of the combustion wave and the peak value corresponds to the combustion front temperature. After the passage of the combustion wave, an appreciable temperature drop is a consequence of heat loss to the surroundings. Profiles #1, #2, and #3 in Figure 3 are associated with Reaction (1) with x = 0.3, 0.6, and 0.8 and their peak temperatures are 1157, 1514, and 1277 °C, respectively. This suggests that the variation of combustion front temperature of Reaction (1) with TiB2 content is in a manner consistent with that of flame-front velocity. For Reaction (1), the highest combustion front temperature of 1514 °C was detected from the sample of x = 0.6.

Figure 3.

Variations of combustion temperature with TiB2 and Fe3Al contents of Fe3Al–TiB2–Al2O3 composites synthesized by self-propagating high-temperature synthesis (SHS) involving reduction reactions.

Profiles #4 and #5 were measured from Reaction (2) with y = 1.4 and 1.6, respectively. It is evident that the increase of Fe3Al lowers the reaction temperature, which is in agreement with its effect on combustion wave velocity. For Reaction (2), the lowest combustion front temperature was around 1061 °C as the sample produced the maximum amount of Fe3Al (i.e., y = 1.6). The highest temperature, reaching up to 1524 °C, was observed in the sample of y = 1.0.

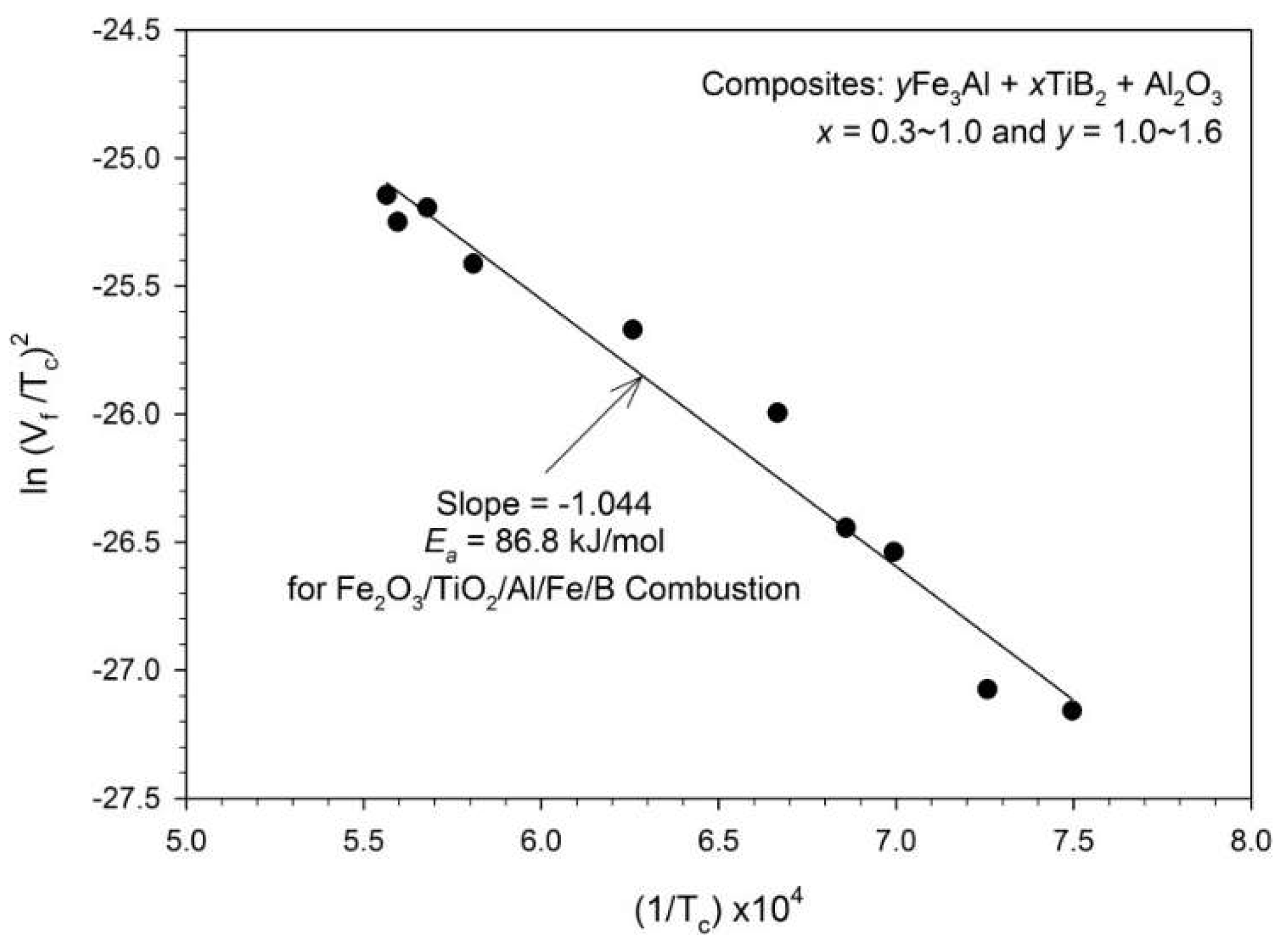

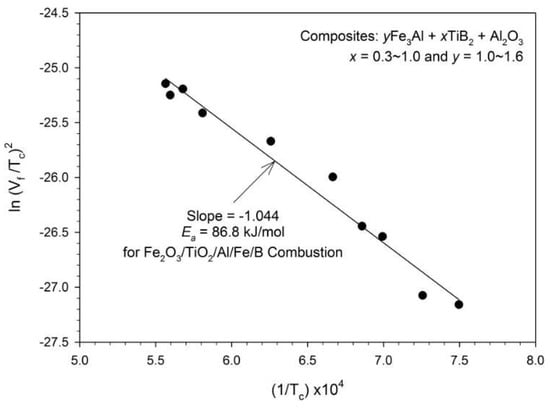

The apparent activation energy (Ea) of the solid-state combustion reaction can be deduced by realizing the dependence of flame-front velocity on combustion temperature [28]. Figure 4 depicts a plot correlating ln(Vf/Tc)2 with 1/Tc from both Reactions (1) and (2). According to the slope of a best-fitted straight line for the data, Ea = 86.8 kJ/mol was determined for in situ formation of Fe3Al–TiB2–Al2O3 composites from the Fe2O3/TiO2/Al/Fe/B combustion reaction. It is useful to note that the activation energy obtained in the present study is close to that of the Fe2O3–Al reaction (Ea = 83.1 kJ/mol) [29]. This implies that aluminothermic reduction of Fe2O3 plays an important role in leading and facilitating the reaction sequences of the Fe2O3/TiO2/Al/Fe/B combustion system.

Figure 4.

Correlation of combustion front velocity (Vf) with temperature (Tc) for determination of the activation energy (Ea) of Fe2O3/TiO2/Al/Fe/B combustion to produce Fe3Al–TiB2–Al2O3 composites.

