Strain Compensation Constitutive Model and Parameter Optimization for Nb-Contained 316LN

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Hot Compression Deformation Behaviors

3.2. Constitutive Model

3.2.1. Determination of Material Constants for the Constitutive Model

3.2.2. Constitutive Model Base on Strain Compensation

3.2.3. Verification

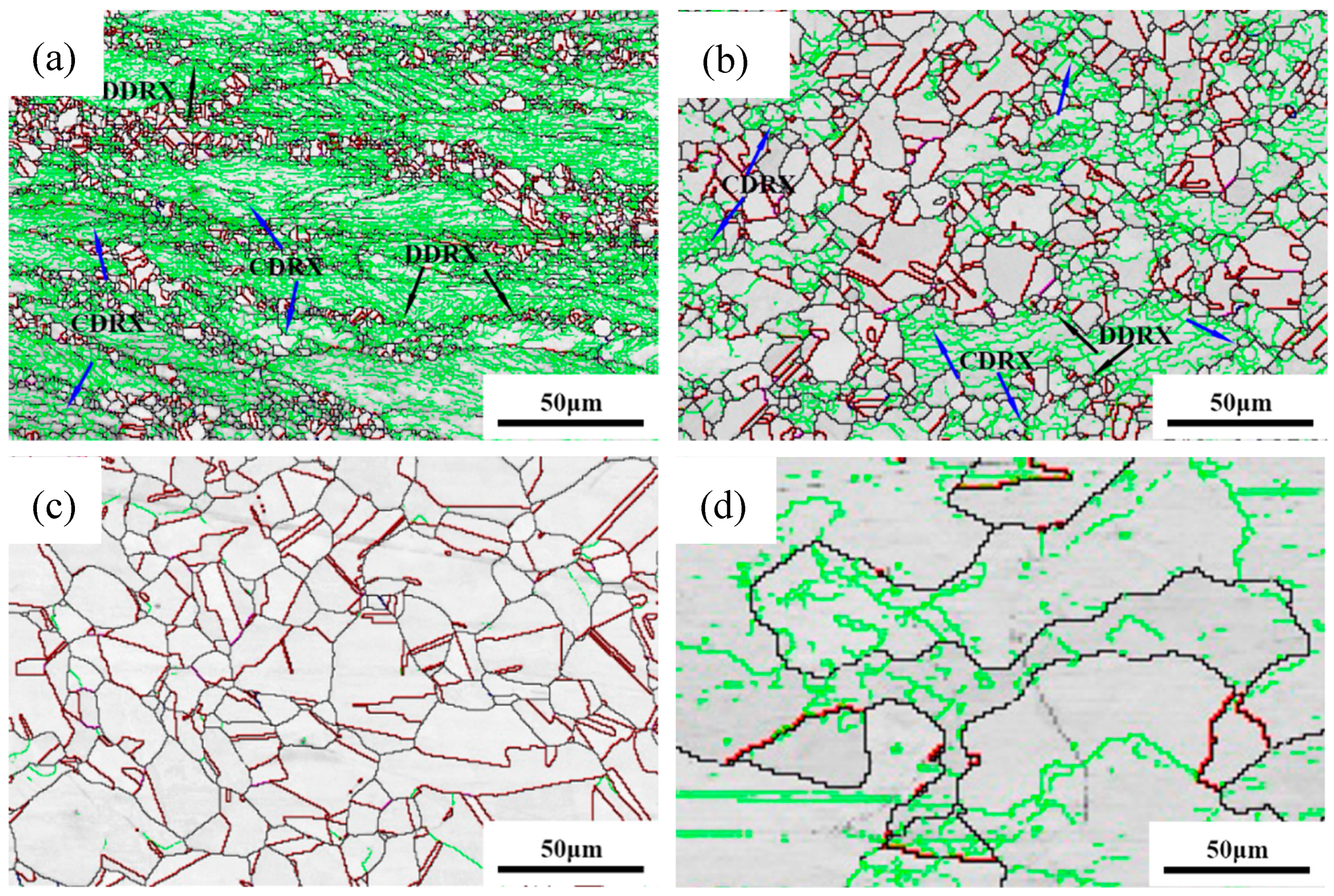

3.3. Microstructure Evolution

4. Conclusions

- (1)

- A strain compensation constitutive model of Nb-contained 316LN was developed. The relationship between material constants and true strain was fitted by fifth order polynomial. The comparison between the predicted flow stress and the experimental flow stress indicates that the proposed model possesses high accuracy and reliability to predict the hot deformation behavior of Nb-contained 316LN.

- (2)

- DDRX characterized by grain boundary bulging nuclei and CDRX characterized by subgrain evolution are two main DRX mechanisms during the hot deformation of Nb-contained 316LN.

