Effect of the High-Pressure Torsion (HPT) and Subsequent Isothermal Annealing on the Phase Transformation in Biomedical Ti15Mo Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

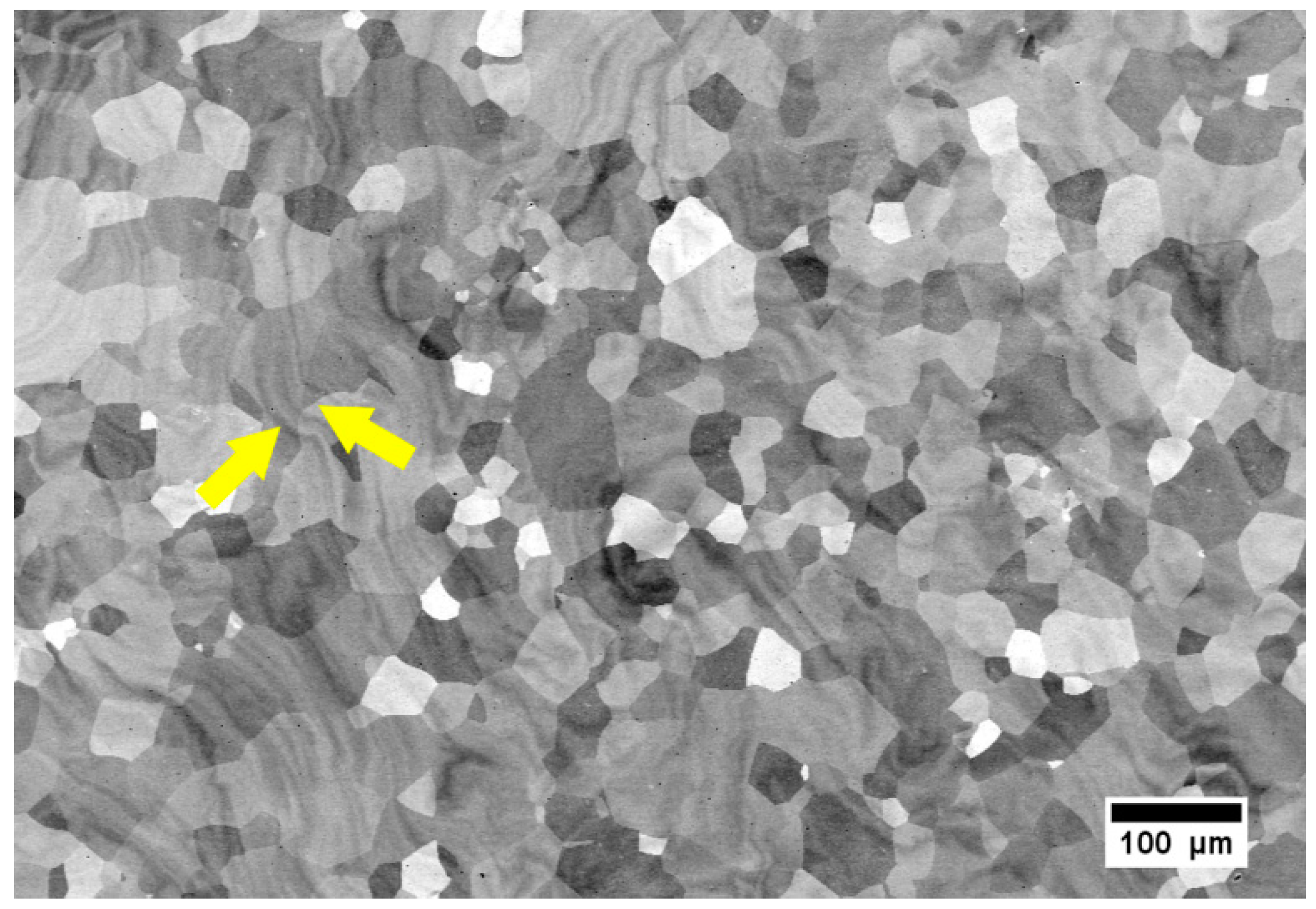

3.1. Initial Conditions

Microstructure

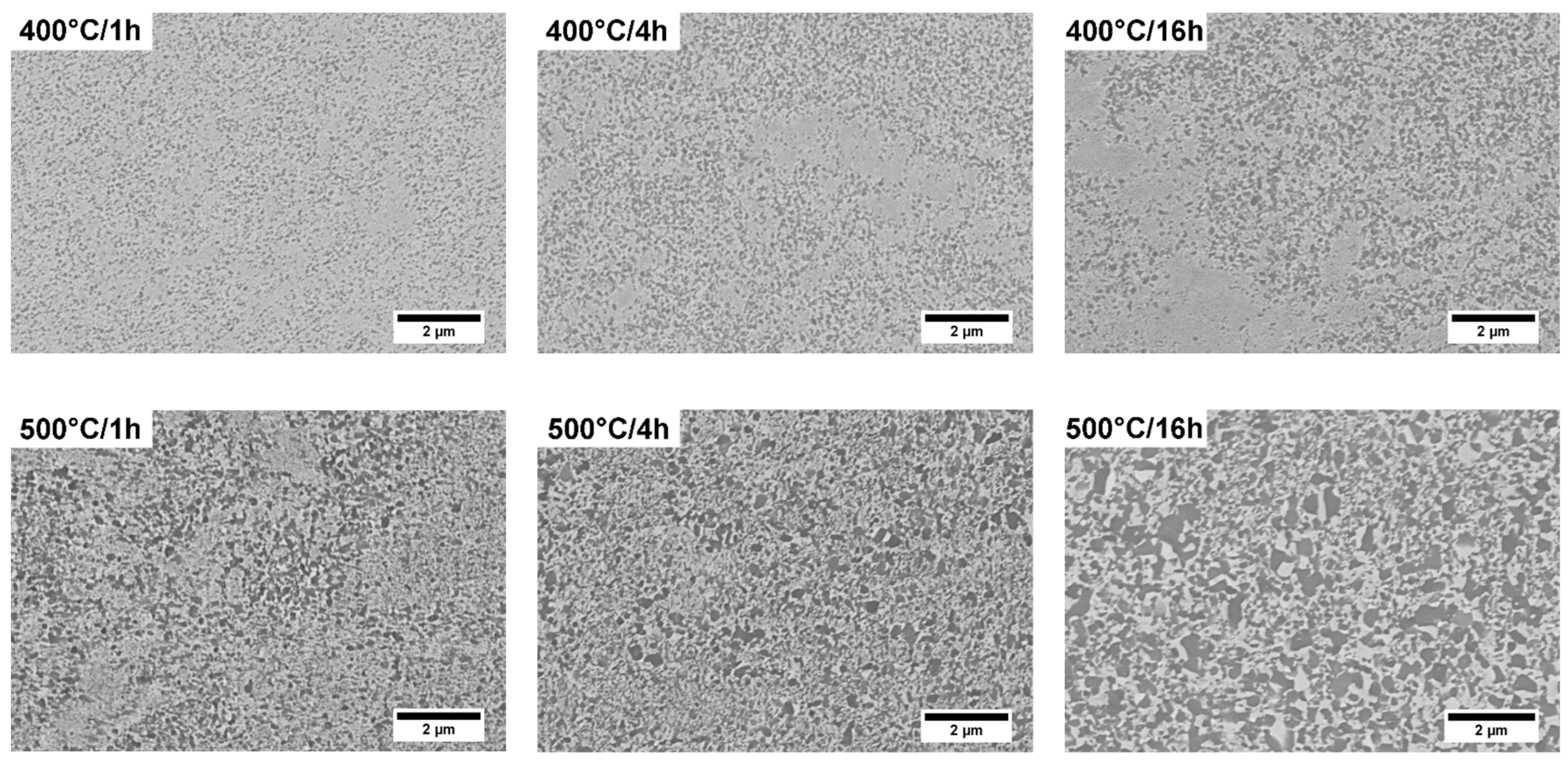

3.2. Non-Deformed and HPT-Deformed Material after Ageing