3.2. Phase Constituents and Properties of Synthesized Composites

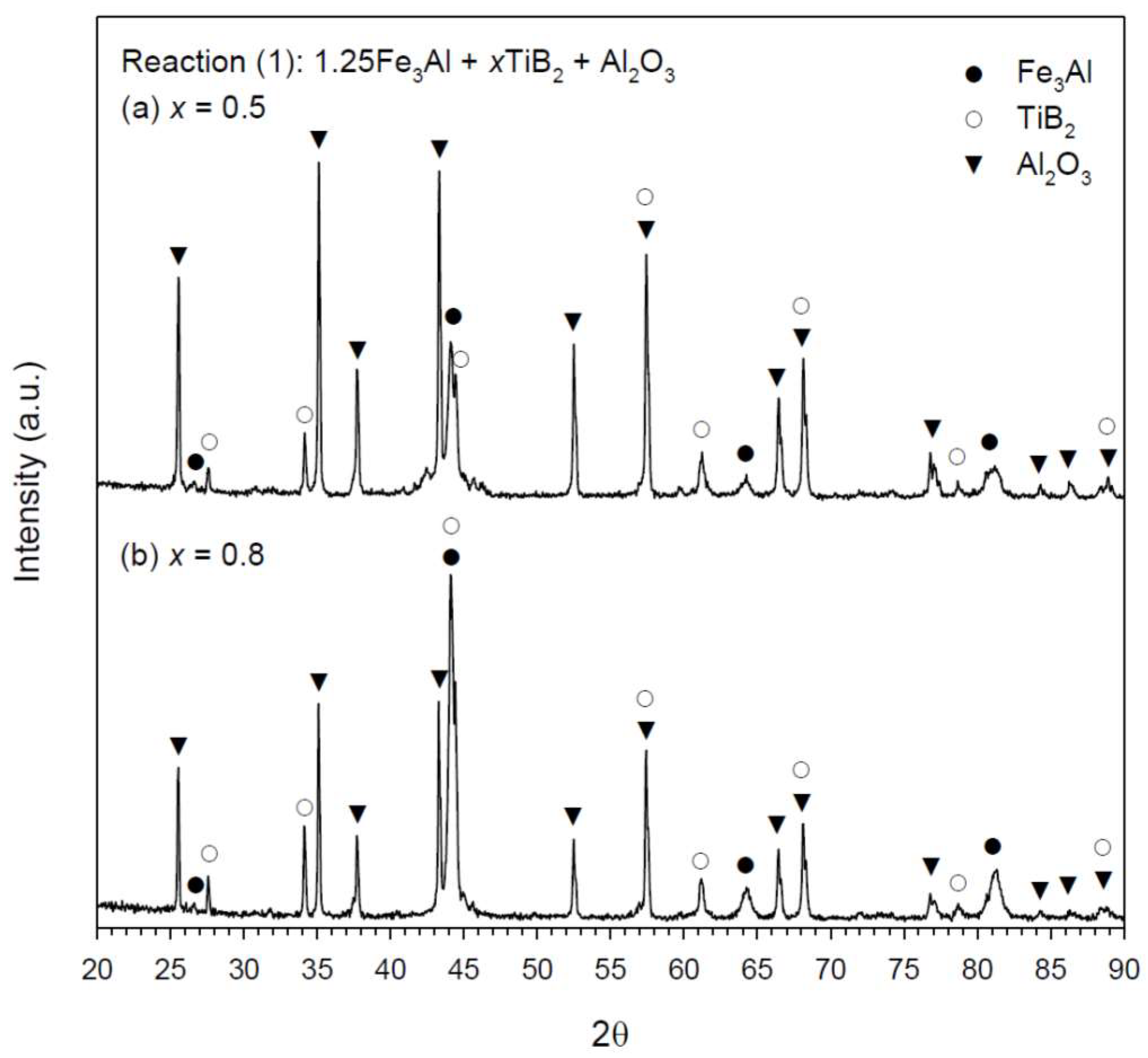

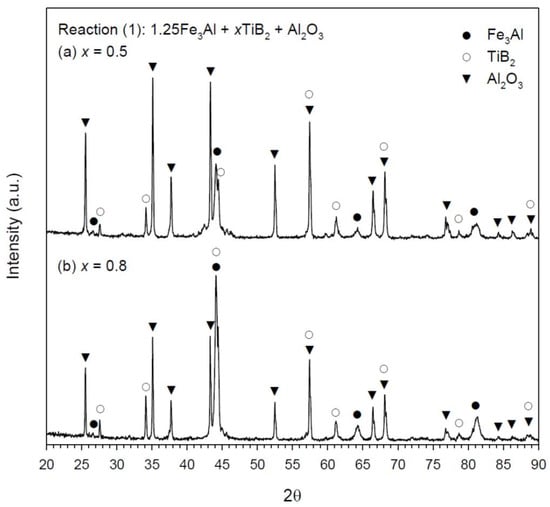

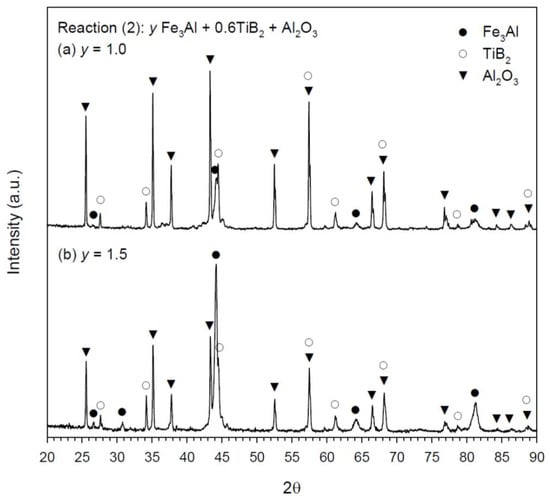

Figure 5a,b displays the XRD patterns of the final products fabricated from Reaction (1) with x = 0.5 and 0.8, respectively. The as-synthesized products composed of Fe3Al, TiB2, and Al2O3 were identified [30]. Figure 5 reveals that with the increase of x the relative intensity of signature peaks of TiB2 becomes stronger, which is indicative of an increase in TiB2 formed in the composite.

Figure 5.

XRD patterns of SHS-derived products from Reaction (1) with (a) x = 0.5 and (b) x = 0.8.

