Thermal Stability and Lubrication Properties of Biodegradable Castor Oil on AISI 4140 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Lubricants

2.2. Castor Oil Extraction

2.3. Characterization of Lubricants

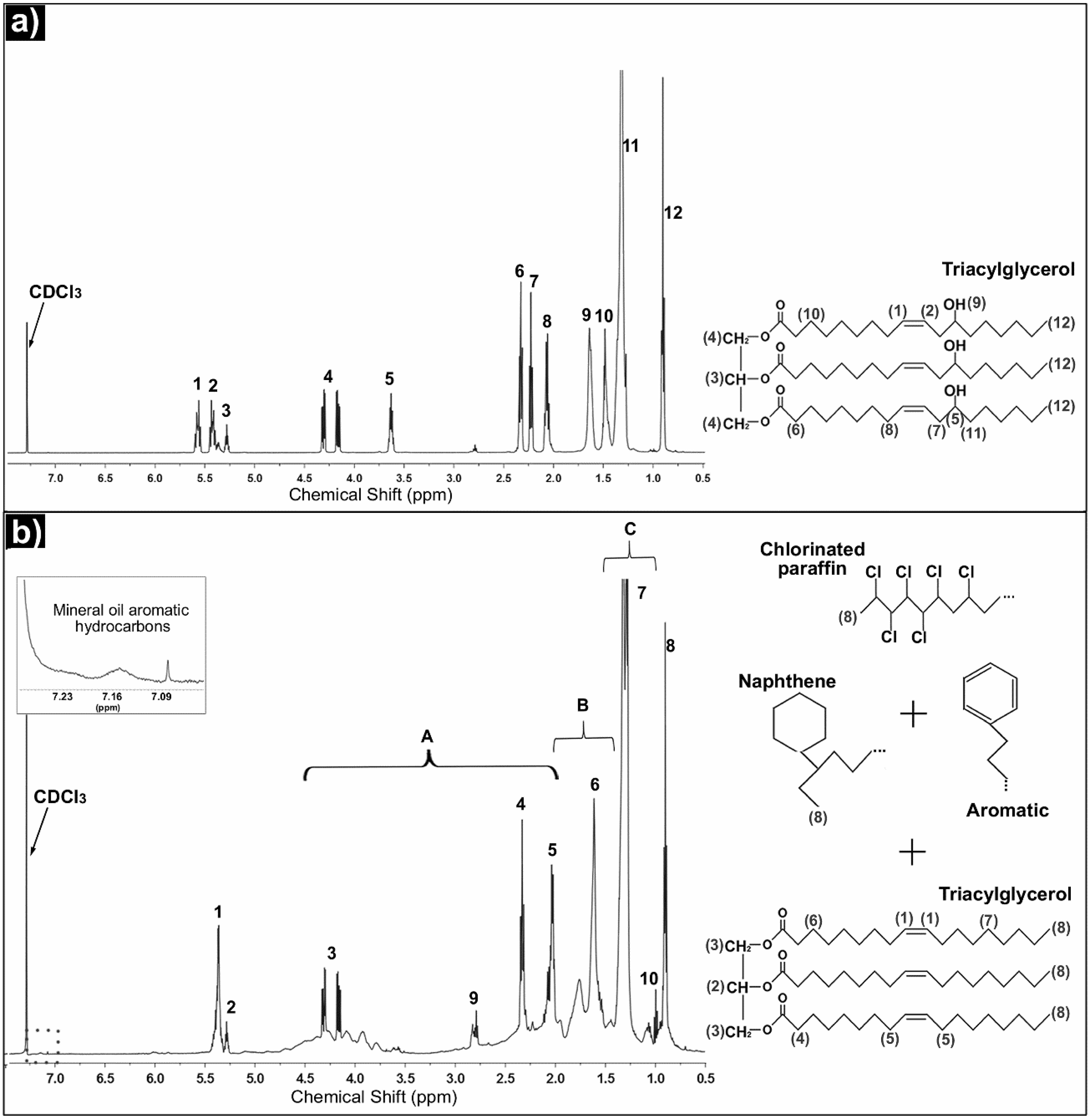

2.3.1. Chemical Characterization

2.3.2. Viscosity Measurements

2.4. Tribological Assessment

2.5. Lubricant Degradation

3. Results and Discussion

3.1. Characterization of Lubricants

3.1.1. Chemical Characterization

3.1.2. Viscosity Measurements

3.2. Tribological Behavior

3.3. Lubricant Degradation

4. Conclusions

- The friction behavior of 4140 steel/WC with Castor Oil lubrication at the two temperatures was notably better than those obtained using Reference oil lubrication. There were reductions of 27% and 76% at 25 and 70 °C, respectively.

- With the use of Castor oil as a lubricant, an increase in steel wear was observed compared to that generated under lubrication with Reference oil. The wear rate was up to an order of magnitude greater.

- A notable change in the microstructure of the steel was observed due to the friction process. A layer of ferrite (created on the surface as result of friction forces) could cause a reduction in hardness, consequently giving rise to greater wear of materials.

- Castor oil exhibited better oxidation resistance than the base of the reference oil.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Lubrication Regime

| Lubricant | Temperature (°C (K)) | βT a (Pa−1) | αT b (K−1) | SV/T (K) | αp (Pa−1) |

|---|---|---|---|---|---|

| Castor oil | 25 (298.15) | 4.20 × 10−10 | −7.47 × 10−4 | 5266 | 1.67 × 10−8 |

