Research and Development of Powder Brazing Filler Metals for Diamond Tools: A Review

Abstract

:1. Introduction

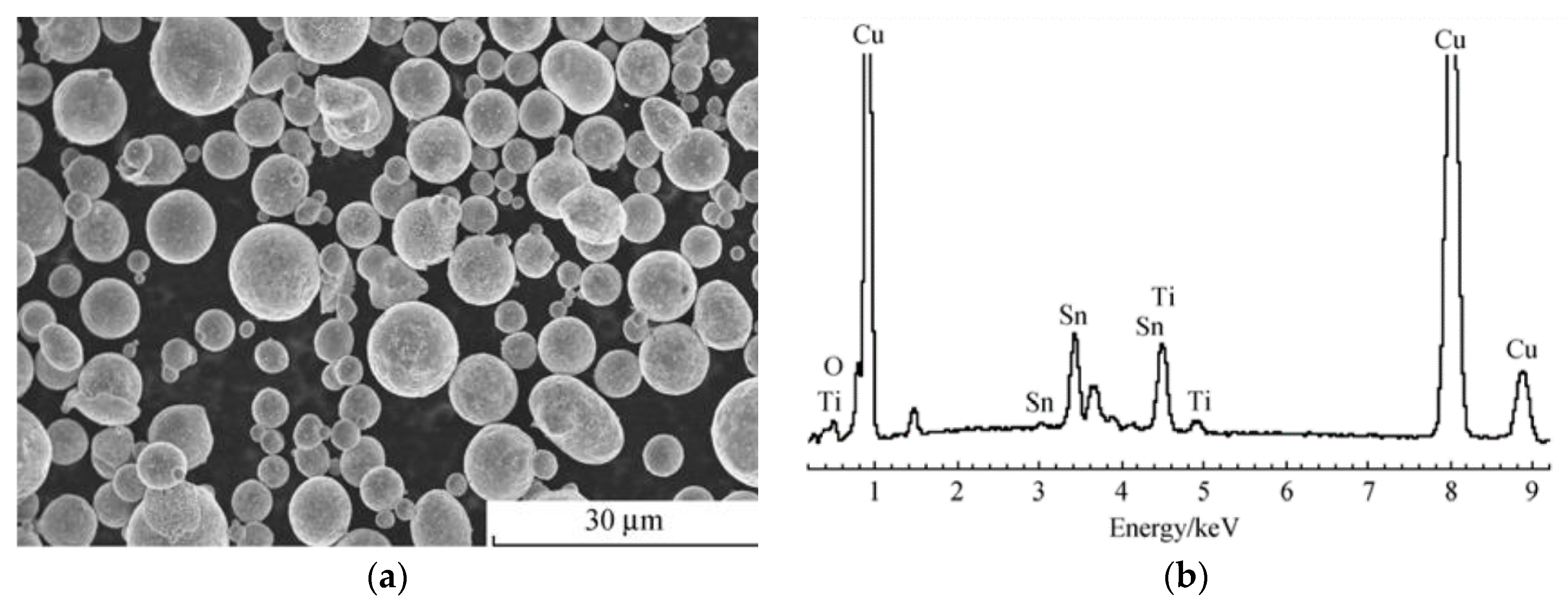

2. Powder Brazing Filler Metals (PBFMs) in Diamond Tool Industry

3. The Research Status of PBFMs for Monolayer Brazing Diamond Tools

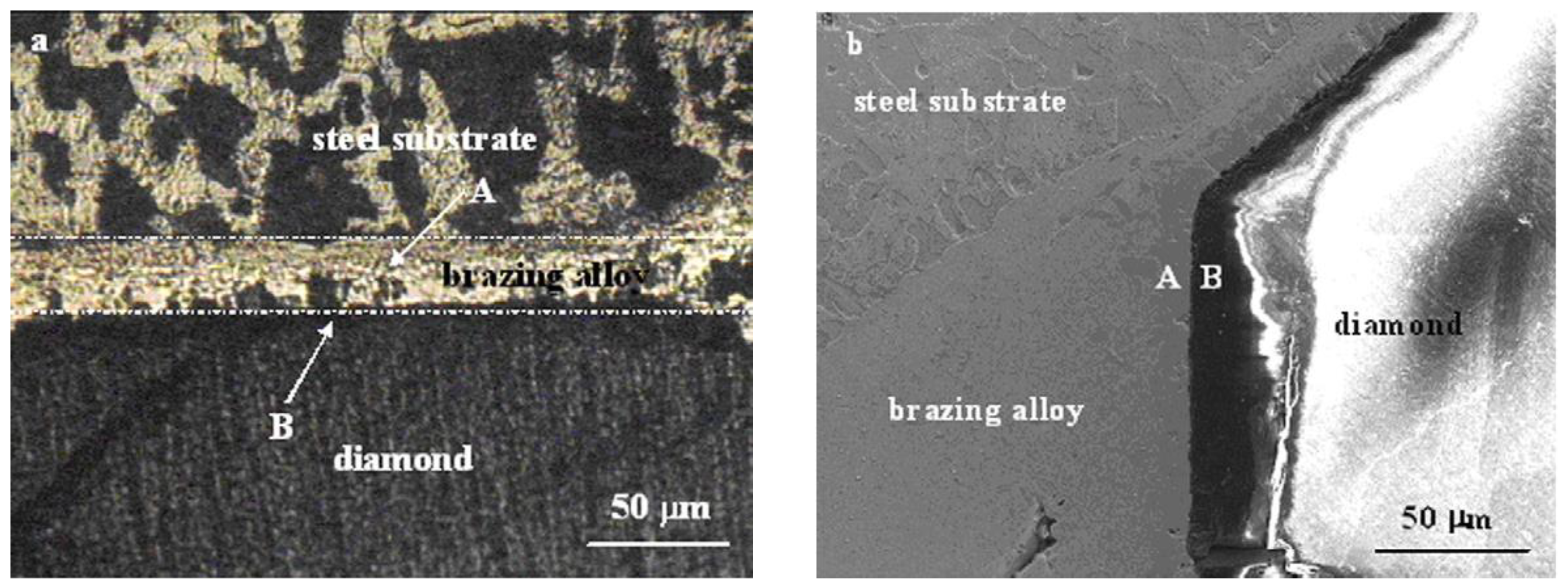

3.1. Medium-Temperature PBFMs (between 450 and 900 °C)

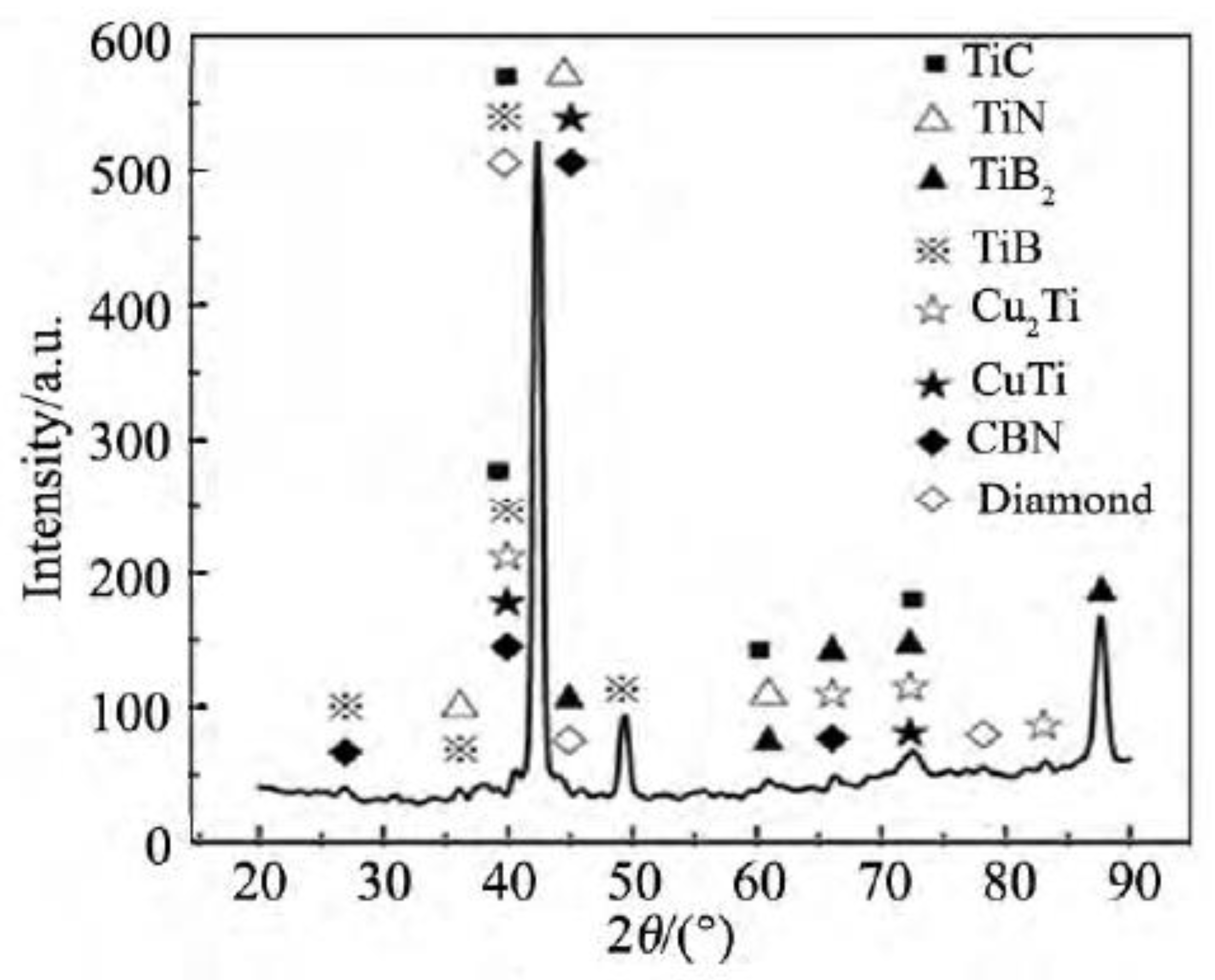

3.2. High Temperature (≥900 °C) PBFMs

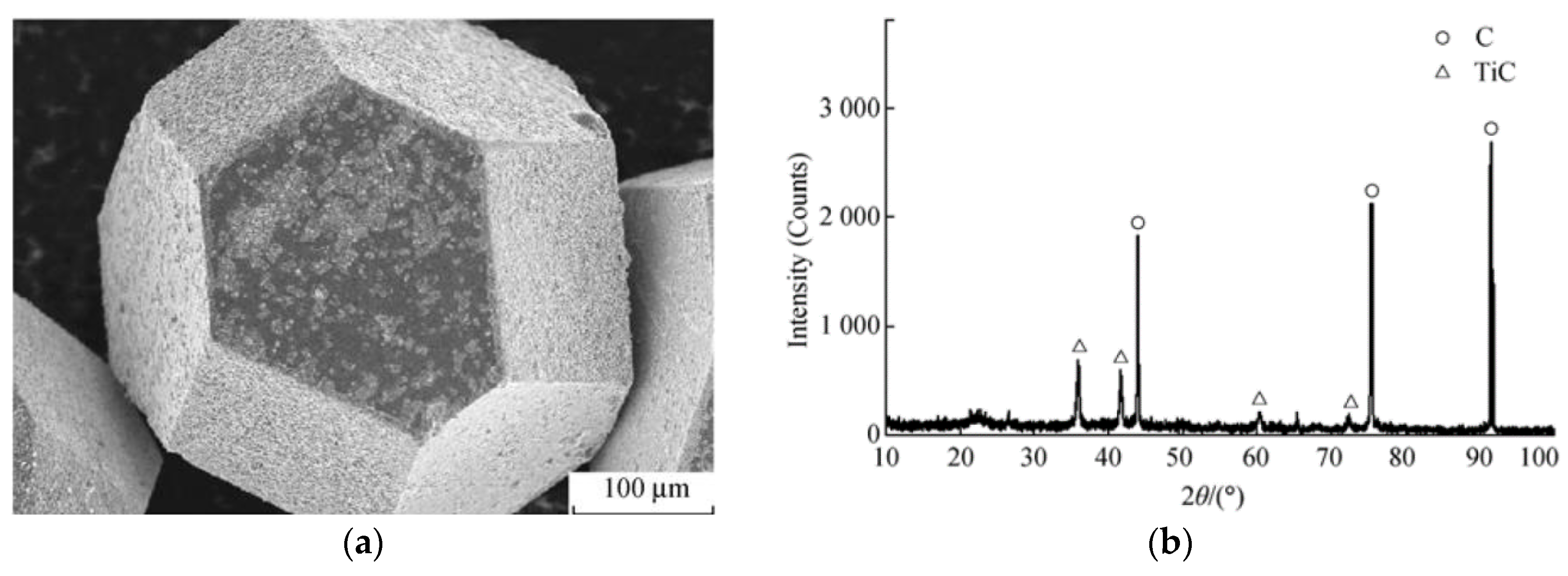

4. The Research Status of PBFMs for Impregnated Diamond Tools

