Semi-Continuous Equal-Channel Angular Extrusion and Rolling of AA5083 and AZ31 Alloys

Abstract

:1. Introduction

2. Experimental Procedures

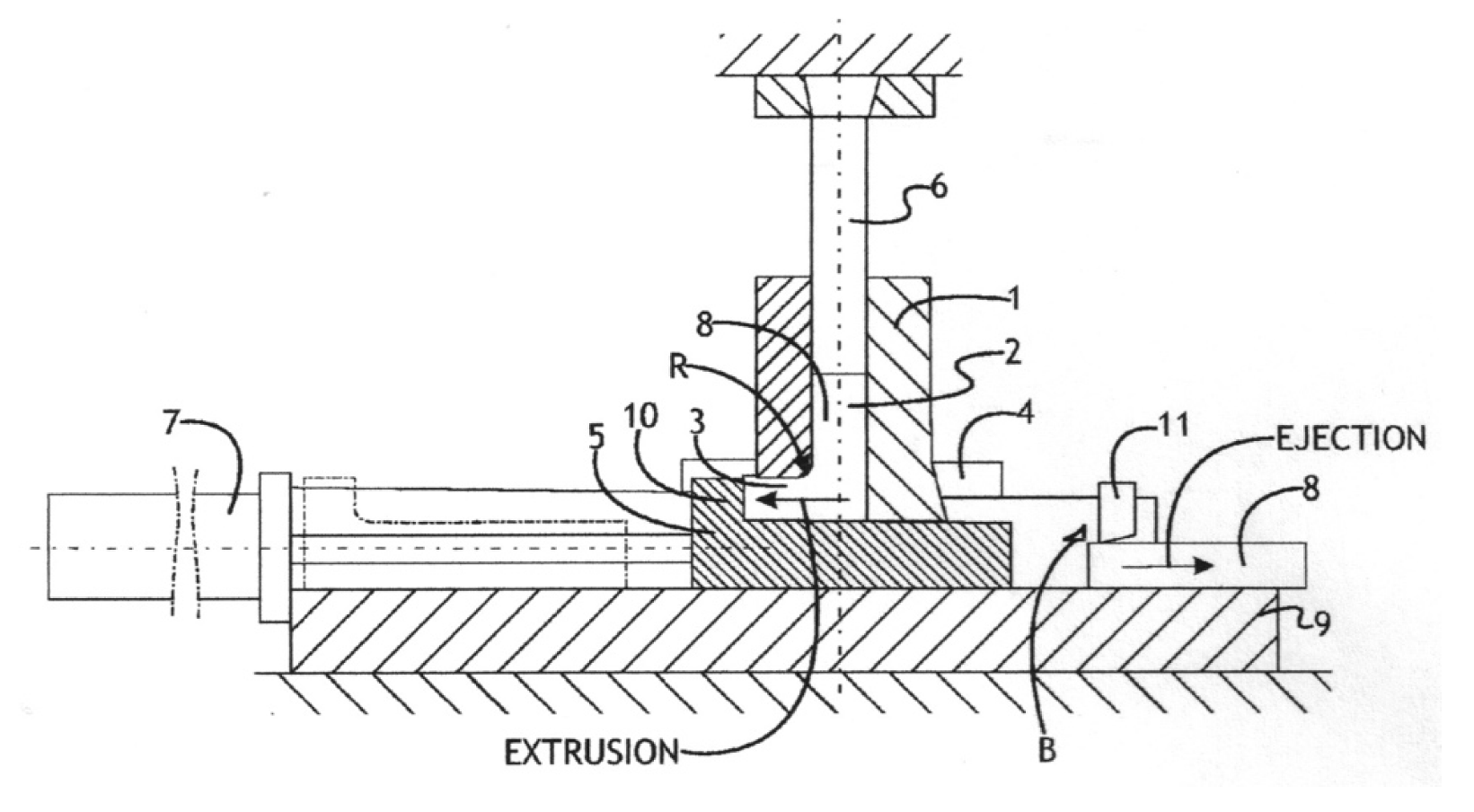

2.1. Semi-Continuous ECAE

2.2. Material Selection, Processing, and Characterization

3. Experimental Results

3.1. Semi-Continuous ECAE and Rolling of AA5083 Alloy

3.1.1. Structures of the Original Material

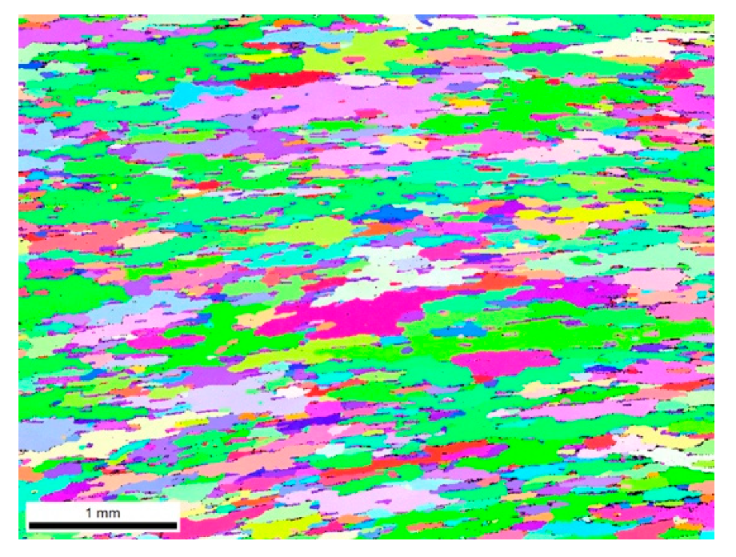

3.1.2. Structures after Sc-ECAE

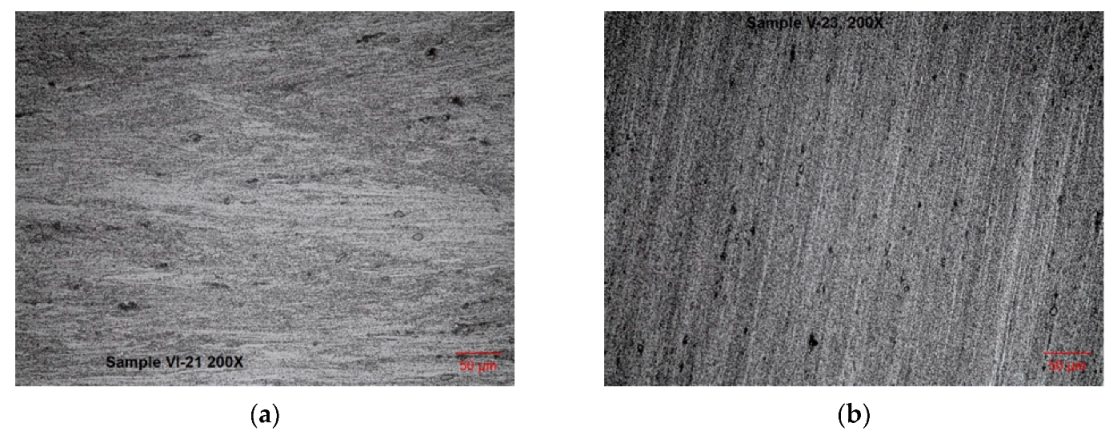

3.1.3. Structures after Rolling of Sc-ECAE-Processed Materials

