Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications

Abstract

1. Introduction

1.1. Car Industry Context

1.2. Car Industry Requirements

1.3. Overview of Current Technologies

1.4. Scope of this Review

- -

- resistance spot welding, for final-assembly;

- -

- resistance element welding, for final-assembly;

- -

- laser beam fusion welding, for both TWB manufacturing and final assembly;

- -

- electric arc fusion welding, for both TWB manufacturing and final assembly;

- -

- joining by means of transition joints, for both TWB manufacturing and final assembly;

- -

- magnetic pulse sheet welding, mainly for final assembly;

- -

- friction stir welding, including the spot variant, mainly for TWB manufacturing;

- -

- friction bit joining, for final-assembly;

- -

- ultrasonic spot welding, for final-assembly only.

2. Fusion welding technologies

2.1. Introduction

2.2. Plain Resistance Spot Welding

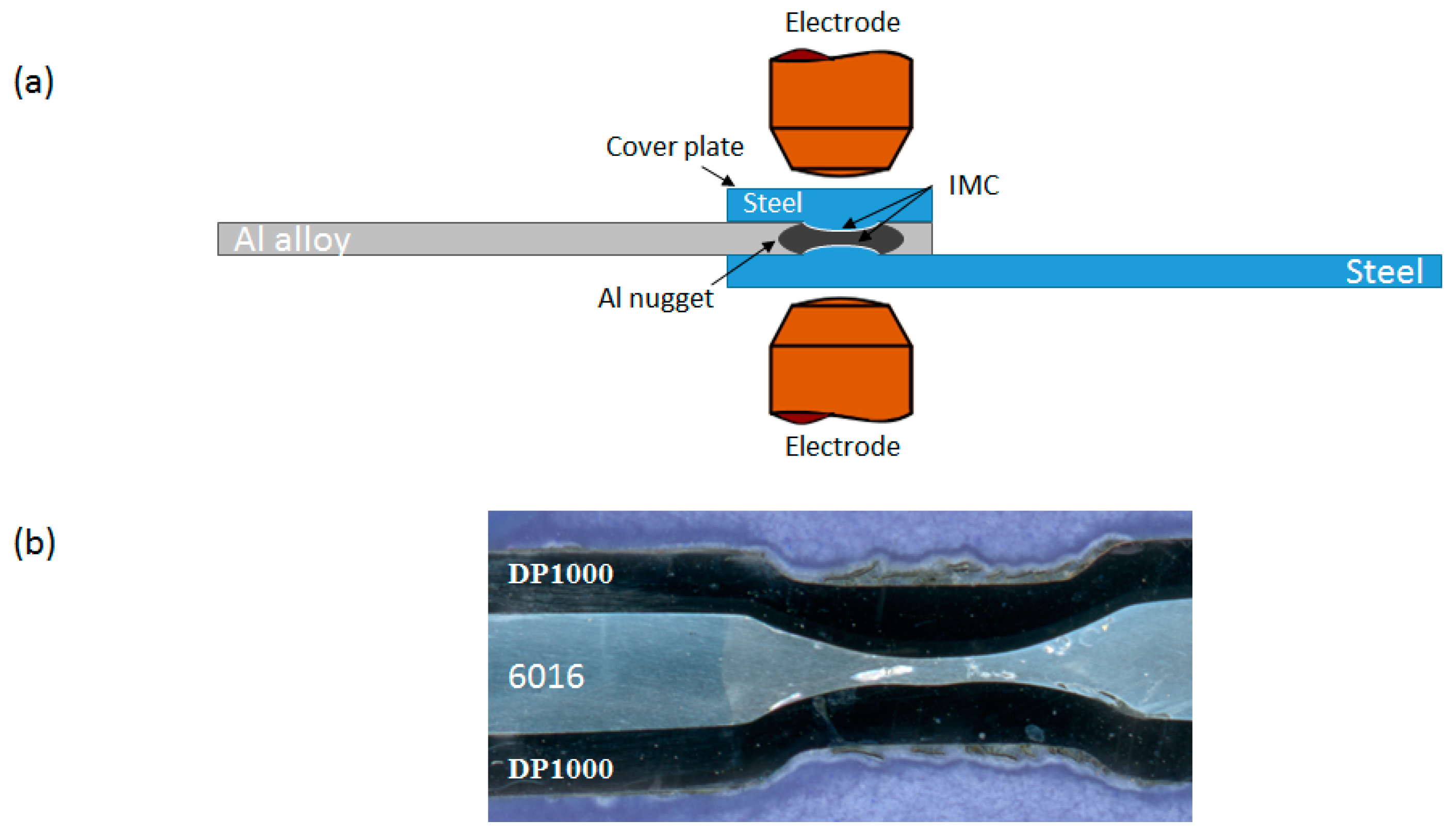

2.3. Resistance Spot Welding with Cover Plate

2.4. Resistance Spot Welding with Interlayer

2.5. Resistance Element Welding

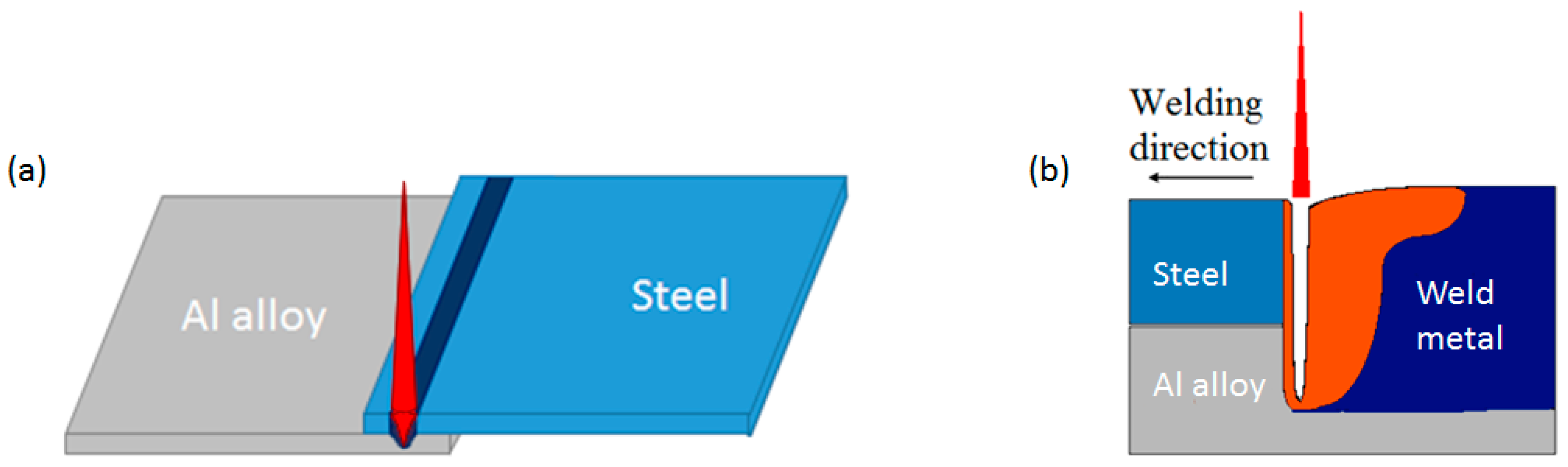

2.6. Laser Beam Welding

2.7. Arc Welding

3. Solid-State Welding

3.1. Introduction

3.2. Explosion Welding and Transition Joints

3.3. Magnetic Pulse Welding

3.4. Roll Bonding

3.5. Friction Stir Welding

3.6. Friction Bit Joining

3.7. Ultrasonic Spot Welding

4. Discussion and Conclusion

Funding

Conflicts of Interest