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Theorin, A.; Bengtsson, K.; Provost, J.; Lieder, M.; Johnsson, C.; Lundholm, T.; Lennartson, B. An event-driven manufacturing information system architecture for Industry 4.0. Int. J. Prod. Res. 2016, 48, 1–15. [Google Scholar] [CrossRef]

- Chen, Z.X.; Chen, P.; Cai, Z.H.; Zeng, Y.; Liu, H.J. Introduction to production and application of soldering and brazing filler metal powders and pastes in China. Rare Met. 2009, 28, 471–473. [Google Scholar]

- Wan, C.; Xiong, H.; Zhou, Z. Joining of Si3N4/Si3N4 with CuNiTiB paste brazing filler metals and interfacial reactions of the joints. J. Mater. Sci. 1999, 34, 3013–3019. [Google Scholar] [CrossRef]

- Nadkarni, A.V.; Cowan, G.L.; Garrard, A.V.; Khattar, R. Powder metal pastes for brazing and soldering applications. Int. J. Powder Metall. 2001, 37, 49–60. [Google Scholar]

- Ivanov, E.Y.; Shapiro, A.E.; Horne, M.G. Exploring solid-state synthesis of powder filler metals for vacuum brazing of titanium alloys. Weld. J. 2006, 85, 196–199. [Google Scholar]

- He, P.; Liu, D.; Shang, E.; Wang, M. Effect of mechanical milling on Ni-TiH powder alloy filler metal for brazing TiAl intermetallic alloy: The microstructure and joint’s properties. Mater. Charact. 2009, 60, 30–35. [Google Scholar] [CrossRef]

