Influences of Different Die Bearing Geometries on the Wire-Drawing Process

Abstract

:1. Introduction

2. Materials and Methods

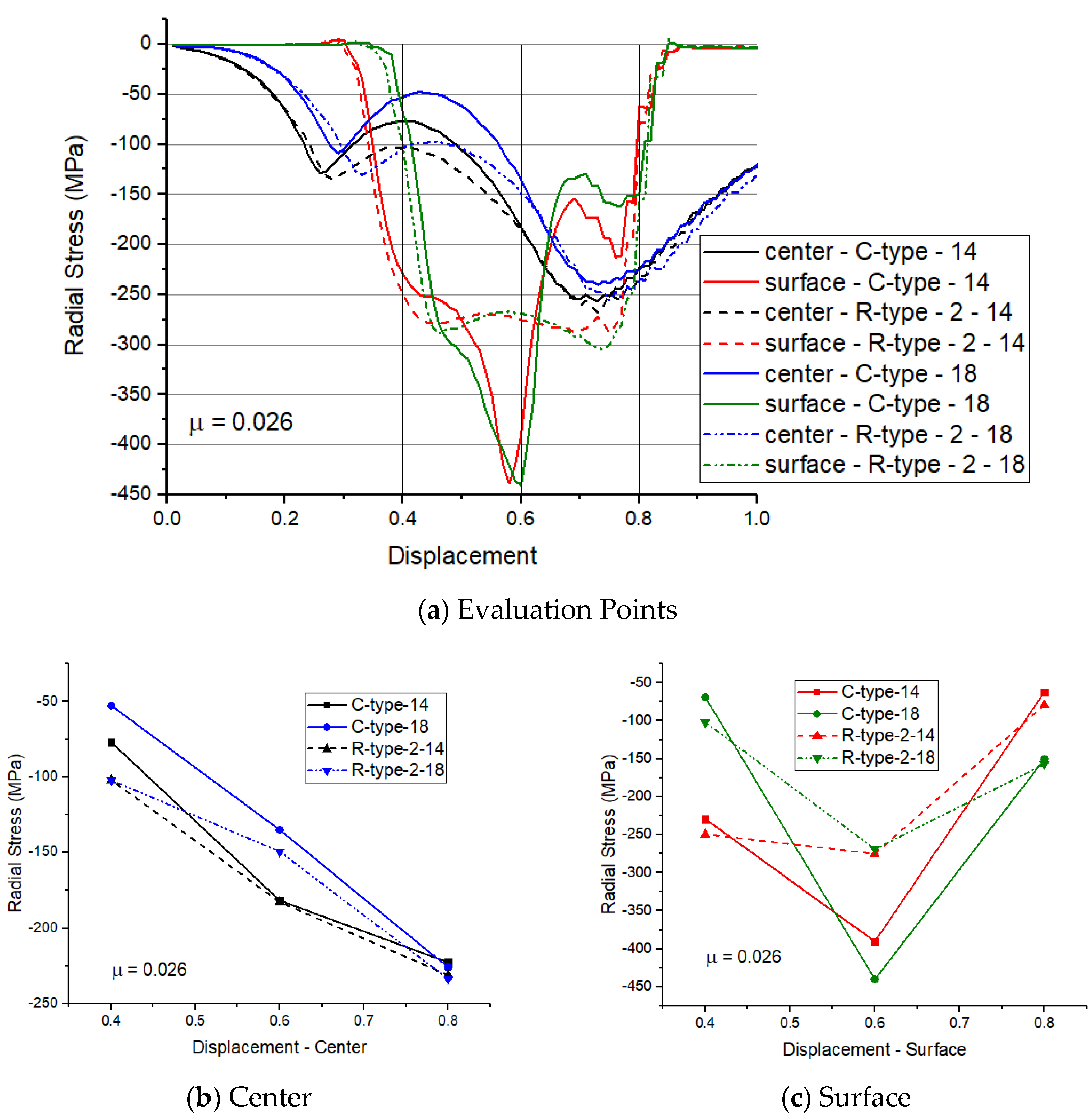

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ajiboye, J.S.; Adeyemi, M.B. Upper bound analysis of die land length in cold extrusion. J. Mater. Process. Technol. 2006, 177, 608–611. [Google Scholar] [CrossRef]

