Numerical Modelling of the Influence of Argon Flow Rate and Slag Layer Height on Open-Eye Formation in a 150 Ton Steelmaking Ladle

Abstract

:1. Introduction

2. Mathematical Model

2.1. Governing Equations

2.2. Physical Properties and Operating Condictions

2.3. Execution of the Experiments

2.4. Initial and Boundary Conditions

2.5. Employed Physical Properties of Slag

2.6. Numerical Details

3. Results and Discussion

3.1. Influence of Argon Flow Rate on Open-Eye Formation for Slag Layer Thickness of 40 cm

3.2. Influence of Increasing Slag Layer Height to 55 cm from 40 cm on Open-Eye Formation

3.3. Influence of Decreasing Slag Layer Thickness to 25 cm from 40 cm on Open-Eye Formation

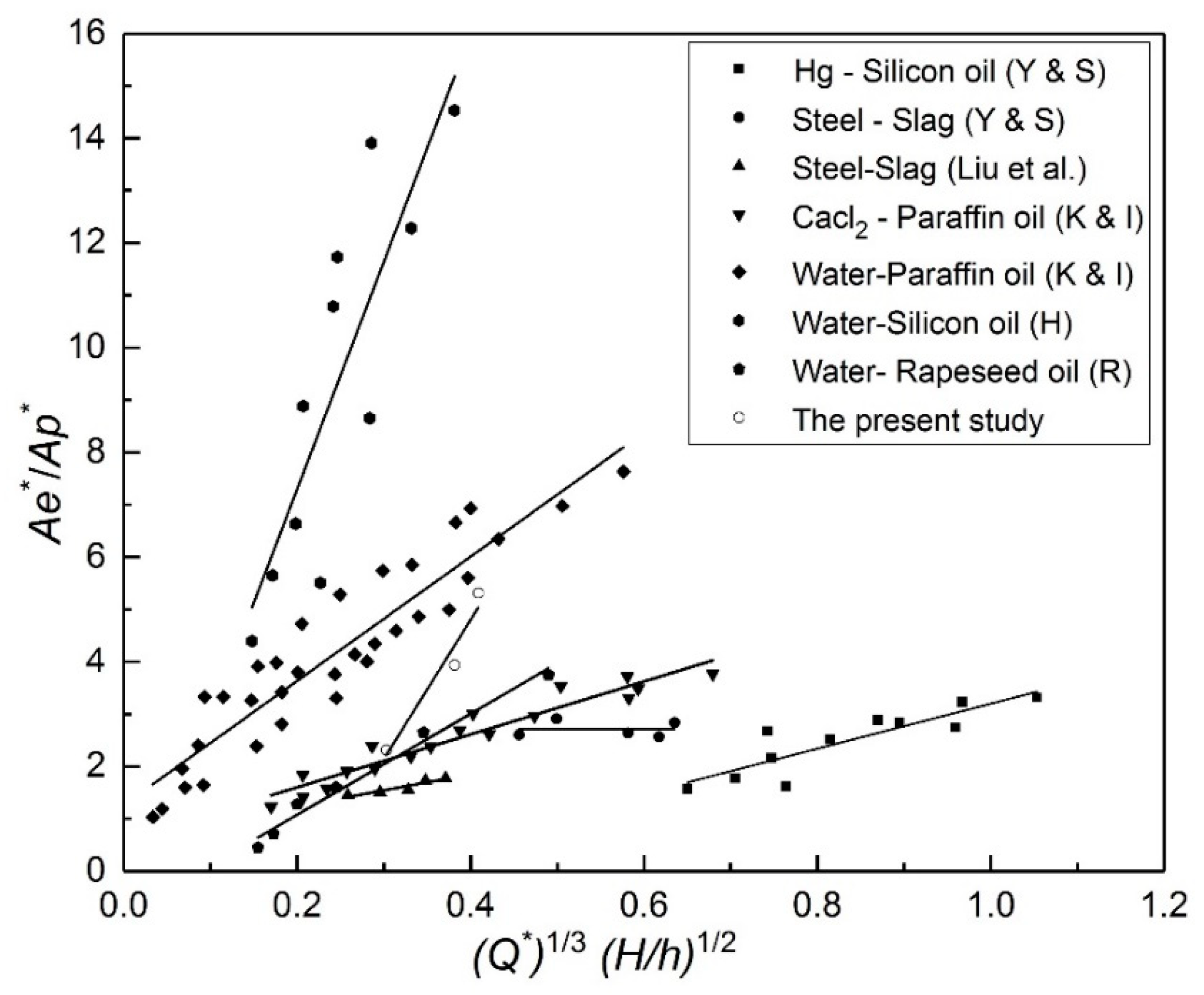

3.4. Summary of Open-Eye Area for Different Argon Flow Rates and Slag Layer Heights

4. Conclusions

- (1)

- The injected argon flow rate has a significant influence on the fluid flow velocities and the open-eye size generated in the ladle.