- Liu, G.W.; Qiao, G.J.; Wang, H.J.; Yang, J.F.; Lu, T.J. Pressureless brazing of zirconia to stainless steel with Ag-Cu filler metal and TiH powder. J. Eur. Ceram. Soc. 2008, 28, 2701–2708. [Google Scholar] [CrossRef]

- Zhang, L.; Tu, K.N. Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Eng. R 2014, 82, 1–32. [Google Scholar] [CrossRef]

- Chattopadhyay, A.K.; Roy, P.; Sarangi, S.K. Study of wettability test of pure aluminum against uncoated and coated carbide inserts. Surf. Coat. Technol. 2009, 204, 410–417. [Google Scholar] [CrossRef]

- Sekulic, D.P. Advances in brazing: Science, technology and applications. Woodhead 2013, 80, 423–471. [Google Scholar]

- Saunders, N.; Miodownik, A.P. The Cu-Sn (Copper-Tin) system. Bull. Alloy Phase Diagr. 1990, 11, 278–287. [Google Scholar] [CrossRef]

- Klotz, U.E.; Khalid, F.A.; Elsener, H.R. Nanocrystalline phases and epitaxial interface reactions during brazing of diamond grits with silver based Incusil-ABA alloy. Diam. Relat. Mater. 2006, 15, 1520–1524. [Google Scholar] [CrossRef]

- Murray, J.L. The Cu-Ti (Copper-Titanium) system. Bull. Alloy Phase Diagr. 1983, 4, 81–95. [Google Scholar] [CrossRef]

- Khalid, F.A.; Klotz, U.E.; Elsener, H.R.; Zigerlig, B.; Gasser, P. On the interfacial nanostructure of brazed diamond grits. Scr. Mater. 2004, 50, 1139–1143. [Google Scholar] [CrossRef]

- Deng, Z.; Wu, Q.; Zhang, R.; Pan, Z. Vacuum brazing of Ti-coated diamonds with Cu-based alloy powder. J. Chin. Ceram. Soc. 2011, 39, 343–348. [Google Scholar]

- Guo, Z.C.; Chen, Y.; Hong-Hua, S.U.; Yu-Can, F.U. Microstructure for interface between diamond and 45 steel vacuum-brazed by Cu-Sn-Ti alloy. Mater. Mech. Eng. 2012, 36, 20–22. [Google Scholar]

- Li, Y.; He, P.; Feng, J. Interface structure and mechanical properties of the TiAl/42CrMo steel joint vacuum brazed with Ag-Cu/Ti/Ag-Cu filler metal. Scr. Mater. 2006, 55, 171–174. [Google Scholar] [CrossRef]

- Liu, S.X.; Xiao, B.; Zhang, Z.Y.; Duan, D.Z.; Xu, F.L.; Wang, B. Microanalysis of interface characteristics of brazed diamond and cubic boron nitride abrasive with Cu-Sn-Ti filler alloy. J. Synth. Cryst. 2015, 44, 1161–1165. [Google Scholar]

- Terakubo, M.; Oh, J.; Kirihara, S.; Miyamoto, Y.; Matsuura, K.; Kudoh, M. Freeform fabrication of Ti-Ni and Ti-Fe intermetallic alloys by 3D micro welding. Intermetallics 2007, 15, 133–138. [Google Scholar] [CrossRef]

