Internal Material Flow Layers in AA6082-T6 Butt-Joints during Bobbin Friction Stir Welding

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Macrostructure of the Cross-Section

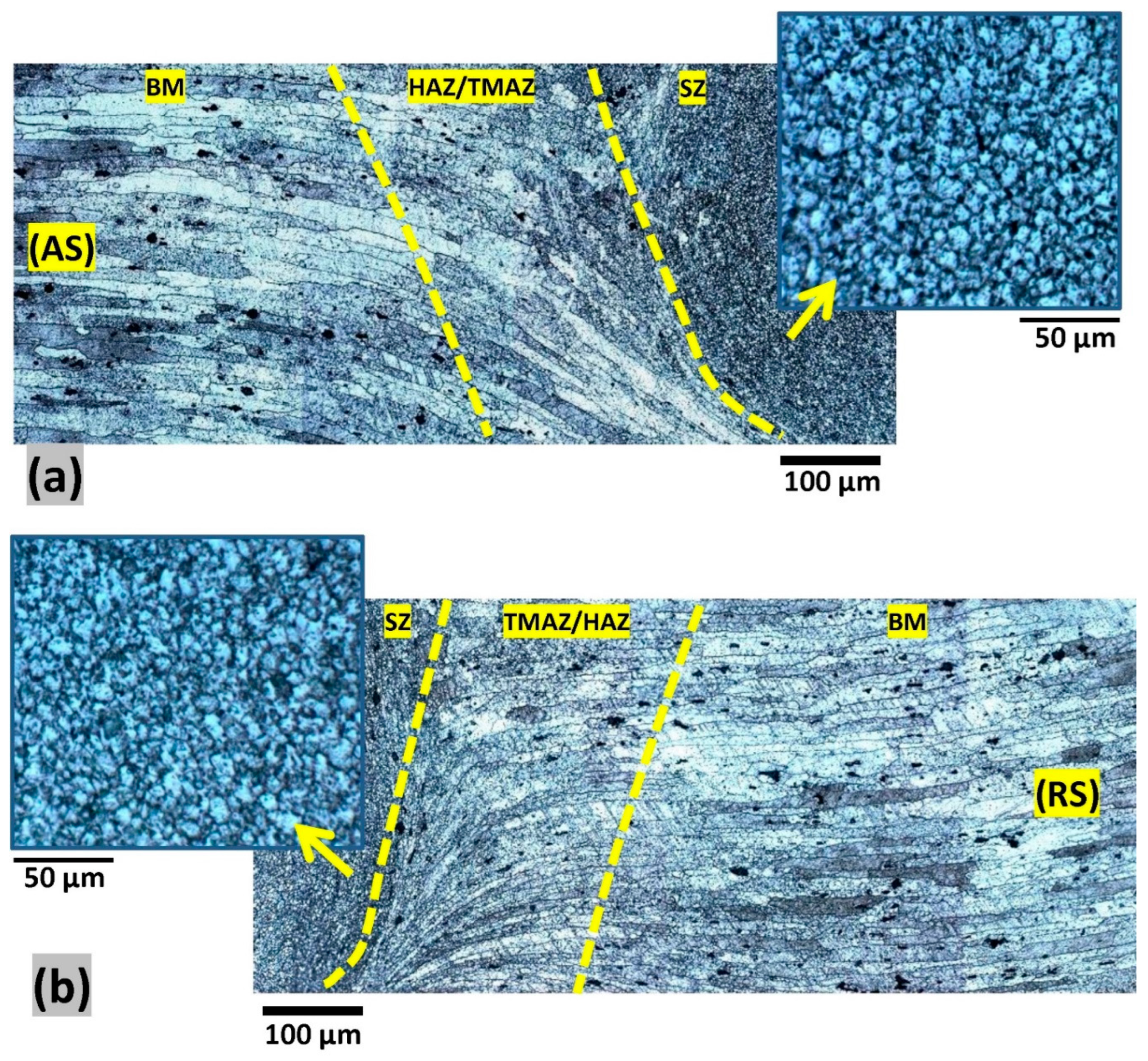

3.2. Microstructure Evolution

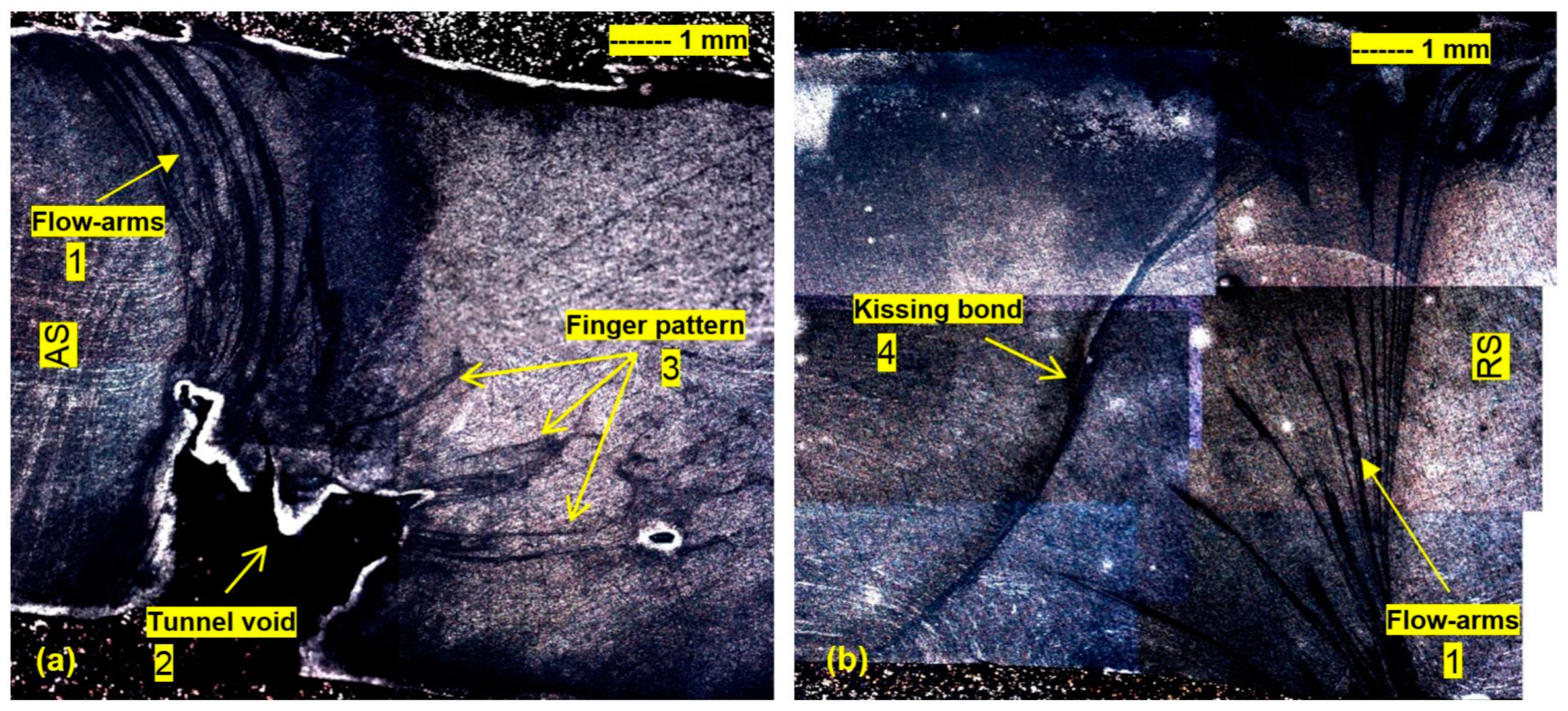

3.3. Material Flow Features in the Weld Cross-Section

3.4. Sub-Surface Features of the Weld

3.4.1. Cross-Section under the Weld Shoulder

3.4.2. Plan View under the Shoulder (Longitudinal Axis)

3.4.3. Exit Zone

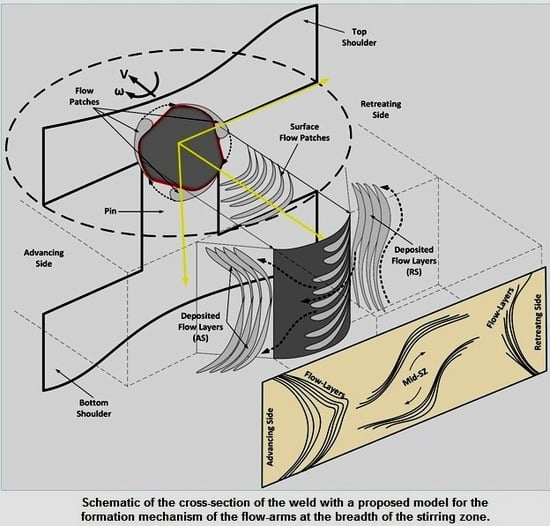

3.5. Building a Model of Internal Flow and Defect Formation

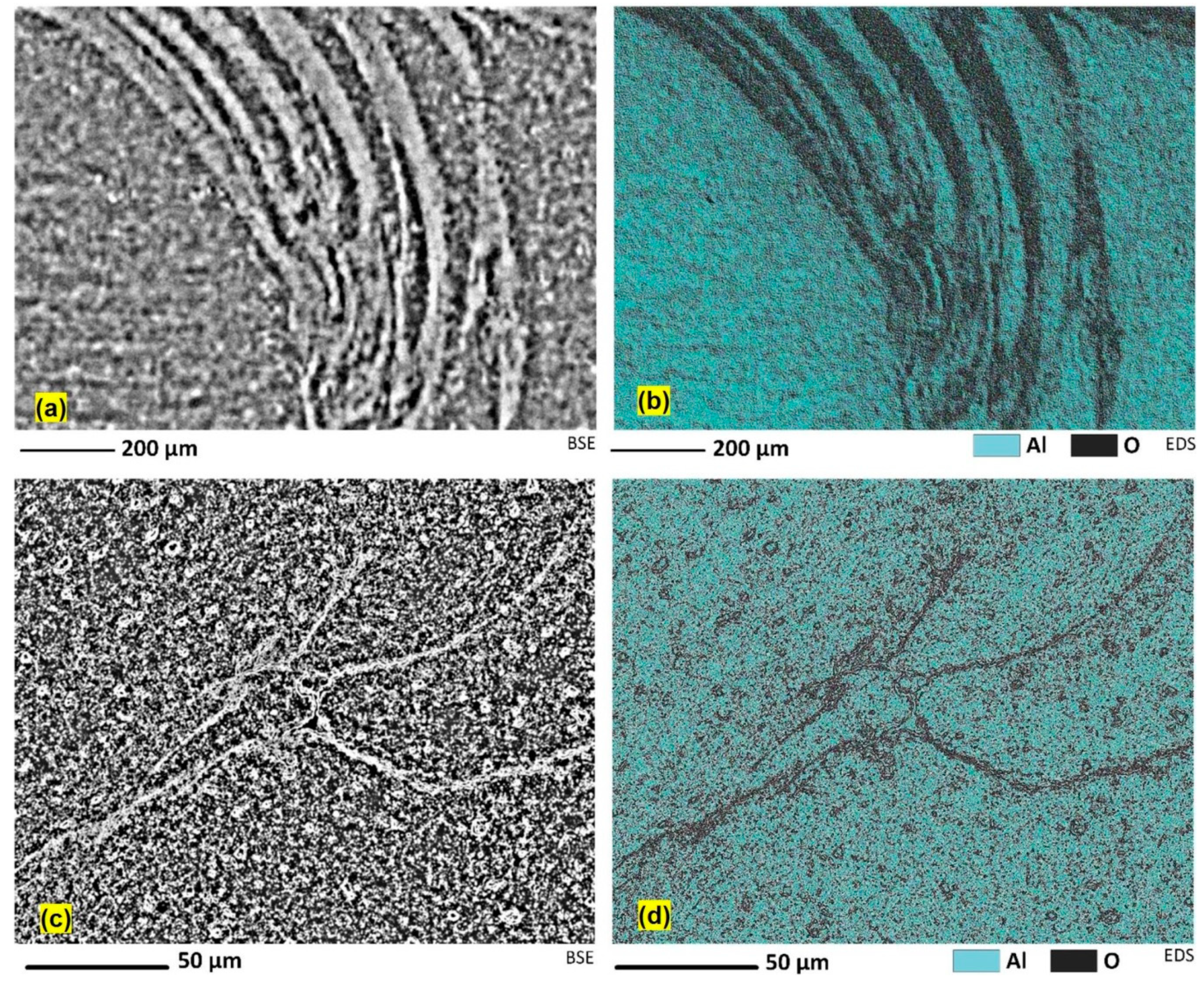

3.5.1. Proposed Composition of Flow Layers

3.5.2. Proposed Principles of Motion of Flow Layers

3.5.3. Proposed Principles of Formation of Surface Features

3.5.4. Integrated Weld Transport Model

4. Discussion

4.1. Originality

4.1.1. Characterization of the Flow Layers at the Hourglass-Borders