3.2.1. The Evolution of Microstructure during Ageing

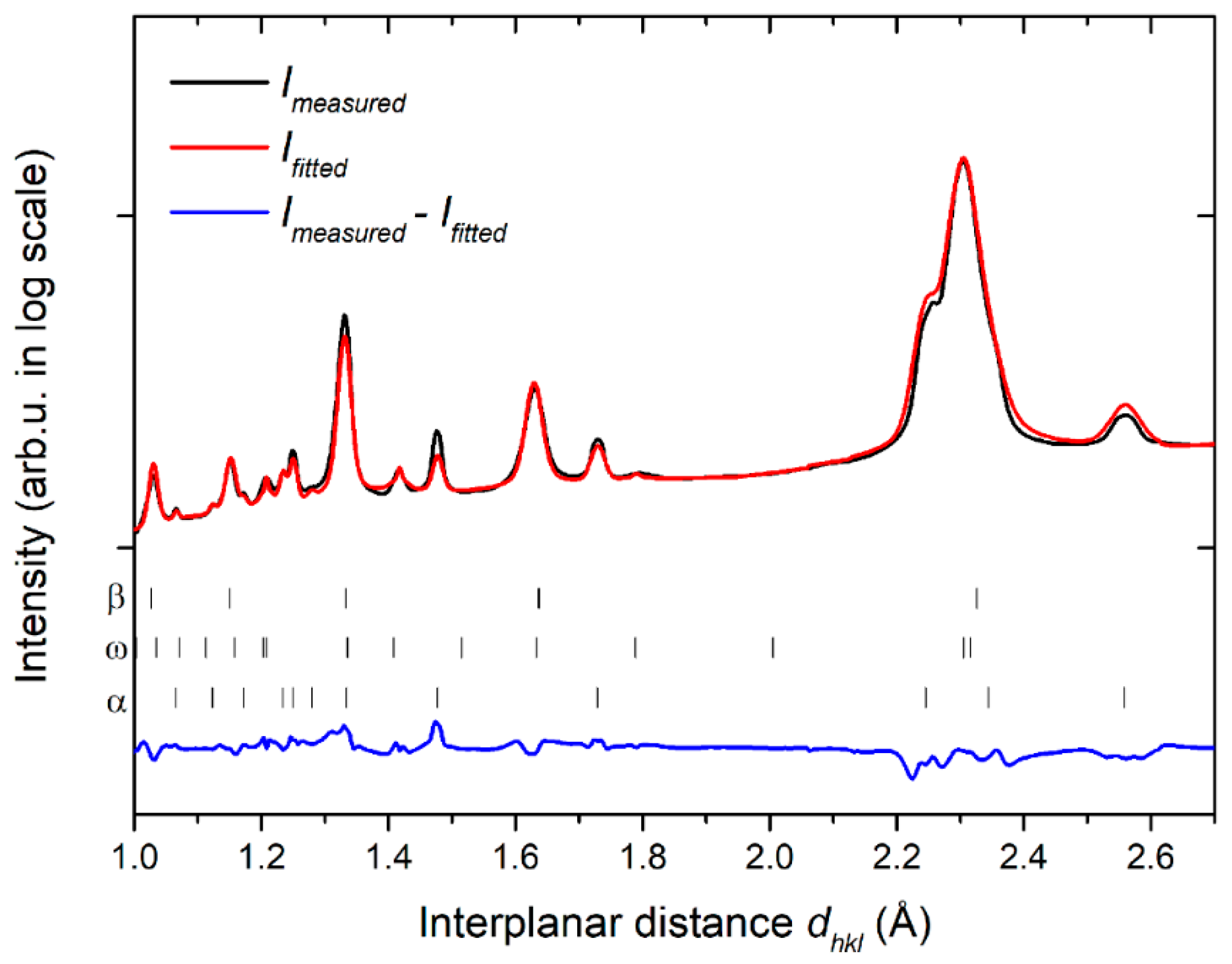

3.2.2. Evolution of Phase Composition during Ageing

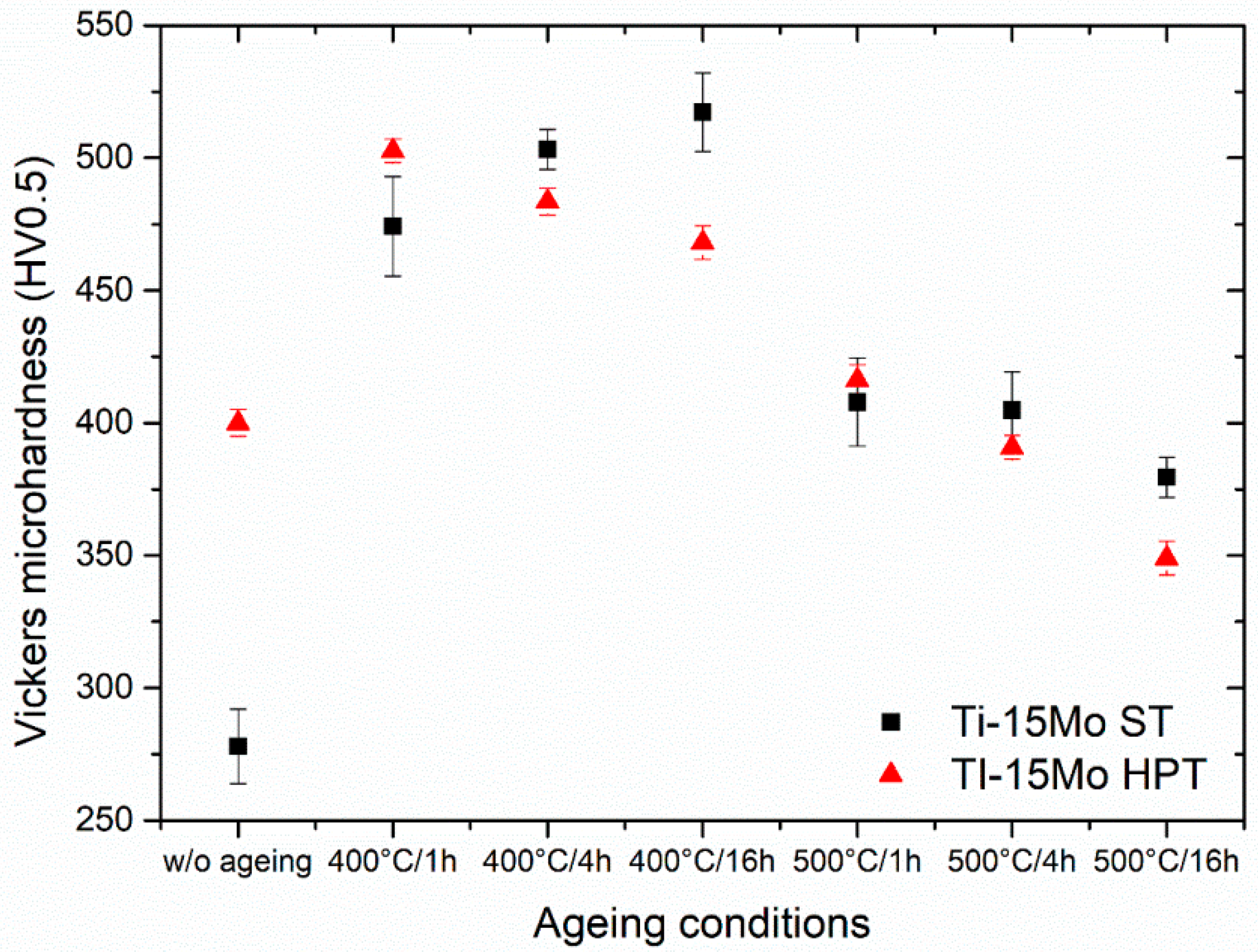

3.2.3. Microhardness Evolution during Ageing

4. Discussion

4.1. Enhanced α Phase Precipitation

4.2. Microhardness Evolution

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Steinemann, S.G. Titanium—the material of choice? Periodontol 2000 1998, 17, 7–21. [Google Scholar] [CrossRef]

- Weiss, I.; Semiatin, S.L. Thermomechanical processing of beta titanium alloys—An overview. Mater. Sci. Eng. A 1998, 243, 46–65. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Kawabe, Y.; Muneki, S. Strengthening and Toughening of Titanium Alloys. ISIJ Int. 1991, 31, 785–791. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Václavová, K.; Stráský, J.; Polyakova, V.; Stráská, J.; Nejezchlebová, J.; Seiner, H.; Semenova, I.; Janeček, M. Microhardness and microstructure evolution of ultra-fine grained Ti-15Mo and TIMETAL LCB alloys prepared by high pressure torsion. Mater. Sci. Eng. A 2017, 682, 220–228. [Google Scholar] [CrossRef]