- (3)

- Parameters were optimized based on the results of microstructure analyses. Parameters with temperature ≤1000 °C, strain rate ≥0.1 s−1 and temperature ≥1200 °C, strain rate ≤0.01 s−1 should be avoided. The optimum processing parameters should be chosen in the temperature range of 1100~1200 °C and strain rate range of 0.01~1 s−1.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, D.W.; Chang, J.H.; Ryu, W.S. Evaluation of the creep-fatigue damage mechanism of type 316L and type 316LN stainless steel. Int. J. Pres. Ves. Pip. 2008, 85, 378–384. [Google Scholar] [CrossRef]

- Li, X.Q.; Zhao, J.J.; Xu, J.C.; Liu, X. Mechanical Properties and Defective Effects of 316LN Stainless Steel by First-Principles Simulations. J. Mater. Sci. Technol. 2011, 27, 1029–1033. [Google Scholar] [CrossRef]

- Ganesh Kumar, J.; Ganesan, V.; Laha, K.; Mathew, M.D. Time dependent design curves for a high nitrogen grade of 316LN stainless steel for fast reactor applications. Nucl. Eng. Des. 2013, 265, 949–956. [Google Scholar] [CrossRef]

- Xiao, W.K.; Zhu, L.; Zhang, F.J.; Dai, K.S.; Zai, X.; Yang, X.; Chen, B.J. Effect of heat input on cryogenic toughness of 316LN austenitic stainless steel NG-MAG welding joints with large thickness. Mater. Des. 2015, 86, 160–167. [Google Scholar]

- Dai, K.S.; He, P.; Zhu, L.; Zhang, F.J.; Chen, F.Y.; Zhai, X.; Xiao, W.K. Effect of solution treatment on microstructure and cryogenic toughness of 316LN austenite stainless steel weld metal welded by NG-MAG arc welding. Fusion Eng. Des. 2017, 125, 178–188. [Google Scholar] [CrossRef]

- Xu, D.M.; Li, G.Q.; Wan, X.L.; Xiong, R.L.; Xu, G.; Wu, K.M.; Somani, M.C.; Misra, R.D.K. Deformation behavior of high yield strength—High ductility ultrafine-grained 316LN austenitic stainless steel. Mater. Sci. Eng. A 2017, 688, 407–415. [Google Scholar] [CrossRef]

- Kim, D.W. Influence of nitrogen-induced grain refinement on mechanical properties of nitrogen alloyed type 316LN stainless steel. J. Nucl. Mater. 2012, 420, 473–478. [Google Scholar] [CrossRef]

- Vodárek, V. Creep behaviour and microstructural evolution in AISI 316LN + Nb steels at 650 °C. Mater. Sci. Eng. A 2011, 528, 4232–4238. [Google Scholar] [CrossRef]

- Perron, A.; Toffolon-Masclet, C.; Ledoux, X.; Buy, F.; Guilbert, T.; Urvoy, S.; Bosonnet, S.; Marini, B.; Cortial, F.; Tecier, G.; et al. Understanding sigma-phase precipitation in a stabilized austenitic stainless steel (316Nb) through complementary CALPHAD-based and experimental investigations. Acta Mater. 2014, 79, 16–29. [Google Scholar] [CrossRef]

- Lu, W.J.; Hua, X.Z.; Zhou, X.L.; Huang, J.H.; Peng, X.Y. Aging precipitation behaviors of Nb-contained 316LN SS. J. Alloy. Compd. 2017, 701, 993–1002. [Google Scholar] [CrossRef]

- Lin, Y.C.; Ding, Y.; Chen, M.S.; Deng, J. A new phenomenological constitutive model for hot tensile deformation behaviors of a typical Al–Cu–Mg alloy. Mater. Des. 2013, 52, 118–127. [Google Scholar] [CrossRef]

- EI Mehtedi, M.; Gabrielli, F.; Spigarelli, S. Hot workability in process modeling of a bearing steel by using combined constitutive equations and dynamic material model. Mater. Des. 2014, 53, 398–404. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.T.; Jiang, Y.Q. A Phenomenological Constitutive Model for Describing Thermo-Viscoplastic Behavior of Al-Zn-Mg-Cu Alloy Under Hot Working Condition. Exp. Mech. 2012, 52, 993–1002. [Google Scholar] [CrossRef]

- Vilamosa, V.; Clausen, A.H.; Børvik, T.; Holmedal, B.; Hopperstad, O.S. A physically-based constitutive model applied to AA6082 aluminium alloy at large strains, high strain rates and elevated temperatures. Mater. Des. 2016, 103, 391–405. [Google Scholar] [CrossRef]

- Bobbili, R.; Ramudu, B.V.; Madhu, V. A physically-based constitutive model for hot deformation of Ti-10-2-3 alloy. J. Alloys Compd. 2017, 696, 295–303. [Google Scholar] [CrossRef]

- Dong, D.Q.; Chen, F.; Cui, Z.S. A physically-based constitutive model for SA508-III steel: Modeling and experimental verification. Mater. Sci. Eng. A 2015, 634, 103–115. [Google Scholar] [CrossRef]

