Evaluation of the Applicability of Concrete Sludge for the Removal of Cu, Pb, and Zn from Contaminated Aqueous Solutions

Abstract

:1. Introduction

2. Materials and Methods

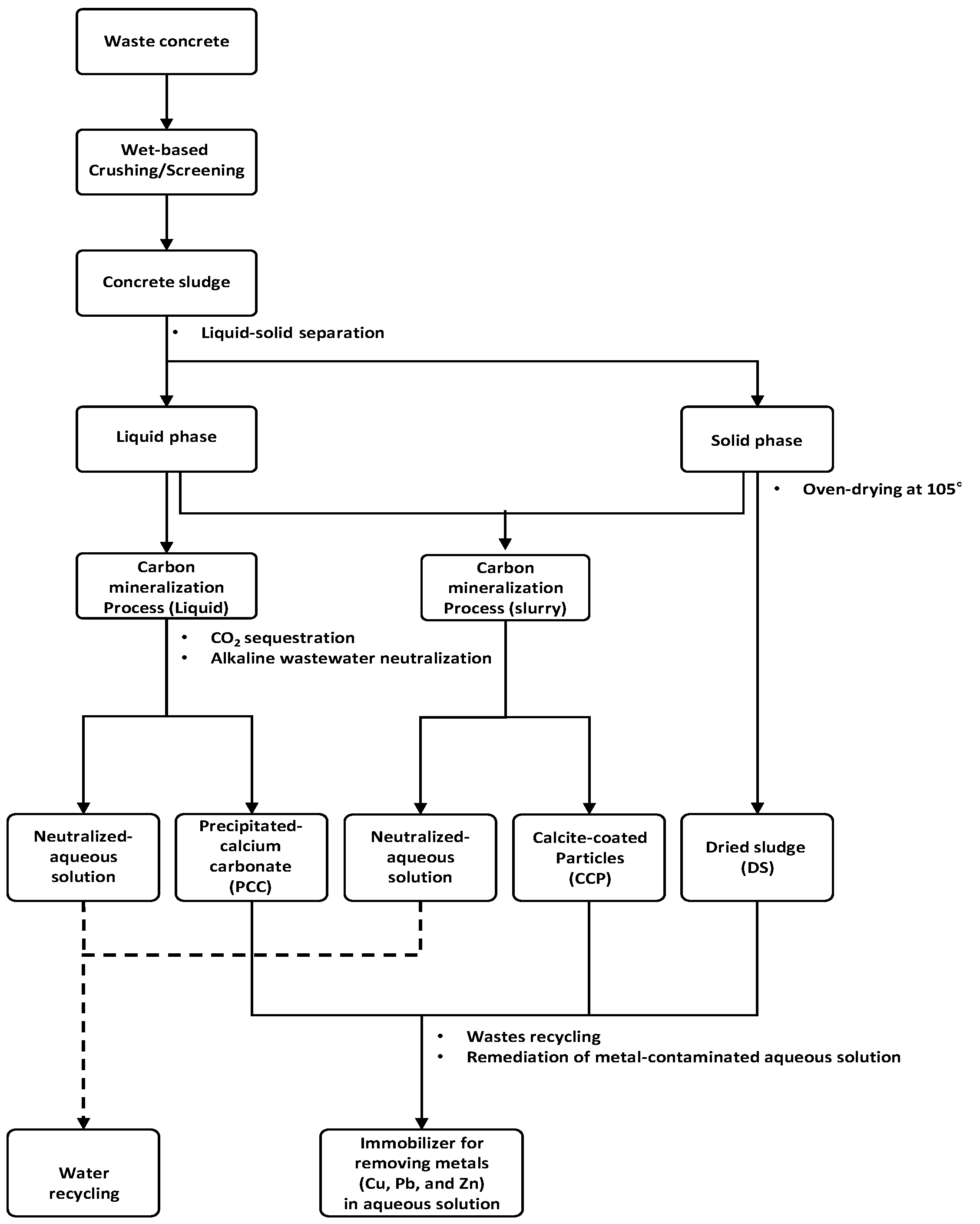

2.1. Preparation of Immobilizers

2.1.1. Dried Sludge (DS)

2.1.2. Precipitated Calcium Carbonate (PCC) and Calcite-Coated Particles (CCP)

2.1.3. Characterization of Immobilizers

2.2. Immobilization Experiments

2.2.1. Reaction Time

2.2.2. Solution pH and Immobilizer Dosage

3. Results and Discussion

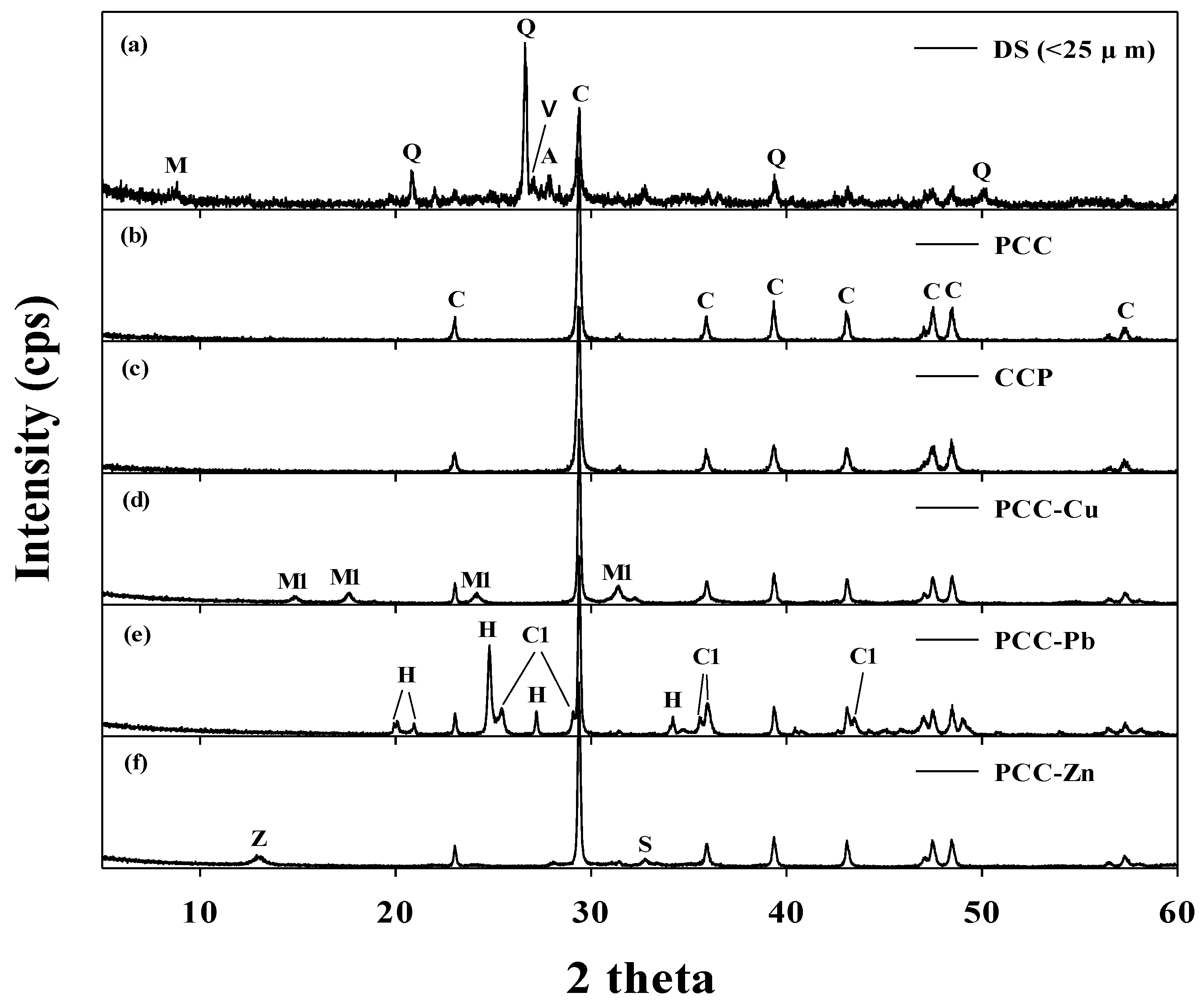

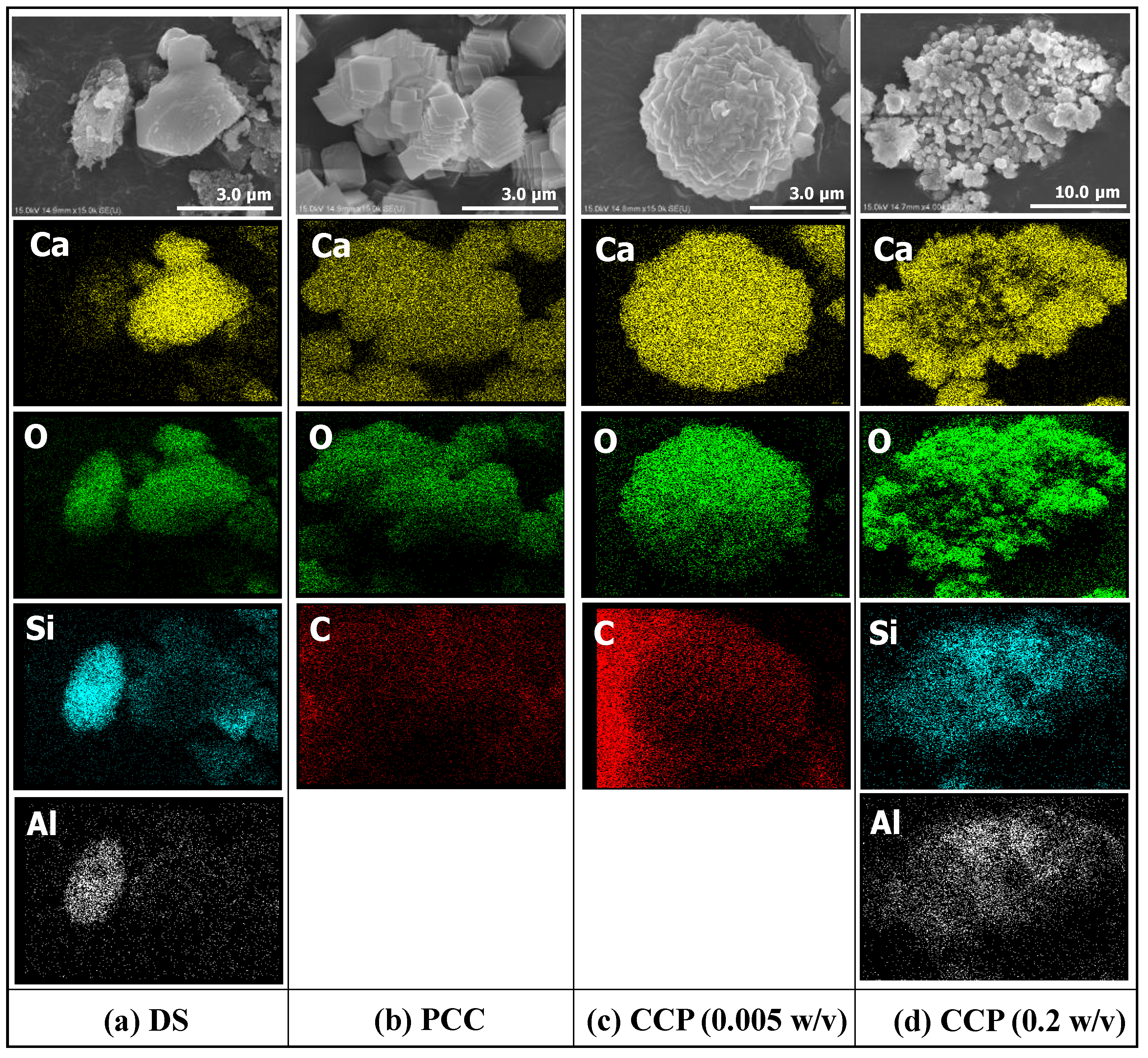

3.1. Properties of Immobilizers

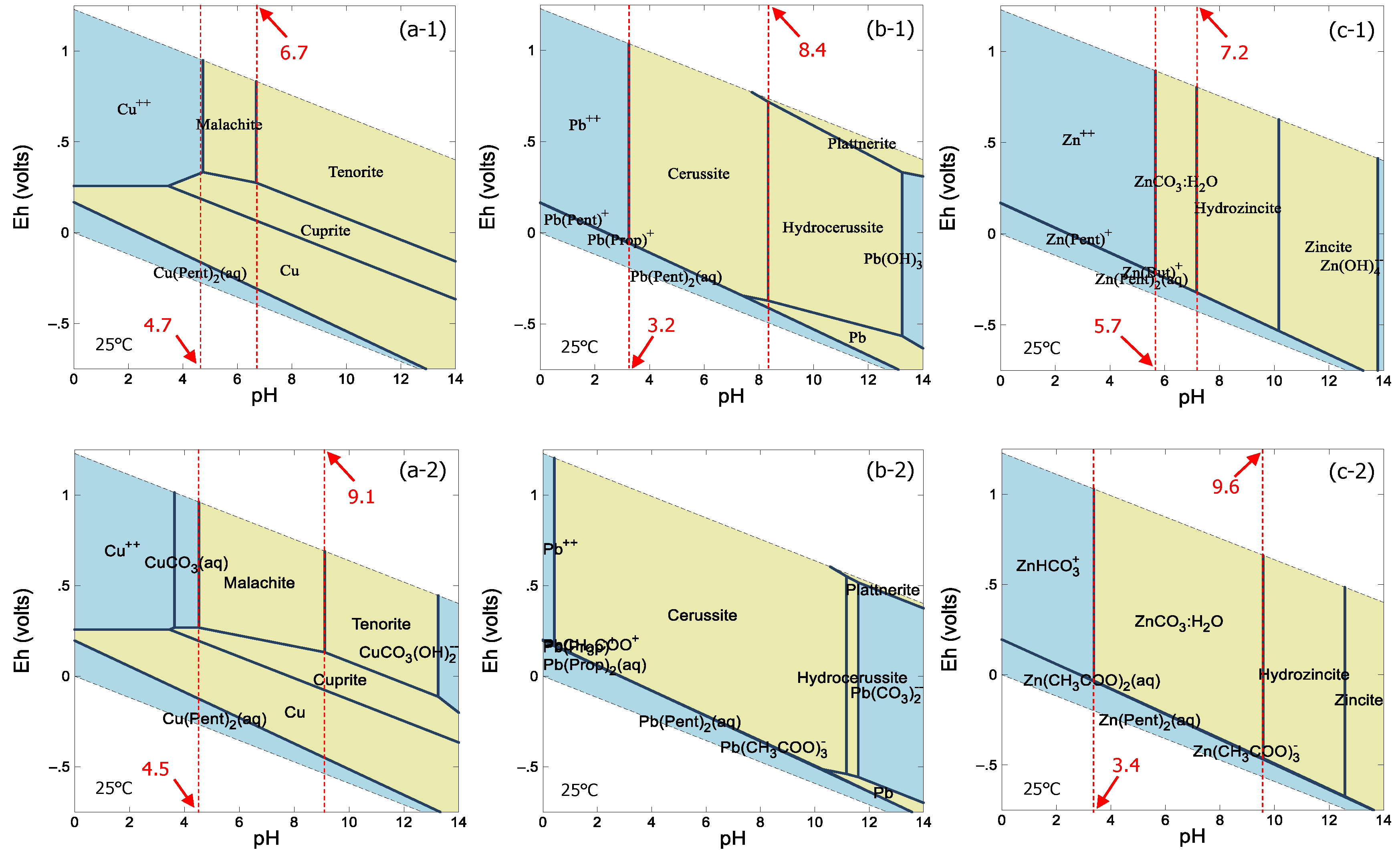

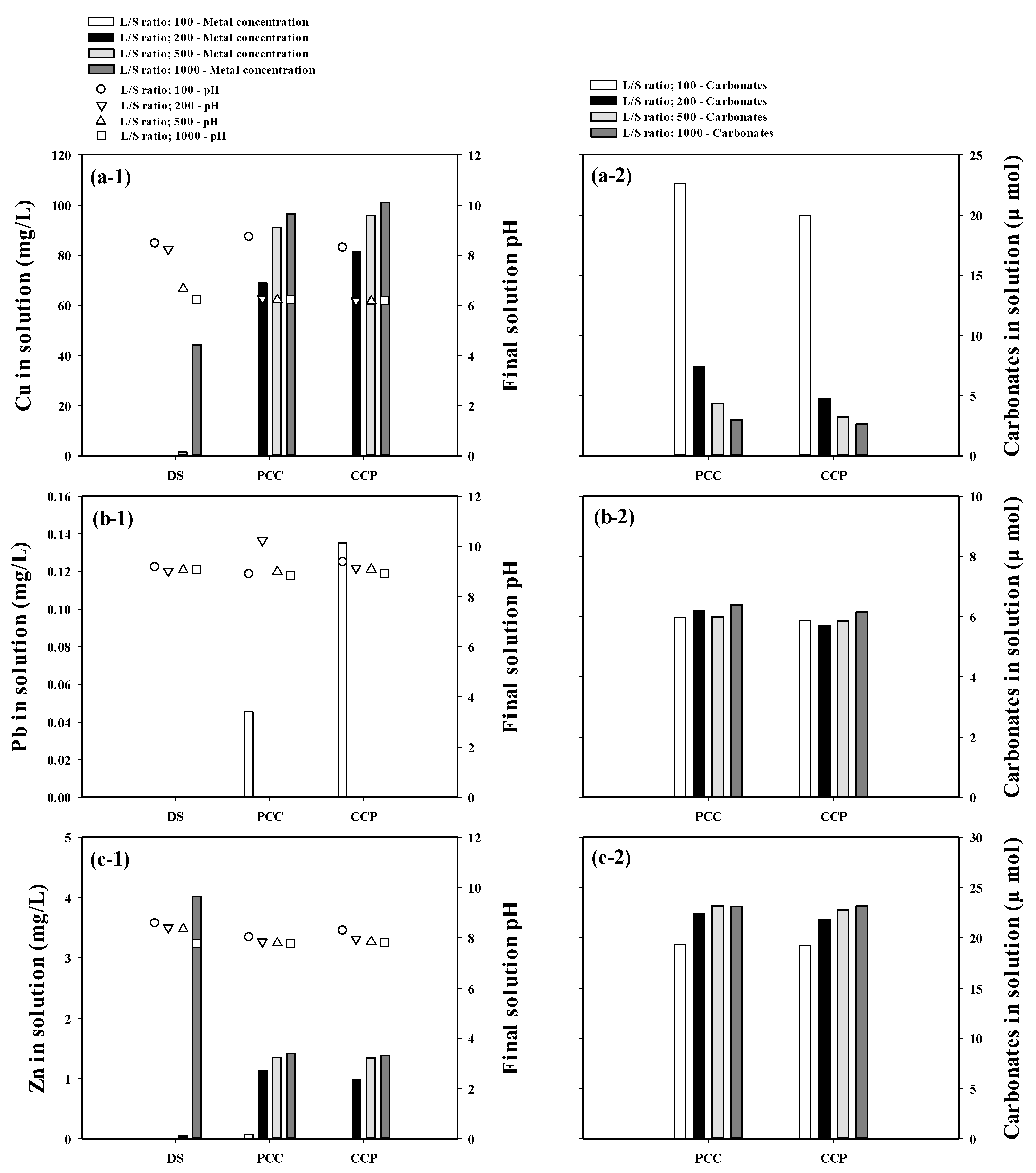

3.2. Metal Immobilization in Aqueous Solution