- Kent, D.; Wang, G.; Yu, Z.; Ma, X.; Dargusch, M. Strength enhancement of a biomedical titanium alloy through a modified accumulative roll bonding technique. J. Mech. Behav. Biomed. 2011, 4, 405–416. [Google Scholar] [CrossRef]

- Yilmazer, H.; Niinomi, M.; Nakai, M.; Cho, K.; Hieda, J.; Todaka, Y.; Miyazaki, T. Mechanical properties of a medical β-type titanium alloy with specific microstructural evolution through high-pressure torsion. Mater. Sci. Eng. C 2013, 33, 2499–2507. [Google Scholar] [CrossRef]

- Janeček, M.; Čížek, J.; Stráský, J.; Václavová, K.; Hruška, P.; Polyakova, V.; Gatina, S.; Semenova, I. Microstructure evolution in solution treated Ti15Mo alloy processed by high pressure torsion. Mater. Charact. 2014, 98, 233–240. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Semiatin, S.L.; Ward, C.H. Aging response of coarse- and fine-grained β titanium alloys. Mater. Sci. Eng. A 2005, 405, 296–305. [Google Scholar] [CrossRef]

- Makino, T.; Chikaizumi, R.; Nagaoka, T.; Furuhara, T.; Makino, T. Microstructure development in a thermomechanically processed Ti15V3Cr3Sn3Al alloy. Mater. Sci. Eng. A 1996, 213, 51–60. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Requena, G.; Schwarz, S.; Warchomicka, F.; Buslaps, T. Influence of phase transformation kinetics on the formation of α in a β-quenched Ti–5Al–5Mo–5V–3Cr–1Zr alloy. Acta Mater. 2015, 95, 90–101. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Requena, G.; Warchomicka, F.; Stark, A.; Schell, N.; Buslaps, T. Phase transformation kinetics during continuous heating of a β-quenched Ti–10V–2Fe–3Al alloy. J. Mater. Sci. 2015, 50, 1412–1426. [Google Scholar] [CrossRef]

- Zheng, Y.; Williams, R.E.A.; Sosa, J.M.; Talukder, A.; Wang, Y.; Banerjee, R.; Fraser, H.L. The indirect influence of the ω phase on the degree of refinement of distributions of the α phase in metastable β-Titanium alloys. Acta Mater. 2016, 103, 165–173. [Google Scholar] [CrossRef]

- Zheng, Y.; Williams, R.E.A.; Wang, D.; Shi, R.; Nag, S.; Kami, P.; Banerjee, R.; Wang, Y.; Fraser, H.L. Role of ω phase in the formation of extremely refined intragranular α precipitates in metastable β-titanium alloys. Acta Mater. 2016, 103, 850–858. [Google Scholar] [CrossRef]

- Li, T.; Kent, D.; Sha, G.; Liu, H.; Fries, S.G.; Ceguerra, A.V.; Dargusch, M.S.; Cairney, J.M. Nucleation driving force for ω-assisted formation of α and associated ω morphology in β-Ti alloys. Scripta Mater. 2018, 155, 149–154. [Google Scholar] [CrossRef]

- Zháňal, P.; Harcuba, P.; Hájek, M.; Smola, B.; Stráský, J.; Šmilauerová, J.; Veselý, J.; Janeček, M. Evolution of ω phase during heating of metastable β titanium alloy Ti–15Mo. J. Mater. Sci. 2018, 53, 837–845. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. ω-Assisted nucleation and growth of α precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Šmilauerová, J.; Harcuba, P.; Kriegner, D.; Holý, V. On the completeness of the β→ω transformation in metastable β titanium alloys. J. Appl. Crystallogr. 2017, 50, 283–287. [Google Scholar] [CrossRef]

