Properties of Jet-Plated Ni Coating on Ti Alloy (Ti6Al4V) with Laser Cleaning Pretreatment

Abstract

1. Introduction

2. Experimental System

2.1. Experimental Mechanism and Device

2.2. Experimental Conditions

2.3. Characterization Techniques and Methods

3. Results and Discussion

3.1. Surface Morphology

3.2. XRD Analysis

3.3. Coating Adhesion

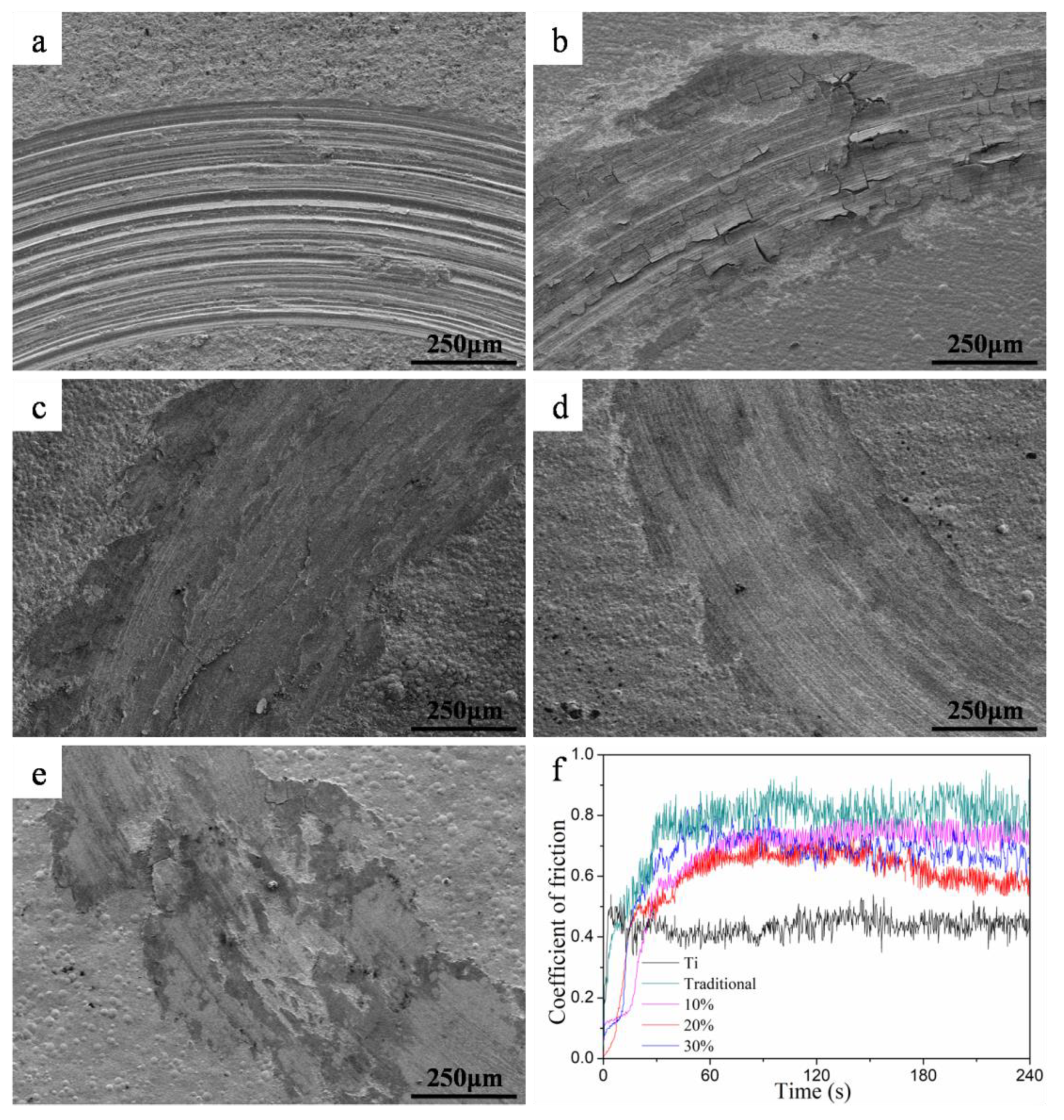

3.4. Friction Properties and Microhardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Li, L.; Bai, P.K.; Jin, Y.; Wu, L.Y.; Li, J.; Guan, R.G.; Qu, H.Q. The heat treatment influence on the microstructure and hardness of TC4 titanium alloy manufactured via selective laser melting. Materials 2018, 11, 1318. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, X.; Zou, J.; Yang, H. Sliding wear of selective laser melting processed Ti6Al4V under boundary lubrication conditions. Wear 2016, 368, 485–495. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, S.; Fan, Y.; Xu, N.; He, Y. Preparation of dense Pd composite membranes on porous Ti–Al alloy supports by electroless plating. J. Membr. Sci. 2012, 387–388, 24–29. [Google Scholar] [CrossRef]

