Effect of α′ Martensite Content Induced by Tensile Plastic Prestrain on Hydrogen Transport and Hydrogen Embrittlement of 304L Austenitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimens

2.2. Prestraining

2.3. Microstructural Examinations

2.4. Martensite Content and Dislocation Density Measurements

2.5. Hydrogen Precharging and Total Hydrogen Amount Measurements

2.6. Tensile Testing and HE Degree Evaluation

3. Results

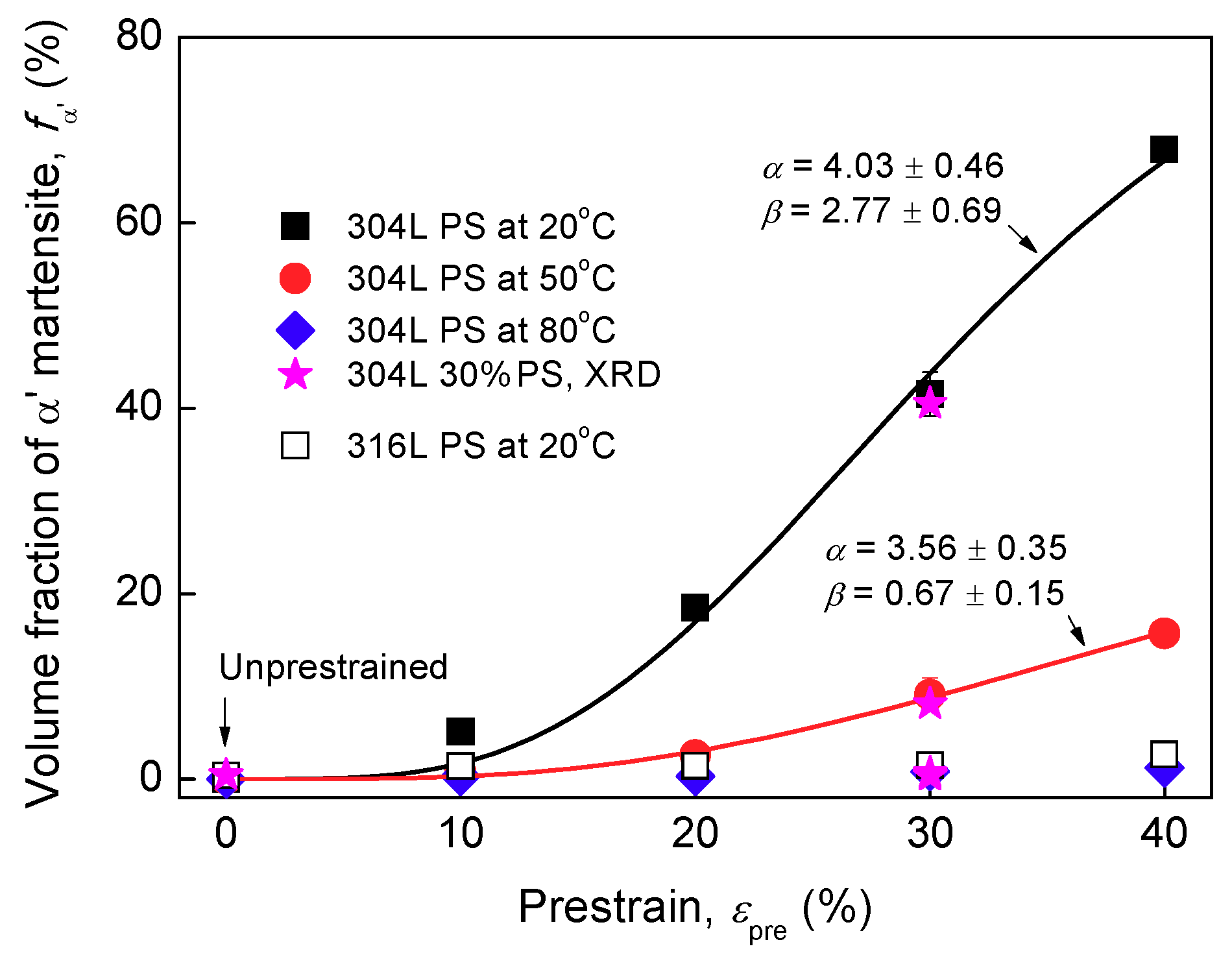

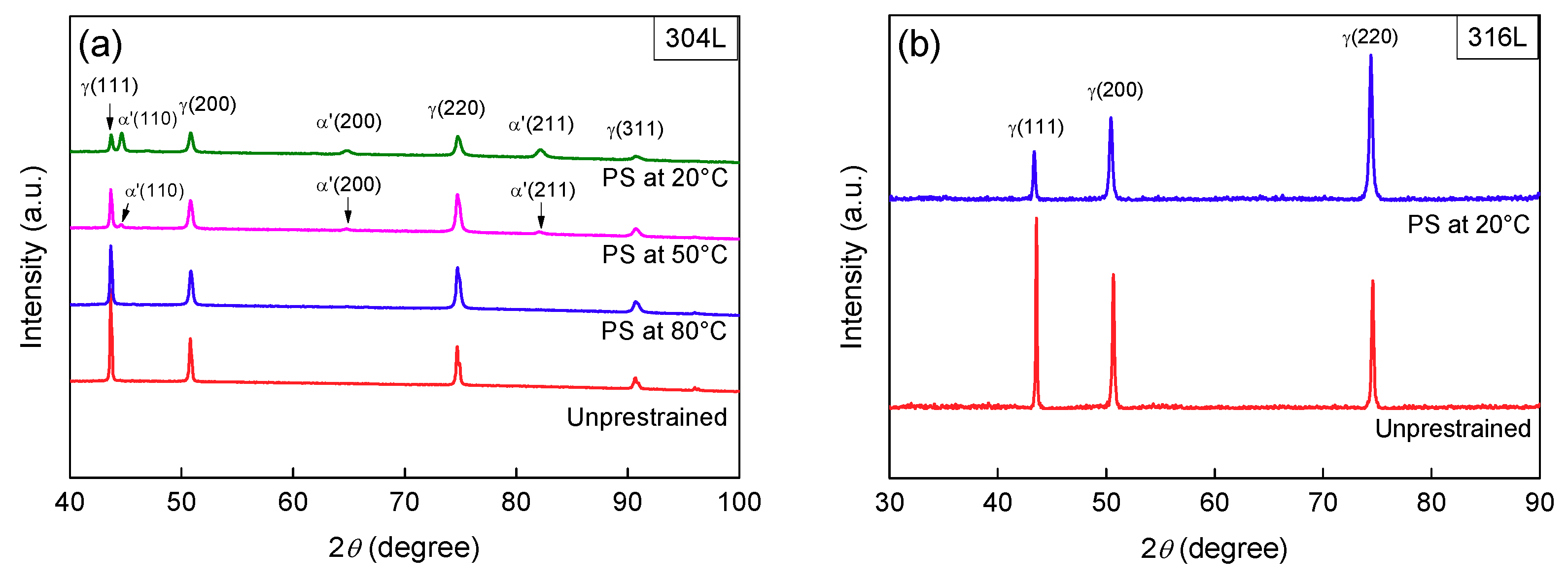

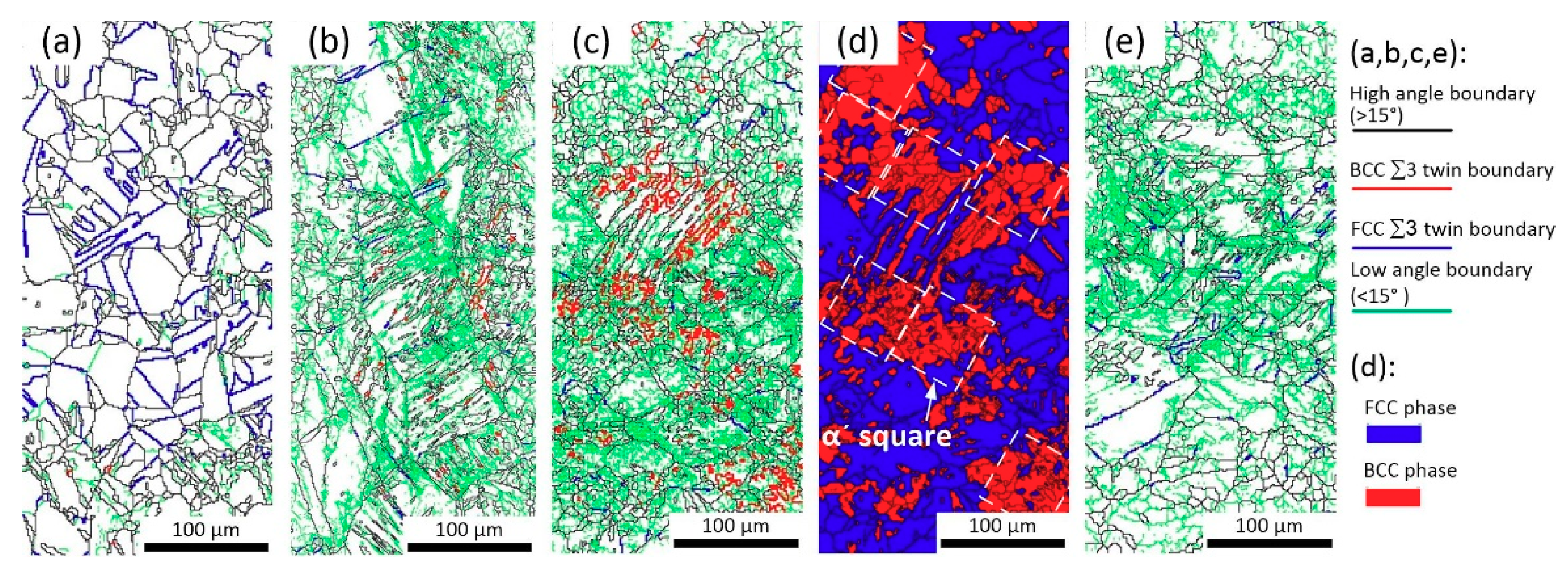

3.1. Martensite Transformation and Microstructures

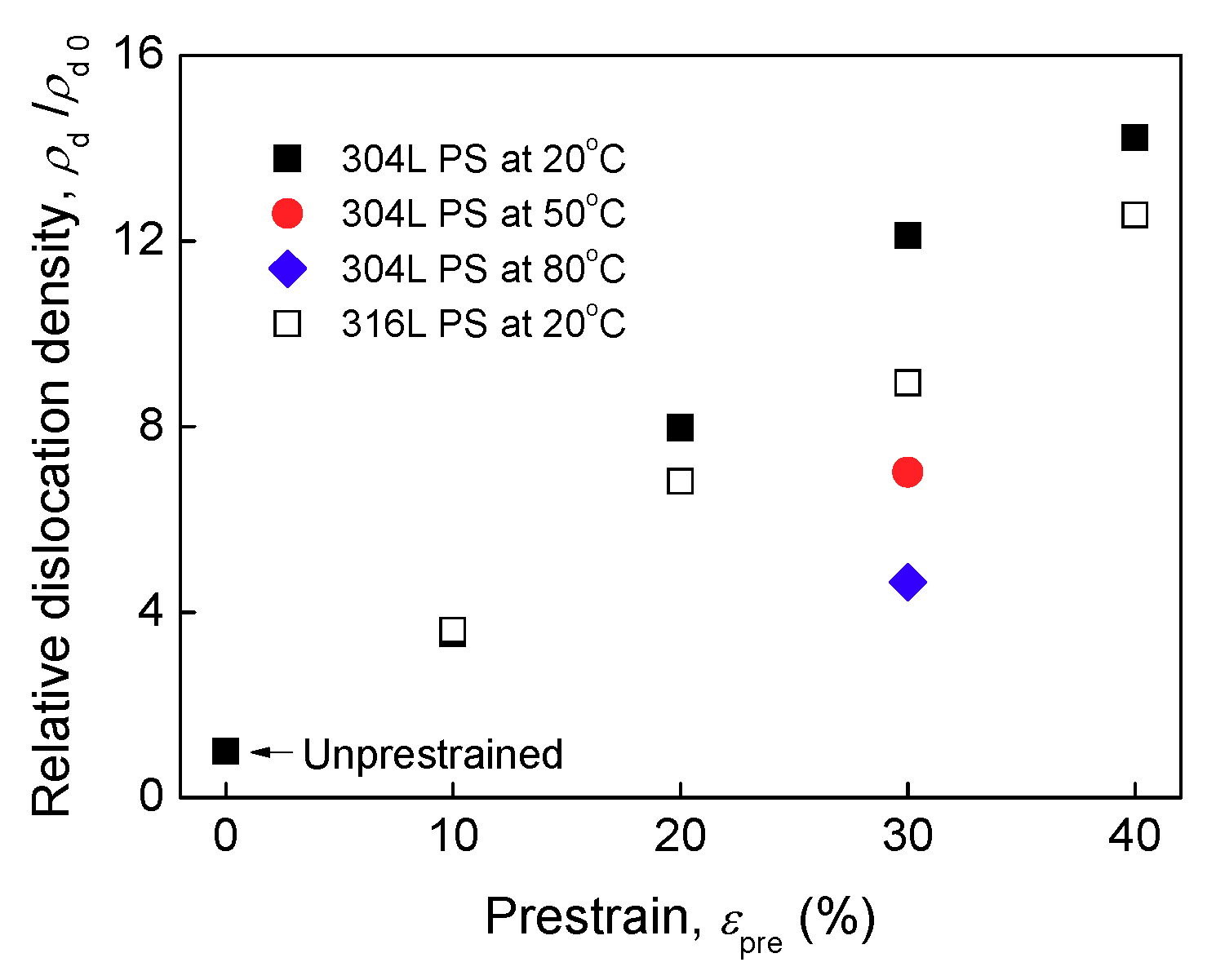

3.2. Twin Boundaries and Dislocation Densities