4.1.2. Visualization of Flow Layers

- Packets of material (‘flow patches’) are transported around the pin.

- Flow patches are transported round the RS to the back of the tool, where they experience high localized shearing at their mutual boundaries, as evidenced in high density of sub-grain boundaries.

- Flow patches are transported all the way round the tool to the AS, where they are stacked on each other and flattened in the process. Air enters at or before this stage and causes oxidization of the boundaries, as evidenced in EDS elemental mapping.

4.1.3. Proposing a Model of the Internal Flow Processes

4.2. Implications for Practitioners

4.3. Limitations of this Work and Implications for Future Research

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, W. Friction Stir Welding. International Patent Application No. PCT/GB92/02203, 6 December 1991. [Google Scholar]

- Thomas, W.; Wiesner, C.; Marks, D.; Staines, D. Conventional and bobbin friction stir welding of 12% chromium alloy steel using composite refractory tool materials. Sci. Technol. Weld. Join. 2009, 14, 247–253. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Ahmed, M.; Martin, J.P.; Perrett, J.G.; Wynne, B.P. The use of bobbin tools for friction stir welding of aluminium alloys. Mater. Sci. Forum 2010, 638, 1179–1184. [Google Scholar] [CrossRef]

- Thomas, W.; Wiesner, C. Recent developments of FSW technologies: Evaluation of root defects, composite refractory tools for steel joining and one-pass welding of thick sections using self-reacting bobbin tools. In Trends in Welding Research, Proceedings of the 8th International Conference, Pine Mountain, GA, USA, 1–6 June 2008; ASM International: Novelty, OH, USA, 2009; p. 25. [Google Scholar]

- Thomas, W.; Nicholas, E. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Svensson, L.E.; Karlsson, L.; Larsson, H.; Karlsson, B.; Fazzini, M.; Karlsson, J. Microstructure and mechanical properties of friction stir welded aluminium alloys with special reference to AA 5083 and AA 6082. Sci. Technol. Weld. Join. 2000, 5, 285–296. [Google Scholar] [CrossRef]

- Russell, M.; Shercliff, H. Analytical modelling of microstructure development in friction stir welding. In Proceedings of the 1st International Symposium On Friction Stir Welding, Thousand Oaks, CA, USA, 14–16 June 1999. [Google Scholar]

- Sued, M.; Tamadon, A.; Pons, D. Material flow visualization in bobbin friction stir welding by analogue model. Proc. Mech. Eng. Res. Day 2017, 2017, 368–369. [Google Scholar]

- Waldron, D.J.; Roberts, R.W.; Dawes, C.J.; Tubby, P.J. Friction Stir Welding—A Revolutionary New Joining Method. J. Aerosp. 1998, 107, 1247–1252. [Google Scholar]

- Xu, H.; Tang, H.; Liu, Z.; Xie, M.; Jiao, J. Microstructure and Mechanical Properties of 6082 Aluminum Alloy Joints Welded by MIG. Hot Work. Technol. 2010, 1, 42. [Google Scholar]