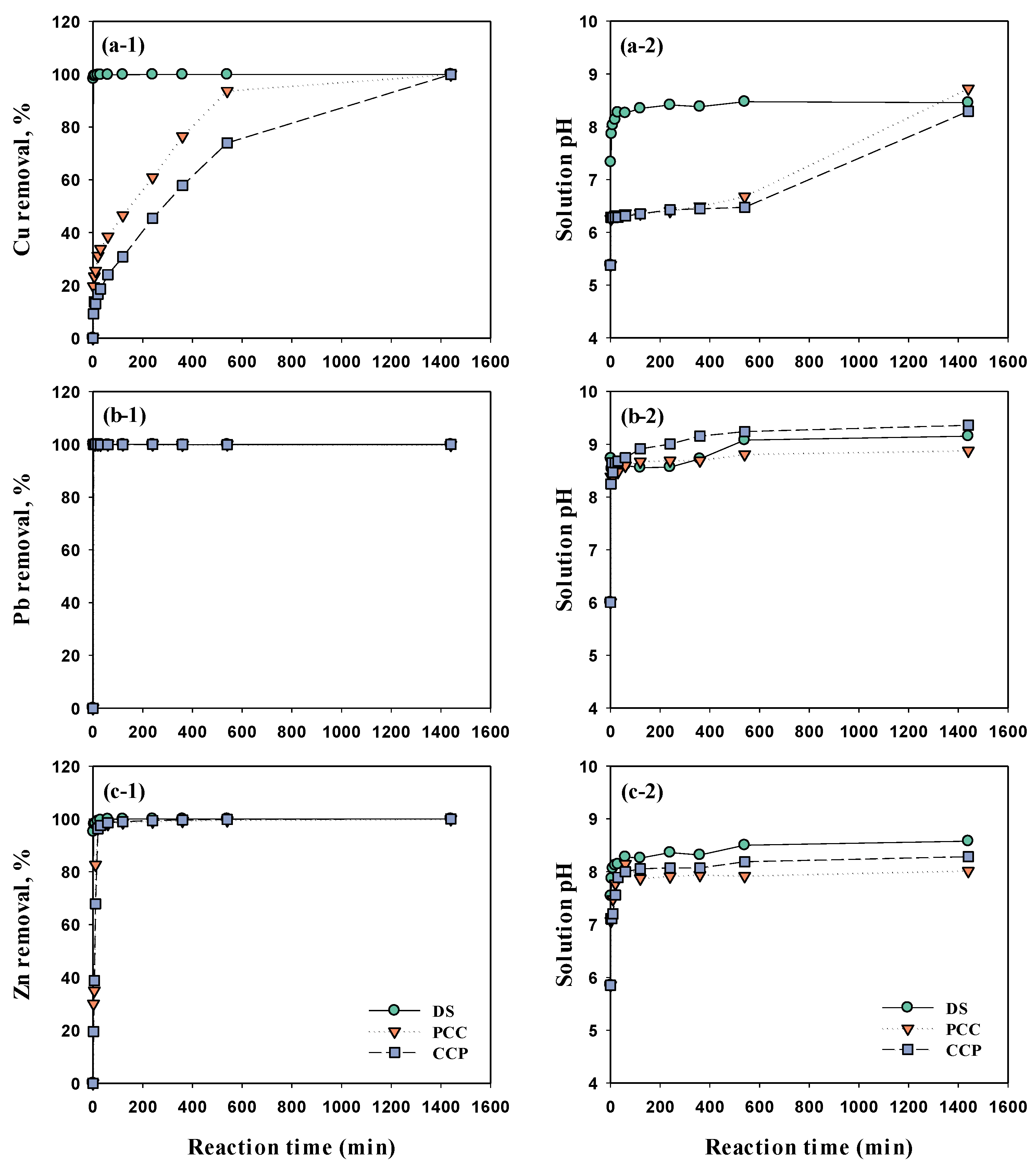

3.2.1. Effect of Reaction Time

3.2.2. Effect of Initial Solution pH and Immobilizer Dosage

3.3. Estimation of Environmental Impact

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mulligan, C.; Yong, R.; Gibbs, B. Remediation technologies for metal-contaminated soils and groundwater: An evaluation. Eng. Geol. 2001, 60, 193–207. [Google Scholar] [CrossRef]

- Hashim, M.A.; Mukhopadhyay, S.; Sahu, J.N.; Sengupta, B. Remediation technologies for heavy metal contaminated groundwater. J. Environ. Manag. 2011, 92, 2355–2388. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Paik, I.S.; Kim, I.; Kang, H.; Lee, S. Remediation of heavy metal contaminated groundwater originated from abandoned mine using lime and calcium carbonate. J. Hazard. Mater. 