FeSiBPNbCu Bulk Nanocrystalline Alloys with High GFA and Excellent Soft-Magnetic Properties

Abstract

:1. Introduction

2. Experimental Procedures

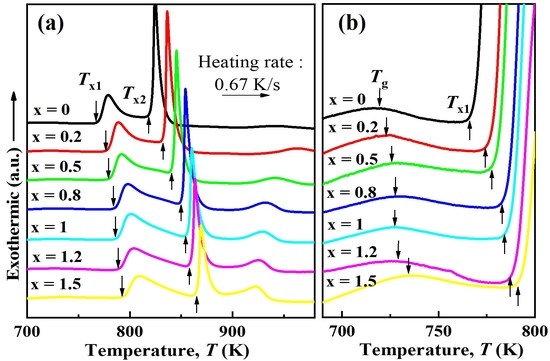

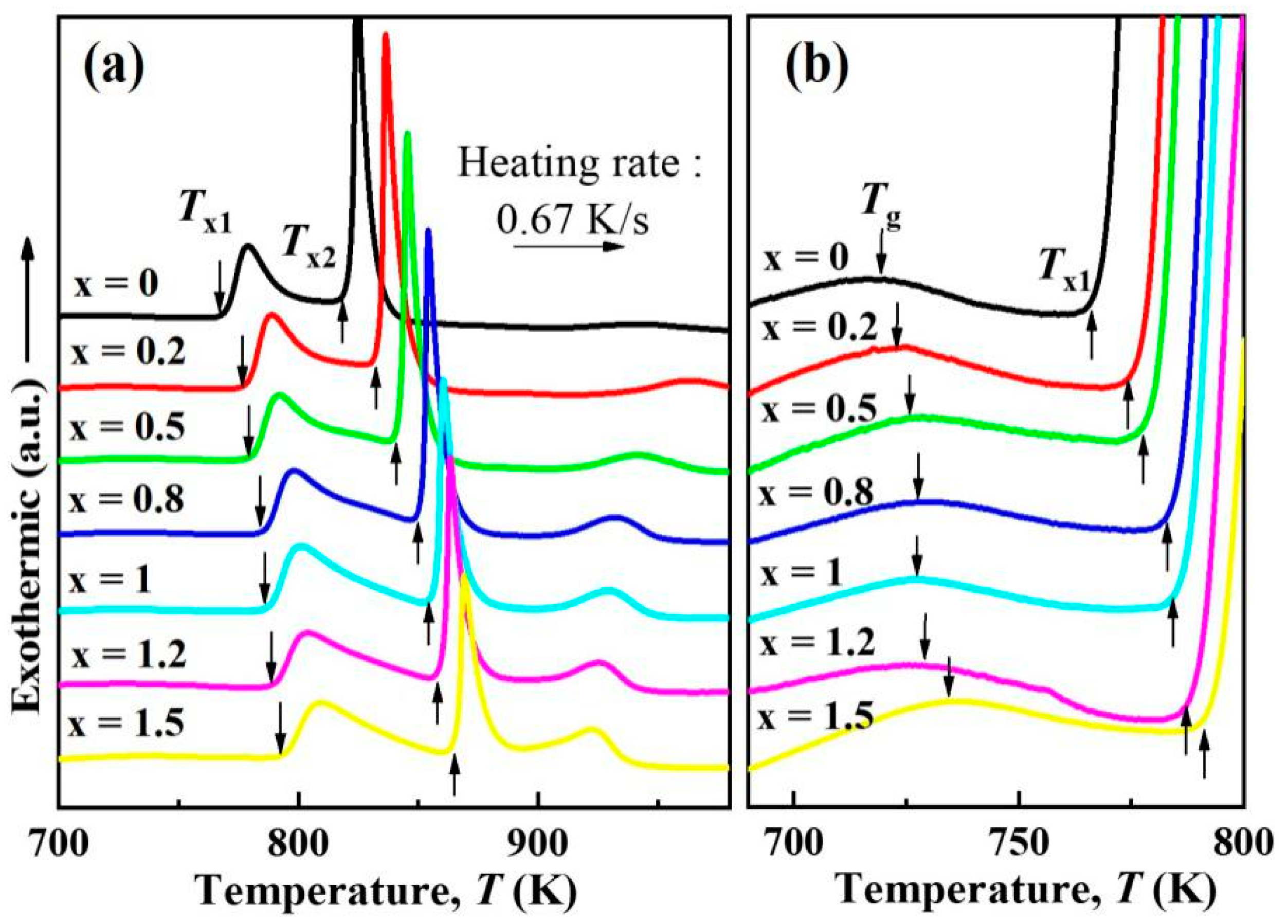

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yoshizawa, Y.; Oguma, S.; Yamauchi, K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- Gheiratmand, T.; Hosseini, H.R.M. Finemet nanocrystalline soft magnetic alloy: Investigation of glass forming ability, crystallization mechanism, production techniques, magnetic softness and the effect of replacing the main constituents by other elements. J. Magn. Magn. Mater. 2016, 408, 177–192. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Wang, Y.C.; Zhang, Y.; Takeuchi, A.; Makino, A.; Kawazoe, Y. Investigation on the crystallization mechanism difference between FINEMET (R) and NANOMET (R) type Fe-based soft magnetic amorphous alloys. J. Appl. Phys. 2016, 120, 6. [Google Scholar] [CrossRef]

- Ohta, M.; Yoshizawa, Y. Magnetic properties of nanocrystalline Fe82.65Cu1.35SixB16−x alloys (x = 0–7). Appl. Phys. Lett. 2007, 91, 062517. [Google Scholar] [CrossRef]

- Makino, A.; Men, H.; Kubota, T.; Yubuta, K.; Inoue, A. New Fe-metalloids based nanocrystalline alloys with high Bs of 1.9T and excellent magnetic softness. J. Appl. Phys. 2009, 105. [Google Scholar] [CrossRef]

- Yu, Q.; Wang, X.D.; Lou, H.B.; Cao, Q.P.; Jiang, J.Z. Atomic packing in Fe-based metallic glasses. Acta Mater. 2016, 102, 116–124. [Google Scholar] [CrossRef]