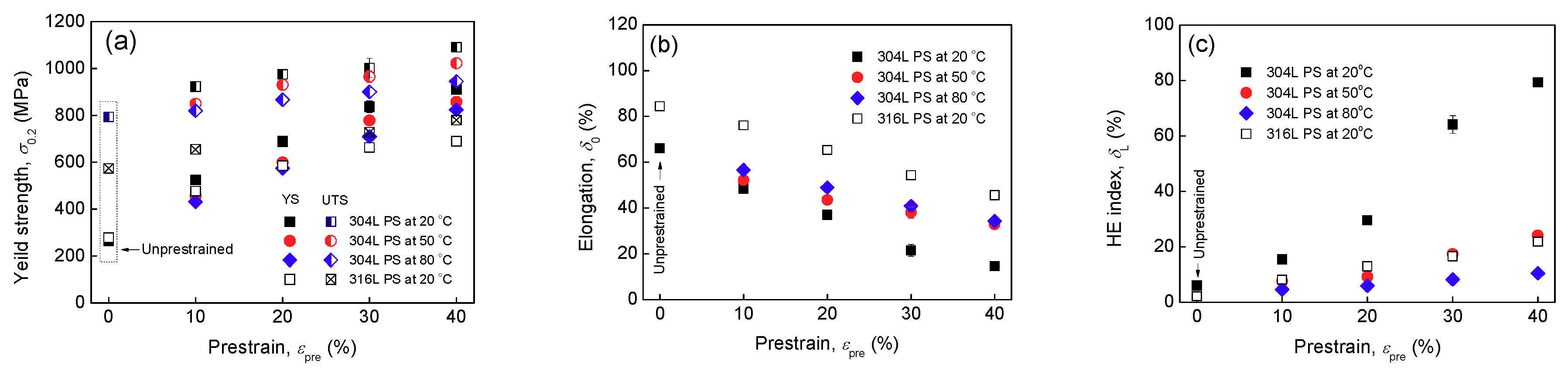

3.3. Mechanical Properties

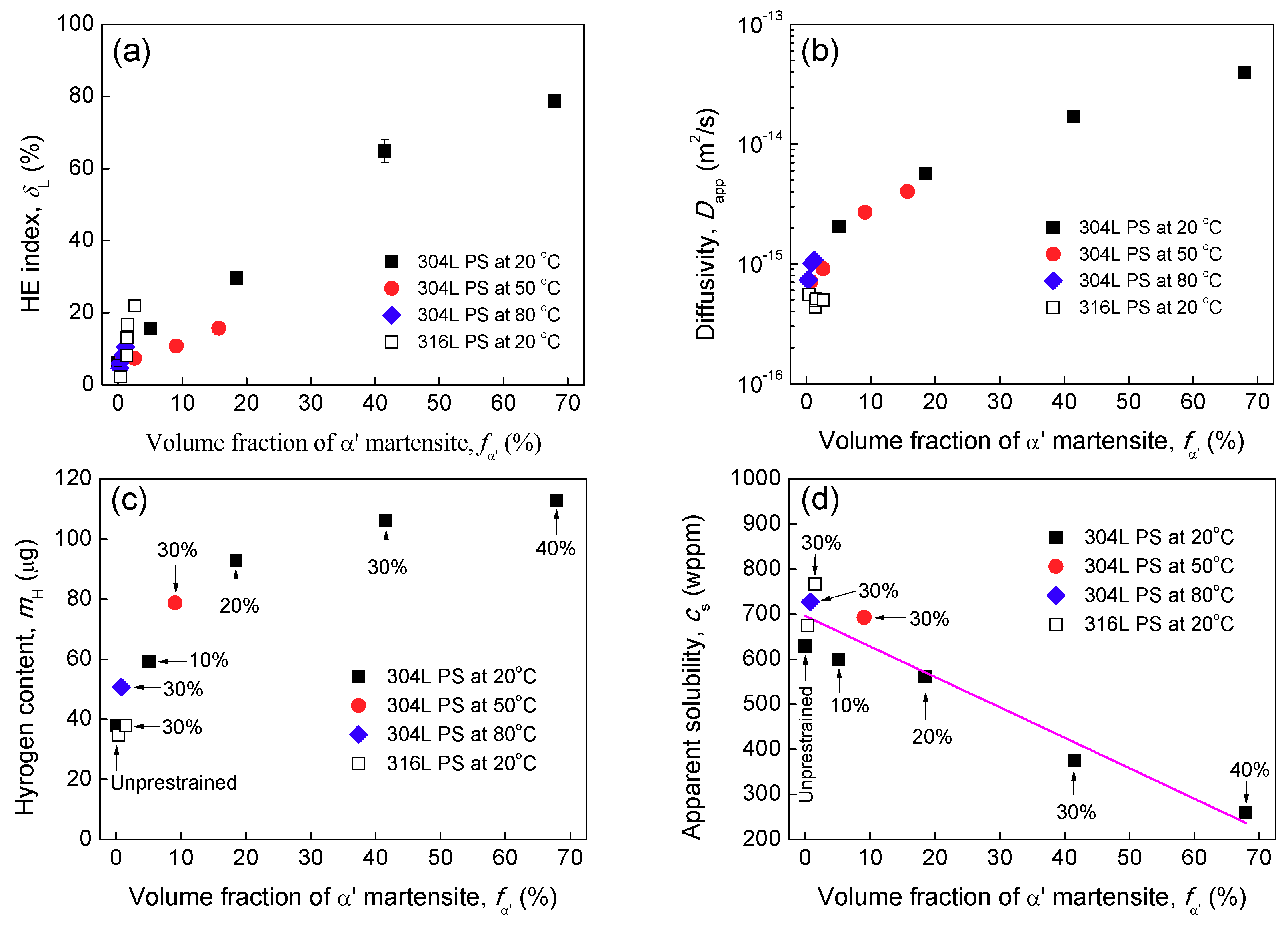

3.4. HE Susceptibility Index

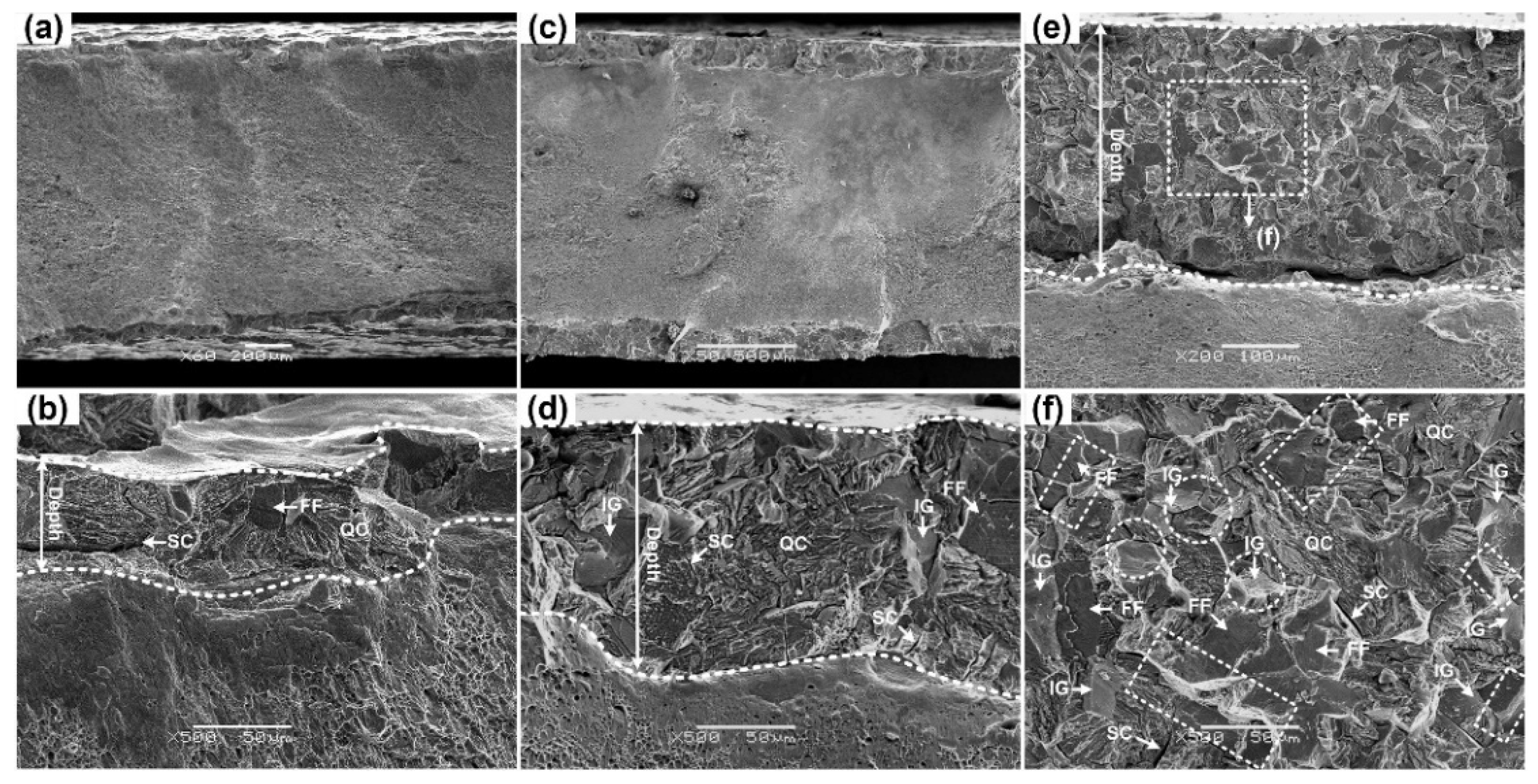

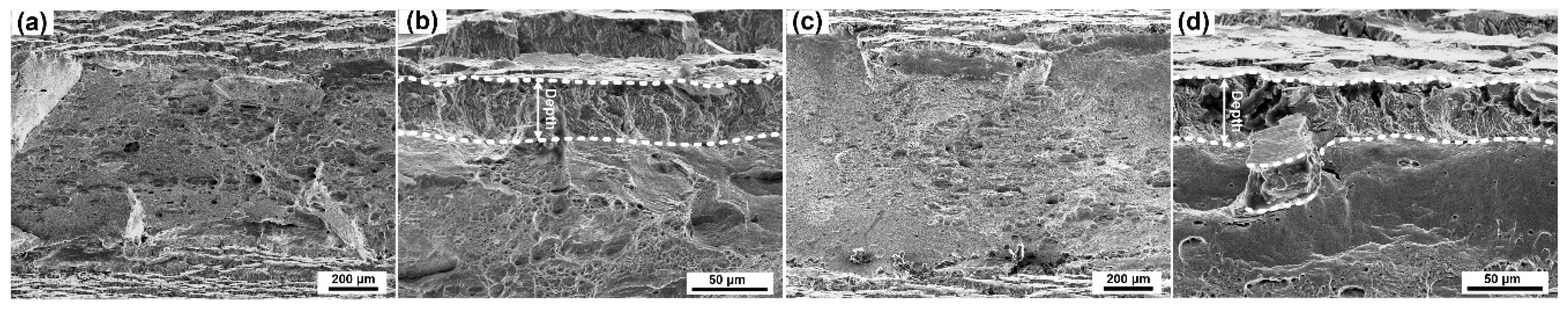

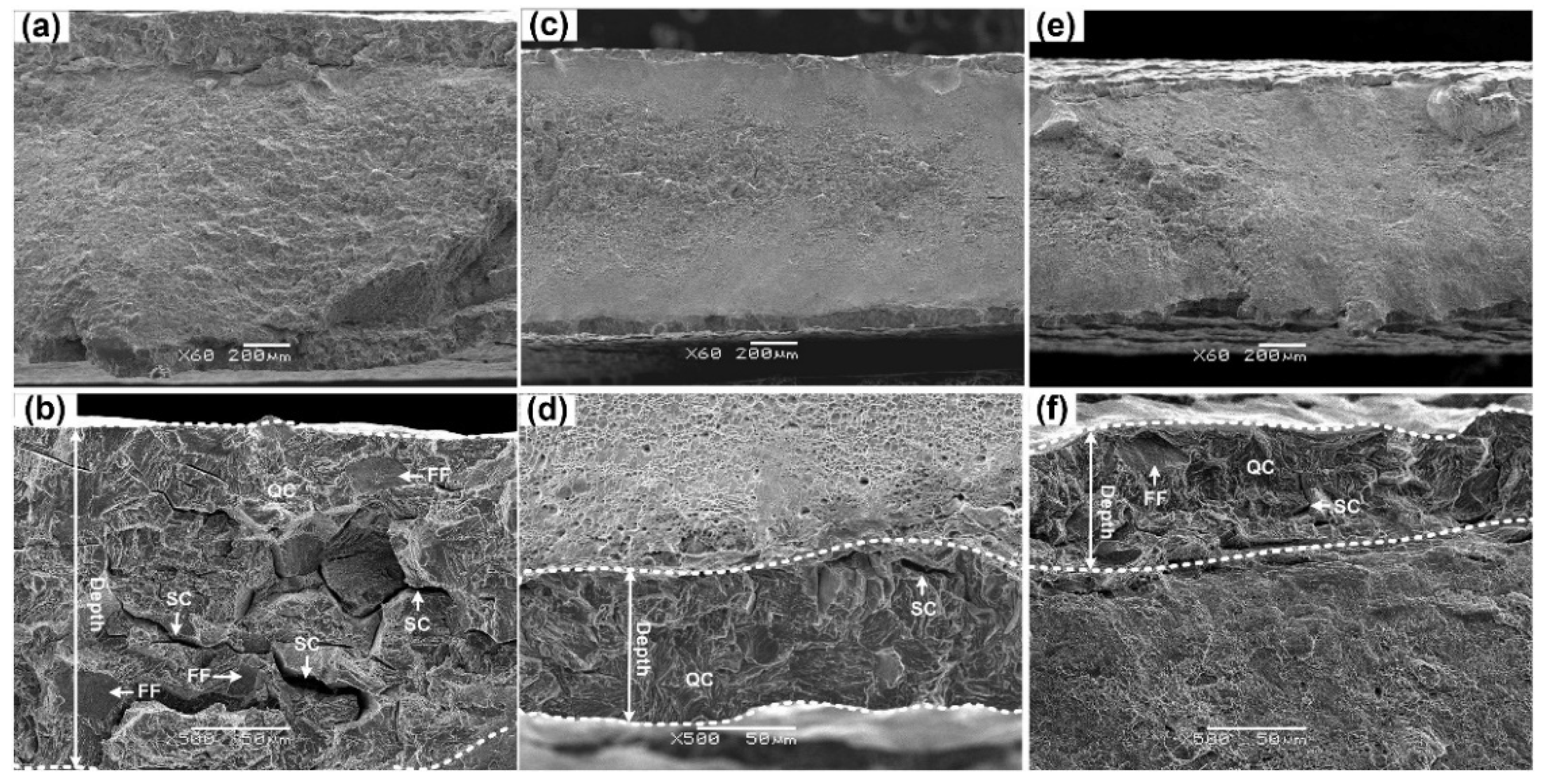

3.5. Fracture Surface Morphologies

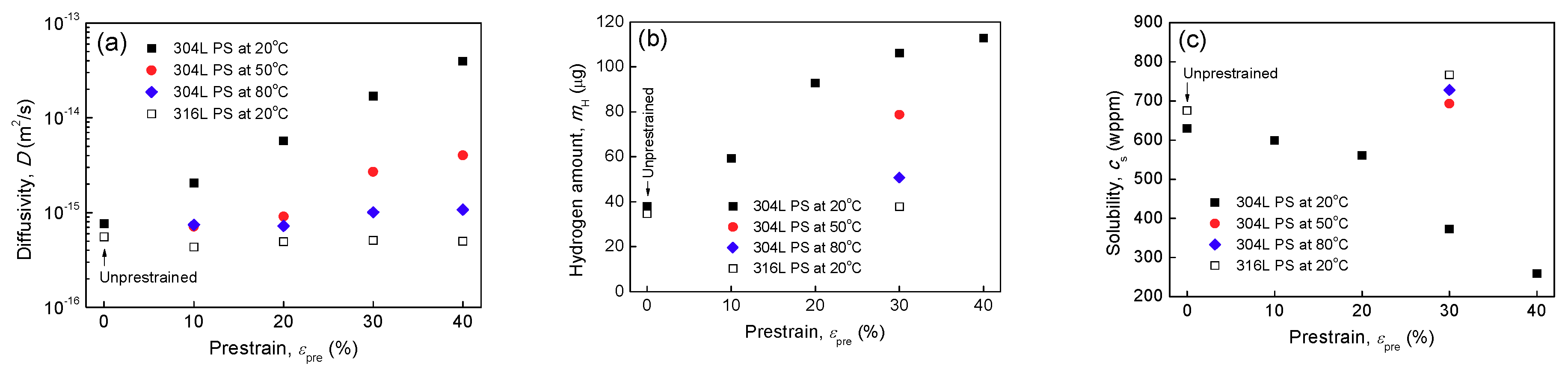

3.6. Hydrogen Diffusivity and Solubility

4. Discussion

4.1. Role of Pre-Existing α′ Martensite

4.2. Role of Initial Dislocation Density

- Compared with pre-existing α′, the effect of initial dislocation density on apparent parameters is minor.

- Compared with pre-existing α′, the effect of initial dislocation density on HE degree is minor.