- Lim, Y.M.; Park, Y.J.; Yun, Y.H.; Hwang, K.S. Functionally graded Ti/HAP coatings on Ti–6Al–4V obtained by chemical solution deposition. Ceram. Int. 2002, 28, 37–41. [Google Scholar] [CrossRef]

- Hicham, B.; Richard, D.; Joel, F.; Sylvain, P.; Thierry, G.; Hassane, O.; Dominique, L.M. Elaboration of Monophasic and Biphasic Calcium Phosphate Coatings on Ti6Al4V Substrate by Pulsed Electrodeposition Current. Adv. Eng. Mater. 2010, 12, B192–B199. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, D.; Yan, W.; Zheng, Y. Microstructure and wear properties of TiCN/Ti coatings on titanium alloy by laser cladding. Opt. Lasers Eng. 2010, 48, 119–124. [Google Scholar] [CrossRef]

- Meng, Q.; Geng, L.; Ni, D. Laser cladding NiCoCrAlY coating on Ti-6Al-4V. Mater. Lett. 2005, 59, 2774–2777. [Google Scholar] [CrossRef]

- Hager, C.H., Jr.; Sanders, J.; Sharma, S.; Voevodin, A.; Segall, A. The effect of temperature on gross slip fretting wear of cold-sprayed nickel coatings on Ti6Al4V interfaces. Tribol. Int. 2009, 42, 491–502. [Google Scholar] [CrossRef]

- Martinez, J.M.V.; Pedemonte, F.J.B.; Galvin, M.B.; Gomez, J.S.; Barcena, M.M. Sliding wear behavior of UNS R56400 titanium alloy samples thermally oxidized by laser. Materials 2017, 10, 830–843. [Google Scholar]

- Przestacki, D.; Radomir, M.; Lidia, M.P. Experimental research of surface roughness and surface texture after laser cladding. Appl. Surf. Sci. 2016, 388, 420–423. [Google Scholar] [CrossRef]

- Chwalczuk, T.; Przestacki, D.; Piotr, S.; Bartkowska, A. Microstructure characterization of Inconel 718 after laser assisted turning. MATEC Web Conf. 2018, 188, 02004. [Google Scholar] [CrossRef]

- Bartkowska, A.; Aleksandra, P.; Mikolaj, P.; Dariusz, B.; Przestacki, D.; Andrzej, M. Effect of laser modification of B-Ni complex layer on wear resistance and microhardness. Opt. Laser Technol. 2015, 72, 116–124. [Google Scholar] [CrossRef]

- Przestacki, D.; Mateusz, K.; Bartkowska, A. Influence of laser heat treatment on microstructure and properties of surface layer of Waspaloy aimed for laser-assisted machining. Int. J. Adv. Manuf. Technol. 2017, 93, 3111–3123. [Google Scholar] [CrossRef]

- Mateusz, K.; Bartkowska, A.; Przestacki, D. Microstructure and selected properties of Monel 400 alloy after laser heat treatment and laser boriding using diode laser. Int. J. Adv. Manuf. Technol. 2018, 98, 3005–3017. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, D.; Kang, Z. One-step electrodeposition process to fabricate corrosion-resistant superhydrophobic surface on magnesium alloy. ACS Appl. Mat. Interfaces 2015, 7, 1859–1867. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Shen, L.; Qiu, M.; Tian, Z.; Jiang, W. Preparation and Properties of Nanocomposite Coatings by Pulsed Current-Jet Electrodeposition. Int. J. Electrochem. Sci. 2017, 12, 8578–8590. [Google Scholar] [CrossRef]

- Shen, L.; Wang, C.; Tian, Z.; Jiang, W.; Zhuo, W.; Zhao, K. Study on the Properties of Jet Electrodeposited Nickel Coating by Rotating Interlacing Method. Int. J. Electrochem. Sci. 2018, 13, 1831–1843. [Google Scholar] [CrossRef]

- Jiang, W.; Shen, L.; Qiu, M.; Wang, X.; Fan, M.; Tian, Z. Preparation of Ni-SiC composite coatings by magnetic field-enhanced jet electrodeposition. J. Alloys Compd. 2018, 762, 115–124. [Google Scholar] [CrossRef]

- Wang, C.; Shen, L.; Qiu, M.; Tian, Z.; Jiang, W. Characterizations of Ni-CeO 2, nanocomposite coating by interlaced jet electrodeposition. J. Alloys Compd. 2017, 727, 269–277. [Google Scholar] [CrossRef]

- Ma, C.; Yu, W.; Jiang, M.; Cui, W.; Xia, F. Jet pulse electrodeposition and characterization of Ni–AlN nanocoatings in presence of ultrasound. Ceram. Int. 2018, 44, 5163–5170. [Google Scholar] [CrossRef]

- Lin, C.; Zhao, L. Electroless Ni-P Wear-Resistant Coating on TC4 Titanium Alloy. Rare Metal. Mat. Eng. 2013, 42, 507–512. [Google Scholar] [CrossRef]

- Tang, J.; Azumi, K. Effect of copper pretreatment on the zincate process and subsequent electroplating of a protective copper/nickel deposit on the AZ91D magnesium alloy. Electrochim. Acta 2011, 56, 8776–8782. [Google Scholar] [CrossRef]