3.1.4. Mechanical Properties

3.2. Semi-Continuous ECAE and Rolling of AZ31 Alloy

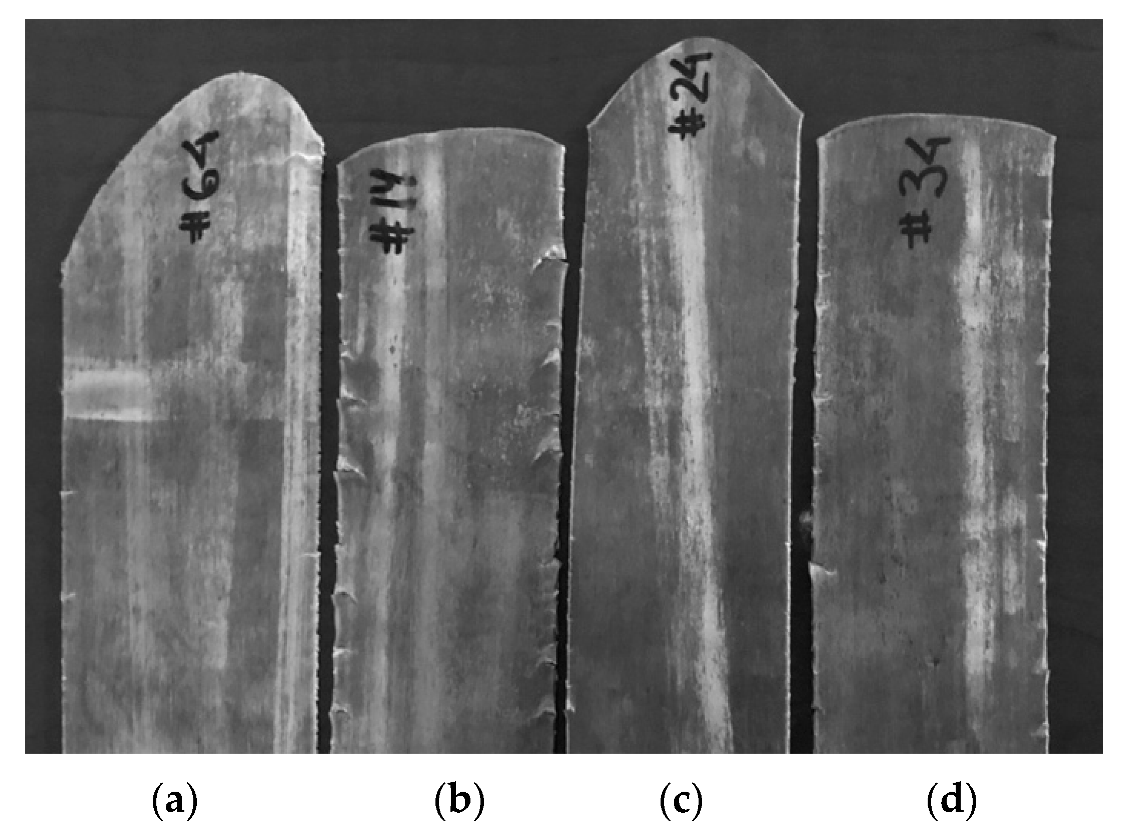

3.2.1. Sc-ECAE Processing of AZ31

3.2.2. Rolling of Sc-ECAE-Processed AZ31

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Availability Statement

References

- Segal, V.M. Modes and processes of severe plastic deformation. Materials 2018, 11, 1175. [Google Scholar] [CrossRef] [PubMed]

- Ferrasse, S.; Segal, V.M.; Alford, F.; Strothers, S.; Kardocus, J.; Grabmeier, S.; Evans, J. Scale-up and commercialization of ECAE sputtering products with sub-microcrystalline structures. In Severe Plastic Deformation. Toward Bulk Products of Nanostructured Materials; Altan, B.S., Ed.; Nova Publishers: New York, NY, USA, 2006; pp. 585–601. [Google Scholar]

- Segal, V.M. Method and Apparatus for Intensive Plastic Deformation of Flat Billets. U.S. Patent No. 5,850,755, 22 December 1998. Available online: http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=5850755.PN.&OS=PN/5850755&RS=PN/5850755 (accessed on 16 September 2019).