- Parghazed, A.; Haghighat, H. Prediction of central bursting defects in rod extrusion process with upper bound analysis method. Trans. Nonferrous Met. Soc. China 2016, 26, 2892–2899. [Google Scholar] [CrossRef]

- Suliga, M.; Wartacz, R.; Michalczyk, J. The influence of the angle of the working part of the die on the high speed drawing process of low carbon steel wires. Arch. Metall. Mater. 2017, 62, 483–487. [Google Scholar] [CrossRef]

- Stolyarov, A.; Polyakova, M.; Atangulova, G.; Alexandrov, S.; Lang, L. Effect of Frictional Conditions on the Generation of Fine Grain Layers in Drawing of Thin Steel Wires. Metals 2019, 9, 819. [Google Scholar] [CrossRef]

- Vannes, A.; Thierry, P. Effects of die characteristic on the strength and residual stresses during wire drawing. J. Mech. Work. Technol. 1981, 5, 251–266. [Google Scholar] [CrossRef]

- Castro, A.L.R.; Campos, H.B.; Cetlin, P.R. Influence of die semi-angle on mechanical properties of single and multiple pass drawn copper. J. Mater. Process. Technol. 1996, 60, 179–182. [Google Scholar] [CrossRef]

- Kraft, F.F.; Chakkingal, U.; Baker, G.; Wright, R.N. The effects of die angle on the texture and annealing response of ETP copper wire. J. Mater. Process. Technol. 1996, 60, 171–178. [Google Scholar] [CrossRef]

- Nakagiri, A.; Yamano, T.; Konaka, M.; Asakawa, M.; Sasaki, W.; Yoshida, K. Behavior of residual stress and drawing stress in conical-type die and circle-type die drawing by FEM simulation and experiment. Wire J. Int. 2001, 34, 72–80. [Google Scholar]

- Överstam, H. The influence of bearing geometry on the residual stress state in cold drawn wire, analyzed by the FEM. J. Mater. Process. Technol. 2006, 171, 446–450. [Google Scholar] [CrossRef]

- Ikumapayi, O.; Ojolo, S.; Afolalu, A. Experimental and theoretical investigation of tensile stress distribution during aluminum wire drawing. Eur. Sci. J. 2015, 11, 86–102. [Google Scholar]

- Teja, C.S.N.; Murty, G.N.; Reddy, P.S. Finite Element Analysis of Wire Drawing Process with different die contours. Int. J. Sci. Eng. Adv. Technol. 2016, 4, 134–143. [Google Scholar]

- Tintelecan, M.; Sas-Boca, I.M.; Ilutiu-Varvara, D.A. The influence of the dies geometry on the drawing force for steel wires. Procedia Eng. 2017, 181, 193–199. [Google Scholar] [CrossRef]

- Atienza, J.; Elices, M. Influence of residual stresses in the tensile test of cold drawn wires. Mater. Struct. 2003, 36, 548–552. [Google Scholar] [CrossRef]

- Martínez-Pérez, M.; Mompean, F.; Ruiz-Hervias, J.; Borlado, C.; Atienza, J.; García-Hernández, M.; Elices, M.; Gil-Sevillano, J.; Peng, R.; Buslaps, T. Residual stress profiling in the ferrite and cementite phases of cold-drawn steel rods by synchrotron X-ray and neutron diffraction. Acta Mater. 2004, 52, 5303–5313. [Google Scholar] [CrossRef]

- Atienza, J.M.; Martínez-Pérez, M.L.; Ruiz-Hervias, J.; Mompean, F.; GarcíaHernández, M.; Elices, M. Residual stresses in cold drawn ferritic rods. Scr. Mater. 2005, 52, 305–309. [Google Scholar] [CrossRef]

- Martínez-Pérez, M.; Borlado, C.; Mompean, F.; García-Hernández, M.; GilSevillano, J.; Ruiz-Hervias, J.; Atienza, J.; Elices, M.; Peng, R.; Daymond, M. Measurement and modelling of residual stresses in straightened commercial eutectic steel rods. Acta Mater. 2005, 53, 4415–4425. [Google Scholar] [CrossRef]

