Effect of Stress Triaxiality on Plastic Damage Evolution and Failure Mode for 316L Notched Specimen

Abstract

:1. Introduction

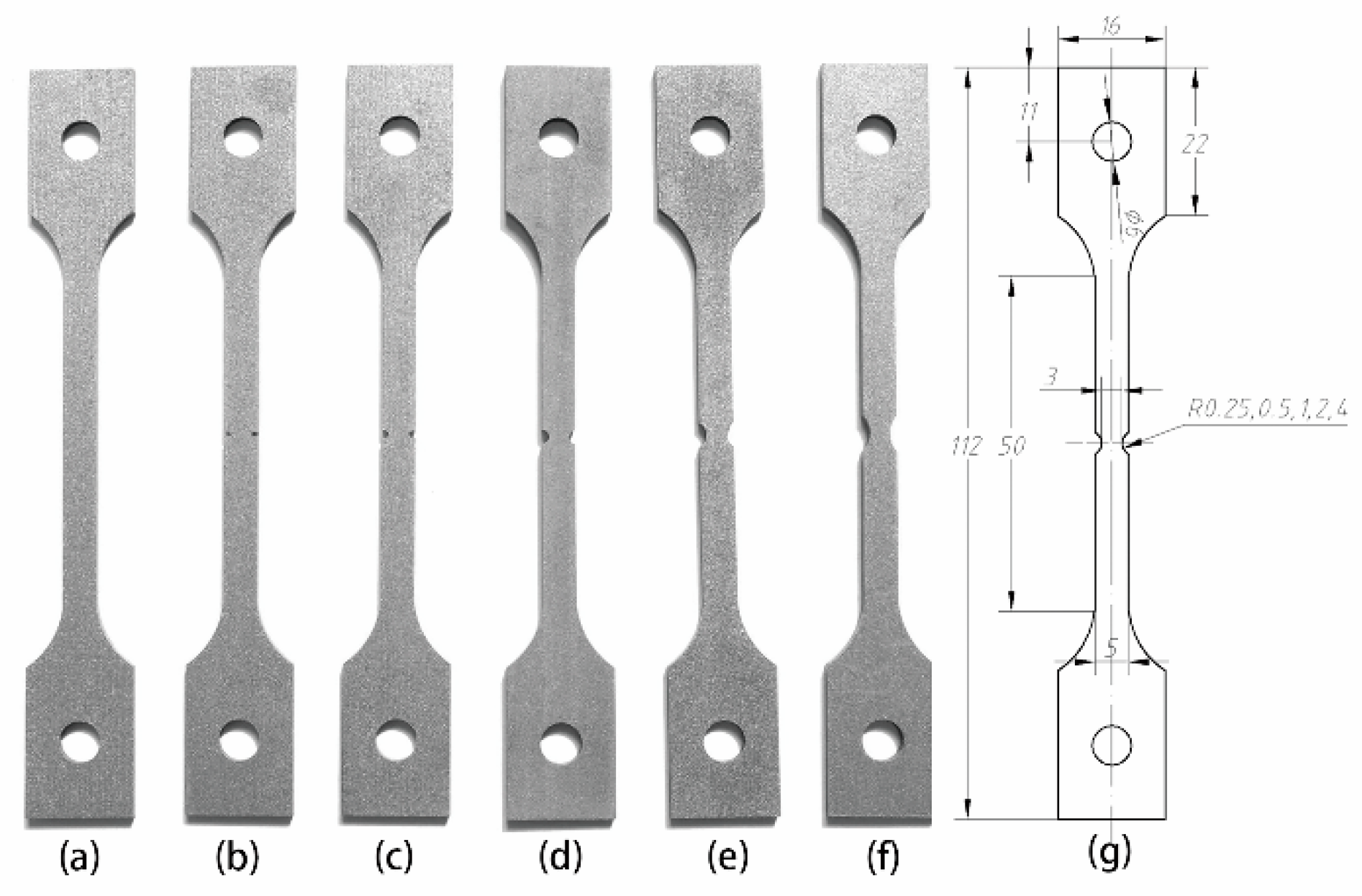

2. Experiments and FES

2.1. Tensile Test and DIC Observation

2.2. FES of Plastic Damage Evolution

2.3. Comparison of FES Results and DIC Experimental Results

3. Results and Discussion

3.1. The Evolution of Stress Triaxiality for the Notched Specimen

3.2. Effect of Stress Triaxiality on Strain Distribution and Fracture Ductility

3.2.1. Strain Observation by DIC

3.2.2. Strain Observation by FES

3.2.3. Effect of Stress Triaxiality on Fracture Ductility

3.3. Effect of Stress Triaxiality on Plastic Damage Evolution and Failure Mode

3.3.1. Effect of Stress Triaxiality on Plastic Damage Evolution

VVFN

VVFG

VVF

3.3.2. Transition of Failure Mode with Stress Triaxiality

4. Conclusions

- (1)

- Combined with void fraction calculation by OM observation and plastic damage simulation by FES, the GTN damage parameters were determined for 316L, and the FES results were verified by experimental DIC observation.