| 70 (343.15) | 4.92 × 10−10 | 1.47 × 10−8 | |||

| Reference oil | 25 (298.15) | 3.30 × 10−10 | −5.08 × 10−4 | 5750 | 2.10 × 10−8 |

| 70 (343.15) | 3.87 × 10−10 | 1.86 × 10−8 |

| Lubricant | Temperature (°C) | U | W | k | G | Hmin | hmin (μm) | λ | Lubrication Regime |

|---|---|---|---|---|---|---|---|---|---|

| Castor oil | 25 | 4.62 × 10−12 | 1.62 × 10−6 | 1 | 5715 | 6.44 × 10−6 | 0.019 | 0.39 | Boundary |

| 70 | 4.32 × 10−13 | 1.62 × 10−6 | 1 | 5046 | 1.21 × 10−6 | 0.004 | 0.07 | Boundary | |

| Reference oil | 25 | 8.55 × 10−12 | 1.62 × 10−6 | 1 | 7194 | 1.09 × 10−5 | 0.033 | 0.66 | Boundary |

| 70 | 7.05 × 10−13 | 1.62 × 10−6 | 1 | 6372 | 1.89 × 10−6 | 0.006 | 0.11 | Boundary |

References

- Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A. Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol. Int. 2014, 69, 110–117. [Google Scholar] [CrossRef]

- Menezes, P.L.; Reeves, C.J.; Lovell, M.R. Fundamentals of Lubrication. In Tribology for Scientists and Engineers, 1st ed.; Menezes, P.L., Ingole, S.P., Nosonovsky, M., Kailas, S.V., Lovell, M.R., Eds.; Springer: New York, NY, USA, 2013; pp. 295–336. ISBN 978-1-4614-1944-0. [Google Scholar]

- Kabir, M.A.; Higgs, C.F.; Lovell, M.R. A Pin-on-Disk Experimental Study on a Green Particulate-Fluid Lubricant. J. Tribol. 2008, 130, 1–6. [Google Scholar] [CrossRef]

- Sanchez, R.; Fiedler, M.; Kuhn, E.; Franco, J.M. Tribological characterization of green lubricating greases formulated with castor oil and different biogenic thickener agents: A comparative experimental study. Ind. Lubr. Tribol. 2011, 63, 446–452. [Google Scholar] [CrossRef]