2007, 144, 208–214. [Google Scholar] [CrossRef] [PubMed]

- Komárek, M.; Vaněk, A.; Ettler, V. Chemical stabilization of metals and arsenic in contaminated soils using oxides–a review. Environ. Pollut. 2013, 172, 9–22. [Google Scholar] [CrossRef] [PubMed]

- Merrikhpour, H.; Jalali, M. Waste calcite sludge as an adsorbent for the removal of cadmium, copper, lead, and zinc from aqueous solutions. Clean Technol. Environ. 2012, 14, 845–855. [Google Scholar] [CrossRef]

- Udeigwe, T.K.; Eze, P.N.; Teboh, J.M.; Stietiya, M.H. Application, chemistry, and environmental implications of contaminant-immobilization amendments on agricultural soil and water quality. Environ. Int. 2011, 37, 258–267. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; He, Z.; Ma, L.Q.; Yang, Y.; Yang, X.; Stoffella, P.J. Immobilization of copper in contaminated sandy soils using calcium water treatment residue. J. Hazard. Mater. 2011, 189, 710–718. [Google Scholar] [CrossRef] [PubMed]

- Hale, B.; Evans, L.; Lambert, R. Effects of cement or lime on Cd, Co, Cu, Ni, Pb, Sb and Zn mobility in field-contaminated and aged soils. J. Hazard. Mater. 2012, 199, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Moon, D.H.; Park, J.-W.; Cheong, K.H.; Hyun, S.; Koutsospyros, A.; Park, J.-H.; Ok, Y.S. Stabilization of lead and copper contaminated firing range soil using calcined oyster shells and fly ash. Environ. Geochem. Health 2013, 35, 705–714. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, T.; Sakai, Y.; Iizuka, A.; Nakae, T.; Kato, S.; Kojima, T.; Yamasaki, A. Evaluation of the capacity of hydroxyapaptite prepared from concrete sludge to remove lead from water. Ind. Eng. Chem. Res. 2011, 50, 9564–9568. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–a breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Bertos, M.F.; Simons, S.; Hills, C.; Carey, P. A review of accelerated carbonation technology in the treatment of cement-based materials and sequestration of CO2. J. Hazard. Mater. 2004, 112, 193–205. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Chiang, A.; Chang, E.; Lin, Y.-P.; Kim, H.; Chiang, P.-C. An innovative approach to integrated carbon mineralization and waste utilization: A review. Aerosol Air Qual. Res. 2015, 15, 1072–1091. [Google Scholar] [CrossRef]

- Yoo, J.; Shin, H.; Ji, S. An eco-friendly neutralization process by carbon mineralization for Ca-rich alkaline wastewater generated from concrete sludge. Metals 2017, 7, 371. [Google Scholar] [CrossRef]

- Sasaki, T.; Sakai, Y.; Hongo, T.; Iizuka, A.; Yamasaki, A. Preparation of a solid adsorbent derived from concrete sludge and its boron removal performance. Ind. Eng. Chem. Res. 2012, 51, 5813–5817. [Google Scholar] [CrossRef]

- Sasaki, T.; Iizuka, A.; Watanabe, M.; Hongo, T.; Yamasaki, A. Preparation and performance of arsenate (v) adsorbents derived from concrete wastes. Waste Manag. 2014, 34, 1829–1835. [Google Scholar] [CrossRef] [PubMed]