- (2)

- From the damage simulation, the VVF at root position increases with the decrease in the notch radius, and the VVF due to growth dominates the void volume fraction evolution during tensile testing.

- (3)

- From both mesoscopic voids observation and plastic damage simulation, the failure mode changes from crack initiation at notch root to ductile fracture at the center position, with notch radius increasing and stress triaxiality decreasing. The position where the initial stress triaxiality is the largest is the position where the failure starts.

Author Contributions

Funding

Conflicts of Interest

References

- Martínez-Donaire, A.J.; Borregoo, M.; Morales-Palma, D.; Centeno, G.; Vallellano, C. Analysis of the influence of stress triaxiality on formability of hole-flanging by single-stage SPIF. Int. J. Mech. Sci. 2019, 151, 76–84. [Google Scholar] [CrossRef]

- Rodriguez-Millan, M.; Garcia-Gonzalez, D.; Rusinek, A.; Arias, A. Influence of stress state on the mechanical impact and deformation behaviors of aluminum alloys. Metals 2018, 8, 520. [Google Scholar] [CrossRef]

- Kato, T.; Ohata, M.; Nogami, S.; Tanigawa, H. Evaluation of impacts of stress triaxiality on plastic deformability of RAFM steel using various types of tensile specimen. Fusion Eng. Des. 2016, 109, 1631–1636. [Google Scholar] [CrossRef]

- Ma, Y.S.; Sun, D.Z.; Aurieux, F.; Zhang, K.S. Influences of initial porosity, stress triaxiality and Lode parameter on plastic deformation and ductile fracture. Acta Mech. Solida Sin. 2017, 30, 493–506. [Google Scholar] [CrossRef]

- Wen, J.F.; Tu, S.T.; Xuan, F.Z.; Zhang, X.W.; Gao, X.L. Effects of stress level and stress state on creep ductility, evaluation of different models. J. Mater. Sci. Technol. 2016, 32, 695–704. [Google Scholar] [CrossRef]

- Chandan, P.; Mahapatra, M.M.; Pradeep, K.; Saini, N. Effect of strain rate and notch geometry on tensile properties and fracture mechanism of creep strength enhanced ferritic P91 steel. J. Nucl. Mater. 2018, 498, 176–186. [Google Scholar]

- Erice, B.; Roth, C.C.; Mohr, D. Stress-state and strain-rate dependent ductile fracture of dual and complex phase steel. Mech. Mater. 2018, 116, 11–32. [Google Scholar] [CrossRef]

- Keshavarz, A.; Ghajar, R.; Mirone, G. A new experimental failure model based on triaxiality factor and Lode angle for X-100 pipeline steel. Int. J. Mech. Sci. 2014, 80, 175–182. [Google Scholar] [CrossRef]

- Yu, F.; Jar, P.Y.B.; Hendry, M.T. Constitutive analysis of pressure-insensitive metals under axisymmetric tensile loading, A stress triaxiality-dependent plasticity damage model. Int. J. Mech. Sci. 2018, 142, 21–32. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H.; Li, F.; Cao, J. A Novel Damage Model to Predict Ductile Fracture Behavior for Anisotropic Sheet Metal. Metals 2019, 9, 595. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Jiang, W.C.; Tu, S.T.; Wen, J.F. Simulation of creep and damage in the bonded compliant seal of planar solid oxide fuel cell. Int. J. Hydrogen Energy 2014, 39, 17941–17951. [Google Scholar] [CrossRef]

- Luo, Y.; Jiang, W.C.; Zhang, Y.C.; Zhou, F.; Tu, S.T. A new damage evolution model to estimate the creep fracture behavior of brazed joint under multiaxial stress. Int. J. Mech. Sci. 2018, 149, 178–189. [Google Scholar] [CrossRef]

- Luo, Y.; Jiang, W.C.; Zhang, W.Y.; Zhang, Y.C.; Woo, W.; Tu, S.T. Notch effect on creep damage for Hastelloy C276-BNi2 brazing joint. Mater. Des. 2015, 84, 212–222. [Google Scholar] [CrossRef]

- Huang, J.; Shi, D.Q.; Yang, X.G.; Pan, B.; Shi, H. Experimental investigation and numerical modeling for elasto-plastic notch-root stress/strain analysis under monotonic loadings. Sci. China Technol. Sci. 2014, 57, 1411–1424. [Google Scholar] [CrossRef]