- Patel, V.R.; Dumancas, G.G.; Kasi Viswanath, L.C.; Maples, R.; Subong, B.J.J. Castor Oil: Properties, Uses, and Optimization of Processing Parameters in Commercial Production. Lipid Insights 2016, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Perdomo, F.A.; Acosta-Osorio, A.A.; Herrera, G.; Vasco-Leal, J.F.; Mosquera-Artamonov, J.D.; Millan-Malo, B.; Rodriguez-Garcia, M.E. Physicochemical characterization of seven Mexican Ricinus communis L. seeds & oil contents. Biomass Bioenergy 2013, 48, 17–24. [Google Scholar] [CrossRef]

- Jain, A.K.; Suhane, A. Investigation of Tribological Characteristics of Non Edible Castor and Mahua Oils as Bio Lubricant for Maintenance Applications. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, Assam, India, 12–14 December 2014; Volume 416, pp. 1–6. [Google Scholar]

- Madankar, C.S.; Pradhana, S.; Naika, S.N. Parametric study of reactive extraction of castor seed (Ricinus Communis L.) for methyl ester production and its potential use as bio lubricant. Ind. Crop. Prod. 2013, 43, 283–290. [Google Scholar] [CrossRef]

- Hernández-Sierra, M.T.; Ortega-Álvarez, R.; Bravo-Sánchez, M.G.; Aguilera-Camacho, L.D.; García-Miranda, J.S.; Moreno, K.J. Tribological improvement of hardened and tempered AISI 4140 steel against Al2O3 by using bio-lubricant. MRS Adv. 2017, 2, 3873–3881. [Google Scholar] [CrossRef]

- Zeng, Q.; Dong, G. Superlubricity behaviors of Nitinol 60 alloy under oil lubrication. Trans. Nonferr. Met. Soc. China 2014, 24, 354–359. [Google Scholar] [CrossRef]

- Nagarajan, V.R.; Putatunda, S.K.; Boileau, J. Fatigue Crack Growth Behavior of Austempered AISI 4140 Steel with Dissolved Hydrogen. Metals 2017, 7, 466. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology, 4th ed.; Elsevier, Butterworth-Heinemann: Boston, MA, USA, 2013; pp. 51–68. ISBN 978-0-12-397047-3. [Google Scholar]

- Macián, V.; Tormos, B.; Gómez, Y.A.; Salavert, J.M. Proposal of an FTIR Methodology to Monitor Oxidation Level in Used Engine Oils: Effects of Thermal Degradation and Fuel Dilution. Tribol. Trans. 2012, 55, 872–882. [Google Scholar] [CrossRef] [Green Version]

- Al-Ghouti, M.A.; Al-Atoum, L. Virgin and recycled engine oil differentiation: A spectroscopic study. J. Environ. Manag. 2009, 90, 187–195. [Google Scholar] [CrossRef] [PubMed]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2001; pp. 1–48. ISBN 0-470-09307-2. [Google Scholar]

- Ahuja, D.; Kaushik, A. Castor oil-based polyurethane nanocomposites reinforced with organically modified clay: Synthesis and characterization. J. Elastom. Plast. 2016, 49, 315–331. [Google Scholar] [CrossRef]

- Ducrocq, P.; Duquesne, S.; Magnet, S.; Bourbigot, S.; Delobel, R. Interactions between chlorinated paraffins and melamine in intumescent paint—Investing a way to suppress chlorinated paraffins from the formulations. Prog. Org. Coat. 2006, 57, 430–438. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, A.; Spikes, H. Effect of base oil structure on elastohydrodynamic friction. Tribol. Lett. 2017, 65, 1–24. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamental of Fluid Film Lubrication, 2nd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2004; ISBN 0-8247-5371-2. [Google Scholar]

- Edward, J.C. A Review of Applications of NMR Spectroscopy in the Petroleum Industry. In Spectroscopic Analysis of Petroleum Products and Lubricants; Nadkarni, R.A., Ed.; ASTM International: West Conshohocken, PA, USA, 2011; pp. 423–443. ISBN 978-0-8031-7020-9. [Google Scholar]

- Lachenmeier, D.W.; Mildau, G.; Rullmann, A.; Marx, G.; Walch, S.G.; Hartwig, A.; Kuballa, T. Evaluation of mineral oil saturated hydrocarbons (MOSH) and mineral oil aromatic hydrocarbons (MOAH) in pure mineral hydrocarbon-based cosmetics and cosmetic raw materials using 1H NMR spectroscopy [version 1; referees: 2 approved, 1 approved with reservations]. F1000Research 2017, 6. [Google Scholar] [CrossRef]