- Segal, V.M. Method of Equal Channel Angular Extrusion. U.S. Patent Application No. 20,170,320,115, 9 November 2017. Available online: http://appft.uspto.gov/netacgi/nph-Parser?Sect1=PTO2&Sect2=HITOFF&u=%2Fnetahtml%2FPTO%2Fsearch-adv.html&r=142&f=G&l=50&d=PG01&s1=segal.IN.&p=3&OS=IN/segal&RS=IN/segal (accessed on 16 September 2019).

- Vinogradov, A.; Serebryany, V.N.; Dobatkin, S.V. Tailoring microstructure and properties of fine-grained magnesium alloys by severe plastic deformation. Adv. Eng. Mater. 2018, 20, 1700785. [Google Scholar] [CrossRef]

- Segal, V.M. Equal channel angular extrusion (ECAE). In Severe Plastic Deformation Technology; Rosochowsky, A., Ed.; Whittles Publishing Limited: Dunbeath, UK, 2017; pp. 1–40. [Google Scholar]

- Luri, R.; Luis, C.J.; Leon, J.; Sebastian, M. A new configuration for equal channel angular extrusion dies. J. Manuf. Sci. Eng. 2006, 128, 860–865. [Google Scholar] [CrossRef]

- Dupuy, L.; Blandin, J.J.; Rauch, E.F. Structural and mechanical properties in AA5083 processed by ECAE. Mater. Sci. Tech. 2000, 16, 1256–1258. [Google Scholar] [CrossRef]

- Jin, H. Improvement superplasticity in AA5083 by equal-channel angular extrusion and rolling. Mater. Sci. Tech. 2017, 33, 1696–1702. [Google Scholar] [CrossRef]

- Gzyl, M.; Rosochowski, A.; Boczkal, S.; Olejnik, L.; Katimon, M.N. Producing high-strength metals by I-ECAP. Adv. Eng. Mater. 2016, 18, 219–223. [Google Scholar] [CrossRef]

- Ma, A.; Jiang, J.; Saito, N.; Ichnori, S.; Yuan, Y.; Nishida, Y. Improving both strength and ductility of a Mg alloy through a large number of ECAP passes. Mater. Sci. Eng. A 2009, 513, 122–1217. [Google Scholar] [CrossRef]

- Jin, L.; Lin, D.; Mao, D.; Zeng, F.; Chen, B.; Ding, W. Microstructure evolution of AZ31 Mg alloy during equal-channel angular extrusion. Mater. Sci. Eng. A 2006, 423, 247–252. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Aguilar, M.T.P.; Cetlin, P.R.; Langdon, T.G. Processing magnesium alloys by severe plastic deformation. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012171. [Google Scholar] [CrossRef] [Green Version]

- McQuenn, H.J.; Spigarelli, S.; Kassner, M.E.; Evangelista, E. Hot Deformation and Processing of Aluminum Alloys; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Lee, C. Thermo-Mechanical Processing of an Al-Mg Alloy. Ph.D. Thesis, University of London, Imperial College, London, UK, 1989. [Google Scholar]

- Segal, V.M.; Beyerlein, I.J.; Tome, C.N.; Chuvil’deev, V.I.; Kopylov, V.I. Fundamentals and Engineering of Severe Plastic Deformation; Nova Science Publishers: New York, NY, USA, 2010. [Google Scholar]

- Kim, S.J.; Jang, S.K. Effects of solution heat treatment on corrosion resistance of 5083F alloy. Trans. Non-Ferr. Meter. Soc. China 2009, 19, 887–891. [Google Scholar] [CrossRef]

- Huang, C.; Wu, Z.; Huang, R.; Wang, W.; Li, L. Mechanical properties of AA5083 in different tempers at low temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 279, 012002. [Google Scholar] [CrossRef]

- Sivam, S.P.S.S.; Kumar, A.L.; Moorthy, K.S.; Kumar, R. Investigation exploration outcome of heat treatment on corrosion resistance of AA5083 in marine applications. Int. J. Chem. Sci. 2016, 14, 453–460. [Google Scholar]