- Zhang, H.; Wang, M.; Zhang, X.; Yang, G. Microstructural characteristics and mechanical properties of bobbin tool friction stir welded 2A14-T6 aluminum alloy. Mater. Des. 2015, 65, 559–566. [Google Scholar] [CrossRef]

- Martin, J.; Wei, S. Friction Stir Welding Technology for Marine Applications. In Friction Stir Welding and Processing VIII; Springer: Berlin/Heidelberg, Germany, 2015; pp. 219–226. [Google Scholar]

- Esmaily, M.; Mortazavi, N.; Osikowicz, W.; Hindsefelt, H.; Svensson, J.; Halvarsson, M.; Martin, J.; Johansson, L. Bobbin and conventional friction stir welding of thick extruded AA6005-T6 profiles. Mater. Des. 2016, 108, 114–125. [Google Scholar] [CrossRef]

- Chen, C.; Kovacevic, R. Thermomechanical modelling and force analysis of friction stir welding by the finite element method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 509–519. [Google Scholar] [CrossRef]

- Chen, Z.; Pasang, T.; Qi, Y. Shear flow and formation of Nugget zone during friction stir welding of aluminium alloy 5083-O. Mater. Sci. Eng. A 2008, 474, 312–316. [Google Scholar] [CrossRef]

- Gopi, S.; Manonmani, K. Microstructure and mechanical properties of friction stir welded 6082-T6 aluminium alloy. Aust. J. Mech. Eng. 2013, 11, 131–138. [Google Scholar] [CrossRef]

- Sued, M.; Pons, D.; Lavroff, J.; Wong, E.H. Design features for bobbin friction stir welding tools: Development of a conceptual model linking the underlying physics to the production process. Mater. Des. 2014, 54, 632–643. [Google Scholar] [CrossRef]

- Krishnan, K. On the formation of onion rings in friction stir welds. Mater. Sci. Eng. A 2002, 327, 246–251. [Google Scholar] [CrossRef]

- Liechty, B.; Webb, B. Modeling the frictional boundary condition in friction stir welding. Int. J. Mach. Tools Manuf. 2008, 48, 1474–1485. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.; Sued, M.; Clucas, D.; Wong, E. Analogue Modelling of Bobbin Tool Friction Stir Welding. In Proceedings of the International Conference on Innovative Design and Manufacturing, Auckland, New Zealand, 24–26 January 2016. [Google Scholar]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds. Metals 2017, 7, 423. [Google Scholar] [CrossRef]

- Prangnell, P.; Heason, C. Grain structure formation during friction stir welding observed by the ‘stop action technique’. Acta Mater. 2005, 53, 3179–3192. [Google Scholar] [CrossRef]

- Fonda, R.; Knipling, K.; Bingert, J. Microstructural evolution ahead of the tool in aluminum friction stir welds. Scr. Mater. 2008, 58, 343–348. [Google Scholar] [CrossRef]

- Fonda, R.; Reynolds, A.; Feng, C.; Knipling, K.; Rowenhorst, D. Material flow in friction stir welds. Metall. Mater. Trans. A 2013, 44, 337–344. [Google Scholar] [CrossRef]

- Coelho, R.S.; Kostka, A.; Dos Santos, J.; Pyzalla, A.R. EBSD Technique Visualization of Material Flow in Aluminum to Steel Friction-stir Dissimilar Welding. Adv. Eng. Mater. 2008, 10, 1127–1133. [Google Scholar] [CrossRef]

- Hilgert, J.; Schmidt, H.; Dos Santos, J.; Huber, N. Thermal models for bobbin tool friction stir welding. J. Mater. Process. Technol. 2011, 211, 197–204. [Google Scholar] [CrossRef]

- Hilgert, J.; Hütsch, L.L.; dos Santos, J.; Huber, N. Material flow around a bobbin tool for friction stir welding. In Proceedings of the COMSOL Conference, Paris, France, 17–19 November 2010. [Google Scholar]

- Hilgert, J.; Dos Santos, J.; Huber, N. Shear layer modelling for bobbin tool friction stir welding. Sci. Technol. Weld. Join. 2012, 17, 454–459. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Novelty, OH, USA, 1993. [Google Scholar]