- Coser, T.B.; Souza, T.F.D.; Rocha, A.D.S. Avaliação numérica da influência da geometria do ferramental na geração de tensões residuais durante o processo de trefilação de barras de aço. Rev. Matéria 2015, 20, 819–831. [Google Scholar] [CrossRef]

- Kesavulu, P.; Reddy, G.R.; Sreedhar, N. Finite element analysis of concave and convex die contours in wire drawing process. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 477–480. [Google Scholar]

- Wistreich, J.G. Investigation of the Mechanics of Wire Drawing. Proc. Inst. Mech. Eng. 1955, 169, 654–678. [Google Scholar] [CrossRef]

- Backofen, W.A. Deformation Processing; Addison-Wesley Pub Co.: Boston, MA, USA, 1972. [Google Scholar]

- Wright, R.N. Practical Use of Mechanical Analysis in Wire Drawing; Wire Technology: Kaukauna, WI, USA, 1976; Volume 9, pp. 57–61. [Google Scholar]

- Atkins, A.G.; Caddell, R.M. The incorporation of work hardening and redundant work in rod drawing analyses. Int. J. Mech. Sci. Pergamon Press. 1968, 10, 15–28. [Google Scholar] [CrossRef]

- Godfrey, H.J.; Richards, J.F.; Sason, A.S. The benefits of using wiredrawing dies with smaller included angles and long nibs. Wire J. Int. 2000, 6, 102–113. [Google Scholar]

- Avitzur, B. Handbook of Metal. Forming; John Wiley and Sons: New York, NY, USA, 1983. [Google Scholar]

- Vega, G.; Haddi, A.; Imad, A. Investigation of process parameters effect on the copper-wire drawing. Mater. Des. 2009, 30, 330–3312. [Google Scholar] [CrossRef]

| Temp. (°C) | Viscosity (Pa.s) | |

|---|---|---|

| Soluble | Mineral | |

| 25 | Out of range | 0.2940 |

| 50 | 0.0704 | |

| 70 | 0.0448 | |

| C-Type | R-Type | ||||||

|---|---|---|---|---|---|---|---|

|  | ||||||

| L/Di. | L (mm) | Hc (%) | 2β (°) | R | L | L/Di | |

| (mm) | |||||||

| 0.889 | 0.4443 | 35 | 10 | 1.0 | 0.4443 | 0.889 | |

| ----- | ----- | ----- | 2.0 | 0.4442 | 0.888 | ||

| 0.726 | 0.3631 | 35 | 14 | 0.3629 | 0.726 | ||

| 0.636 | 0.3182 | 18 | 0.3176 | 0.635 | |||

| 2β | Δ | Φ |

|---|---|---|

| 14 | 2.32 | 1.62 |

| 18 | 2.98 | 1.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez, G.A.S.; Santos, E.F.d.; Kabayama, L.K.; Guidi, E.S.; Silva, F.d.A. Influences of Different Die Bearing Geometries on the Wire-Drawing Process. Metals 2019, 9, 1089. https://doi.org/10.3390/met9101089

Martinez GAS, Santos EFd, Kabayama LK, Guidi ES, Silva FdA. Influences of Different Die Bearing Geometries on the Wire-Drawing Process. Metals. 2019; 9(10):1089. https://doi.org/10.3390/met9101089

Chicago/Turabian StyleMartinez, Gustavo Aristides Santana, Eduardo Ferro dos Santos, Leonardo Kyo Kabayama, Erick Siqueira Guidi, and Fernando de Azevedo Silva. 2019. "Influences of Different Die Bearing Geometries on the Wire-Drawing Process" Metals 9, no. 10: 1089. https://doi.org/10.3390/met9101089

APA StyleMartinez, G. A. S., Santos, E. F. d., Kabayama, L. K., Guidi, E. S., & Silva, F. d. A. (2019). Influences of Different Die Bearing Geometries on the Wire-Drawing Process. Metals, 9(10), 1089. https://doi.org/10.3390/met9101089