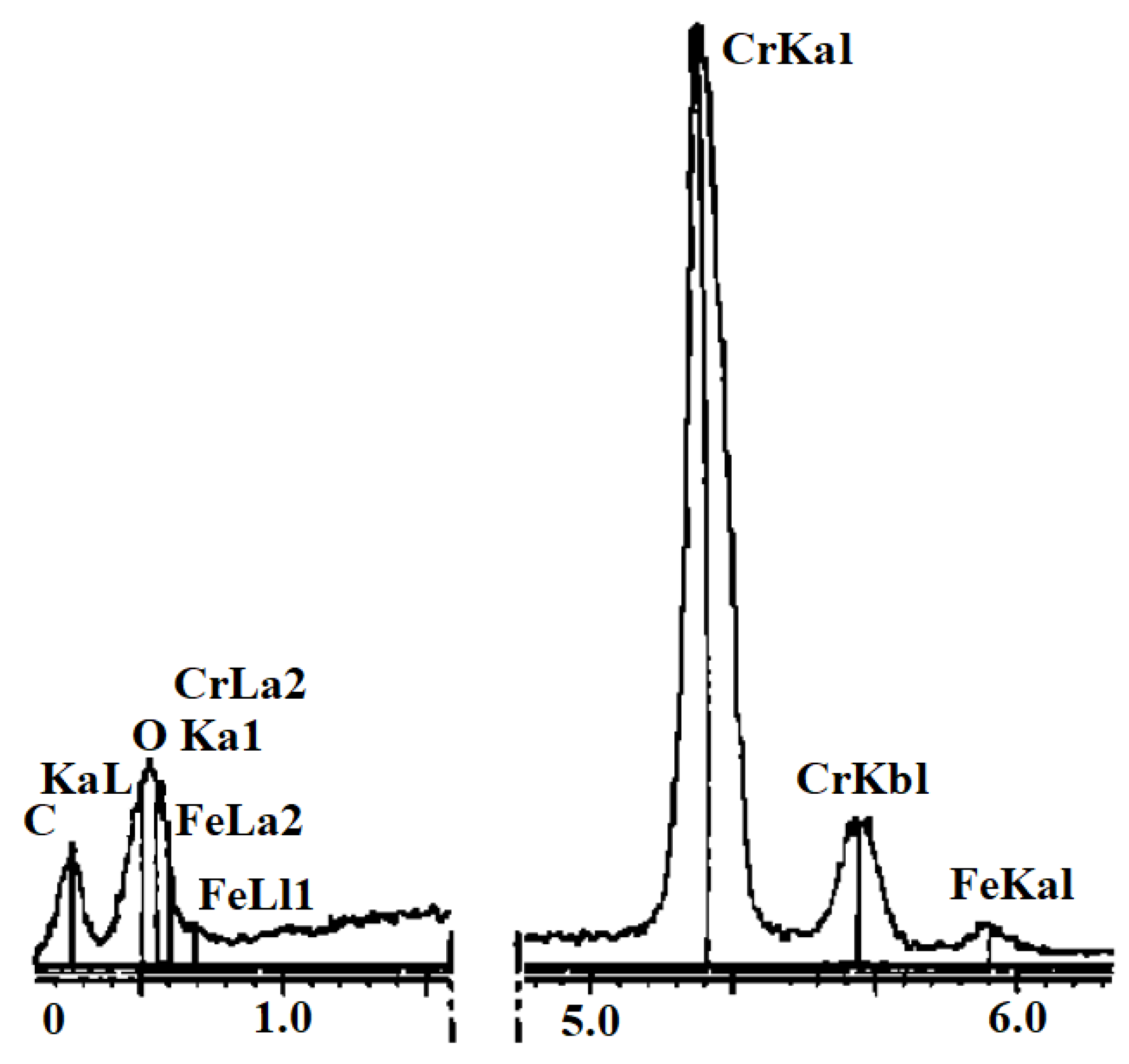

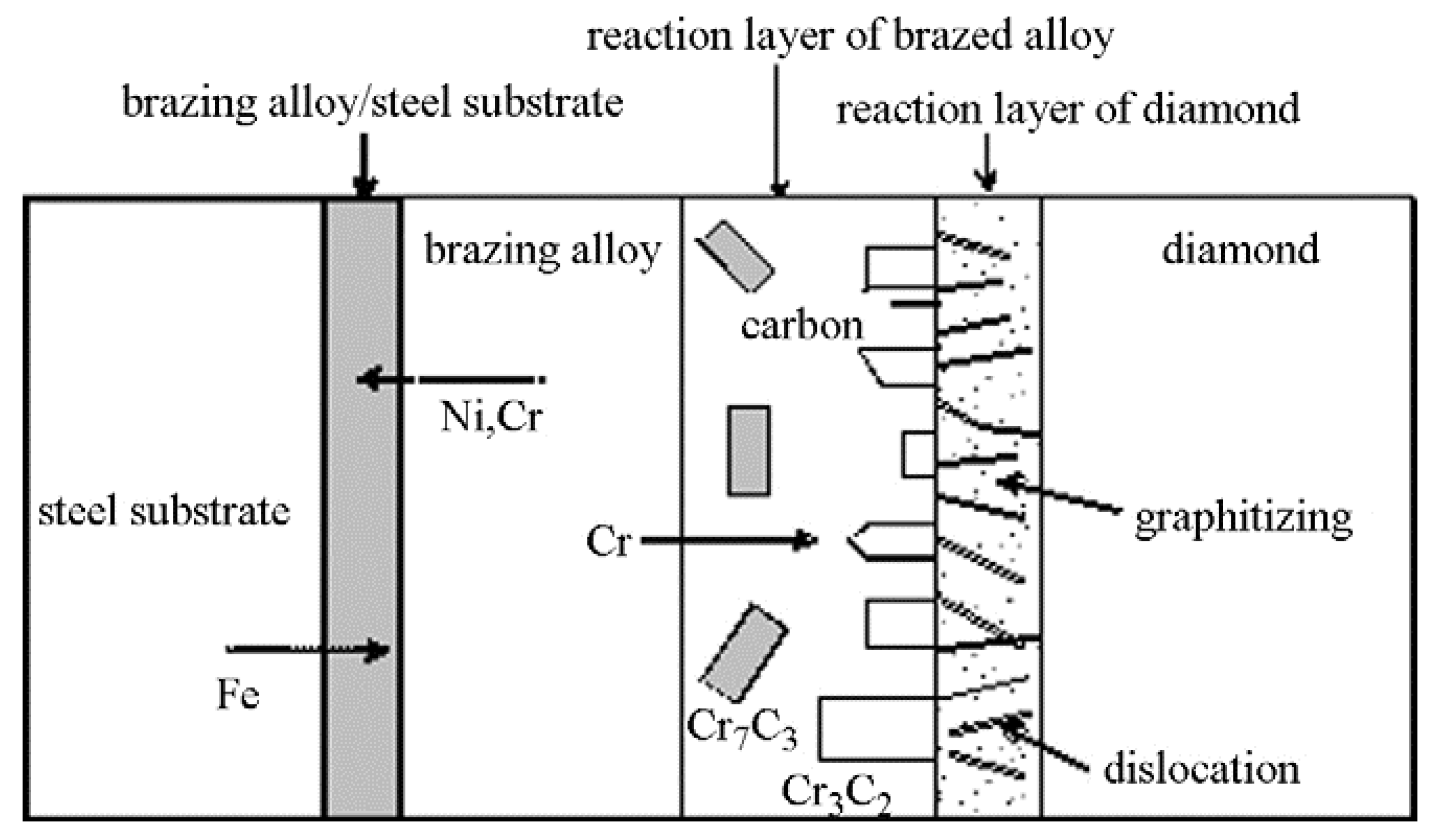

- Wang, C.Y.; Zhou, Y.M.; Zhang, F.L.; Xu, Z.C. Interfacial microstructure and performance of brazed diamond grits with Ni-Cr-P alloy. J. Alloys Compd. 2009, 476, 884–888. [Google Scholar] [CrossRef]

- Trenker, A.; Seidemann, H. High-vacuum brazing of diamond tools. Ind. Diam. Rev. 2002, 62, 49–51. [Google Scholar]

- Zhang, F.L.; Zhou, Y.M.; Guo, C.W.; Mao, J.B.; Huang, H.P. Performance of brazed diamond tool for machining dental ceramic. Adv. Mater. Res. 2014, 1027, 84–87. [Google Scholar] [CrossRef]

- Xiao, B.; Xu, H.J.; Wu, Z.B.; Xi, P. Furnace brazing of diamond grinding wheel with Ni-Cr alloy under vacuum atmosphere. Mech. Sci. Technol. 2001, 22, 23–26. [Google Scholar]

- Wu, Z.B.; Xu, H.J.; Xiao, B. Experimental investigation on induction brazing of diamond grinding wheel. Trans. China Weld. Inst. 2001, 22, 24–26. [Google Scholar]

- Xiao, B.; Wu, Z.B.; Xu, H.J. Expermental investigation on induction brazing of diamond grinding wheel with Ni-Cr alloy under vacuum atmosphere. Tool Eng. 2000, 34, 3–5. [Google Scholar]

- Yang, Z.B.; Xu, J.H.; Liu, A.J. Delaminating behavior and formation mechanism of the interfacial microstructure in the laser brazing diamond with Ni-Cr alloys. Chin. J. Lasers 2009, 36, 3079–3083. [Google Scholar] [CrossRef]