- Sued, M.K. Fixed Bobbin Friction Stir Welding of Marine Grade Aluminium. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2015. [Google Scholar]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Formation Mechanisms for Entry and Exit Defects in Bobbin Friction Stir Welding. Metals 2018, 8, 33. [Google Scholar] [CrossRef]

- DS, K.C.; Tamadon, A.; Pons, D.; Sued, M.; Clucas, D.; Wong, E. Preparation of Plasticine Material for Analogue Modelling. In Proceedings of the International Conference on Innovative Design and Manufacturing (ICIDM 2016), Auckland, New Zealand, 24–26 January 2016. [Google Scholar]

- Tamadon, A.; Pons, D.; Sued, K.; Clucas, D. Thermomechanical grain refinement in AA6082-T6 thin plates under Bobbin friction stir welding. Metals 2018, 8, 375. [Google Scholar] [CrossRef]

- Sued, M.K.; Pons, D.J. Dynamic Interaction between Machine, Tool, and Substrate in Bobbin Friction Stir Welding. Int. J. Manuf. Eng. 2016, 1–14. [Google Scholar] [CrossRef]

| AA6082-T6 Aluminium Alloy | |

|---|---|

| Chemical Element | % Present |

| Silicon (Si) | (0.70–1.30) |

| Magnesium (Mg) | (0.60–1.20) |

| Manganese (Mn) | (0.40–1.00) |

| Iron (Fe) | (0.0–0.50) |

| Chromium (Cr) | (0.0–0.25) |

| Zinc (Zn) | (0.0–0.20) |

| Titanium (Ti) | (0.0–0.10) |

| Copper (Cu) | (0.0–0.10) |

| Other (Each) | (0.0–0.05) |

| Other (total) | (0.0–0.15) |

| Aluminium (Al) | Balance |

| Work Temp (°C) | DShoulder (mm) | DPin (mm) | DShoulder/DPin | Plate Thickness (mm) | Compression Ratio | Feed ω (rpm) | Speed V (mm/min) | Thread Pitch (mm) | Number of Threads |

|---|---|---|---|---|---|---|---|---|---|

| 18 °C | 21 | 7 | 3 | 6 | 3.75% | 400 | 350 | 1.2 | 5 |

| 650 | 400 |

| Name of Etchant | Etchant Composition |

|---|---|

| A | 2.5 mL HF + 2.5 mL HCl + 95 mL H2O (30 s, 50 °C), then: 15 mL H3PO4 + 85 mL H2O (30 s, 70 °C) |

| B | 0.5 g (NH4)2MoO4 + 3.0 g NH4Cl + 1 mL HF + 18 mL HNO3 + 80 mL H2O (90 s, 70 °C) |

| C | 10 g CrO3 + 2 g Na2SO4 + 10 mL HNO3 + 10 mL CH3COOH + 1 mL HF + 80 mL H2O (60 s, 70 °C) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamadon, A.; Pons, D.J.; Clucas, D.; Sued, K. Internal Material Flow Layers in AA6082-T6 Butt-Joints during Bobbin Friction Stir Welding. Metals 2019, 9, 1059. https://doi.org/10.3390/met9101059

Tamadon A, Pons DJ, Clucas D, Sued K. Internal Material Flow Layers in AA6082-T6 Butt-Joints during Bobbin Friction Stir Welding. Metals. 2019; 9(10):1059. https://doi.org/10.3390/met9101059

Chicago/Turabian StyleTamadon, Abbas, Dirk J. Pons, Don Clucas, and Kamil Sued. 2019. "Internal Material Flow Layers in AA6082-T6 Butt-Joints during Bobbin Friction Stir Welding" Metals 9, no. 10: 1059. https://doi.org/10.3390/met9101059

APA StyleTamadon, A., Pons, D. J., Clucas, D., & Sued, K. (2019). Internal Material Flow Layers in AA6082-T6 Butt-Joints during Bobbin Friction Stir Welding. Metals, 9(10), 1059. https://doi.org/10.3390/met9101059