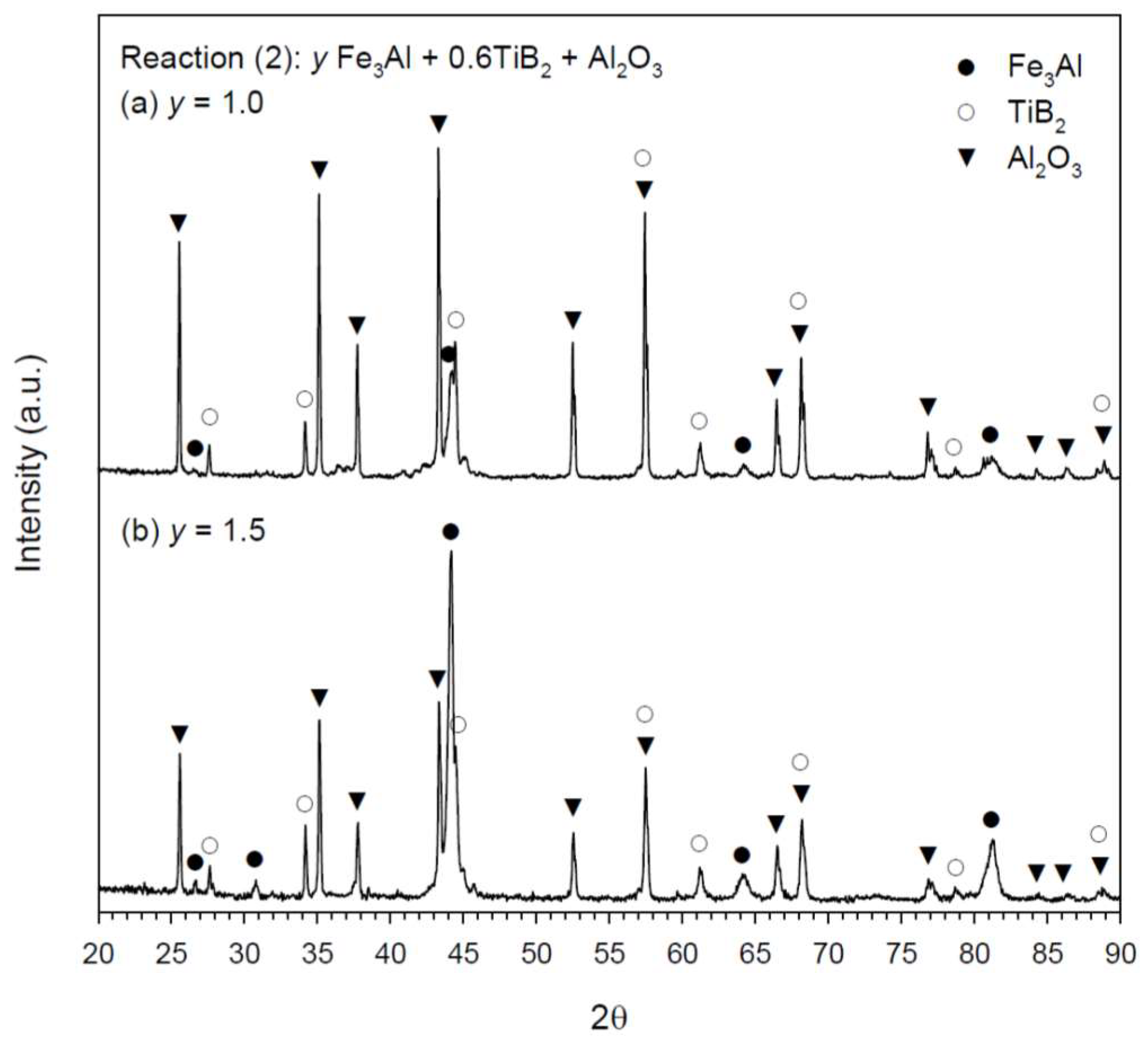

The phase composition of SHS-derived products from Reaction (2) is presented in Figure 6a,b for y = 1.0 and 1.5, respectively. Complete conversion from the reactants to products of Fe3Al, TiB2, and Al2O3 was achieved. The characteristic peaks of Fe3Al in Figure 6b exhibit much higher intensity than those in Figure 6a. This confirms that more Fe3Al was produced from the SHS process as Reaction (2) contains additional metallic Fe and Al. In summary, the composition range of the TiB2/Al2O3-added Fe3Al composites produced in this study can be described by yFe3Al + xTiB2 + Al2O3 with x = 0.3–1.0 and y = 1.0–1.6.

Figure 6.

XRD patterns of SHS-derived products from Reaction (2) with (a) y = 1.0 and (b) y = 1.5.

The relative fraction of constituents was analyzed by the Rietveld refinement for two selected SHS-derived products. The measured lattice parameters (a and c) of Fe3Al, TiB2, and Al2O3 are reported in Table 1. For the composite of 1.25Fe3Al + 0.8TiB2 + Al2O3 synthesized from Reaction (1), the Rietveld method indicates that the weight percentages are 61.88 wt % of Fe3Al, 3.72 wt % of TiB2, and 24.40 wt % of Al2O3. The relative fractions of Fe3Al (65.98 wt %), TiB2 (9.56 wt %), and Al2O3 (24.46 wt %) are determined for the composite of 1.5Fe3Al + 0.6TiB2 + Al2O3 obtained from Reaction (2). It is useful to note that the results of the Rietveld method for the phase composition are in good agreement with those of Reactions (1) and (2).

Table 1.

Lattice parameters (a and c) for the components in two selected composites.