- Kuan, T.S.; Ahrens, R.R.; Sass, S.L. The stress-induced omega phase transformation in Ti-V alloys. Metall. Trans. A 1975, 6, 1767–1774. [Google Scholar] [CrossRef]

- Zháňal, P.; Harcuba, P.; Šmilauerová, J.; Stráský, J.; Janeček, M.; Smola, B.; Hájek, M. Phase Transformations in Ti-15Mo Investigated by in situ Electrical Resistance. Acta Phys. Pol. A 2015, 128, 779–783. [Google Scholar] [CrossRef]

- Devaraj, A.; Nag, S.; Srinivasan, R.; Williams, R.E.A.; Banerjee, S.; Banerjee, R.; Fraser, H.L. Experimental evidence of concurrent compositional and structural instabilities leading to ω precipitation in titanium–molybdenum alloy. Acta Mater. 2012, 60, 596–609. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Ivanisenko, Y.V.; Rauch, E.F.; Baudelet, B. Structure and deformaton behaviour of Armco iron subjected to severe plastic deformation. Acta Mater. 1996, 44, 4705–4712. [Google Scholar] [CrossRef]

- Václavová, K.; Stráský, J.; Zháňal, P.; Veselý, J.; Polyakova, V.; Semenova, I.; Janeček, M. Ultra-fine grained microstructure of metastable beta Ti-15Mo alloy and its effects on the phase transformations. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 012021. [Google Scholar] [CrossRef]

- Schell, N.; King, A.; Beckmann, F.; Fischer, T.; Müller, M.; Schreyer, A. The High Energy Materials Science Beamline (HEMS) at PETRA III. Mater. Sci. Forum 2014, 772, 57–61. [Google Scholar] [CrossRef]

- Dollase, W.A. Correction of intensities for preferred orientation in powder diffractometry: Application of the March model. J. Appl. Crystallogr. 1986, 19, 267–272. [Google Scholar] [CrossRef]

- Bartha, K. Phase transformation in ultra-fine grained titnaium alloys. Ph.D. Thesis, Charles University, Prague, Czech Republic, 19 June 2019. [Google Scholar]

- Hauk, V. Structural and Residual Stress Analysis by Nondestructive Methods, 1st ed.; Elsevier: Amsterdam, Netherlands, 1997. [Google Scholar]

- Šmilauerová, J.; Janeček, M.; Harcuba, P.; Stráský, J.; Veselý, J.; Kužel, R.; Rack, H.J. Ageing response of sub-transus heat treated Ti–6.8Mo–4.5Fe–1.5Al alloy. J. Alloy. Compd. 2017, 724, 373–380. [Google Scholar] [CrossRef]

- Furuhara, T.; Nakamori, H.; Maki, T. Crystallography of α Phase Precipitated on Dislocations and Deformation Twin Boundaries in a β Titanium Alloy. Mater. Trans. JIM 1992, 33, 585–595. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, T.; Huang, M.; Wang, D.; Sun, Q.; Wang, Y.; Sun, J. Design of uniform nano α precipitates in a pre-deformed β-Ti alloy with high mechanical performance. J. Mater. Res. Technol. 2019, 8, 777–787. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Knisley, S.L.; Fagin, P.N.; Barker, D.R.; Zhang, F. Microstructure evolution during alpha-beta heat treatment of Ti-6Al-4V. Metall. Mater. Trans. A 2003, 34, 2377–2386. [Google Scholar] [CrossRef]

- Legros, M.; Dehm, G. Obsevation of Giant diffusivitiy along dislocation core. Science 2008, 319, 1646–1649. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Tsuchiya, K.; Emura, S.; Min, X. Effect of High-Pressure Torsion Process on Precipitation Behavior of α Phase in β-Type Ti–15Mo Alloy. Mater. Trans. 2014, 55, 877–884. [Google Scholar] [CrossRef]

- Zafari, A.; Xia, K. Formation of equiaxed α during ageing in a severely deformed metastable β Ti alloy. Scr. Mater. 2016, 124, 151–154. [Google Scholar] [CrossRef]

- Furuhara, T.; Makino, T.; Idei, Y.; Ishigaki, H.; Takada, A.; Maki, T. Morphology and Crystallography of α Precipitates in β Ti–Mo Binary Alloys. Mater. Trans. JIM 1998, 39, 31–39. [Google Scholar] [CrossRef]