- Jin, H.; Gallerneault, M.; Segal, V.M.; Young, P.J.; Lloyd, D.J. Grain structure and texture in aluminum alloy AA5083 after equal angular extrusion, warm rolling and subsequent annealing. Mater. Sci. Tech. 2011, 27, 789–792. [Google Scholar] [CrossRef]

- Lapovok, R.Y. The positive role of back-pressure in equal-channel angular extrusion. Mater. Sci. Forum 2006, 503, 37–44. [Google Scholar] [CrossRef]

- Biswas, S.; Dhinwal, S.S.; Suwas, S. Room temperature equal channel angular extrusion of pure magnesium. Acta Mater. 2010, 58, 3247–3261. [Google Scholar] [CrossRef]

- Foley, D.C.; Al-Maharbi, M.; Hartwig, K.T.; Karaman, I.; Kecskes, L.J.; Mathaudhu, S.N. Grain refinement vs. crystallographic texture: Mechanical anisotropy in magnesium alloy. Scr. Mater. 2011, 64, 193–196. [Google Scholar] [CrossRef]

| Material Condition | As-Received Material | Solution-Treated Material | Over-Aged Material |

|---|---|---|---|

| Original hardness | 32.2 | 24.2 | 22.2 |

| Hardness after 10 days | 32.2 | 26.2 | 22.2 |

| Hardness after sc-ECAE | 47.5 | 53.8 | 44.5 |

| Processing Route | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|

| As-received AA5083 H321 | 228 | 317 | 16 |

| As-received AA5083 + four (D) sc-ECAE passes | 290 | 366 | 18 |

| Solution-treated AA5083 + four (D) sc-ECAE passes | 296 | 370 | 18 |

| As-received AA5083 + four (D) sc-ECAE passes + 87.5% rolling reduction | 450 | 475 | 10 |

| Solution-treated AA 5083 + four (D) sc-ECAE passes + 87.5% rolling reduction | 455 | 470 | 14 |

| Material Conditions | Average Grain Size (μm) | Yield Stress (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| As-received, annealed | 35 | 140 | 248 | 22 |

| As-received + rolling with reductions: | - | - | - | - |

| 50% | 13 | 200 | 278 | 19 |

| 75% | 9 | 190 | 275 | 18 |

| 87.5% | 8 | 165 | 275 | 16 |

| 93.75% | 6 | 170 | 280 | 15 |

| As-received + two (B) sc-ECAE passes | 2 | 240 | 335 | 28 |

| As received + two (B) sc-ECAE passes + rolling with reductions: | - | - | - | - |

| 50% | 15 | 170 | 270 | 22 |

| 75% | 8 | 210 | 280 | 17 |

| 87.5% | 6 | 185 | 280 | 15 |

| 93.75% | 6 | 180 | 282 | 13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segal, V.; Reznikov, S.V.; Murching, N.; Hammond, V.H.; Kecskes, L.J. Semi-Continuous Equal-Channel Angular Extrusion and Rolling of AA5083 and AZ31 Alloys. Metals 2019, 9, 1035. https://doi.org/10.3390/met9101035

Segal V, Reznikov SV, Murching N, Hammond VH, Kecskes LJ. Semi-Continuous Equal-Channel Angular Extrusion and Rolling of AA5083 and AZ31 Alloys. Metals. 2019; 9(10):1035. https://doi.org/10.3390/met9101035

Chicago/Turabian StyleSegal, Vladimir, Svetlana V. Reznikov, Nagendra Murching, Vincent H. Hammond, and Laszlo J. Kecskes. 2019. "Semi-Continuous Equal-Channel Angular Extrusion and Rolling of AA5083 and AZ31 Alloys" Metals 9, no. 10: 1035. https://doi.org/10.3390/met9101035

APA StyleSegal, V., Reznikov, S. V., Murching, N., Hammond, V. H., & Kecskes, L. J. (2019). Semi-Continuous Equal-Channel Angular Extrusion and Rolling of AA5083 and AZ31 Alloys. Metals, 9(10), 1035. https://doi.org/10.3390/met9101035