- Lu, Y.F.; Song, W.D.; Low, T.S. Laser cleaning of micro-particles from a solid surface—Theory and applications. Mater. Chem. Phys. 1998, 54, 181–185. [Google Scholar] [CrossRef]

- Tam, A.C.; Park, H.K.; Grigoropoulos, C.P. Laser cleaning of surface contaminants. Appl. Surf. Sci. 1998, 127–129, 721–725. [Google Scholar] [CrossRef]

- Lei, Z.; Tian, Z.; Chen, Y. Summary and Prospect of Research Status of Laser Cleaning in Industrial Field. Las. Optoelect. Prog. 2018, 55, 030005. [Google Scholar] [CrossRef]

- Yue, L.; Wang, Z.; Li, L. Material morphological characteristics in laser ablation of alpha case from titanium alloy. Appl. Surf. Sci. 2012, 158, 8065–8071. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, L.; Jiang, W.; Wang, X.; Fan, M.; Tian, Z.; Han, X. Laser processing as an alternative electrodeposition pretreatment. Surf. Coat. Technol. 2019, 357, 957–964. [Google Scholar] [CrossRef]

- Baburaj, E.G.; Starikov, D.; Evans, J.; Shafeev, G.A.; Bensaoula, A. Enhancement of adhesive joint strength by laser surface modification. Int. J. Adhes. Adhes. 2007, 27, 268–276. [Google Scholar] [CrossRef]

- Basu, B.J.; Hariprakash, V.; Aruna, S.T.; Lakshmi, R.V.; Manasa, J.; Shruthi, B.S. Effect of microstructure and surface roughness on the wettability of superhydrophobic sol–gel nanocomposite coatings. J. Sol.-Gel Sci. Technol. 2010, 56, 278–286. [Google Scholar] [CrossRef]

- Guo, H.; Sun, T.; Li, J.; Yang, H. Microstructure and properties of Ni-WC coating prepared by plasma spraying of titanium alloy. China Surf. Eng. 2013, 26, 21–28. [Google Scholar] [CrossRef]

- Jeong, D.H.; Gonzalez, F.; Palumbo, G.; Aust, K.T.; Erb, U. The effect of grain size on the wear properties of electrodeposited nanocrystalline nickel coatings. Scr. Mater. 2001, 44, 493–499. [Google Scholar] [CrossRef]

- Jeong, D.H.; Erb, U.; Aust, K.T.; Palumbo, G. The relationship between hardness and abrasive wear resistance of electrodeposited nanocrystalline Ni–P coatings. Scr. Mater. 2003, 48, 1067–1072. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wave length (nm) | 1064 |

| Pulse width (ns) | 100 |

| Spot diameter (µm) | 35 |

| Output power (W) | 30 |

| Energy density (J/cm2) | 20 |

| Frequency (KHz) | 20 |

| Scanning line speed (mm/s) | 500 |

| Bath Compositions and Operating Conditions | Content |

|---|---|

| NiSO4.6H2O (g/L) | 260 |

| NiCl2.6H2O (g/L) | 40 |

| H3BO4 (g/L) | 40 |

| C7H5O3NS (g/L) | 5 |

| Temperature (°C) | 50 |

| pH | 4.0 |

| Current density (A/dm2) | 100 |

| Scanning speed (mm/s) | 4 |

| Plating Time (min) | 30 |

| Sample | Wear Volume/mm3 |

|---|---|

| Substrate | 1.673 |

| Traditional pretreatment | 0.113 |

| 10% laser energy density | 0.083 |

| 20% laser energy density | 0.046 |

| 30% laser energy density | 0.061 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xu, M.; Wang, Z.; Shen, L.; Qiu, M.; Tian, Z.; Ahsan, M.N.; Wang, C. Properties of Jet-Plated Ni Coating on Ti Alloy (Ti6Al4V) with Laser Cleaning Pretreatment. Metals 2019, 9, 248. https://doi.org/10.3390/met9020248

Wang X, Xu M, Wang Z, Shen L, Qiu M, Tian Z, Ahsan MN, Wang C. Properties of Jet-Plated Ni Coating on Ti Alloy (Ti6Al4V) with Laser Cleaning Pretreatment. Metals. 2019; 9(2):248. https://doi.org/10.3390/met9020248

Chicago/Turabian StyleWang, Xiao, Mingyang Xu, Zhanwen Wang, Lida Shen, Mingbo Qiu, Zongjun Tian, Muhammad Naveed Ahsan, and Changjiang Wang. 2019. "Properties of Jet-Plated Ni Coating on Ti Alloy (Ti6Al4V) with Laser Cleaning Pretreatment" Metals 9, no. 2: 248. https://doi.org/10.3390/met9020248

APA StyleWang, X., Xu, M., Wang, Z., Shen, L., Qiu, M., Tian, Z., Ahsan, M. N., & Wang, C. (2019). Properties of Jet-Plated Ni Coating on Ti Alloy (Ti6Al4V) with Laser Cleaning Pretreatment. Metals, 9(2), 248. https://doi.org/10.3390/met9020248