4.3. Role of Twin Boundaries

4.4. Warm Prestrain: Strengthening ASSs without Impairing Their HE Resistance

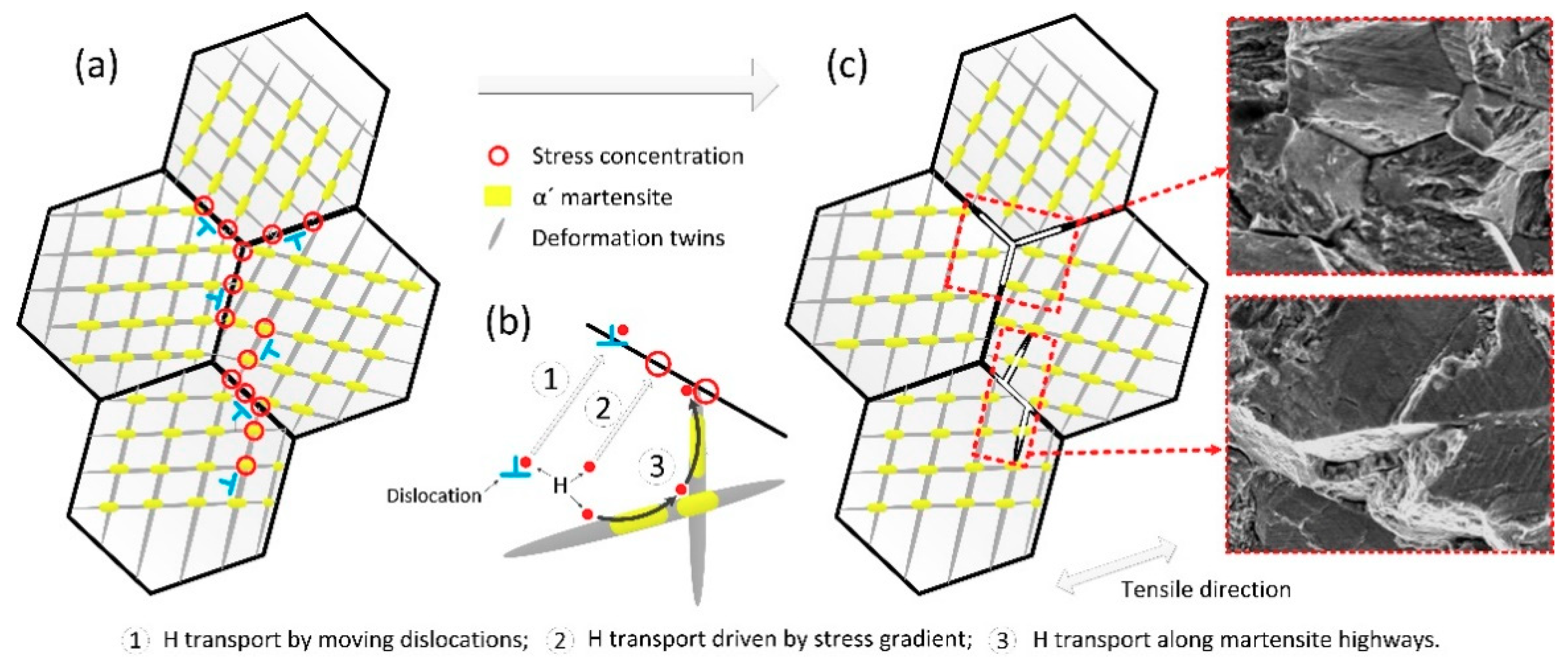

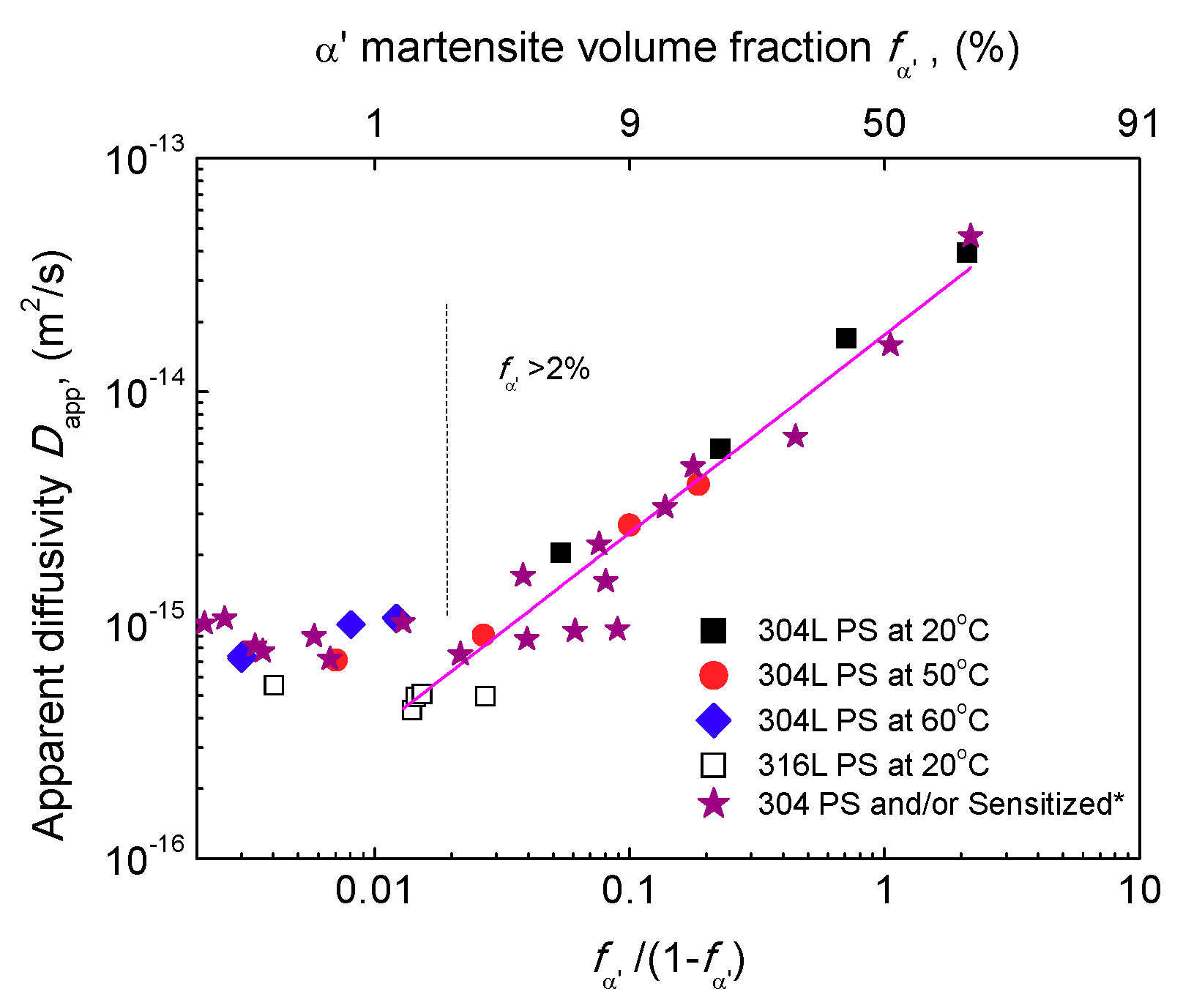

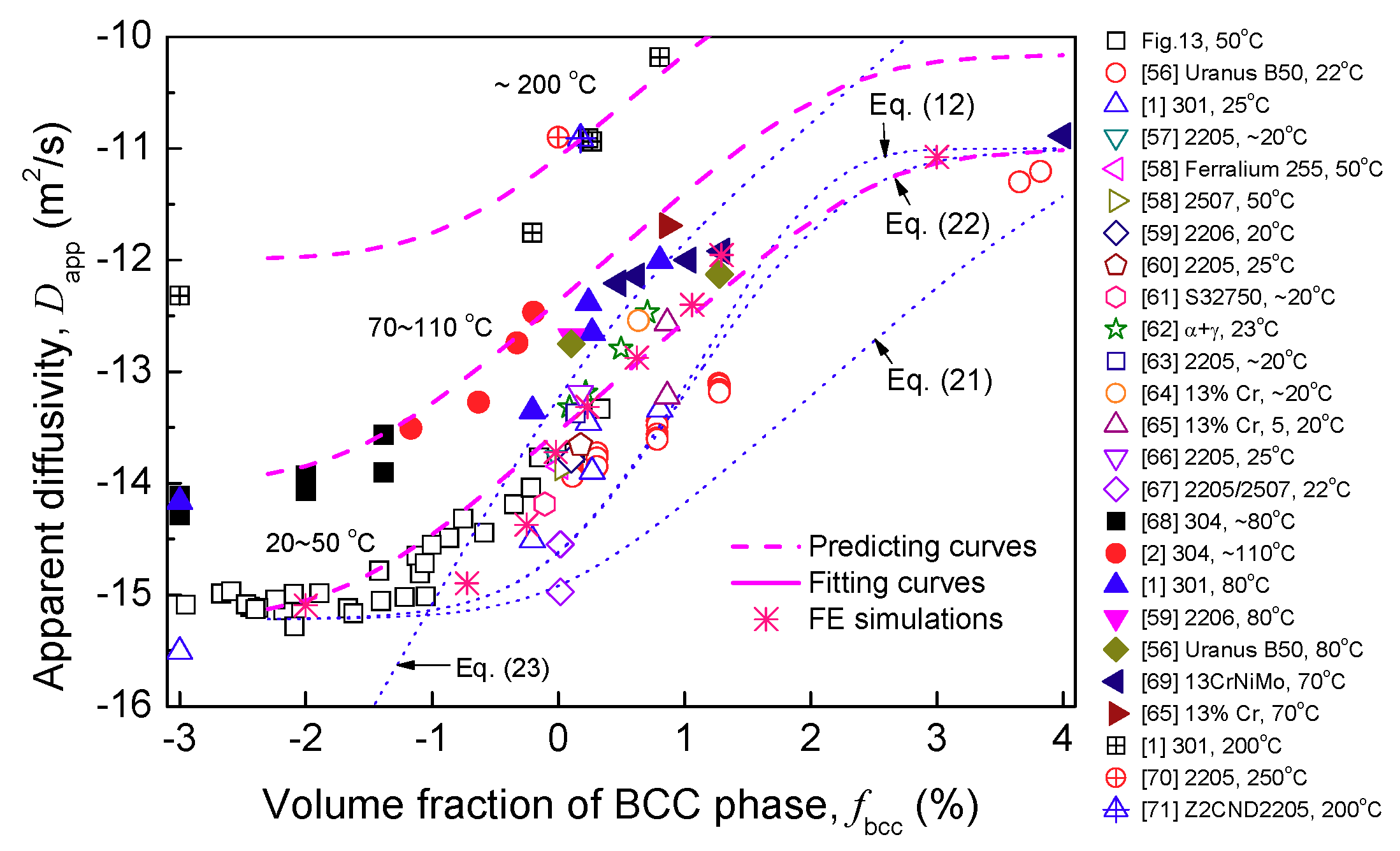

5. Hydrogen Transport in Duplex Materials

5.1. Theoretical Analysis

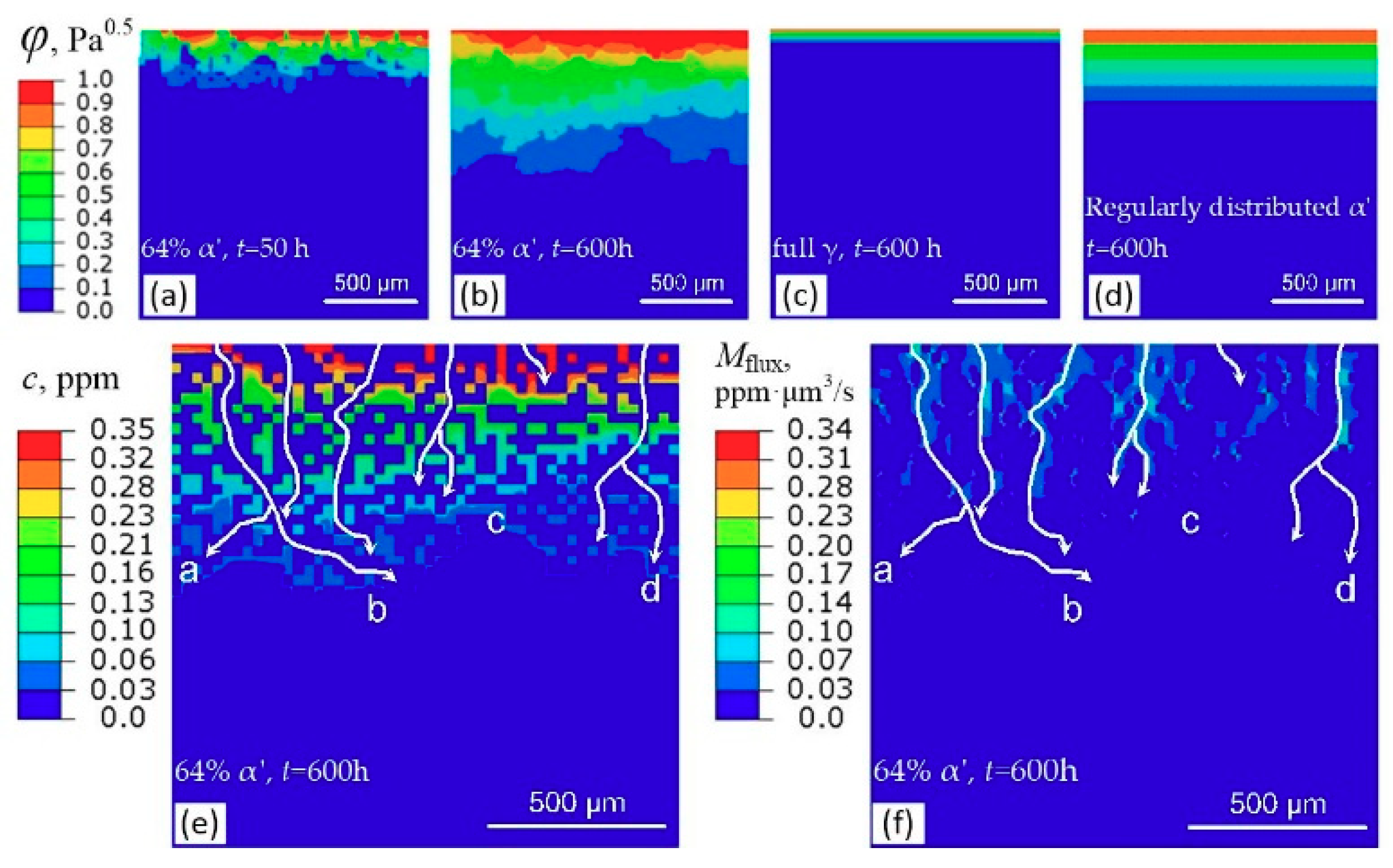

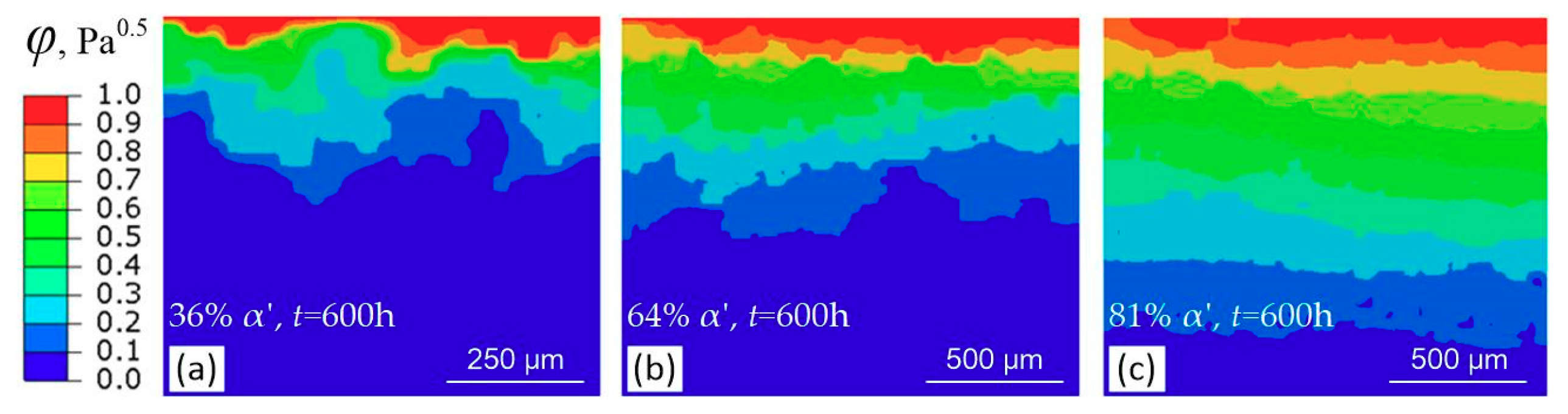

5.2. FE Simulations

6. Conclusions

- Room temperature prestrains higher than 20% can significantly increase the HE degree of 304L steel after hydrogen exposure, because they can induce severe α′ transformation. During hydrogen exposure, the pre-existing α′ platelets, acting as hydrogen diffusion “highways”, increase significantly the hydrogen transport, thus increasing the HE degree.

- 304L steel prestrained at higher temperatures (50 and 80 °C) and 316L steel prestrained at 20 °C exhibit more dislocations but much less α′ after prestraining, consequently their HE degree and hydrogen diffusivity are just slightly increased by prestraining. HEE can be enhanced by the increase of dislocations after prestraining by transporting more hydrogen into the steel during concurrent loading and hydrogen exposure. However, in the IHE condition studied, where no macroscopic plastic deformation occurs during hydrogen exposure, hydrogen entry is mainly enhanced by α′ “highways” rather than by dislocations. The increase of dislocations has a negligible influence on the apparent hydrogen diffusivity, as compared with the pre-existing α′.

- Deformation twins can provide easier cracking paths for HE, it can assist IG fracture in the heavily prestrained 304L steel after hydrogenation. The fracture surfaces of heavily prestrained and hydrogenated 304L steel show many flat facets and intergranular (IG) fracture.

- Warm prestrains result in much less α′ but they can still strengthen the 304L steel by a large degree, thus there is a potential to use warm prestrains to strengthen the metastable ASSs without compromising their HE resistance.