- Matsuura, M.; Nishijima, M.; Takenaka, K.; Takeuchi, A.; Ofuchi, H.; Makino, A. Evolution of fcc Cu clusters and their structure changes in the soft magnetic Fe85.2Si1B9P4Cu0.8 (NANOMET) and FINEMET alloys observed by X-ray absorption fine structure. J. Appl. Phys. 2015, 117, 4. [Google Scholar] [CrossRef]

- Hono, K.; Ping, D.H.; Ohnuma, M.; Onodera, H. Cu clustering and Si partitioning in the early crystallization stage of an Fe73.5Si13.5B9Nb3Cu1 amorphous alloy. Acta Mater. 1999, 47, 997–1006. [Google Scholar] [CrossRef]

- Ghidelli, M.; Idrissi, H.; Sébastien, G.; Blandin, J.J.; Raskin, J.P.; Schryvers, D.; Pardoen, T. Homogeneous flow and size dependent mechanical behavior in highly ductile Zr65Ni35, metallic glass films. Acta Mater. 2017, 131, 246–259. [Google Scholar] [CrossRef]

- Tian, L.; Cheng, Y.Q.; Shan, Z.W.; Li, J.; Wang, C.C.; Han, X.D.; Sun, J.; Ma, E. Approaching the ideal elastic limit of metallic glasses. Nat. Commun. 2012, 3, 609. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aykol, M.; Akdeniz, M.V.; Mekhrabov, A.O. Solidification behavior, glass forming ability and thermal characteristics of soft magnetic Fe–Co–B–Si–Nb–Cu bulk amorphous alloys. Intermetallics 2011, 19, 1330–1337. [Google Scholar] [CrossRef]

- Stoica, M.; Roth, S.; Eckert, J.; Karan, T.; Ram, S.; Vaughan, G.; Yavari, A.R. FeCoBSiNb bulk metallic glasses with Cu additions. Phys. Status Solidi C 2010, 7, 1331–1335. [Google Scholar] [CrossRef]