- Xu, W.; Wu, X.; Stoica, M.; Calin, M.; Kühn, U.; Eckert, J.; Xia, K. On the formation of an ultrafine-duplex structure facilitated by severe shear deformation in a Ti–20Mo β-type titanium alloy. Acta Mater. 2012, 60, 5067–5078. [Google Scholar] [CrossRef]

- Xu, W.; Edwards, D.P.; Wu, X.; Stoica, M.; Calin, M.; Kühn, U.; Eckert, J.; Xia, K. Promoting nano/ultrafine-duplex structure via accelerated α precipitation in a β-type titanium alloy severely deformed by high-pressure torsion. Scr. Mater. 2013, 68, 67–70. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.; Hu, L.; Liao, G.; Zhao, X.; Xu, H. Suppression of isothermal ω phase by dislocation tangles and grain boundaries in metastable β-type titanium alloys. J. Alloy. Compd. 2013, 550, 35–38. [Google Scholar] [CrossRef]

- Friedel, J. Dislocations, 1st ed.; Smoluchovski, R., Kurti, N., Eds.; Pergamon Press: Oxford, UK, 1964. [Google Scholar]

- Labusch, R. A Statistical Theory of Solid Solution Hardening. Phys. Status Solidi (b) 1970, 41, 659–669. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Klimova, M.; Stepanov, N.; Vershinina, T.; Ivanisenko, Y.; Salishchev, G. Effect of High-Pressure Torsion on Structure and Properties of Ti-15Mo/TiB Metal-Matrix Composite. Materials 2018, 11, 2426. [Google Scholar] [CrossRef] [PubMed]

| Element | Brighter Part (wt.%) | Darker Part (wt.%) |

|---|---|---|

| Ti | 83.3 ± 0.5 | 85.7 ± 0.4 |

| Mo | 16.7 ± 0.5 | 14.3 ± 0.4 |

| Material | Volume Fraction of the β Phase | Volume Fraction of the ω Phase | Volume Fraction of the α Phase |

|---|---|---|---|

| Ti15Mo HPT | 72% ± 5% | 28% ± 5% | - |

| Ti15Mo HPT + ageing 400 °C/1 h | 67% ± 5% | 9% ± 3% | 23% ± 4% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartha, K.; Stráský, J.; Veverková, A.; Barriobero-Vila, P.; Lukáč, F.; Doležal, P.; Sedlák, P.; Polyakova, V.; Semenova, I.; Janeček, M. Effect of the High-Pressure Torsion (HPT) and Subsequent Isothermal Annealing on the Phase Transformation in Biomedical Ti15Mo Alloy. Metals 2019, 9, 1194. https://doi.org/10.3390/met9111194

Bartha K, Stráský J, Veverková A, Barriobero-Vila P, Lukáč F, Doležal P, Sedlák P, Polyakova V, Semenova I, Janeček M. Effect of the High-Pressure Torsion (HPT) and Subsequent Isothermal Annealing on the Phase Transformation in Biomedical Ti15Mo Alloy. Metals. 2019; 9(11):1194. https://doi.org/10.3390/met9111194

Chicago/Turabian StyleBartha, Kristína, Josef Stráský, Anna Veverková, Pere Barriobero-Vila, František Lukáč, Petr Doležal, Petr Sedlák, Veronika Polyakova, Irina Semenova, and Miloš Janeček. 2019. "Effect of the High-Pressure Torsion (HPT) and Subsequent Isothermal Annealing on the Phase Transformation in Biomedical Ti15Mo Alloy" Metals 9, no. 11: 1194. https://doi.org/10.3390/met9111194

APA StyleBartha, K., Stráský, J., Veverková, A., Barriobero-Vila, P., Lukáč, F., Doležal, P., Sedlák, P., Polyakova, V., Semenova, I., & Janeček, M. (2019). Effect of the High-Pressure Torsion (HPT) and Subsequent Isothermal Annealing on the Phase Transformation in Biomedical Ti15Mo Alloy. Metals, 9(11), 1194. https://doi.org/10.3390/met9111194