Aluminum Alloy Sheet-Forming Limit Curve Prediction Based on Original Measured Stress–Strain Data and Its Application in Stretch-Forming Process

Abstract

:1. Introduction

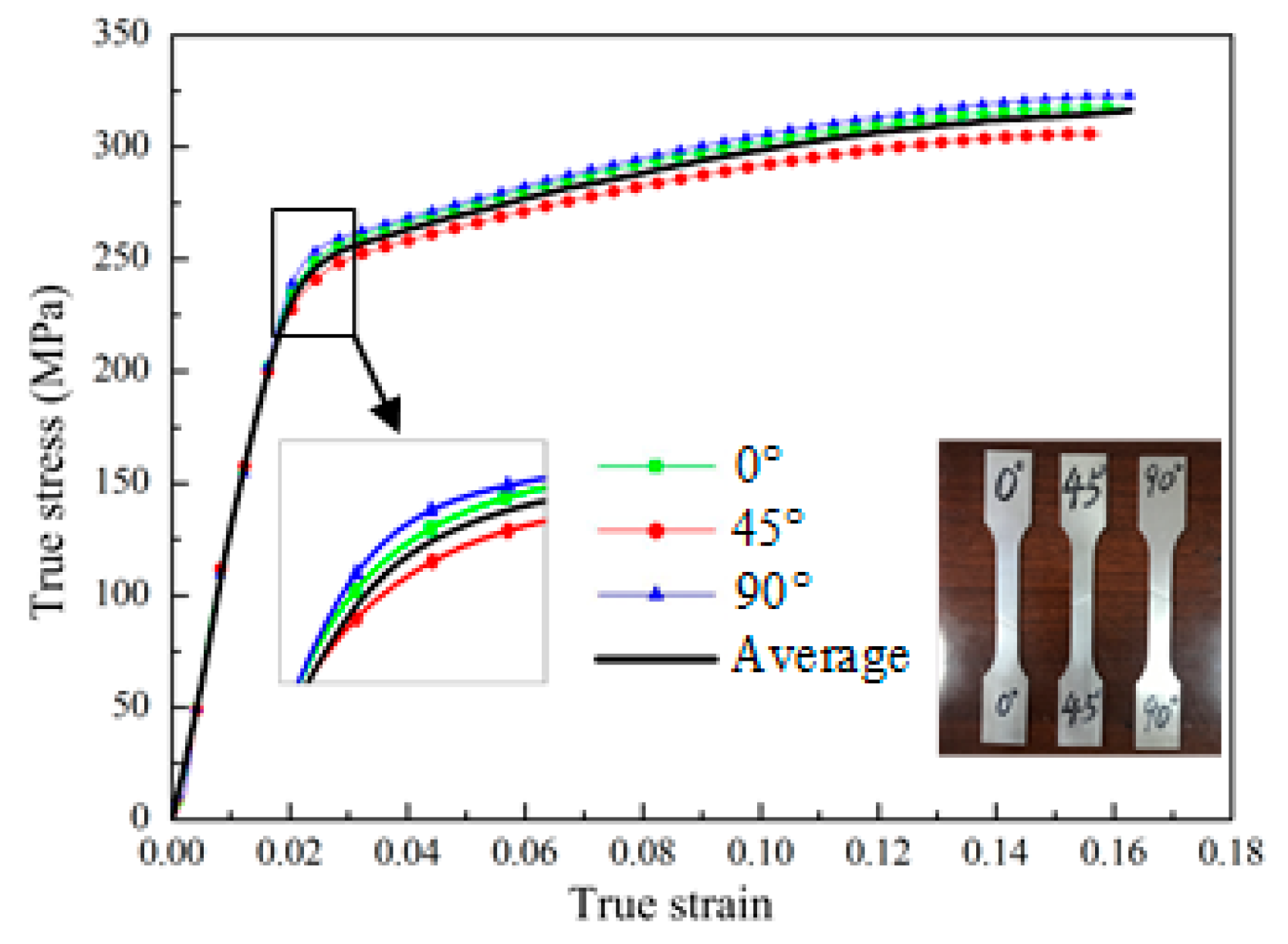

2. Uniaxial Tensile Tests

3. M–K Model Based on OMD of Stress–Strain

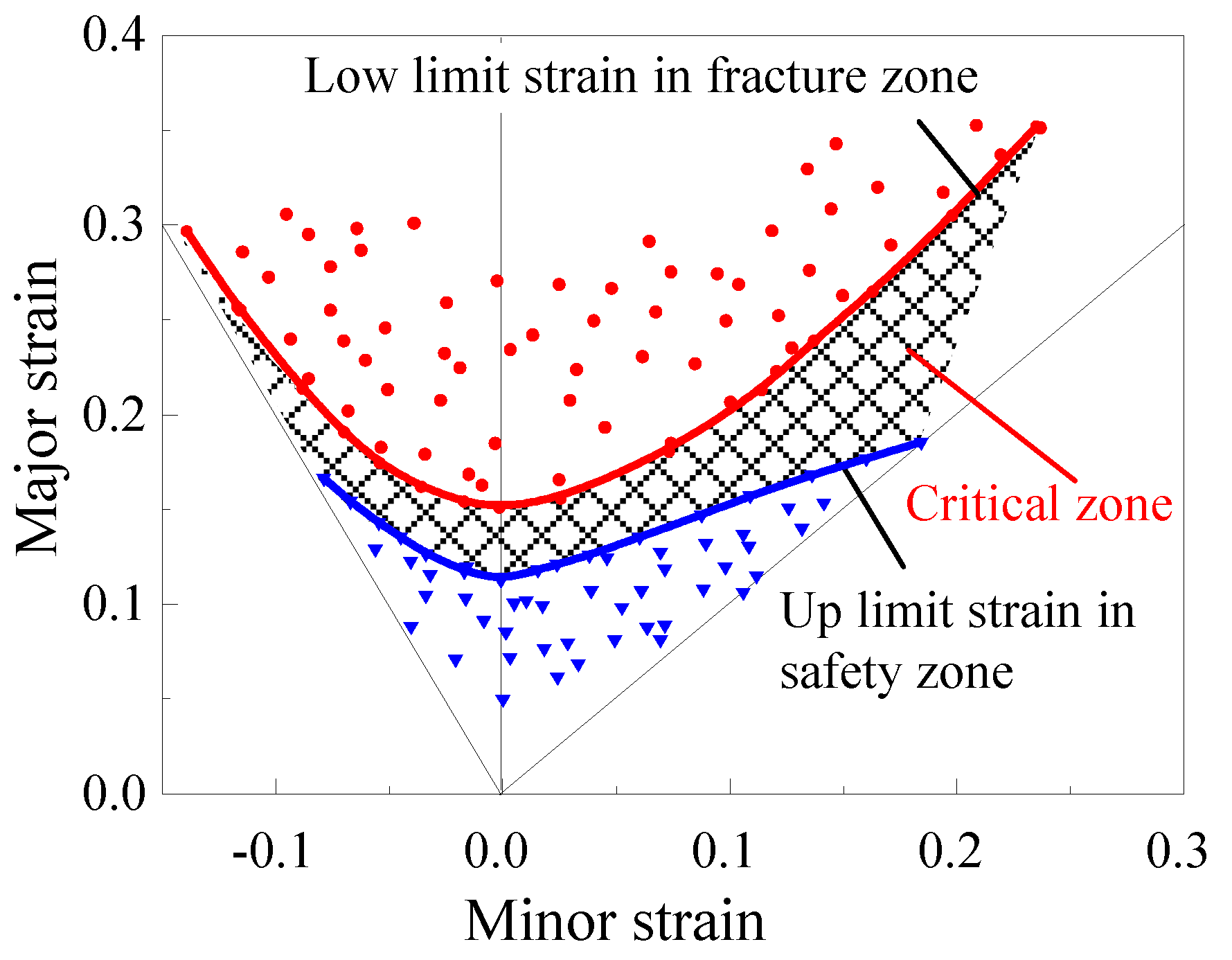

4. Experiments’ Determination on FLC

4.1. Numerical Simulations and Experiment Scheme

4.2. Analysis of Experiments Results

5. Results and Discussion

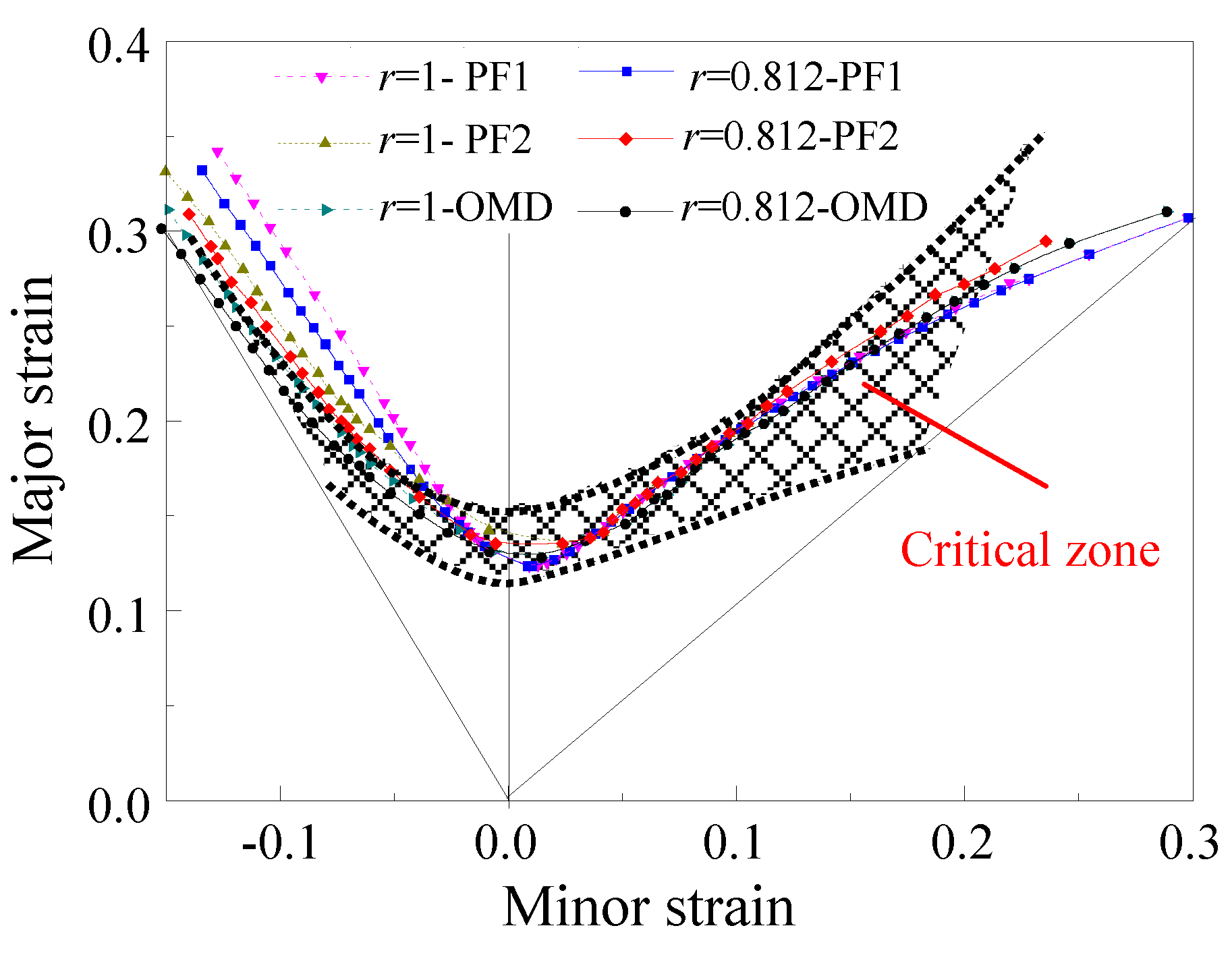

5.1. Comparison of FLCs Calculated by OMD of Stress–Strain and Power Function

5.2. Influence of Anisotropic Parameter and Groove Angle on FLCs

6. Application of FLC in the Stretch-Forming Process Based on Loading at Multi-Positions

6.1. Loading Trajectories for the Stretch-Forming Process Based on Loading at Multi-Positions

6.2. Numerical Simulation Results and Experimental Validation

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminum alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Eyckens, P.; Bael, A.V.; Houtte, P.V. Marciniak-Kuczynski type modelling of the effect of through-thickness shear on the forming limits of sheet metal. Int. J. Plast. 