- Guo, L.F.; Li, B.C.; Zhang, Z.M. Constitutive relationship model of TC21 alloy based on artificial neural network. Trans. Nonferrous Met. Soc. China 2013, 23, 1761–1765. [Google Scholar] [CrossRef]

- He, A.; Wang, X.T.; Xie, G.L.; Yang, X.Y.; Zhang, H.L. Modified Arrhenius-type Constitutive Model and Artificial Neural Network-based Model for Constitutive Relationship of 316LN Stainless Steel during Hot Deformation. J. Iron Steel Res. Int. 2015, 22, 721–729. [Google Scholar] [CrossRef]

- Rezaei Ashtiani, H.R.; Shahsavari, P. A comparative study on the phenomenological and artificial neural network models to predict hot deformation behavior of AlCuMgPb alloy. J. Alloys Compd. 2016, 687, 263–273. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H.S.; Misra, R.D.K.; Yi, X.; Zhang, J.C.; Ma, T.J. On the hot deformation behavior of AISI 420 stainless steel based on constitutive analysis and CSL model. Mater. Sci. Eng. A 2014, 593, 111–119. [Google Scholar] [CrossRef]

- Pu, E.X.; Feng, H.; Liu, M.; Zheng, W.; Dong, H.; Song, Z. Constitutive Modeling for Flow Behaviors of Superaustenitic Stainless Steel S32654 during Hot Deformation. J. Iron Steel Res. Int. 2016, 23, 178–184. [Google Scholar] [CrossRef]

- Tan, Y.B.; Ma, Y.H.; Zhao, F. Hot deformation behavior and constitutive modeling of fine grained Inconel 718 superalloy. J. Alloys Compd. 2018, 741, 85–96. [Google Scholar] [CrossRef]

- Lin, Y.C.; Nong, F.Q.; Chen, X.M.; Chen, D.D.; Chen, M.S. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy. Vacuum 2017, 137, 104–114. [Google Scholar] [CrossRef]

- Li, J.; Li, F.G.; Cai, J.; Wang, R.T.; Yuan, Z.W.; Ji, G.L. Comparative investigation on the modified Zerilli-Armstrong model and Arrhenius-type model to predict the elevated-temperature flow behaviour of 7050 aluminium alloy. Comput. Mater. Sci. 2013, 71, 56–65. [Google Scholar] [CrossRef]

- Changizian, P.; Zarei-Hanzak, A.; Ali, A.R. The high temperature flow behavior modeling of AZ81 magnesium alloy considering strain effects. Mater. Des. 2012, 39, 384–389. [Google Scholar] [CrossRef]

- Mandal, S.; Bhadur, A.K.; Sarma, V.S. Role of twinning on dynamic recrystallization and microstructure during moderate to high strain rate hot deformation of a Ti-Modified austenitic stainless steel. Metall. Mater. Trans. A 2012, 43, 2056–2068. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Pavese, M.; Manfredi, D.; Biamino, S. Hot deformation behavior of Zr-1%Nb alloy: Flow curve analysis and microstructure observations. Mater. Sci. Eng. A 2017, 696, 366–373. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Mataya, M.C.; Nilsson, E.R.; Brown, E.L.; Krauss, G. Hot working and recrystallization of as-cast 317L. Metall. Mater. Trans. A 2003, 34, 3021–3041. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. App. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Liao, C.; Wu, H.; Wu, C.; Zhu, F.; Lee, S. Hot deformation behavior and flow stress modeling of annealed AZ61 Mg alloys. Prog. Natl. Sci. Mater. Int. 2014, 24, 253–265. [Google Scholar] [CrossRef]

| Material Constants | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 |

| 0.0083 | 0.0076 | 0.0074 | 0.0075 | 0.0077 | 0.0078 | 0.0079 | 0.0079 | |

| n | 5.96 | 5.45 | 5.06 | 4.66 | 4.28 | 4.04 | 3.94 | 3.93 |

| Q(KJ/mol) | 507.661 | 495.109 | 485.028 | 468.141 | 447.376 | 430.784 | 425.602 | 421.504 |

| lnA | 41.96 | 40.57 | 40.286 | 38.86 | 37.06 | 35.61 | 35.12 | 34.74 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liu, J. Strain Compensation Constitutive Model and Parameter Optimization for Nb-Contained 316LN. Metals 2019, 9, 212. https://doi.org/10.3390/met9020212

Li J, Liu J. Strain Compensation Constitutive Model and Parameter Optimization for Nb-Contained 316LN. Metals. 2019; 9(2):212. https://doi.org/10.3390/met9020212

Chicago/Turabian StyleLi, Jingdan, and Jiansheng Liu. 2019. "Strain Compensation Constitutive Model and Parameter Optimization for Nb-Contained 316LN" Metals 9, no. 2: 212. https://doi.org/10.3390/met9020212

APA StyleLi, J., & Liu, J. (2019). Strain Compensation Constitutive Model and Parameter Optimization for Nb-Contained 316LN. Metals, 9(2), 212. https://doi.org/10.3390/met9020212