- Tsunashima, Y.; Iizuka, A.; Akimoto, J.; Hongo, T.; Yamasaki, A. Preparation of sorbents containing ettringite phase from concrete sludge and their performance in removing borate and fluoride ions from waste water. Chem. Eng. J. 2012, 200, 338–343. [Google Scholar] [CrossRef]

- Sdiri, A.; Higashi, T. Simultaneous removal of heavy metals from aqueous solution by natural limestones. Appl. Water Sci. 2013, 3, 29–39. [Google Scholar] [CrossRef]

- Chen, Q.; Luo, Z.; Hills, C.; Xue, G.; Tyrer, M. Precipitation of heavy metals from wastewater using simulated flue gas: Sequent additions of fly ash, lime and carbon dioxide. Water Res. 2009, 43, 2605–2614. [Google Scholar] [CrossRef] [PubMed]

- Mo, L.; Zhang, F.; Deng, M.; Jin, F.; Al-Tabbaa, A.; Wang, A. Accelerated carbonation and performance of concrete made with steel slag as binding materials and aggregates. Cem. Concr. Compos. 2017, 83, 138–145. [Google Scholar] [CrossRef]

- Lin, Y.-P.; Singer, P.C. Effects of seed material and solution composition on calcite precipitation. Geochim. Cosmochim. Acta 2005, 69, 4495–4504. [Google Scholar] [CrossRef]

- Aziz, H.A.; Adlan, M.N.; Ariffin, K.S. Heavy metals (Cd, Pb, Zn, Ni, Cu and Cr (iii)) removal from water in malaysia: Post treatment by high quality limestone. Bioresour. Technol. 2008, 99, 1578–1583. [Google Scholar] [CrossRef] [PubMed]

- Moghal, A.A.B.; Reddy, K.R.; Mohammed, S.A.S.; Al-Shamrani, M.A.; Zahid, W.M. Lime-amended semi-arid soils in retaining copper, lead, and zinc from aqueous solutions. Water Air Soil Poll. 2016, 227, 372. [Google Scholar] [CrossRef]

- Lakshtanov, L.; Stipp, S.L.S. Interaction between dissolved silica and calcium carbonate: 1. Spontaneous precipitation of calcium carbonate in the presence of dissolved silica. Geochim. Cosmochim. Acta 2010, 74, 2655–2664. [Google Scholar] [CrossRef]

- Kaufmann, G.; Dreybrodt, W. Calcite dissolution kinetics in the system CaCO3–H2O–CO2 at high undersaturation. Geochim. Cosmochim. Acta 2007, 71, 1398–1410. [Google Scholar] [CrossRef]

- Du, Y.; Lian, F.; Zhu, L. Biosorption of divalent Pb, Cd and Zn on aragonite and calcite mollusk shells. Environ. Pollut. 2011, 159, 1763–1768. [Google Scholar] [CrossRef] [PubMed]

- Sarioglu, M.; Güler, U.A.A.; Beyazit, N. Removal of copper from aqueous solutions using biosolids. Desalination 2009, 239, 167–174. [Google Scholar] [CrossRef]

- Kumpiene, J.; Lagerkvist, A.; Maurice, C. Stabilization of Pb-and Cu-contaminated soil using coal fly ash and peat. Environ. Pollut. 2007, 145, 365–373. [Google Scholar] [CrossRef] [PubMed]

- Perlatti, F.; Ferreira, T.O.; Sartor, L.R.; Otero, X.L. Copper biogeochemistry in response to rhizosphere soil processes under four native plant species growing spontaneously in an abandoned mine site in NE Brazil. Water Air Soil Poll. 2016, 227, 142. [Google Scholar] [CrossRef]

- Elzinga, E.J.; Rouff, A.A.; Reeder, R.J. The long-term fate of Cu2+, Zn2+, and Pb2+ adsorption complexes at the calcite surface: An x-ray absorption spectroscopy study. Geochim. Cosmochim. Acta 2006, 70, 2715–2725. [Google Scholar] [CrossRef]

- Ahmad, M.; Moon, D.H.; Lim, K.J.; Shope, C.L.; Lee, S.S.; Usman, A.R.; Kim, K.-R.; Park, J.-H.; Hur, S.-O.; Yang, J.E. An assessment of the utilization of waste resources for the immobilization of Pb and Cu in the soil from a Korean military shooting range. Environ. Earth Sci. 2012, 67, 1023–1031. [Google Scholar] [CrossRef]

- Shi, Q.; Zhang, G.; Feng, Q.; Ou, L.; Lu, Y. Effect of the lattice ions on the calcite flotation in presence of Zn (ii). Miner. Eng. 2013, 40, 24–29. [Google Scholar] [CrossRef]