- Li, J.F.; Shao, Y.; Liu, X.; Yao, K.F. Fe-based bulk amorphous alloys with high glass formation ability and high saturation magnetization. Sci. Bull. 2015, 60, 396–399. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Ohsuna, T. Soft magnetic properties of nanocystalline Fe-Si-B-Nb-Cu rod alloys obtained by crystallization of cast amorphous phase. Mater. Trans. 2002, 43, 2337–2341. [Google Scholar] [CrossRef]

- Shi, M.; Li, R.; Wang, J.; Liu, Z.; Luo, X.; Zhang, T. Effects of minor Cu addition on glass-forming ability and magnetic properties of FePCBCu alloys with high saturation magnetization. Philos. Mag. 2013, 93, 2182–2189. [Google Scholar] [CrossRef]

- Li, H.X.; Gao, J.E.; Wu, Y.; Jiao, Z.B.; Ma, D.; Stoica, A.D.; Wang, X.L.; Ren, Y.; Miller, M.K.; Lu, Z.P. Enhancing glass-forming ability via frustration of nano-clustering in alloys with a high solvent content. Sci Rep. 2013, 3, 1983. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Wang, A.; Chang, C.; Wang, Y.; Dong, B.; Zhou, S. FeSiBPNbCu alloys with high glass-forming ability and good soft magnetic properties. Intermetallics 2014, 54, 225–231. [Google Scholar] [CrossRef]

- Li, Z.; Wang, A.; Chang, C.; Wang, Y.; Dong, B.; Zhou, S. Synthesis of FeSiBPNbCu nanocrystalline soft-magnetic alloys with high saturation magnetization. J. Alloy. Compd. 2014, 611, 197–201. [Google Scholar] [CrossRef]

- Chang, C.; Qin, C.; Makino, A.; Inoue, A. Enhancement of glass-forming ability of FeSiBP bulk glassy alloys with good soft-magnetic properties and high corrosion resistance. J. Alloy. Compd. 2012, 533, 67–70. [Google Scholar] [CrossRef]

- Miao, X.F.; Wang, Y.G.; Guo, M. Structural, thermal and magnetic properties of Fe–Si–B–P–Cu melt-spun ribbons: Application of non-isothermal kinetics and the amorphous random anisotropy model. J. Alloy. Compd. 2011, 509, 2789–2792. [Google Scholar] [CrossRef]

- Ayers, J.; Harris, V.; Sprague, J.; Elam, W.; Jones, H. On the formation of nanocrystals in the soft magnetic alloy Fe73.5Nb3Cu1Si13.5B9. Acta Mater. 1998, 46, 1861–1874. [Google Scholar] [CrossRef]

- Nutor, R.K.; Xu, X.J.; Fan, X.Z.; He, X.W.; Lu, X.N.; Fang, Y.Z. Effects of applying tensile stress during annealing on the GMI and induced anisotropy of Fe–Cu–Nb–Si–B alloys. J. Magn. Magn. Mater. 2019, 471, 544–548. [Google Scholar] [CrossRef]

- Ohnuma, M.; Hono, K.; Onodera, H.; Pedersen, J.; Linderoth, S. Cu clustering stage before the crystallization in Fe–Si–B–Nb–Cu amorphous alloys. Nanostruct. Mater. 1999, 12, 693–696. [Google Scholar] [CrossRef]

- Liu, Q.L.; Mo, J.Y.; Liu, H.S.; Xue, L.; Hou, L.; Yang, W.M.; Dou, L.T.; Shen, B.L.; Dou, L.M. Effects of Cu substitution for Nb on magnetic properties of Fe-based bulk metallic glasses. J. Non-Cryst. Solids. 2016, 443, 108–111. [Google Scholar] [CrossRef]

- Hono, K.; Ping, D. Atom probe studies of nanocrystallization of amorphous alloys. Mater. Charact. 2000, 44, 203–217. [Google Scholar] [CrossRef]

- Yang, W.M.; Liu, H.S.; Fan, X.D.; Xue, L.; Dun, C.C.; Shen, B.L. Enhanced glass forming ability of Fe-based amorphous alloys with minor Cu addition. J. Non-Cryst. Solids. 2015, 419, 65–68. [Google Scholar] [CrossRef]