- Benzerga, A.A. Plastic potentials for anisotropic porous solids. Eur. J. Mech. 2001, 20, 397–434. [Google Scholar] [CrossRef]

- Decamp, K.; Bauvineau, L.; Besson, J. Size and geometry effects on ductile rupture of notched bars in a C-Mn steel: Experiments and modelling. Int. J. Fract. 1997, 88, 1–18. [Google Scholar] [CrossRef]

- Besson, J.; Devillers-Guerville, L.; Pineau, A. Modeling of scatter and size effect in ductile fracture: Application to thermal embrittlement of duplex stainless steels. Eng. Fract. Mech. 2000, 67, 169–190. [Google Scholar] [CrossRef]

- Gurson, A.L. Porous rigid-plastic materials containing rigid inclusions-yield function, plastic potential, and void nucleation. In The Physical Metallurgy of Fracture, Proceedings of the Fourth International Conference on Fracture, Waterloo, Canada, 19–24 June 1977; Taplin, D.M.R., Ed.; Elsevier: Amsterdam, The Netherlands, 1978; Volume 2, pp. 357–364. [Google Scholar]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Chen, M.S.; Lin, Y.C. Numerical simulation and experimental verification of void evolution inside large forgings during hot working. Int. J. Plast. 2013, 49, 53–70. [Google Scholar] [CrossRef]

- Besson, J. Continuum models of ductile fracture, a review. Int. J. Damage Mech. 2010, 19, 3–52. [Google Scholar] [CrossRef]

- Needleman, A.; Tvergaard, V. An analysis of ductile rupture in notched bars. J. Mech. Phys. Solids 1984, 32, 461–490. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the cup-cone fracture in a round tensile bar. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Ten, B.G.; Wang, W.N.; Xu, Y.C. Ductile fracture prediction in aluminium alloy 5A06 sheet forming based on GTN damage model. Eng. Fract. Mech. 2017, 186, 242–254. [Google Scholar]

- Giang, N.A.; Kuna, M.; Hütter, G. Influence of carbide particles on crack initiation and propagation with competing ductile-brittle transition in ferritic steel. Theor. Appl. Fract. Mech. 2017, 92, 89–98. [Google Scholar] [CrossRef]

- Sun, Q.; Zan, D.; Chen, J.J.; Pan, H.L. Analysis of edge crack behavior of steel sheet in multi-pass cold rolling based on a shear modified GTN damage model. Theor. Appl. Fract. Mech. 2015, 80, 259–266. [Google Scholar] [CrossRef]

- Peng, J.; Li, K.S.; Zhou, C.Y. Construction of whole stress-strain curve by small punch test and inverse finite element. Results Phys. 2018, 11, 440–448. [Google Scholar]

- Lin, Y.C.; Jiang, X.Y.; Shuai, C.J.; Zhao, C.Y.; He, D.G.; Chen, M.S.; Chen, C. Effects of initial microstructures on hot tensile deformation behaviors and fracture characteristics of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2018, 711, 293–302. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yang, H.; Xin, Y.C.; Li, C.Z. Effects of initial microstructures on serrated flow features and fracture mechanisms of a nickel-based superalloy. Mater. Charact. 2018, 144, 9–21. [Google Scholar] [CrossRef]

- Gerstein, G.; Besserer, H.B.; Nürnberger, F.; Barrales-Mora, L.A.; Shvindlerman, L.S.; Estrin, Y.; Maier, H.J. Formation and growth of voids in dual-phase steel at microscale and nanoscale levels. J. Mater. Sci. 2017, 52, 4234–4243. [Google Scholar] [CrossRef]

- Wen, J.F.; Tu, S.T. A multiaxial creep-damage model for creep crack growth considering cavity growth and microcrack interaction. Eng. Fract. Mech. 2014, 123, 197–210. [Google Scholar] [CrossRef]

- Garrison, W. Ductile fracture. J. Phys. Chem. Solids 1987, 48, 1035–1074. [Google Scholar] [CrossRef]

- Needleman, A. A continuum model for void nucleation by inclusion debonding. J. App. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Saeidia, N.; Ashrafizadeha, F.; Niroumanda, B.; Forouzanb, M.R.; Mohseni-Mofidib, S.; Barlatc, F. Void coalescence and fracture behavior of notched and un-notched tensile tested specimens in fine grain dual phase steel. Mater. Sci. Eng. A 2015, 644, 210–217. [Google Scholar] [CrossRef]

- Peng, J.; Li, K.S.; Dai, Q.; Peng, J. Mechanical properties of pre-strained austenitic stainless steel from the view of energy density. Results Phys. 2018, 10, 187–193. [Google Scholar] [CrossRef]