2009, 25, 2249–2268. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Wang, S.H.; Xu, X.D.; Li, M.Z. Numerical simulation for the multi-point stretch forming process of sheet metal. J. Mater. Process. Technol. 2009, 209, 396–407. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Liang, X.B.; Yang, Z.; Li, X.J. Force-controlled sheet metal stretch forming process based on loading at discrete points. Int. J. Adv. Manuf. Technol. 2007, 93, 1781–1789. [Google Scholar] [CrossRef]

- Kim, W.J.; Sa, Y.K.; Kim, H.K.; Yoon, U.S. Plastic forming of the equal-channel angular pressing processed 6061 aluminum alloy. Mater. Sci. Eng. 2008, 487, 360–368. [Google Scholar] [CrossRef]

- Yang, H.; Fan, X.; Sun, Z.; Guo, L.; Zhan, M. Recent developments in plastic forming technology of titanium alloys. Sci. China Technol. Sci. 2011, 54, 490–501. [Google Scholar] [CrossRef]

- Aghaie-Khafri, M.; Mahmudi, R. Predicting of plastic instability and forming limit diagrams. Int. J. Mech. Sci. 2004, 46, 1289–1306. [Google Scholar] [CrossRef]

- Lopes, A.B.; Rauch, E.F.; Gracio, J.J. Textural vs. structural plastic instabilities in sheet metal forming. Acta Mater. 1999, 47, 859–866. [Google Scholar] [CrossRef]

- Watanabe, I.; Terada, K. A method of predicting macroscopic yield strength of polycrystalline metals subjected to plastic forming by micro-macro de-coupling scheme. Int. J. Mech. Sci. 2010, 52, 343–355. [Google Scholar] [CrossRef]

- Chen, M.H.; Gao, L.; Wang, H. Research progresses on sheet metal forming limit stress diagram. China Mech. Eng. 2005, 16, 1593–1597. [Google Scholar]

- Ding, J.; Zhang, C.; Chu, X.; Zhao, G.; Leotoing, L.; Guines, D. Investigation of the influence of the initial groove angle in the M–K model on limit strains and forming limit curves. Int. J. Mech. Sci. 2015, 98, 59–69. [Google Scholar] [CrossRef]

- Prasad, D.; Kaan, I.; Raja, M. The effects of anisotropic yield functions and their material parameters on prediction of forming limit diagrams. Int. J. Solids Struct. 2012, 49, 3528–3550. [Google Scholar] [Green Version]

- Hu, Q.; Li, X.F.; Chen, J. New robust algorithms for Marciniak-Kuczynski model to calculate the forming limit diagrams. Int. J. Mech. Sci. 2018, 148, 293–306. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Hill, R. On discontinuous plastic states, with special reference to localized necking in thin sheets. J. Mech. Phys. Solids 1952, 1, 19–30. [Google Scholar] [CrossRef]

- Jaamialahmadi, A.; Kadkhodayani, M. A modified Storen-Rice bifurcation analysis of sheet metal forming limit diagrams. J. Appl. Mech. 2012, 79, 061004. [Google Scholar] [CrossRef]

- Manopulo, N.; Hora, P.; Peters, P.; Gorji, M.; Barlat, F. An extended Modified Maximum Force Criterion for the prediction of localized necking under non-proportional loading. Int. J. Plast. 2015, 75, 189–203. [Google Scholar] [CrossRef]

- Morales-Palma, D.; Martínez-Donaire, A.J.; Vallellano, C. On the use of Maximum Force Criteria to predict localised necking in metal sheets under stretch-bending. Metals 2017, 7, 469. [Google Scholar] [CrossRef]

- Marciniak, Z.; Kuczynski, K. Limit strains in the processes of stretch-forming sheet metal. Int. J. Mech. Sci. 1967, 9, 609–612. [Google Scholar] [CrossRef]

- Butuc, M.C.; Gracio, J.J.; Barata, D.R. A theoretical study on forming limit diagrams prediction. J. Mater. Proc. Technol. 2003, 142, 714–724. [Google Scholar] [CrossRef]