- Hono, K.; Inoue, A.; Sakurai, T. Atom probe analysis of Fe73.5Si13.5B9Nb3Cu1 nanocrystalline soft magnetic material. Appl. Phys. Lett. 1991, 58, 2180–2182. [Google Scholar] [CrossRef]

- Inoue, A.; Masumoto, T.; Chen, H. Enthalpy relaxation behaviour of (Fe, Co, Ni) 75Si10B15 amorphous alloys upon low temperature annealing. J. Mater. Sci. 1984, 19, 3953–3966. [Google Scholar] [CrossRef]

- Ohta, M.; Yoshizawa, Y. High Bs nanocrystalline Fe84−x−yCuxNbySi4B12 alloys (x = 0.0–1.4, y = 0.0–2.5). J. Magn. Magn. Mater. 2009, 321, 2220–2224. [Google Scholar] [CrossRef]

- Ohta, M.; Yoshizawa, Y. Cu addition effect on soft magnetic properties in Fe–Si–B alloy system. J. Appl. Phys. 2008, 103, 07E722. [Google Scholar] [CrossRef]

- Ohta, M.; Yoshizawa, Y. Improvement of Soft Magnetic Properties in (Fe0.85B0.15)100−xCux Melt-Spun Alloys. Mater. Trans. 2007, 48, 2378–2380. [Google Scholar] [CrossRef]

| Composition (at. %) | Dcr (mm) | Magnetic Properties | ||

|---|---|---|---|---|

| Bs (T) | Hc (A/m) | μe | ||

| Fe73.5Si13.5B9Nb3Cu1 [1] | <1 | 1.24 | 0.53 | 100,000 |

| Fe72.5Si10B12.5Nb4Cu1 [13] | 0.5 | 1.21 | 1.8 | - |

| Fe61.5Co10B13.5Si10Nb4Cu1 [9] | 1.5 | 1.26 | 5 | - |

| The present alloys: | ||||

| (Fe0.76Si0.09B0.1P0.05)99.1Nb0.2Cu 0.7 | 1 | 1.5 | 2 | 15,600 |

| (Fe0.76Si0.09B0.1P0.05)98.8Nb0.5Cu 0.7 | 1.5 | 1.49 | 0.96 | 18,500 |

| (Fe0.76Si0.09B0.1P0.05)98.5Nb0.8Cu 0.7 | 2 | 1.46 | 1.28 | 17,800 |

| (Fe0.76Si0.09B0.1P0.05)98.3Nb1Cu 0.7 | 2.5 | 1.45 | 1.02 | 15,500 |

| (Fe0.76Si0.09B0.1P0.05)98.1Nb1.2Cu 0.7 | 2 | 1.44 | 1.3 | 17,800 |

| (Fe0.76Si0.09B0.1P0.05)97.8Nb1.5Cu 0.7 | 2 | 1.42 | 0.86 | 16,900 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Zhou, B.; Zhang, Y.; He, A.; Zhang, T.; Li, F.; Dong, Y.; Wang, X. FeSiBPNbCu Bulk Nanocrystalline Alloys with High GFA and Excellent Soft-Magnetic Properties. Metals 2019, 9, 219. https://doi.org/10.3390/met9020219

Liu L, Zhou B, Zhang Y, He A, Zhang T, Li F, Dong Y, Wang X. FeSiBPNbCu Bulk Nanocrystalline Alloys with High GFA and Excellent Soft-Magnetic Properties. Metals. 2019; 9(2):219. https://doi.org/10.3390/met9020219

Chicago/Turabian StyleLiu, Lei, Bang Zhou, Yiqun Zhang, Aina He, Tao Zhang, Fushan Li, Yaqiang Dong, and Xinmin Wang. 2019. "FeSiBPNbCu Bulk Nanocrystalline Alloys with High GFA and Excellent Soft-Magnetic Properties" Metals 9, no. 2: 219. https://doi.org/10.3390/met9020219

APA StyleLiu, L., Zhou, B., Zhang, Y., He, A., Zhang, T., Li, F., Dong, Y., & Wang, X. (2019). FeSiBPNbCu Bulk Nanocrystalline Alloys with High GFA and Excellent Soft-Magnetic Properties. Metals, 9(2), 219. https://doi.org/10.3390/met9020219