- The heavily prestrained metastable 304L steel can be considered a duplex material. With increasing α′ platelets, the apparent hydrogen diffusivity of steel increases but its solubility decreases. The apparent hydrogen diffusivity and solubility can be described quantitatively by the parallel configuration model or by the following relations:There two relations can be also applied the other more typical duplex materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Perng, T.P.; Altstetter, C.J. Effects of deformation on hydrogen permeation in austenitic stainless steels. Acta Metall. 1986, 34, 1771–1781. [Google Scholar]

- Mine, Y.; Narazaki, C.; Murakami, K.; Matsuoka, S.; Murakami, Y. Hydrogen transport in solution-treated and pre-strained austenitic stainless steels and its role in hydrogen-enhanced fatigue crack growth. Int. J. Hydrogen Energy 2009, 34, 1097–1107. [Google Scholar] [CrossRef]

- Martin, M.; Weber, S.; Izawa, C.; Wagner, S.; Pundt, A.; Theisen, W. Influence of machining-induced martensite on hydrogen-assisted fracture of AISI type 304 austenitic stainless steel. Int. J. Hydrogen Energy 2011, 36, 11195–11206. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Gong, J.; Shen, L.; Dong, W. Hydrogen embrittlement of catholically hydrogen-precharged 304L austenitic stainless steel: Effect of plastic pre-strain. Int. J. Hydrogen Energy 2014, 39, 13909–13918. [Google Scholar] [CrossRef]

- Buckley, J.R.; Hardie, D. The effect of pre-straining and δ-ferrite on the embrittlement of 304L stainless steel by hydrogen. Corros. Sci. 1993, 34, 93–107. [Google Scholar] [CrossRef]

- Perng, T.P.; Altstetter, C.J. Cracking kinetics of two-phase stainless steel alloys in hydrogen gas. Metall. Trans. A 1988, 19, 145–152. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Zheng, J.; Zhao, Y.; Xu, P.; Zhou, C.; Li, X. Effect of strain-induced martensite on hydrogen embrittlement of austenitic stainless steels investigated by combined tension and hydrogen release methods. Int. J. Hydrogen Energy 2013, 38, 8208–8214. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Zheng, J.; Zhao, Y.; Xu, P.; Liu, X. Influence of low temperature prestrain on hydrogen gas embrittlement of metastable austenitic stainless steels. Int. J. Hydrogen Energy 2013, 38, 11181–11187. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, C.; Zheng, J.; Zhang, L. Effects of α′ martensite and deformation twin on hydrogen-assisted fatigue crack growth in cold/warm-rolled type 304 stainless steel. Int. J. Hydrogen Energy 2018, 43, 3342–3352. [Google Scholar] [CrossRef]