- (2)

- The elevation in flow rate of argon gas, the open-eye size and the spreading area of molten steel increases. The open-eye increases from 10.3% to 33.1% of the ladle’s free top surface area with an increase of flow rate from 200 to 500 NL/min and a 40 cm slag layer thickness.

- (3)

- The velocity of the fluid flow developed due to the injection of argon gas through the nozzle was very high adjacent to the nozzle inlet and reduces as the flow reaches the argon/steel/slag interface.

- (4)

- The slag layer height has a great effect on the formation of the open-eye. The reduction of the slag layer thickness from 40 to 25 cm resulted in a much larger deformation of slag layer and a more rapidly fluctuating open-eye at a high flow rate of 500 NL/min. The increase of the slag layer thickness from 40 to 55 cm resulted in non-formation of an open-eye at 200 NL/min.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yonezawa, K.; Schwerdtfeger, K. Spout eyes formed by an emerging gas plume at the surface of a slag-covered metal melt. Metall. Mater. Trans. B 1999, 30, 411–418. [Google Scholar] [CrossRef]

- Yonezawa, K.; Schwerdtfeger, K. Height of the spout of a gas plume discharging from a metal melt. Metall. Mater. Trans. B 1999, 30, 655–660. [Google Scholar] [CrossRef]

- Yonezawa, K.; Schwerdtfeger, K. Discharging of the spout of gas plumes discharging from a melt: Experimental investigation with a large-scale water model. Metall. Mater. Trans. B 2000, 31, 461–468. [Google Scholar] [CrossRef]

- Krishnapisharody, K.; Irons, G.A. Modeling of slag eye formation over a metal bath due to gas bubbling. Metall. Mater. Trans. B 2006, 37, 763–772. [Google Scholar] [CrossRef]

- Krishnapisharody, K.; Irons, G.A. Modeling of slag eye formation over a metal bath due to gas bubbling. ISIJ Int. 2008, 48, 1807–1809. [Google Scholar] [CrossRef]

- Thunman, M.; Eckert, S.; Hennig, O.; Björkvall, J.; Sichen, D. Study of the Formation of Open-eye and Slag Entrainment in Gas Stirred Ladle. Steel Res. Int. 2010, 78, 849–856. [Google Scholar] [CrossRef]

- Lv, N.N.; Wu, L.S.; Wang, H.C.; Dong, Y.C.; Su, C.J. Size analysis of slag eye formed by gas blowing in ladle refining. J. Iron Steel Res. Int. 2017, 24, 243–250. [Google Scholar] [CrossRef]

- Amaro-Villeda, A.M.; Ramirez-Argaez, M.A.; Conejo, A.N. Effect of Slag Properties on Mixing Phenomena in Gas-stirred Ladles by Physical Modeling. ISIJ Int. 2014, 54, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Maruyama, A.; Iguchi, M. Cold model study of spout eye area in the presence of the slag layer simulated by low-density particles. JSEM 2012, 12, s7–s10. [Google Scholar]

- Mazumdar, D.; Guthrie, R.I.L. Numerical computation of flow and mixing in ladle metallurgy steelmaking operations (C.A.S. method). Appl. Math. Model. 1986, 10, 25–32. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. On mathematical models and numerical solutions of gas stirred ladle systems. Appl. Math. Model. 1993, 5, 255–262. [Google Scholar] [CrossRef]

- Mazumdar, D.; Yadhav, R.; Mahato, B. Transient flow and mixing in steelmaking ladles during the initial period of gas stirring. ISIJ Int. 2002, 42, 106–108. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. The physical and mathematical modelling of gas stirred ladle systems. ISIJ Int. 1995, 35, 1–20. [Google Scholar] [CrossRef]

- Mazumdar, D.; Evans, J.W. A model for estimating exposed plume eye area in steel refining ladles covered with thin slag. Metall. Mater. Trans. B. 2004, 35, 400–404. [Google Scholar] [CrossRef]