- Yang, X.Y.; Lang, L.H.; Liu, K.N.; Cai, G.C.; Guo, C. Prediction of forming limit diagram of AA7075-O aluminum alloy sheet based on modified M-K model. J. Beijing Univ. Aeronaut. Astronaut. 2015, 41, 675–679. [Google Scholar]

- Wang, H.B.; Xu, Y.H. Sheet forming limit based on shear failure criterion under different constitutive relations. J. North. China Univ. Technol. 2017, 29, 61–68. [Google Scholar]

- Le, K.C.; Piao, Y. Thermodynamic dislocation theory: Size effect in torsion. Int. J. Plast. 2019, 115, 56–70. [Google Scholar] [CrossRef]

- Le, K.C.; Tran, T.M.; Langer, J.S. Thermodynamic dislocation theory of adiabatic shear banding in steel. Scr. Mater. 2018, 149, 62–65. [Google Scholar] [CrossRef] [Green Version]

- Langer, J.S.; Bouchbinder, E.; Lookman, T. Thermodynamic theory of dislocation-mediated plasticity. Acta Mater. 2010, 58, 3718–3732. [Google Scholar] [CrossRef] [Green Version]

- Du, P.M.; Lang, L.H.; Liu, B.S.; Gao, C. Theoretical prediction and parameter influence of FLDs based on M-K model. J. Plast. Eng. 2011, 18, 84–89. [Google Scholar]

- Hou, B.; Yu, Z.Q.; Li, S.H.; Lin, Z.Q. Prediction of forming limit diagram of aluminum sheet at elevated temperatures. Mater. Sci. Technol. 2009, 17, 616–619. [Google Scholar]

- Nader, A.; Farhang, P.; John, C. Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int. J. Plast. 2007, 23, 841–875. [Google Scholar]

- Barata, D.R.; Barlat, F.; Jalinier, J.M. Prediction of the forming limit diagrams of anisotropic sheets in linear and non-linear loading. Mater. Sci. Eng. 1985, 68, 151–164. [Google Scholar] [CrossRef]

- Li, X.; Guo, G.; Xiao, J.; Song, N.; Li, D. Constitutive modeling and the effects of strain-rate and temperature on the formability of Ti-6Al-4V alloy sheet. Mater. Des. 2014, 55, 325–334. [Google Scholar] [CrossRef]

- Chu, G.N.; Lin, Y.L.; Song, W.N.; Zhang, L. Forming limit of FSW aluminum alloy blank based on a new constitutive model. Acta Metal. Sin. 2017, 53, 114–122. [Google Scholar]

- Zhang, H.; Zhang, H.; Li, F.Q.; Cao, J. A novel damage model to predict ductile fracture behavior for anisotropic sheet metal. Metals 2019, 9, 595. [Google Scholar] [CrossRef]

- Woo, M.A.; Song, W.J.; Kang, B.S.; Kim, J. Acquisition and evaluation of theoretical forming limit diagram of Al 6061-T6 in electrohydraulic forming process. Metals 2019, 9, 401. [Google Scholar] [CrossRef]

- Tomáš, m.; Evin, E.; Kepič, J.; Hudák, J. Physical modelling and numerical simulation of the deep drawing process of a box-shaped product focused on material limits determination. Metals 2019, 9, 1058. [Google Scholar] [CrossRef]

- Pepelnjak, T.; Barišić, B. Computer-assisted engineering determination of the formability limit for thin sheet metals by a modified Marciniak method. J. Strain Anal. Eng. Des. 2009, 44, 459–472. [Google Scholar] [CrossRef]

- Nakazima, K.; Kikuma, T.; Hasuka, K. Study on the formability of steel sheets. Yawata Tech. Rep. 1971, 284, 678–680. [Google Scholar]

- Marciniak, Z.; Kuczynski, K.; Pokora, T. Influence of the plastic properties of the material on the forming limit diagram for sheet metal tension. Int. J. Mech. Sci. 1973, 15, 789–800. [Google Scholar] [CrossRef]