- Lai, C.L.; Tsay, L.W.; Chen, C. Effect of microstructure on hydrogen embrittlement of various stainless steels. Mater. Sci. Eng. A 2013, 584, 14–20. [Google Scholar] [CrossRef]

- Chen, T.C.; Chen, S.T.; Tasy, L.W. The role of induced α′-martensite on the hydrogen-assisted fatigue crack growth of austenitic stainless steels. Int. J. Hydrogen Energy 2014, 39, 10293–10302. [Google Scholar] [CrossRef]

- Choo, W.Y.; Lee, J.Y. Effect of cold working on the hydrogen trapping phenomena in pure iron. Metall. Trans. A 1983, 14, 1299–1305. [Google Scholar] [CrossRef]

- Huang, Y.; Nakajim, A.; Nishikata, A.; Tsuru, T. Effect of mechanical deformation on permeation of hydrogen in iron. ISIJ Int. 2003, 43, 548–554. [Google Scholar] [CrossRef]

- Michler, T.; Naumann, J.; Hock, M.; Berreth, K.; Balogh, M.P.; Sattler, E. Microstructural properties controlling hydrogen environment embrittlement of cold worked 316 type austenitic stainless steels. Mater. Sci. Eng. A 2015, 628, 252–261. [Google Scholar] [CrossRef]

- Louthan, M.R., Jr.; Caskey, G.R., Jr.; Donovan, J.A.; Rawl, D.E., Jr. Hydrogen embrittlement of metals. Mater. Sci. Eng. 1972, 10, 357–368. [Google Scholar] [CrossRef]

- Koyama, M.; Akiyama, E.; Sawaguchi, T.; Raabe, D.; Tsuzaki, K. Hydrogen-induced cracking at grain and twin boundaries in an Fe-Mn-C austenitic steel. Scr. Mater. 2012, 66, 459–462. [Google Scholar] [CrossRef]

- Koyama, M.; Akiyama, E.; Tsuzaki, K.; Raabe, D. Hydrogen-assisted failure in a twinning-induced plasticity steel studied under in situ hydrogen charging by electron channeling contrast imaging. Acta Mater. 2013, 61, 4607–4618. [Google Scholar] [CrossRef]

- Koyama, M.; Akiyama, E.; Tsuzaki, K. Hydrogen embrittlement in a Fe-Mn-C ternary twinning-induced plasticity steel. Corros. Sci. 2012, 54, 1–4. [Google Scholar] [CrossRef]

- Caskey, G.R., Jr. The role of twinning and transformation in hydrogen embrittlement of austenitic stainless steels. In Proceedings of the Conference of the Environmental Degradation of Engineering Materials, Blacksburg, VA, USA, 10 October 1977. [Google Scholar]

- Caskey, G.R., Jr. Fractography of hydrogen-embrittled iron-chromium-nickel alloys. In Proceedings of the 13th Annual Technical Meeting of the International Metallographic Society, Brighton, UK, 18–20 August 1980. [Google Scholar]

- Eliezer, D.; Chakrapani, D.G.; Altstetter, C.J.; Pugh, E.N. The influence of austenite stability on the hydrogen embrittlement and stress-corrosion cracking of stainless steel. Metall. Trans. A 1979, 10, 935–941. [Google Scholar] [CrossRef]

- Ji, H.; Park, I.J.; Lee, S.M.; Lee, Y.K. The effect of pre-strain on hydrogen embrittlement in 310S stainless steel. J. Alloys Compd. 2014, 598, 205–212. [Google Scholar] [CrossRef]

- Park, I.J.; Jung, J.G.; Jo, S.Y.; Lee, S.M.; Lee, Y.K. The effect of pre-strain on the resistance to hydrogen embrittlement in 316L austenitic stainless steel. Mater. Trans. 2014, 55, 964–970. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Ahmedabadi, P.M.; Kain, V.; Agrawal, A. Modelling kinetics of strain-induced martensite transformation during plastic deformation of austenitic stainless steel. Mater. Des. 2016, 109, 466–475. [Google Scholar] [CrossRef]

- Shin, H.C.; Ha, T.K.; Chang, Y.W. Kinetics of deformation induced martensitic transformation in a 304 stainless steel. Scr. Mater. 2001, 45, 823–829. [Google Scholar] [CrossRef]

- Nohara, K.; Ono, Y.; Ohashi, N. Composition and grain size dependencies of strain-induced martensitic transformation in metastable austenitic stainless steels. Tetsu-to-Hagane 1977, 63, 212–222. [Google Scholar] [CrossRef]

- ASTM International. Metallography, Nondestructive Testing; ASTM International: New York, NY, USA, 1986; pp. 115–117. [Google Scholar]

- Wu, Z.; Huang, Y. Mechanical behavior and fatigue performance of austenitic stainless steel under consideration of martensitic phase transformation. Mater. Sci. Eng. A 2017, 679, 249–257. [Google Scholar]

- Tian, Y.; Gorbatov, O.I.; Borgenstam, A.; Ruban, A.V.; Hedström, P. Deformation microstructure and deformation-induced martensite in austenitic Fe-Cr-Ni alloys depending on stacking fault energy. Metall. Mater. Trans. A 2017, 48, 1–7. [Google Scholar] [CrossRef]

- Ahmadzade-Beiraki, E.; Mazinani, M.; Kashefi, M. Examination of Barkhausen noise parameters for characterisation of strain-induced martensitic transformation in AISI 304 stainless steel. Insight 2016, 58, 297–301. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Cabrera, J.M.; Najafizadeh, A.; Calvillo, P.R. EBSD study of a hot deformed austenitic stainless steel. Mater. Sci. Eng. A 2012, 538, 236–245. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction; Addison-Wesley: Reading MA, USA, 1978; pp. 392–393. [Google Scholar]

- De, A.K.; Murdock, D.C.; Mataya, M.C.; Speer, J.G.; Matlock, D.K. Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scr. Mater. 2004, 50, 1445–1449. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. 1955, 1, 34–36. [Google Scholar] [CrossRef]

- Dini, G.; Ueji, R.; Najafizadeh, A.; Monir-Vaghefi, S.M. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 2010, 527, 2759–2763. [Google Scholar] [CrossRef]

- Peng, Y.; Gong, J.; Jiang, Y.; Fu, M.; Rong, D. The effect of plastic pre-strain on low-temperature surface carburization of AISI 304 austenitic stainless steel. Surf. Coat. Technol. 2016, 304, 16–22. [Google Scholar] [CrossRef]

- Steel and Iron—Determination of Hydrogen Content—Inert Gas Impulse Fusion Heat Conductivity Method; SAC: Beijing, China, 2007; GB/T 223.82-2007.

- Olson, G.B.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Mishra, S.; Narasimhan, K.; Samajdar, I. Deformation twinning in AISI 316L austenitic stainless steel: role of strain and strain path. Mater. Sci. Technol. 2007, 23, 1118–1126. [Google Scholar] [CrossRef]

- Shen, Y.F.; Li, X.X.; Sun, X.; Wang, Y.D.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng. A 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Shintani, T.; Murata, Y. Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater. 2011, 59, 4314–4322. [Google Scholar] [CrossRef]

- Lebedev, A.A.; Kosarchuk, V.V. Influence of phase transformations on the mechanical properties of austenitic stainless steels. Int. J. Plast. 2000, 16, 749–767. [Google Scholar] [CrossRef]

- Olden, V.; Thaulow, C.; Johnsen, R. Modelling of hydrogen diffusion and hydrogen induced cracking in supermartensitic and duplex stainless steels. Mater. Des. 2008, 29, 1934–1948. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion; Oxford University Press: Clarendon, UK, 1975; pp. 231–232. [Google Scholar]

- Zhu, W.Y.; Qiao, L.J.; Li, J.X.; Su, Y.J.; Yan, Y.; Bai, Y.; Ren, X.C.; Huang, H.Y. Hydrogen Embrittlement and Stress Corrosion Cracking; Science Press: Beijing, China, 2013; p. 124. [Google Scholar]

- Turnbull, A.; Hutchings, R.B. Analysis of hydrogen atom transport in a two-phase alloy. Mater. Sci. Eng. A 1994, 177, 161–171. [Google Scholar] [CrossRef]

- Walter, R.J.; Jewett, R.P.; Chandler, W.T. On the mechanism of hydrogen-environment embrittlement of iron- and nickel-base alloys. Mater. Sci. Eng. 1970, 5, 99–110. [Google Scholar] [CrossRef]

- West, A.J.; Louthan, M.R. Dislocation Transport and Hydrogen Embrittlement. Metall. Trans. A 1979, 10, 1675–1682. [Google Scholar] [CrossRef]