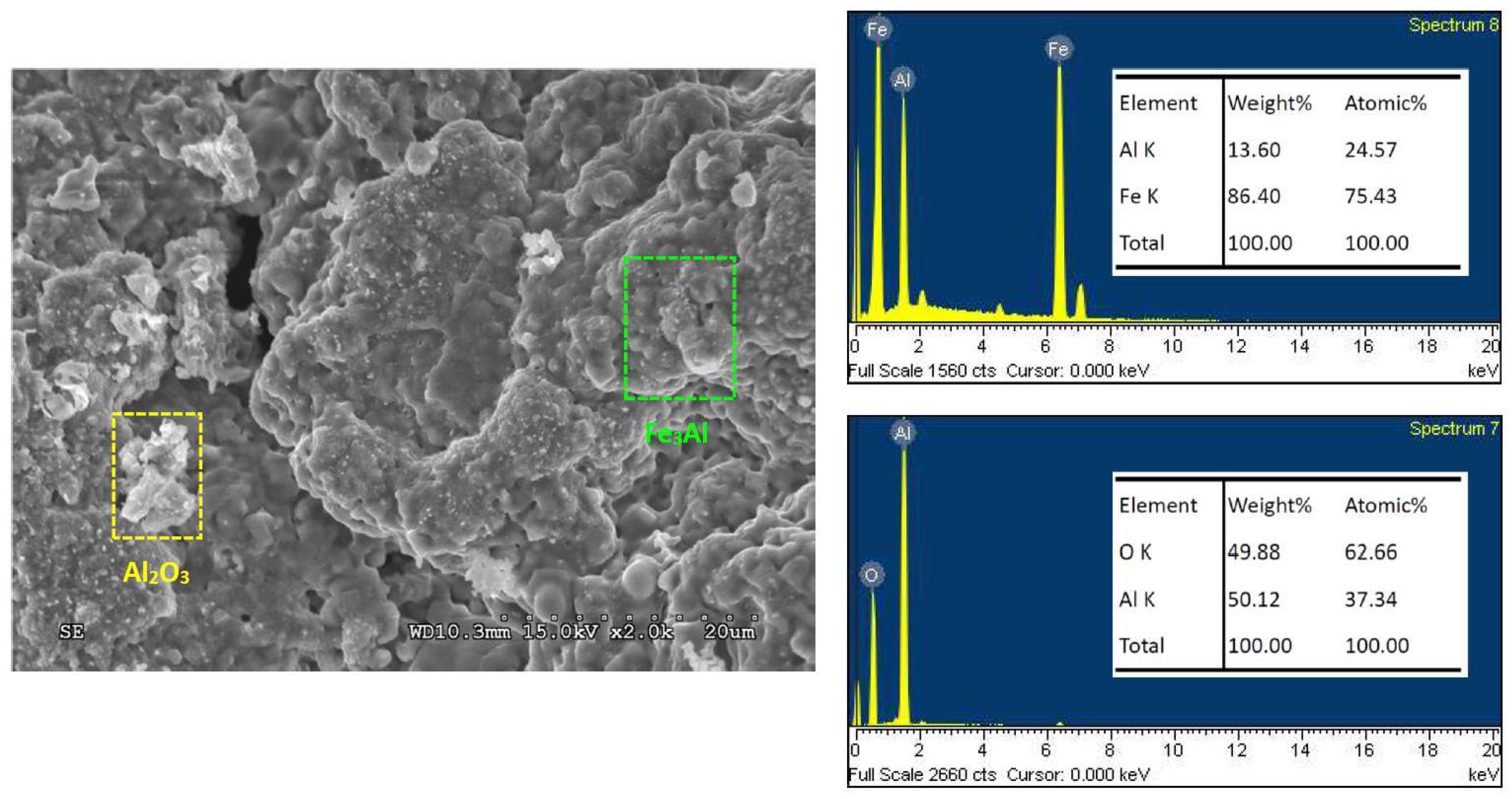

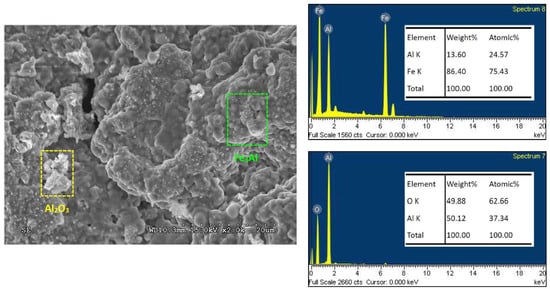

The typical microstructure of a fracture surface of the SHS-produced Fe3Al–TiB2–Al2O3 composite is displayed in Figure 7, which presents the product of Reaction (2) with y = 1.6. The microstructure exhibits the agglomeration of micro-sized grains. The agglomerates have a dense and contiguous morphology. For those gray agglomerates shown in Figure 7, the EDS analysis indicates their atomic ratio to be Fe:Al = 75.43:24.57, which matches well with that of Fe3Al. It is believed that most of the TiB2 grains are embedded in the agglomerates. The other distinct morphology is characterized by bright alumina grains, whose atomic proportion determined by the EDS spectrum is Al:O = 37.34:62.66.

Figure 7.

SEM micrograph and EDS spectra of the Fe3Al–TiB2–Al2O3 composite synthesized from Reaction (2) with y = 1.6.