- Lin, L.X.; Xu, M.J.; Xu, J.J.; Lu, H.; Ye, C.H.; Yu, C.; Chen, J.M. Measurement and evaluation of strain fields in T23 steel based on digital image correlation method. J. Cent. South. Univ. 2017, 24, 1977–1985. [Google Scholar] [CrossRef]

- Chu, C.C.; Needleman, A. Void nucleation effects in biaxially stretched sheets. J. Eng. Mater. Technol. 1980, 102, 249–256. [Google Scholar] [CrossRef]

- Qian, L.Y.; Fang, G.; Zeng, P.; Wang, Q. Experimental and numerical investigations into the ductile fracture during the forming of flat-rolled 5083-O aluminum alloy sheet. J. Mater. Process. Technol. 2015, 220, 264–275. [Google Scholar] [CrossRef]

- Tvergaard, V. On localization in ductile materials containing spherical voids. Int. J. Fract. 1982, 18, 237–252. [Google Scholar]

- Huang, J.; Guo, Y.Z.; Qin, D.Y.; Zhou, Z.X.; Li, D.D.; Li, Y.L. Influence of stress triaxiality on the failure behavior of Ti-6Al-4V alloy under a broad range of strain rates. Theor. Appl. Fract. Mech. 2018, 97, 48–61. [Google Scholar] [CrossRef]

- Ying, L.; Liu, W.Q.; Wang, D.T.; Hu, P. Parameter calibration of GTN damage model and formability analysis of 22MnB5 in hot forming process. J. Mater. Eng. Perform. 2017, 26, 5155–5165. [Google Scholar] [CrossRef]

- Jiang, W.; Li, Y.Z.; Su, J. Modified GTN model for a broad range of stress states and application to ductile fracture. Eur. J. Mech. A-Solid 2016, 57, 132–148. [Google Scholar] [CrossRef]

- Geramita, A.V.; Seberry, J. Orthogonal Designs: Quadratic Forms and Hadamard Matrices; Marcel Dekker: New York, NY, USA, 1979. [Google Scholar]

- Bridgman, P.W. Studies in Large Plastic Flow and Fracture: With Special Emphasis on the Effects of Hydrostatic Pressure; Harvard University Press: Cambridge, MA, USA, 1964. [Google Scholar]

| Level | [26,41] | [28] | [42,43] |

| Level 1 | 0.2 | 0.08 | 0.004 |

| Level 2 | 0.25 | 0.1 | 0.01 |

| Level 3 | 0.3 | 0.12 | 0.02 |

| Experiment | Error (%) | |||

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 9.74 |

| 2 | 1 | 2 | 3 | 11.2 |

| 3 | 1 | 3 | 2 | 10.9 |

| 4 | 2 | 1 | 3 | 16.7 |

| 5 | 2 | 2 | 2 | 10.7 |

| 6 | 2 | 3 | 1 | 9.66 |

| 7 | 3 | 1 | 2 | 10.21 |

| 8 | 3 | 2 | 1 | 9.69 |

| 9 | 3 | 3 | 3 | 10.47 |

| 10.61 | 12.22 | 9.70 | ||

| 12.35 | 10.53 | 10.60 | ||

| 10.12 | 10.34 | 12.79 |

| 1.5 | 1 | 2.25 | 0.0012 | 0.042 | 0.092 | 0.3 | 0.12 | 0.004 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, J.; Wang, Y.; Dai, Q.; Liu, X.; Liu, L.; Zhang, Z. Effect of Stress Triaxiality on Plastic Damage Evolution and Failure Mode for 316L Notched Specimen. Metals 2019, 9, 1067. https://doi.org/10.3390/met9101067

Peng J, Wang Y, Dai Q, Liu X, Liu L, Zhang Z. Effect of Stress Triaxiality on Plastic Damage Evolution and Failure Mode for 316L Notched Specimen. Metals. 2019; 9(10):1067. https://doi.org/10.3390/met9101067

Chicago/Turabian StylePeng, Jian, Ying Wang, Qiao Dai, Xuedong Liu, Lin Liu, and Zhihong Zhang. 2019. "Effect of Stress Triaxiality on Plastic Damage Evolution and Failure Mode for 316L Notched Specimen" Metals 9, no. 10: 1067. https://doi.org/10.3390/met9101067

APA StylePeng, J., Wang, Y., Dai, Q., Liu, X., Liu, L., & Zhang, Z. (2019). Effect of Stress Triaxiality on Plastic Damage Evolution and Failure Mode for 316L Notched Specimen. Metals, 9(10), 1067. https://doi.org/10.3390/met9101067