- Gesnouin, C.; Hazarabedian, A.; Bruzzoni, P.; Ovejero-García, J.; Bilmes, P.; Llorente, C. Effect of post-weld heat treatment on the microstructure and hydrogen permeation of 13CrNiMo steels. Corros. Sci. 2004, 46, 1633–1647. [Google Scholar] [CrossRef]

- Owczarek, E.; Zakroczymski, T. Hydrogen transport in a duplex stainless steel. Acta Mater. 2000, 48, 3059–3070. [Google Scholar] [CrossRef]

- Olden, V.; Saai, A.; Jemblie, L.; Johnsen, R. FE simulation of hydrogen diffusion in duplex stainless steel. Int. J. Hydrogen Energy 2014, 39, 1156–1163. [Google Scholar] [CrossRef]

- Oriani, R.A. The diffusion and trapping of hydrogen in steel. Acta Metall. 1970, 18, 147–157. [Google Scholar] [CrossRef]

- Thomas, G.J. Hydrogen trapping in fcc metals. In Proceedings of the Conference of Hydrogen Effects in Metals, Jackson Lake Lodge, WY, USA, 26–31 August 1980; pp. 77–85. [Google Scholar]

- Hagi, H.; Hayashi, Y. Effects of interstitial impurities on dislocation trapping on hydrogen in iron. Trans. Jpn. Inst. Met. 1987, 28, 375–382. [Google Scholar] [CrossRef]

- Hutchings, R.B.; Turnbull, A.; May, A.T. Measurement of hydrogen transport in a duplex stainless steel. Scr. Metall. Mater. 1991, 25, 2657–2662. [Google Scholar] [CrossRef]

- Sentence, P. Hydrogen embrittlement of cold worked duplex stainless steel oilfield tubulars. In Proceedings of the Conference of Duplex Stainless Steel 91, Beaune, France, 28–30 October 1991; Volume 2, pp. 895–903. [Google Scholar]

- Alsarraf, J. Hydrogen Embrittlement Susceptibility of Super Duplex Stainless Steels. Ph.D Thesis, Cranfield University, Bedfordshire, UK, 2010. [Google Scholar]

- Wang, X.G.; Dumortier, D.; Riquier, Y. Structural evolution of zeron 100 duplex stainless steel between 550 nd 1100 °C. In Proceedings of the Conference of Duplex Stainless Steel 91, Beaune, France, 28–30 October 1991; Volume 1, pp. 127–134. [Google Scholar]

- Chen, S.S.; Wu, T.I.; Wu, J.K. Effects of deformation on hydrogen degradation in a duplex stainless steel. J. Mater. Sci. 2004, 39, 67–71. [Google Scholar] [CrossRef]

- da Silva, B.R.S.; Salvio, F.; dos Santos, D.S. Hydrogen embrittlement in super duplex stainless steel tubes UNS S32750 under mechanical stress. In Proceedings of the 2012 International Hydrogen Conference on Hydrogen-Materials Interactions, Jackson Lack Lodge, WY, USA, 9–12 September 2012; pp. 245–254. [Google Scholar]

- He, J.; Tang, X.; Chen, N. Diffusion of hydrogen in (α + γ) duplex stainless steel. Acta Metall. Sin. 1989, 25, 42–47. [Google Scholar]

- Chou, S.L.; Tsai, W.T. Effect of grain size on the hydrogen-assisted cracking in duplex stainless steels. Mater. Sci. Eng. A 1999, 270, 219–224. [Google Scholar] [CrossRef]

- Smirnova, A.; Johnsen, R. Effect of Tensile Stress on Hydrogen Permeation in 13% Cr Super Martensitic Stainless Steel. Available online: https://brage.bibsys.no/xmlui/bitstream/handle/11250/248888/506367_FULLTEXT01.pdf?sequence=1 (accessed on 8 June 2018).

- Hinds, G.; Zhao, J.; Griffiths, A.J.; Turnbull, A. Hydrogen diffusion in Super 13% chromium martensitic stainless steel. Corrosion 2005, 61, 348–354. [Google Scholar] [CrossRef]

- Luu, W.C.; Liu, P.W.; Wu, J.K. Hydrogen transport and degradation of a commercial duplex stainless steel. Corros. Sci. 2002, 44, 1783–1791. [Google Scholar] [CrossRef]

- Turnbull, A.; Beylegaard, E.L.; Hutchings, R.B. Hydrogen transport in SAF 2205 and SAF 2507 duplex stainless steels. In Proceedings of the Conference of Hydrogen Transport and Cracking in Metals, Cambridge, UK, 13–14 April 1994; pp. 268–279. [Google Scholar]

- Dayal, R.K.; Grabke, H.K. Dependence of the hydrogen permeation in stainless steel on carbon content, heat treatment and cold work. Steel Res. 2000, 71, 255–260. [Google Scholar] [CrossRef]

- Iacoviello, F.; Habashi, M.; Cavallini, M. Hydrogen embrittlement in the duplex stainless steel Z2CND2205 hydrogen-charged at 200 °C. Mater. Sci. Eng. A 1997, 224, 116–124. [Google Scholar] [CrossRef]

- Iacoviello, F.; Galland, J.; Habashi, M. A thermal outgassing method (T.O.M.) to measure the hydrogen diffusion coefficients in austenitic, austeno-ferritic and ferritic-perlitic steels. Corros. Sci. 1998, 40, 1281–1293. [Google Scholar] [CrossRef]

- Bernabai, U.; Torella, R. Thermal analysis of hydrogen-charged austenitic and duplex stainless steels. Int. J. Hydrogen Energy 1993, 18, 763–771. [Google Scholar] [CrossRef]

- Hsu, J.W.; Tsai, S.Y.; Shih, H.C. Hydrogen Embrittlement of SAF 2205 Duplex Stainless Steel. Corrosion 2002, 58, 858–862. [Google Scholar] [CrossRef]

- Mente, T.; Boellinghaus, T. Modeling of hydrogen distribution in a duplex stainless steel. Weld. World 2012, 56, 66–78. [Google Scholar] [CrossRef]

- Paul, S.K. Micromechanics based modeling of dual phase steels: Prediction of ductility and failure modes. Comput. Mater. Sci. 2012, 56, 34–42. [Google Scholar] [CrossRef]

- Sun, C.T.; Vaidya, R.S. Prediction of composite properties from a representative volume element. Compos. Sci. Technol. 1996, 56, 171–179. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | S | P | Cr | Mo | Ni | Cu | N |

|---|---|---|---|---|---|---|---|---|---|---|

| 304L | 0.020 | 0.37 | 1.15 | 0.004 | 0.031 | 18.30 | 0.01 | 8.10 | 0.064 | 0.044 |

| 316L | 0.017 | 0.34 | 1.15 | 0.002 | 0.030 | 16.78 | 2.20 | 10.23 | 0.323 | 0.043 |

| Parameter | Values Reported in Literatures | Values Used | ||

|---|---|---|---|---|

| 20–50 °C | 70–110 °C | ~200 °C | ||

(×10−11 m2/s) | ~25 °C: 1.5 [51]; 6.0 [52]; 0.6 [47]. (25 °C: 1) [1] 1. | 1.0 | 8 | 80 |

(×10−16 m2/s) | ~25 °C: (1.8~8) [44]; 3.3 [47]; 1.4 [52]; ~7.0 2. 110 °C: 300 [2]. | 6.0 | 100 | 10,000 |

(×10−3) | (T < 170 °C); (T > 170 °C) [1] 1. | 1.0 | 3.0 | 7.0 |

() | [1] 3; [47]. | 0.35 | 0.50 | 0.75 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wu, X.; Wu, W. Effect of α′ Martensite Content Induced by Tensile Plastic Prestrain on Hydrogen Transport and Hydrogen Embrittlement of 304L Austenitic Stainless Steel. Metals 2018, 8, 660. https://doi.org/10.3390/met8090660

Wang Y, Wu X, Wu W. Effect of α′ Martensite Content Induced by Tensile Plastic Prestrain on Hydrogen Transport and Hydrogen Embrittlement of 304L Austenitic Stainless Steel. Metals. 2018; 8(9):660. https://doi.org/10.3390/met8090660

Chicago/Turabian StyleWang, Yanfei, Xuanpei Wu, and Weijie Wu. 2018. "Effect of α′ Martensite Content Induced by Tensile Plastic Prestrain on Hydrogen Transport and Hydrogen Embrittlement of 304L Austenitic Stainless Steel" Metals 8, no. 9: 660. https://doi.org/10.3390/met8090660

APA StyleWang, Y., Wu, X., & Wu, W. (2018). Effect of α′ Martensite Content Induced by Tensile Plastic Prestrain on Hydrogen Transport and Hydrogen Embrittlement of 304L Austenitic Stainless Steel. Metals, 8(9), 660. https://doi.org/10.3390/met8090660