- Wang, S.H.; Cai, Z.Y.; Li, M.Z. Numerical investigation of the influence of punch element in multi-point stretch forming process. Int. J. Adv. Manuf. Technol. 2010, 49, 475–483. [Google Scholar] [CrossRef]

- Hardt, D.E.; Chung, K.; Richmond, O. In process control of strain in a stretch forming process. J. Eng. Mater. Technol. 2001, 123, 497–503. [Google Scholar] [CrossRef]

- Peng, J.; Li, W.; Han, J.; Wan, M.; Meng, B. Kinetic locus design for longitudinal stretch forming of aircraft skin components. Int. J. Adv. Manuf. Technol. 2016, 86, 3571–3582. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Wang, S.H.; Li, M.Z. Numerical investigation of multi-point forming process for sheet metal: Wrinkling, dimpling and springback. Int. J. Adv. Manuf. Technol. 2008, 37, 927–936. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Yang, Z.; Che, C.J.; Li, M.Z. Minimum deformation path sheet metal stretch-forming based on loading at discrete points. Int. J. Adv. Manuf. Technol. 2016, 87, 2683–2692. [Google Scholar] [CrossRef]

- Yang, Z.; Cai, Z.Y.; Che, C.J.; Li, M.Z. Numerical simulation research on the loading trajectory in stretch forming process based on distributed displacement loading. Int. J. Adv. Manuf. Technol. 2016, 82, 1353–1362. [Google Scholar] [CrossRef]

- Petek, A.; Pepelnjak, T.; Kuzman, K. An improved method for determining a forming limit diagram in the digital environment. J. Mech. Eng. 2005, 51, 330–345. [Google Scholar]

- Ramos, G.C.; Stout, M.; Bolmaro, R.E.; Signorelli, J.W.; Serenelli, M.; Bertinetti, M.A.; Turner, P. Study of a drawing-quality sheet steel. II: Forming-limit curves by experiments and micromechanical simulations. Int. J. Solids Struct. 2010, 47, 2294–2299. [Google Scholar] [CrossRef] [Green Version]

- Zahedi, A.; Dariani, B.M.; Mirnia, M.J. Experimental determination and numerical prediction of necking and fracture forming limit curves of laminated Al/Cu sheets using a damage plasticity model. Int. J. Mech. Sci. 2019, 153–154, 341–358. [Google Scholar] [CrossRef]

| Material Properties | Orientation | ||

|---|---|---|---|

| 0° | 45° | 90° | |

| Yield stress (MPa) | 253.8 | 242.2 | 258.8 |

| Ultimate tensile strength (MPa) | 318.1 | 306.0 | 323.1 |

| Uniform elongation (%) | 16.17 | 15.78 | 16.36 |

| Anisotropic parameter (r) | 0.824 | 0.803 | 0.818 |

| Average value of r | 0.812 | ||

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| w (mm) | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| R (mm) | 40 | 37.5 | 35 | 30 | 25 | 20 | * | * | * |

| l (mm) | 40 | 42.5 | 45 | 50 | 55 | 60 | * | * | * |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Cai, Z.; He, D.; Li, L. Aluminum Alloy Sheet-Forming Limit Curve Prediction Based on Original Measured Stress–Strain Data and Its Application in Stretch-Forming Process. Metals 2019, 9, 1129. https://doi.org/10.3390/met9101129

Sun L, Cai Z, He D, Li L. Aluminum Alloy Sheet-Forming Limit Curve Prediction Based on Original Measured Stress–Strain Data and Its Application in Stretch-Forming Process. Metals. 2019; 9(10):1129. https://doi.org/10.3390/met9101129

Chicago/Turabian StyleSun, Lirong, Zhongyi Cai, Dongye He, and Li Li. 2019. "Aluminum Alloy Sheet-Forming Limit Curve Prediction Based on Original Measured Stress–Strain Data and Its Application in Stretch-Forming Process" Metals 9, no. 10: 1129. https://doi.org/10.3390/met9101129

APA StyleSun, L., Cai, Z., He, D., & Li, L. (2019). Aluminum Alloy Sheet-Forming Limit Curve Prediction Based on Original Measured Stress–Strain Data and Its Application in Stretch-Forming Process. Metals, 9(10), 1129. https://doi.org/10.3390/met9101129