- Sun, B.; Meng, P.; Lu, J.B.; Zhao, B.; Liu, J.J. Influence of brazing time on microstructure of high temperature brazing diamond with Ni-Cr alloy. Adv. Mater. Res. 2012, 452–453, 628–632. [Google Scholar]

- Lu, J.B.; Meng, P.; Zhao, B.; Liu, J.J. Nucleation and growth of Cr7C3 of brazing diamond with Ni-Cr alloy in protective atmosphere furnace. Adv. Mater. Res. 2012, 463–464, 505–509. [Google Scholar]

- Zhu, Y.; Wang, L.; Yao, W.; Cao, L. The interface diffusion and reaction between Cr layer and diamond particle during metallization. Appl. Surf. Sci. 2001, 171, 143–150. [Google Scholar] [CrossRef]

- Qian, J.; Pantea, C.; Huang, J.; Zerda, T.W.; Zhao, Y. Graphitization of diamond powders of different sizes at high pressure-high temperature. Carbon 2004, 42, 2691–2697. [Google Scholar] [CrossRef]

- Saguy, C.; Cytermann, C.; Brener, R.; Richter, V.; Shaanan, M.; Kalish, R. Damage threshold for ion-beam induced graphitization of diamond. Appl. Phys. Lett. 1995, 67, 1194–1196. [Google Scholar] [CrossRef]

- Konstanty, J.; Kim, T.W.; Kim, S.B. Resistance to abrasive wear of materials used as metallic matrices in diamond impregnated tools. Mater. Sci. Forum 2007, 534–536, 1125–1128. [Google Scholar] [CrossRef]

- Luo, X.; Ma, H.; Huang, M.; Tang, M. Research and application of cobalt-substitute prealloy powder for diamond tools. Diam. Abras. Eng. 2006, 26, 18–24. [Google Scholar]

- Xiang, B.; Xie, Z.; He, Y.; Huang, Y. Preparation of prealloyed powder for matrix of diamond tools. Diam. Abras. Eng. 2006, 26, 34–38. [Google Scholar]