- Mandal, J.; Patil, S.; Madan, M.; Mazumdar, M. Mixing Time and Correlations for Ladles Stirred with Dual Plugs. Metall. Trans. B 2005, 36, 479–487. [Google Scholar] [CrossRef]

- Patil, S.P.; Satish, D.; Peranadhanathan, M.; Mazumdar, D. Mixing Models for Slag Covered, Argon Stirred Ladles. ISIJ Int. 2010, 50, 1117–1124. [Google Scholar] [CrossRef] [Green Version]

- Peranandhanthan, M.; Mazumdar, D. Modeling of Slag Eye Area in Argon Stirred Ladles. ISIJ Int. 2010, 50, 1622–1631. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Liu, Z.; Li, B.; Matsuura, H.; Tsukihashi, F. Water Model and CFD-PBM Coupled Model of Gas-Liquid-Slag Three Phase Flow in Ladle Metallurgy. ISIJ Int. 2015, 55, 1337–1346. [Google Scholar] [CrossRef]

- Li, L.; Li, B. Investigation of Bubble-Slag Layer Behaviors with Hybrid Eulerian-Lagrangian Modeling and Large Eddy Simulation. JOM 2016, 68, 2160–2169. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.; Cao, M.; Li, B. Large Eddy Simulation of Bubble Flow and Slag Layer Behavior in Ladle with Discrete Phase Model (DPM)-Volume of Fluid (VOF) Coupled Model. JOM 2015, 67, 1459–1467. [Google Scholar] [CrossRef]

- Liu, Z.; Li, L.; Li, B. Modeling of Gas-Steel-Slag Three-Phase Flow in Ladle Metallurgy: Part, I. Physical Modeling. ISIJ Int. 2017, 57, 1971–1979. [Google Scholar] [CrossRef]

- Li, L.; Li, B.; Liu, Z. Modeling of Gas-Steel-Slag Three-Phase Flow in Ladle Metallurgy: Part II. Multi-scale Mathematical Model. ISIJ Int. 2017, 57, 1980–1989. [Google Scholar] [CrossRef] [Green Version]

- Ramasetti, E.K.; Visuri, V.-V.; Sulasalmi, P.; Mattila, R.; Fabritius, T. Modeling of the Effect of the Gas Flow Rate on the Fluid Flow and Open-Eye Formation in a Water Model of a Steel Making Ladle. Steel Res. Int. 2019, 90, 1–12. [Google Scholar] [CrossRef]

- Valentin, P.; Bruch, C.; Kyrylenko, Y.; Köchner, H.; Dannert, C. Influence of the Stirring Gas in a 170-t Ladle on Mixing Phenomena- Formation and On-line Control of Open-eye at an Industrial LD Steel Plant. Steel Res. Int. 2009, 80, 552–558. [Google Scholar]

- Li, B.; Yin, H.; Zhou, C.Q.; Tsukihashi, F. Modeling of Three-phase Flows and Behavior of Slag/Steel Interface in an Argon Gas Stirred Ladle. ISIJ Int. 2008, 48, 1704–1711. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Qi, Z.; Xu, M. Numerical Simulation of Fluid Flow and Interfacial Behavior in Three-Phase Argon-Stirred Ladles with One Plug and Dual Plugs. Steel Res. Int. 2011, 82, 440–458. [Google Scholar] [CrossRef]

- Cloete, S.W.P.; Eksteen, J.J.; Bradshaw, S.M. A Mathematical Modelling Study of Fluid Flow and Mixing in Full-Scale Gas-Stirred Ladles. Prog in Comp Fluid Dyn. 2009, 9, 345–356. [Google Scholar] [CrossRef]

- Cloete, S.W.P.; Eksteen, J.J.; Bradshaw, S.M. A Numerical Modelling Investigation into Design Variables Influencing Mixing Efficiency in Full Scale Gas Stirred Ladles. Miner. Eng. 2013, 46–47, 16–24. [Google Scholar] [CrossRef]

- Liu, W.; Tang, H.; Yang, S.; Wang, M.; Li, J.; Liu, Q.; Liu, J. Numerical Simulation of Slag Eye Formation and Slag Entrapment in a Bottom-Blown Argon-Stirred Ladle. Metall. Trans. B 2018, 49, 2681–2691. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Theory Guide; Version 17; ANSYS Inc.: Canonsburg, PA, USA, 2009. [Google Scholar]

