Transmission of Plasticity Through Grain Boundaries in a Metastable Austenitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

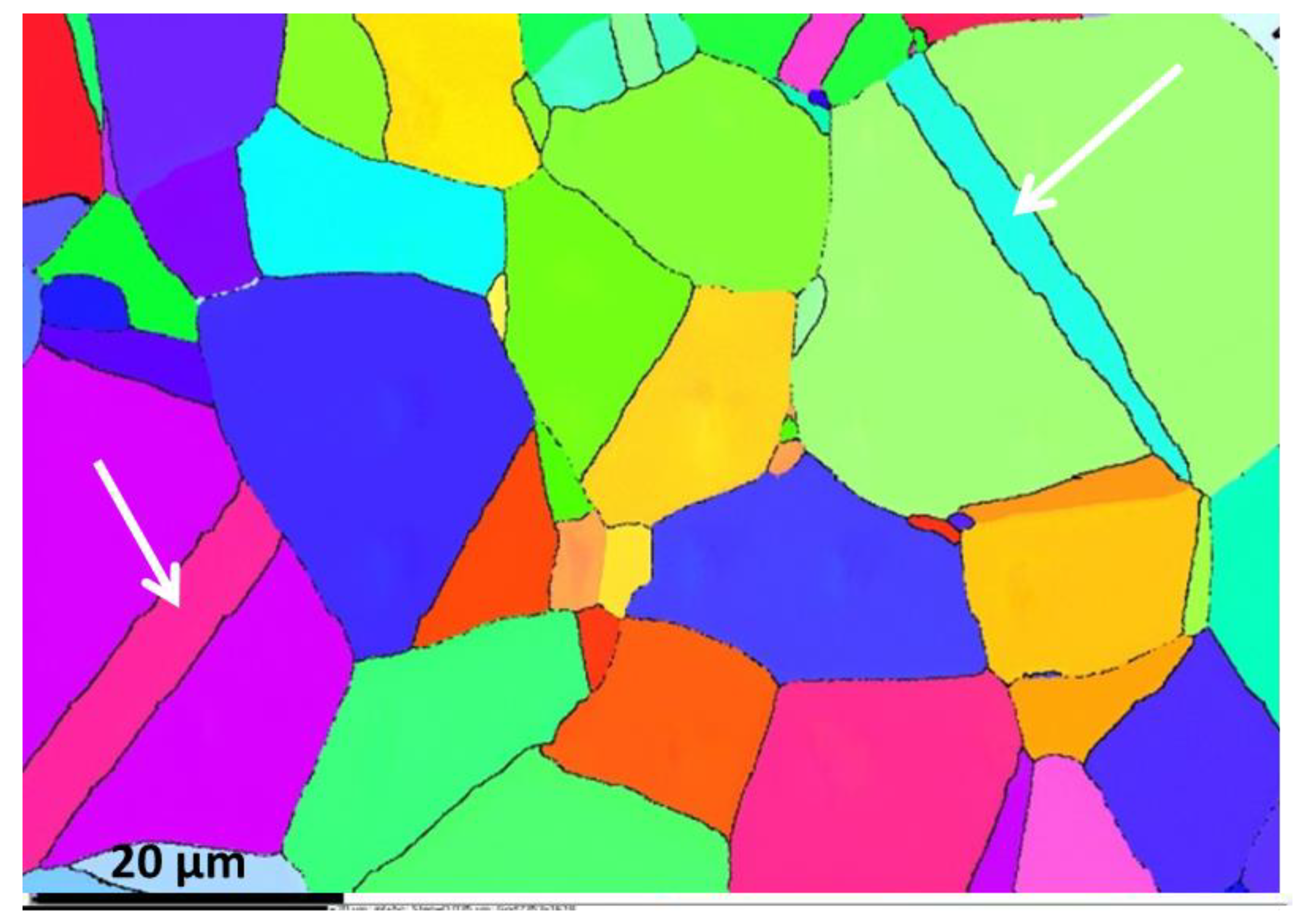

3.1. Microstructure Characterization

3.2. Substructure Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Taheri, S.; Hauet, A.; Taleb, L.; Kpodekon, C. Micro–macro investigations about the fatigue behavior of pre-hardened 304L steel. Int. J. Plast. 2011, 27, 1981–2004. [Google Scholar] [CrossRef]