- Cai, F.; Tang, X.; Qin, Y.; Li, L.; Zhu, G. The research trends of the prealloyed powder used in diamond tools. Diam. Abras. Eng. 2004, 24, 77–80. [Google Scholar]

- Xu, H.; Ma, H.; Luo, X.; Zhao, T. Atomized prealloyed powders and it’s application in diamond tools. Diam. Abras. Eng. 2004, 24, 45–48. [Google Scholar]

- Chu, Z.; Guo, X.; Zhang, L.; Liu, D. Effect of super high pressure water atomization parameters on diameter and micrograph of diamond matrix prealloy powders. Mater. Sci. Eng. Powder Metall. 2015, 20, 808–814. [Google Scholar]

- Elsener, H.R.; Klotz, U.E.; Khalid, F.A.; Piazza, D.; Kiser, M. The role of binder content on microstructure and properties of a Cu-base active brazing filler metal for diamond and cBN. Adv. Eng. Mater. 2005, 7, 375–380. [Google Scholar] [CrossRef]

- Weber, L.; Tavangar, R. On the influence of active element content on the thermal conductivity and thermal expansion of Cu-X (X = Cr, B) diamond composites. Scr. Mater. 2007, 57, 988–991. [Google Scholar] [CrossRef]

- Cao, C.; Liu, Y.; Xu, L.; Shen, N.; Liu, Z. Study on hot pressing sintering behaviors and properties of Cu-Sn pre-alloy powder high Sn content. Diam. Abras. Eng. 2016, 36, 67–72. [Google Scholar]

- Zhang, G.F.; Zhang, J.X.; Wang, S.Y.; Qiu, F.X. Similarities and differences in main characteristics between transient liquid phase bonding and brazing process. Chin. Weld. Inst. 2002, 23, 92–96. [Google Scholar]

- Cao, C.; Liu, Y.; Xu, L.; Shen, N.; Liu, W. Influence of granulating process on the properties of Cu-Sn prealloy powder diamond tools. Diam. Abras. Eng. 2015, 35, 67–71. [Google Scholar]

- Duan, D.; Xiao, B.; Wang, W.; Zhang, Z.; Wang, B. Interface characteristics and performance of pre-brazed diamond grains with Ni-Cr composite alloy. J. Alloys Compd. 2015, 644, 626–631. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, H.; Fu, Y.; Su, H. Surface graphitization on brazed diamond with Ni-Cr alloy in vacuum brazing. Trans. Chin. Weld. Inst. 2009, 30, 21–24. [Google Scholar]

- Lu, J.; Xu, J.; Xu, H.; Fu, Y.; Jiang, C. Thermodynamic studies on interfacial reactions between diamond and Ni-Cr filler metal in vacuum brazing. Trans. Chin. Weld. Inst. 2004, 25, 21–24. [Google Scholar]

- Das, N.K.; Tirtom, I.; Shoji, T. A multiscale modelling study of Ni-Cr crack tip initial stage oxidation at different stress intensities. Mater. Chem. Phys. 2010, 122, 336–342. [Google Scholar] [CrossRef]

- Stoupin, S.; Shvyd’Ko, Y.V. Thermal expansion of diamond at low temperatures. Phys. Rev. Lett. 2010, 104, 085901. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Huan, H.; Zeng, Y.; Song, S.; Cheng, S.; Zhang, C. A study on the failure mechanism and wear loss of impregnated diamond bits during machining process of armor ceramics. J. Mech. Sci. Technol. 2018, 32, 261–268. [Google Scholar] [CrossRef]

- Xu, J.; Sheikh, A.H.; Xu, C. 3-D Finite element modelling of diamond pull-out failure in impregnated diamond bits. Diam. Relat. Mater. 2017, 71, 1–12. [Google Scholar] [CrossRef]

- Li, Q.L.; Xu, J.H.; Su, H.H.; Fu, Y.C. Simulation of temperature field induced in localized ultra-high frequency induction brazing of diamond tools. Adv. Mater. Res. 2012, 565, 633–638. [Google Scholar] [CrossRef]

- Gao, G.; Hu, J.H.; Cheng, C.; Wu, X.; Zhang, D. Forming equation about multivariate mixed metal powder by electromagnetic compaction. Chin. J. Nonferr. Met. 2015, 25, 1937–1942. [Google Scholar]

- Mayappan, R.; Abidin, N.N.Z.; Ghani, N.A.A.; Yahya, I.; Shuhaime, N. Intermetallic study on the modified Sn-3.5Ag-1.0Cu-1.0Zn lead free solder. Mater. Sci. Forum 2016, 857, 3–7. [Google Scholar] [CrossRef]

- Gain, A.K.; Chan, Y.C.; Sharif, A.; Yung, W.K.C. Effect of small Sn-3.5Ag-0.5Cu additions on the structure and properties of Sn-9Zn solder in ball grid array packages. Microelectron. Eng. 2009, 86, 2347–2353. [Google Scholar] [CrossRef]

- Zhang, T.; Xue, S.; Ma, C. Research status of Ag-Cu-Zn series brazing filler metals. Weld. Join. 2014, 58, 10–15. [Google Scholar]