- Ramasetti, E.K.; Visuri, V.-V.; Sulasalmi, P.; Mattila, R.; Fabritius, T. Physical and CFD modeling of the effect of top layer properties on the formation of open-eye in gas-stirred ladles with single and dual-plugs. Steel Res. Int. 2019, 90, 1900088. [Google Scholar] [CrossRef]

- Valencia, J.J.; Quested, P.N. ASM Handbook; ASM International: Cleveland, OH, USA, 2008; pp. 468–481. [Google Scholar]

- GTT Gesellschaft für Technische Thermochemie und –physik mbH. FactSage; Version 7.2; GTT Gesellschaft für Technische Thermochemie und –physik mbH: Sunnyvale, CA, USA, 2018. [Google Scholar]

- Keene, B.J.; Mills, K.C. Densities of molten slags. In Verein Duetscher Eisenhuttenleute: Slag Atlas, 2nd ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1995; p. 313. [Google Scholar]

- Xie, Y.; Oeters, F. Experimental studies on the flow velocity of molten metals in a ladle model at centric gas blowing. Steel Res. Int. 1992, 63, 93–104. [Google Scholar] [CrossRef]

- Xie, Y.; Orsten, S.; Oeters, F. Behaviour of bubbles at gas blowing into liquid wood’s metal. Steel Res. Int. 1992, 32, 66–75. [Google Scholar]

- Han, J.W.; Heo, S.H.; Kam, D.H.; You, B.D.; Pak, J.J.; Song, H.S. Transient fluid flow phenomena in a gas stirred liquid bath with top oil layer-approach by numerical simulation and water model experiments. ISIJ Int. 2001, 41, 1165–1172. [Google Scholar] [CrossRef]

| Physical Properties at 1812 K | Value | Unit |

|---|---|---|

| Density of liquid steel [32] | 6913 | kg/m3 |

| Viscosity of liquid steel [32] | 0.005281 | Pa·s |

| Density of slag | 2746 | kg/m3 |

| Viscosity of slag | 0.081 | Pa · s |

| Density of argon gas | 0.8739 | kg/m3 |

| Viscosity of argon gas | 2.2616 × 10−5 | Pa · s |

| Temperature of bath | 1812 | K |

| Flow rate of argon gas | 200, 400 and 500 | NL/min * |

| Slag layer height | 25, 40 and 55 | cm |

| Slag Layer Height (cm) | 25 | 40 | 55 | |||

|---|---|---|---|---|---|---|

| Flow Rate (NL/min) | Exp. (m2) | Sim. (m2) | Exp. (m2) | Sim. (m2) | Exp.(m2) | Sim. (m2) |

| 200 | 1.08 | 0.95 | 0.72 | 0.69 | NA | NA |

| 400 | 1.82 | 1.89 | 1.58 | 1.59 | 1.32 | 1.44 |

| 500 | NA | NA | 2.24 | 2.30 | 1.81 | 1.95 |

| Average Relative Error | 6.61% | |||||

| R2 | 0.93 | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramasetti, E.K.; Visuri, V.-V.; Sulasalmi, P.; Fabritius, T.; Savolainen, J.; Li, M.; Shao, L. Numerical Modelling of the Influence of Argon Flow Rate and Slag Layer Height on Open-Eye Formation in a 150 Ton Steelmaking Ladle. Metals 2019, 9, 1048. https://doi.org/10.3390/met9101048

Ramasetti EK, Visuri V-V, Sulasalmi P, Fabritius T, Savolainen J, Li M, Shao L. Numerical Modelling of the Influence of Argon Flow Rate and Slag Layer Height on Open-Eye Formation in a 150 Ton Steelmaking Ladle. Metals. 2019; 9(10):1048. https://doi.org/10.3390/met9101048

Chicago/Turabian StyleRamasetti, Eshwar Kumar, Ville-Valtteri Visuri, Petri Sulasalmi, Timo Fabritius, Jari Savolainen, Mingming Li, and Lei Shao. 2019. "Numerical Modelling of the Influence of Argon Flow Rate and Slag Layer Height on Open-Eye Formation in a 150 Ton Steelmaking Ladle" Metals 9, no. 10: 1048. https://doi.org/10.3390/met9101048

APA StyleRamasetti, E. K., Visuri, V. -V., Sulasalmi, P., Fabritius, T., Savolainen, J., Li, M., & Shao, L. (2019). Numerical Modelling of the Influence of Argon Flow Rate and Slag Layer Height on Open-Eye Formation in a 150 Ton Steelmaking Ladle. Metals, 9(10), 1048. https://doi.org/10.3390/met9101048