- Santacreu, P.-O.; Glez, J.C.; Roulet, N.; Fröhlich, T.; Grosbety, Y. Austenitic Stainless Steels for Automotive Structural Parts. SAE Trans. 2006, 115, 805–810. [Google Scholar]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Tavares, S.M.; Pardal, J.M.; Gomes, M.J.; Abreu, H.F.G.; Silva, M.R. Deformation induced martensitic transformation in a 201 modified austenitic stainless steel. Mater. Charact. 2009, 60, 907–911. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Zhang, Z.; Jia, Z.; Venkat Surya, P.K.C.; Somani, M.C.; Karjalainen, L.P. Nanomechanical insights into the deformation behavior of austenitic alloys with different stacking fault energies and austenitic stability. Mater. Sci. Eng. A 2011, 528, 6958–6963. [Google Scholar] [CrossRef]

- Roa, J.J.; Wheeler, J.M.; Trifonov, T.; Michler, J.; Fargas, G.; Mateo, A.; Jiménez-Piqué, E. Deformation of polycrystalline TRIP stainless steel micropillars. Mater. Sci. Eng. A 2015, 647, 51–57. [Google Scholar] [CrossRef]

- Ahn, T.-H.; Oh, C.-S.; Kim, D.H.; Oh, K.H.; Bei, H.; George, E.P.; Han, H.N. Investigation of strain-induced martensitic transformation in metastable austenite using nanoindentation. Scr. Mater. 2010, 63, 540–543. [Google Scholar] [CrossRef]

- Roa, J.J.; Fargas, G.; Mateo, A.; Jiménez-Piqué, E. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. On the relationship between plastic zone radius and maximum depth during nanoindentation. Surf. Coatings Technol. 2006, 201, 4289–4293. [Google Scholar]

- Yang, B.; Vehoff, H. Dependence of nanohardness upon indentation size and grain size—A local examination of the interaction between dislocations and grain boundaries. Acta Mater. 2007, 55, 849–856. [Google Scholar] [CrossRef]

- Zaafarani, N.; Raabe, D.; Roters, F.; Zaefferer, S. On the origin of deformation-induced rotation patterns below nanoindents. Acta Mater. 2008, 56, 31–42. [Google Scholar] [CrossRef] [Green Version]

- Kysar, J.W.; Saito, Y.; Oztop, M.S.; Lee, D.; Huh, W.T. Experimental lower bounds on geometrically necessary dislocation density. Int. J. Plast. 2010, 26, 1097–1123. [Google Scholar] [CrossRef]

- Reuber, C.; Eisenlohr, P.; Roters, F.; Raabe, D. Dislocation density distribution around an indent in single-crystalline nickel: Comparing nonlocal crystal plasticity finite-element predictions with experiments. Acta Mater. 2014, 71, 333–348. [Google Scholar] [CrossRef]

- Roa, J.J.; Sapezanskaia, I.; Fargas, G.; Kouitat, R.; Redjaïmia, A.; Mateo, A. Dynamic Deformation of Metastable Austenitic Stainless Steels at the Nanometric Length Scale. Metall. Mater. Trans. A 2018, 49, 6034–6039. [Google Scholar] [CrossRef]

- Roa, J.J.; Sapezanskaia, I.; Fargas, G.; Kouitat, R.; Redjaïmia, A.; Mateo, A. Influence of testing mode on the fatigue behavior of <111> austenitic grain at the nanometric length scale for TRIP steels. Mat. Sci. Eng. A 2018, 713, 287–293. [Google Scholar] [CrossRef]

- Sapezanskaia, I.; Roa, J.J.; Fargas, G.; Turon-Viñas, M.; Trifonov, T.; Kouitat Njiwab, R.; Redjaïmia, A.; Mateo, A. Deformation mechanisms induced by nanoindentation tests on a metastable austenitic stainless steel: A FIB/SIM investigation. Mater. Charact. 2017, 131, 253–260. [Google Scholar] [CrossRef]

- Bieler, T.R.; Eisenlohr, P.; Zhang, C.; Phukan, H.J.; Crimp, M.A. Grain boundaries and interfaces in slip transfer. Curr. Opin. Solid State Mater. Sci. 2014, 18, 212–226. [Google Scholar] [CrossRef]

- Scheriau, S.; Pippan, R. Influence of grain size on orientation changes during plastic deformation. Mater. Sci. Eng. A 2008, 49, 48–52. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: application to zirconium alloys. Acta Metall. Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Di Martino, S.F.; Riddle, N.B.; Faulkner, R.G. Controlling the ductile to brittle transition in Fe-9% Cr ODS steels. J. Nuclear Mat. 2013, 442, S124–S132. [Google Scholar] [CrossRef]