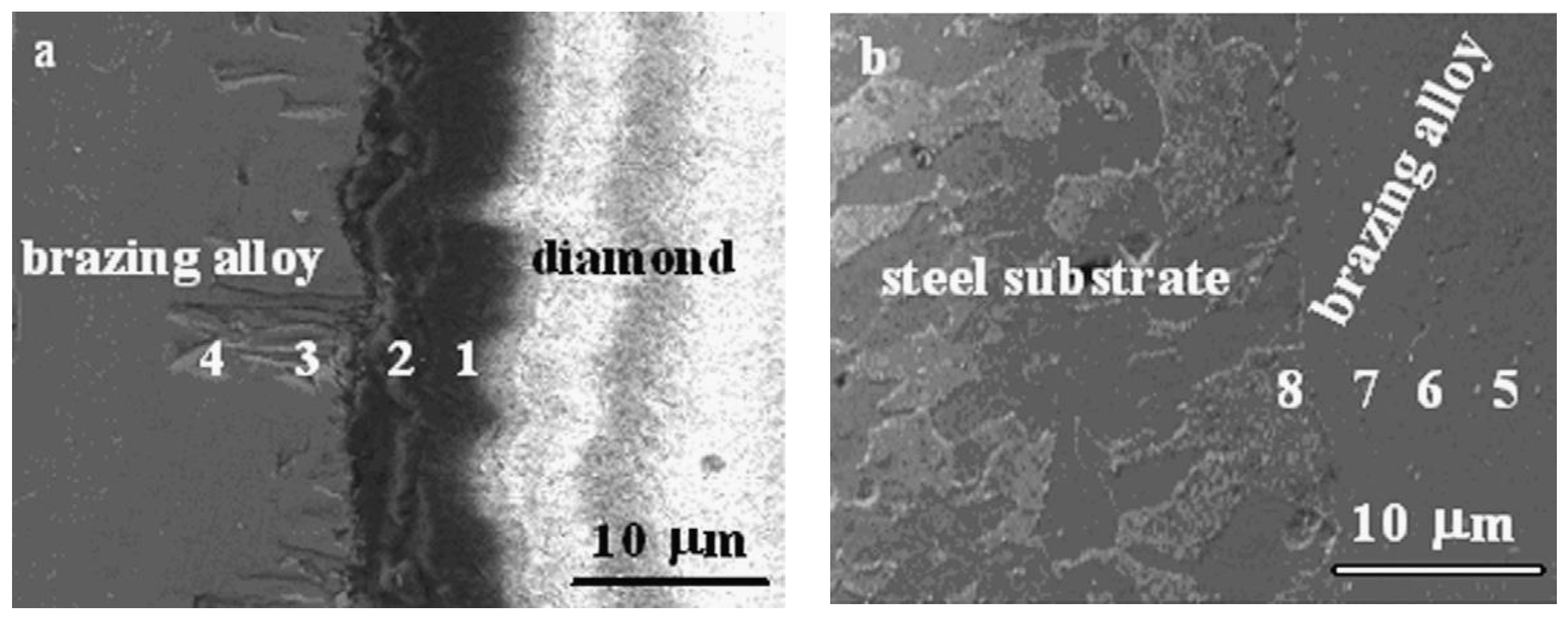

| Points | Elements | ||||

|---|---|---|---|---|---|

| Cr | Ni | Fe | C | P | |

| 1 | 0.2 | - | - | 99.8 | - |

| 2 | 0.8 | - | - | 99.2 | - |

| 3 | 70.9 | 2.6 | 3.5 | 23.0 | - |

| 4 | 7.6 | 61.8 | 20.2 | - | 10.4 |

| Points | Elements | ||||

|---|---|---|---|---|---|

| Cr | Ni | Fe | C | P | |

| 5 | 7.8 | 66.2 | 15.5 | - | 10.5 |

| 6 | 6.5 | 63.5 | 22.5 | - | 7.5 |

| 7 | 7.1 | 61.6 | 20.4 | - | 10.9 |

| 8 | - | - | 100 | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, F.; He, P.; Sekulic, D.P. Research and Development of Powder Brazing Filler Metals for Diamond Tools: A Review. Metals 2018, 8, 315. https://doi.org/10.3390/met8050315

Long F, He P, Sekulic DP. Research and Development of Powder Brazing Filler Metals for Diamond Tools: A Review. Metals. 2018; 8(5):315. https://doi.org/10.3390/met8050315

Chicago/Turabian StyleLong, Fei, Peng He, and Dusan P. Sekulic. 2018. "Research and Development of Powder Brazing Filler Metals for Diamond Tools: A Review" Metals 8, no. 5: 315. https://doi.org/10.3390/met8050315

APA StyleLong, F., He, P., & Sekulic, D. P. (2018). Research and Development of Powder Brazing Filler Metals for Diamond Tools: A Review. Metals, 8(5), 315. https://doi.org/10.3390/met8050315