- Alwan, A.K.; Williams, P.A. Mineral formation from aqueous solution. Part I. The deposition of hydrozincite, Zn5(OH)6(CO3)2, from natural waters. Transit. Metal Chem. 1979, 4, 128–132. [Google Scholar] [CrossRef]

- Park, S.-M.; Yoo, J.-C.; Ji, S.-W.; Yang, J.-S.; Baek, K. Selective recovery of Cu, Zn, and Ni from acid mine drainage. Environ. Geochem. Health 2013, 35, 735–743. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.-C.; Kim, E.-J.; Yang, J.-S.; Baek, K. Step-wise extraction of metals from dredged marine sediments. Sep. Sci. Technol. 2015, 50, 536–544. [Google Scholar] [CrossRef]

| Immobilizer | Time (min) | Conc. of Metals (mg/L) | L/S Ratio 1 | Temp. (°C) | Initial Metal Solution pH |

|---|---|---|---|---|---|

| Effect of reaction time | |||||

| DS | 1440 | 100 | 100 (250 mL : 2.5 g) | 25 | Nonadjusted |

| PCC | |||||

| CCP | |||||

| Effect of initial solution pH | |||||

| DS PCC CCP | 1440 | 100 | 100 (30 mL : 0.3 g) | 25 | 1.0 2.0 3.0 4.0 5.0 |

| Effect of immobilizer dosage | |||||

| DS | 1440 | 100 | 100–1000 (30 mL : 0.03–0.3 g) | 25 | Nonadjusted |

| PCC | |||||

| CCP | |||||

| Concrete Sludge | ||

| pH | 12.4 ± 0.3 | |

| Moisture content (%) | 92.5 ± 2.5 | |

| Ca2+ (mg/L) (liquid phase) | 375.0 ± 63.0 | |

| Na+ (mg/L) (liquid phase) | 426.5 ± 1.9 | |

| K+ (mg/L) (liquid phase) | 307.2 ± 1.3 | |

| Particle size distribution (wt%) | >850 μm | 1.0 ± 0.1 |

| 850–150 μm | 4.2 ± 0.2 | |

| 150–45 μm | 26.2 ± 1.0 | |

| 45–25 μm | 15.2 ± 3.6 | |

| <25 μm | 53.4 ± 3.0 | |

| Immobilizer | ||

| pH | DS (<25 μm) | 8.7 ± 0.2 |

| PCC | 11.0 ± 0.0 | |

| CCP | 10.5 ± 0.1 | |

| Brunauer–Emmett–Teller (BET) surface area (m2/g) | DS (<25 μm) | 23.1 |

| PCC | 2.3 | |

| CCP | 4.7 | |

| Mineralogy | DS (<25 μm) | Quartz (19.3 wt%), Calcite (24.2 wt%), Muscovite (30.9 wt%), Albite (11.3 wt%), Vaterite (6.7 wt%), Orthoclase (5.5 wt%), Chlorite (2.0 wt%) |

| PCC | Calcite (100 wt%) | |

| CCP | Calcite (100 wt%) | |

| Materials | Output (m3/d) | Production 2 (tons/d) | CO2 sequestration 6 (tons/d) | Treatment 7 (m3/d) | |

|---|---|---|---|---|---|

| Concrete sludge | Wastewater (Liquid phase) | 3330.0 1 | - | - | - |

| Waste (Solid phase) | 270.0 1 | - | - | - | |

| DS | - | 345.6 3 | - | 34,560.0 | |

| PCC | - | 3.6 4 | 3.4 | 359.6 | |

| CCP | - | 3.8 5 | 3.4 | 376.3 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.; Shin, H.; Ji, S. Evaluation of the Applicability of Concrete Sludge for the Removal of Cu, Pb, and Zn from Contaminated Aqueous Solutions. Metals 2018, 8, 666. https://doi.org/10.3390/met8090666

Yoo J, Shin H, Ji S. Evaluation of the Applicability of Concrete Sludge for the Removal of Cu, Pb, and Zn from Contaminated Aqueous Solutions. Metals. 2018; 8(9):666. https://doi.org/10.3390/met8090666

Chicago/Turabian StyleYoo, Jongchan, Heeyoung Shin, and Sangwoo Ji. 2018. "Evaluation of the Applicability of Concrete Sludge for the Removal of Cu, Pb, and Zn from Contaminated Aqueous Solutions" Metals 8, no. 9: 666. https://doi.org/10.3390/met8090666

APA StyleYoo, J., Shin, H., & Ji, S. (2018). Evaluation of the Applicability of Concrete Sludge for the Removal of Cu, Pb, and Zn from Contaminated Aqueous Solutions. Metals, 8(9), 666. https://doi.org/10.3390/met8090666