- Knipling, K.E.; Rowenhorst, D.J.; Fonda, R.W.; Spanos, G. Effects of focused ion beam milling on austenite stability in ferrous alloys. Mater. Charact. 2010, 61, 1–6. [Google Scholar] [CrossRef]

- Basa, A.; Thaulow, C.; Barnoush, A. Chemically induced phase transformation in austenite by focused ion beam. Metall. Mater. Trans. A 2014, 45, 1189–1198. [Google Scholar] [CrossRef]

- Dahlberg, C.F.O.; Saito, Y.; Öztop, M.S.; Kysar, J.W. Geometrically necessary dislocation density measurements associated with different angles of indentations. Int. J. Plast. 2014, 54, 81–95. [Google Scholar] [CrossRef]

- Zhang, L.; Ohmura, T.; Shibata, A.; Tsuzaki, K. Characterization of local deformation behavior of Fe–Ni lenticular martensite by nanoindentation. Mater. Sci. Eng. A 2010, 527, 1869–1874. [Google Scholar] [CrossRef]

- Das, A. Dislocation configurations through austenite grain misorientations. Int. J. Fatigue 2015, 70, 473–479. [Google Scholar] [CrossRef]

- Kurdjumov, G.; Sachs, G.Z. Über den Mechanismus der Stahlhärtung. Z. Phys. 1930, 64, 325–343. [Google Scholar] [CrossRef]

- Nishiyama, Z. Martensitic Transformation; Fine, M.E., Meshii, M., Waymann, C.M., Eds.; Academic Press: New York, NY, USA, 1978; pp. 480–488. [Google Scholar]

- Sabooni, S.; Karimzadeh, F.; Enayati, M.H.; Ngan, H.W. The role of martensitic transformation on bimodal grain structure in ultrafine grained AISI 304L stainless steel. Mater. Sci. Eng. A 2015, 636, 221–230. [Google Scholar] [CrossRef] [Green Version]

- Sato, H.; Zaefferer, S.A. A study on the formation mechanisms of butterfly-type martensite in Fe–30% Ni alloy using EBSD-based orientation microscopy. Acta Mater. 2009, 57, 1931–1946. [Google Scholar] [CrossRef]

- Mine, Y.; Hirashita, K.; Matsuda, M.; Takashima, K. Martensite Formation in Hydrogen-Containing Metastable Austenitic Stainless Steel during Micro-Tension Testing. Metall. Mater. Trans. A 2011, 42, 3567–3574. [Google Scholar] [CrossRef]

- Durlu, T.N. Effects of high austenitizing temperature and austenite deformation on formation of martensite in Fe-Ni-C alloys. J. Mater. Sci. 2001, 36, 5665–5671. [Google Scholar] [CrossRef]

- Yang, H.Y.; Li, J.; Yang, P. The Change of Orientation Relationships between Austenite and α′-Martensite during Deformation in High Manganese TRIP Steel. Acta Metall. Sin. 2015, 28, 289–294. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | N | Fe |

|---|---|---|---|---|---|---|---|

| 0.02 | 0.5 | 1.3 | 18.6 | 6.4 | 0.1 | 0.07 | balance |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mateo, A.; Sapezanskaia, I.; Roa, J.J.; Fargas, G.; Redjaïmia, A. Transmission of Plasticity Through Grain Boundaries in a Metastable Austenitic Stainless Steel. Metals 2019, 9, 234. https://doi.org/10.3390/met9020234

Mateo A, Sapezanskaia I, Roa JJ, Fargas G, Redjaïmia A. Transmission of Plasticity Through Grain Boundaries in a Metastable Austenitic Stainless Steel. Metals. 2019; 9(2):234. https://doi.org/10.3390/met9020234

Chicago/Turabian StyleMateo, Antonio, Ina Sapezanskaia, Joan Josep Roa, Gemma Fargas, and Abdelkrim Redjaïmia. 2019. "Transmission of Plasticity Through Grain Boundaries in a Metastable Austenitic Stainless Steel" Metals 9, no. 2: 234. https://doi.org/10.3390/met9020234

APA StyleMateo, A., Sapezanskaia, I., Roa, J. J., Fargas, G., & Redjaïmia, A. (2019). Transmission of Plasticity Through Grain Boundaries in a Metastable Austenitic Stainless Steel. Metals, 9(2), 234. https://doi.org/10.3390/met9020234