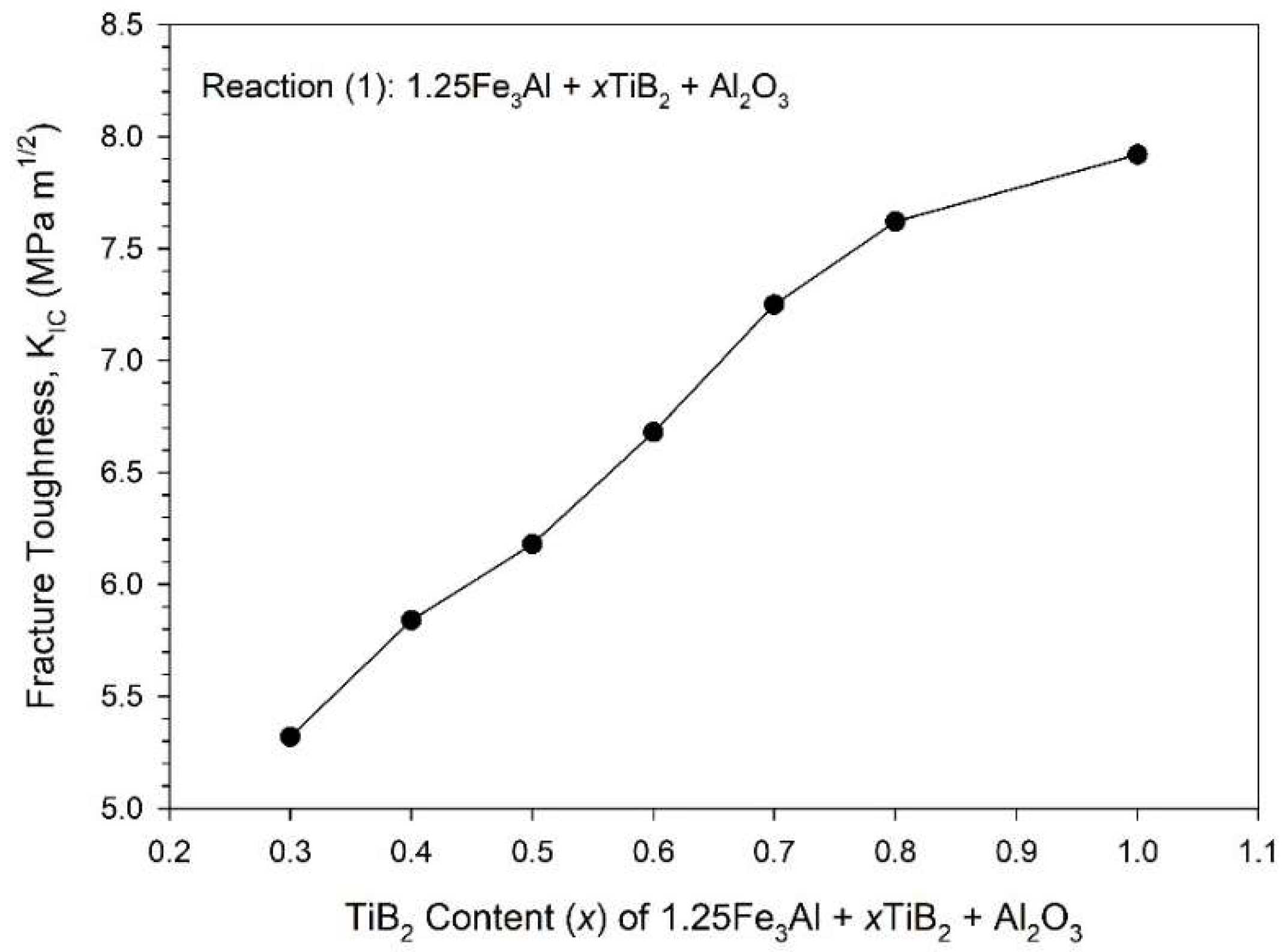

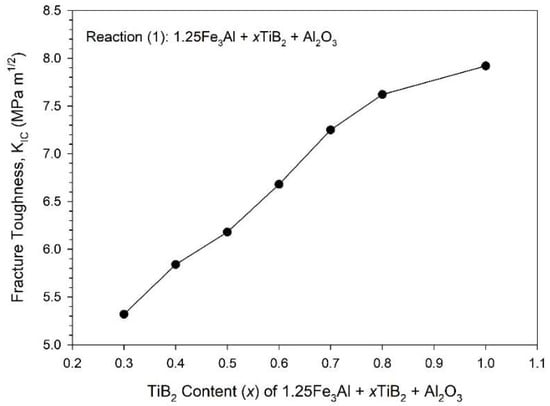

The hardness of the TiB2/Al2O3-added Fe3Al composites synthesized from Reaction (1) is in the range from 11.2 to 19.6 GPa, which increases with increasing TiB2 content from x = 0.3 to 1.0. Figure 8 shows that as the content of TiB2 increases, the fracture toughness of the TiB2/Al2O3-reinforced Fe3Al composite increases from 5.32 to 7.92 MPa·m1/2. This proves the strengthening effect of the ceramic phases on Fe3Al.