- Çelik, O.N.; Ay, N.; Göncü, Y. Effect of Nano Hexagonal Boron Nitride Lubricant Additives on the Friction and Wear Properties of AISI 4140 Steel. Part. Sci. Technol. 2013, 31, 501–506. [Google Scholar] [CrossRef]

- Rübig, B.; Heim, D.; Forsich, C.; Dipolt, C.; Mueller, T.; Gebeshuber, A.; Kullmer, R.; Holecek, R.; Lugmair, C.; Krawinkler, M.; et al. Tribological behavior of thick DLC coatings under lubricated conditions. Surf. Coat. Technol. 2017, 314, 13–17. [Google Scholar] [CrossRef]

- Dyson, C.J.; Priest, M.; Fox, M.F.; Hopkins, B. The tribological behaviour of carbon fibre reinforced polyaryletherketones (PAEKs) through their glass transitions. Proc. Insit. Mech. Eng. Part J J. Eng. Tribol. 2015, 230, 1183–1196. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts: Part 111—Fully Flooded Results. J. Lubr. Technol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Johnston, W.G. A Method to Calculate the Pressure-Viscosity Coefficient from Bulk Properties of Lubricants. ASLE Trans. 1981, 24, 232–238. [Google Scholar] [CrossRef]

- Wright, W.A. Prediction of Bulk Moduli and Pressure-Volume-Temperature Data for Petroleum Oils. ASLE Trans. 1967, 10, 349–356. [Google Scholar] [CrossRef]

| Characteristic | Castor Oil | Reference Oil |

|---|---|---|

| Density at 25 °C (kg/m3) a | 880 | 1030 |

| Density at 70 °C (kg/m3) a | 850 | 1000 |

| Viscosity at 40 °C (mm2/s) a | 173 | 277 |

| Viscosity at 100 °C (mm2/s) a | 15 | 17 |

| Viscosity Index (VI) a | 84 | 49 |

| Flash point (°C) | 200 b | 180 c |

| Pour point (°C) | −27 b | −10 c |

| Lubricant | A (Pa·s) | Ea (kJ·mol−1) | R2 | ||

|---|---|---|---|---|---|

| Value | Standard Error | Value | Standard Error | ||

| Castor oil | 2.18 × 10−9 | 7.13 × 10−10 | 47.0 | 0.78 | 1 |

| Reference oil | 8.28 × 10−10 | 4.41 × 10−10 | 51.2 | 1.27 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Sierra, M.T.; Aguilera-Camacho, L.D.; Báez-García, J.E.; García-Miranda, J.S.; Moreno, K.J. Thermal Stability and Lubrication Properties of Biodegradable Castor Oil on AISI 4140 Steel. Metals 2018, 8, 428. https://doi.org/10.3390/met8060428

Hernández-Sierra MT, Aguilera-Camacho LD, Báez-García JE, García-Miranda JS, Moreno KJ. Thermal Stability and Lubrication Properties of Biodegradable Castor Oil on AISI 4140 Steel. Metals. 2018; 8(6):428. https://doi.org/10.3390/met8060428

Chicago/Turabian StyleHernández-Sierra, María Teresa, Luis Daniel Aguilera-Camacho, José Eduardo Báez-García, J. Santos García-Miranda, and Karla J. Moreno. 2018. "Thermal Stability and Lubrication Properties of Biodegradable Castor Oil on AISI 4140 Steel" Metals 8, no. 6: 428. https://doi.org/10.3390/met8060428

APA StyleHernández-Sierra, M. T., Aguilera-Camacho, L. D., Báez-García, J. E., García-Miranda, J. S., & Moreno, K. J. (2018). Thermal Stability and Lubrication Properties of Biodegradable Castor Oil on AISI 4140 Steel. Metals, 8(6), 428. https://doi.org/10.3390/met8060428