Figure 8.

Effect of TiB2 content on the fracture toughness of 1.25Fe3Al + xTiB2 + Al2O3 composites synthesized by SHS of Reaction (1).

4. Conclusions

The SHS process involving aluminothermic reduction of oxide precursors was conducted to prepare Fe3Al–TiB2–Al2O3 composites with a broad range of phase compositions. The starting materials included elemental Fe, amorphous boron, and thermite reagents made up of Fe2O3, TiO2, and Al. Aluminothermic reduction of Fe2O3 played an important role in thermally and chemically activating the synthesis reaction in a self-sustaining combustion mode. Experimental results showed that for the production of a higher content of TiB2 in the composites of 1.25Fe3Al + xTiB2 + Al2O3 with x = 0.3–1.0, there existed a maximum combustion wave velocity of 5.88 mm/s and a highest reaction front temperature of 1514 °C at x = 0.6. This was caused by the fact that the reaction exothermicity of the thermite mixture decreased but the formation enthalpy of TiB2 increased. On the other hand, for the increase of Fe3Al in the product of yFe3Al + 0.6TiB2 + Al2O3 with y = 1.0–1.6, the additional Fe and Al reduced the overall reaction exothermicity and decelerated the combustion wave. Based upon the dependence of flame-front velocity on combustion temperature, the activation energy (Ea) of 86.8 kJ/mol was determined for the Fe2O3/TiO2/Al/Fe/B combustion system to produce Fe3Al–TiB2–Al2O3 composites.

The XRD analysis of the as-synthesized products indicated that complete conversion from the reactants to Fe3Al–TiB2–Al2O3 composites was achieved. Two SHS systems capable of varying the molar contents of TiB2 and Fe3Al in an effective manner were confirmed. Moreover, it was found that the increase of TiB2 from x = 0.3 to 1.0 in the 1.25Fe3Al + xTiB2 + Al2O3 composites contributed to an increase in fracture toughness from 5.32 to 7.92 MPa·m1/2.

Acknowledgments

This research was sponsored by the Ministry of Science and Technology of Taiwan under the grant of MOST 105-2221-E-035-039-MY2. The authors are grateful for the Precision Instrument Support Center of Feng Chia University in providing materials analysis facilities.

Author Contributions

Chun-Liang Yeh conceived and designed the experiments, analyzed the experimental data, supervised the work, and wrote the paper. Chih-Yao Ke performed the SHS experiments and materials analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Deevi, S.C.; Sikka, V.K. Nickel and iron aluminides: An overview on properties, processing, and applications. Intermetallics 1996, 4, 357–375. [Google Scholar] [CrossRef]

- Stoloff, N.S. Iron aluminides: Present status and future prospects. Mater. Sci. Eng. A 1998, 258, 1–14. [Google Scholar] [CrossRef]

- Joslin, D.L.; Easton, D.S.; Liu, C.T.; Babu, S.S.; David, S.A. Processing of Fe3Al and FeAl alloys by reaction synthesis. Intermetallics 1995, 3, 467–481. [Google Scholar] [CrossRef]

- Schneibel, J.H.; Carmichael, C.A.; Specht, E.D.; Subramanian, R. Liquid-phase sintered iron aluminide-ceramic composites. Intermetallics 1997, 5, 61–67. [Google Scholar] [CrossRef]

- Itoi, T.; Mineta, S.; Kimura, H.; Yoshimi, K.; Hirohashi, M. Fabrication and wear properties of Fe3Al-based composites. Intermetallics 2010, 18, 2169–2177. [Google Scholar] [CrossRef]

- Amiriyan, M.; Blais, C.; Savoie, S.; Schulz, R.; Cariépy, M.; Alamdari, H.D. Mechanical behavior and sliding wear studies on iron aluminide coatings reinforced with titanium carbides. Metals 2017, 7, 177. [Google Scholar] [CrossRef]

- Amiriyan, M.; Blais, C.; Savoie, S.; Schulz, R.; Cariépy, M.; Alamdari, H. Trio-mechanical properties of HVOF deposited Fe3Al coatings reinforced with TiB2 particles for wear-resistance applications. Materials 2016, 9, 117. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.M.; Li, H.; Wang, J.H.; Gong, M. High strength and high fracture toughness ceramic-iron aluminide (Fe3Al) composites. Mater. Lett. 2006, 60, 883–887. [Google Scholar] [CrossRef]

- Li, J.; Kwong, F.; Shi, R.; Ng, D.H.L.; Yin, Y. Microstructure and properties of in situ nanometric Al2O3 reinforced α–Fe(Al)–Fe3Al-based composites. Mater. Sci. Eng. A 2009, 526, 50–55. [Google Scholar] [CrossRef]

- Khodaei, M.; Enayati, M.H.; Karimzadeh, F. The structure and mechanical properties of Fe3Al–30 vol. % Al2O3 nanoparticles. J. Alloys Compd. 2009, 488, 134–137. [Google Scholar] [CrossRef]

- Subramanian, R.; MaKamey, C.G.; Buck, L.R.; Schneibel, J.H. Synthesis of iron aluminide–Al2O3 composites by in-situ displacement reactions. Mater. Sci. Eng. A 1997, 239–240, 640–646. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Vahdati Khaki, J.; Haddad Sabzevar, M. Formation mechanism of TiC–Al2O3–Fe3Al composites during self-propagating high-temperature synthesis of TiO2–Al–C–Fe system. Ceram. Int. 2016, 42, 12361–12370. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, X.; Sun, Z.; Jiao, X.; Akhtar, F.; Wang, J.; Feng, P. A novel fabrication strategy for highly porous FeAl/Al2O3 composite by thermal explosion in vacuum. Vacuum 2018, 149, 225–230. [Google Scholar] [CrossRef]

- Merzhanov, A.G. Combustion and explosion processes in physical chemistry and technology of inorganic materials. Russ. Chem. Rev. 2003, 72, 289–310. [Google Scholar] [CrossRef]

- Liu, G.; Li, J.; Chen, K. Combustion synthesis of refractory and hard materials: A review. Int. J. Refract. Met. Hard Mater. 2013, 39, 90–102. [Google Scholar] [CrossRef]

- Levashov, E.A.; Mukasyan, A.S.; Rogachev, A.S.; Shtansky, D.V. Self-propagating high-temperature synthesis of advanced materials and coatings. Int. Mater. Rev. 2017, 62, 203–239. [Google Scholar] [CrossRef]

- Yeh, C.L.; Peng, J.A. Combustion synthesis of MoSi2–Al2O3 composites from thermite-based reagents. Metals 2016, 6, 235. [Google Scholar] [CrossRef]

- Yeh, C.L.; Chong, M.H. Effects of B4C and BN additions on formation of NbB2–Al2O3 composites from reduction-based Combustion synthesis. Ceram. Int. 2017, 43, 7560–7564. [Google Scholar] [CrossRef]

- Yeh, C.L.; Sung, W.Y. Combustion synthesis of Ni3Al intermetallic compound in self-propagating mode. J. Alloys Compd. 2004, 384, 181–191. [Google Scholar] [CrossRef]

- Yeh, C.L.; Su, S.H. In situ formation of TiAl-TiB2 composite by SHS. J. Alloys Compd. 2006, 407, 150–156. [Google Scholar] [CrossRef]

- Yeh, C.L.; Ke, C.Y.; Chen, Y.C. In situ formation of TiB2/TiC and TiB2/TiN reinforced NiAl by self-propagating combustion synthesis. Vacuum 2018, 151, 185–188. [Google Scholar] [CrossRef]

- Young, R.A.; Wiles, D.B. Profile shape functions in Rietveld refinements. J. Appl. Cryst. 1982, 15, 430–438. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. Recent developments of the program FULLPROF. Newsl. Comm. Powder Diffr. 2001, 26, 12–19. [Google Scholar]

- Evans, A.G.; Charles, E.A. Fracture toughness determinations by indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- Yeh, C.L.; Lin, J.Z. Combustion synthesis of Cr-Al and Cr-Si intermetallics with Al2O3 additions from Cr2O3-Al and Cr2O3-Al-Si reaction systems. Intermetallics 2013, 33, 126–133. [Google Scholar] [CrossRef]

- Wang, L.L.; Munir, Z.A.; Maximov, Y.M. Thermite reactions: Their utilization in the synthesis and processing of materials. J. Mater. Sci. 1993, 28, 3693–3708. [Google Scholar] [CrossRef]

- Binnewies, M.; Milke, E. Thermochemical Data of Elements and Compounds; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2002. [Google Scholar]

- Bertolino, N.; Anselmi-Tamburini, U.; Maglia, F.; Spinolo, G.; Munir, Z.A. Combustion synthesis of Zr-Si intermetallic compounds. J. Alloys Compd. 1999, 288, 238–248. [Google Scholar] [CrossRef]

- Rafiei, M.; Enayati, M.H.; Karimzadeh, F. Kinetic analysis of thermite reaction in Al–Ti–Fe2O3 system to produce (Fe,Ti)3Al–Al2O3 nanocomposite. Powder Technol. 2014, 253, 553–560. [Google Scholar] [CrossRef]

- Mighell, A.D.; Karen, V.L. NIST crystallographic databases for research and analysis. J. Res. Natl. Inst. Stand. Technol. 1996, 101, 273–280. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).