References

- Kusuda, Y. Honda develops robotized FSW technology to weld steel and aluminum and applied it to a mass-production vehicle. Ind. Rob. Int. J. 2013, 40, 208–212. [Google Scholar] [CrossRef]

- Ohhama, S.; Hata, T.; Yahaba, T.; Kobayashi, T.; Miyahara, T.; Sayama, M. Application of an FSW Continuous Welding Technology for Steel and Aluminum to an Automotive Subframe; SAE Tech. Paper No. 2013-01-0372; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Huland, S.; Moller, M.; Franke, M.; Vakalopoulos, T. The electrification of the Passat, the GTE. Viavision. July 2015. Available online: http://www.viavision.org.uk/ftp/1794.pdf (accessed on 6 March 2019).

- New Technology Saves Weight in Composite Structures; Arnold Umformtechnik GmbH & Co. KG: Forchtenberg-Ernsbach, Germany, 2017; Available online: www.arnold-fastening.com (accessed on 6 March 2019).

- Barnes, T.A.; Pashby, I.R. Joining techniques for aluminium spaceframes used in automobiles: Part II—Adhesive bonding and mechanical fasteners. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar] [CrossRef]

- Groche, P.; Wohletz, S.; Brenneis, M.; Pabst, C.; Resch, F. Joining by forming—A review on joint mechanisms, applications and future trends. J. Mater. Process. Technol. 2014, 214, 1972–1994. [Google Scholar] [CrossRef]

- He, X. A review of finite element analysis of adhesively bonded joints. Int. J. Adhes. Adhes. 2011, 31, 248–264. [Google Scholar] [CrossRef]

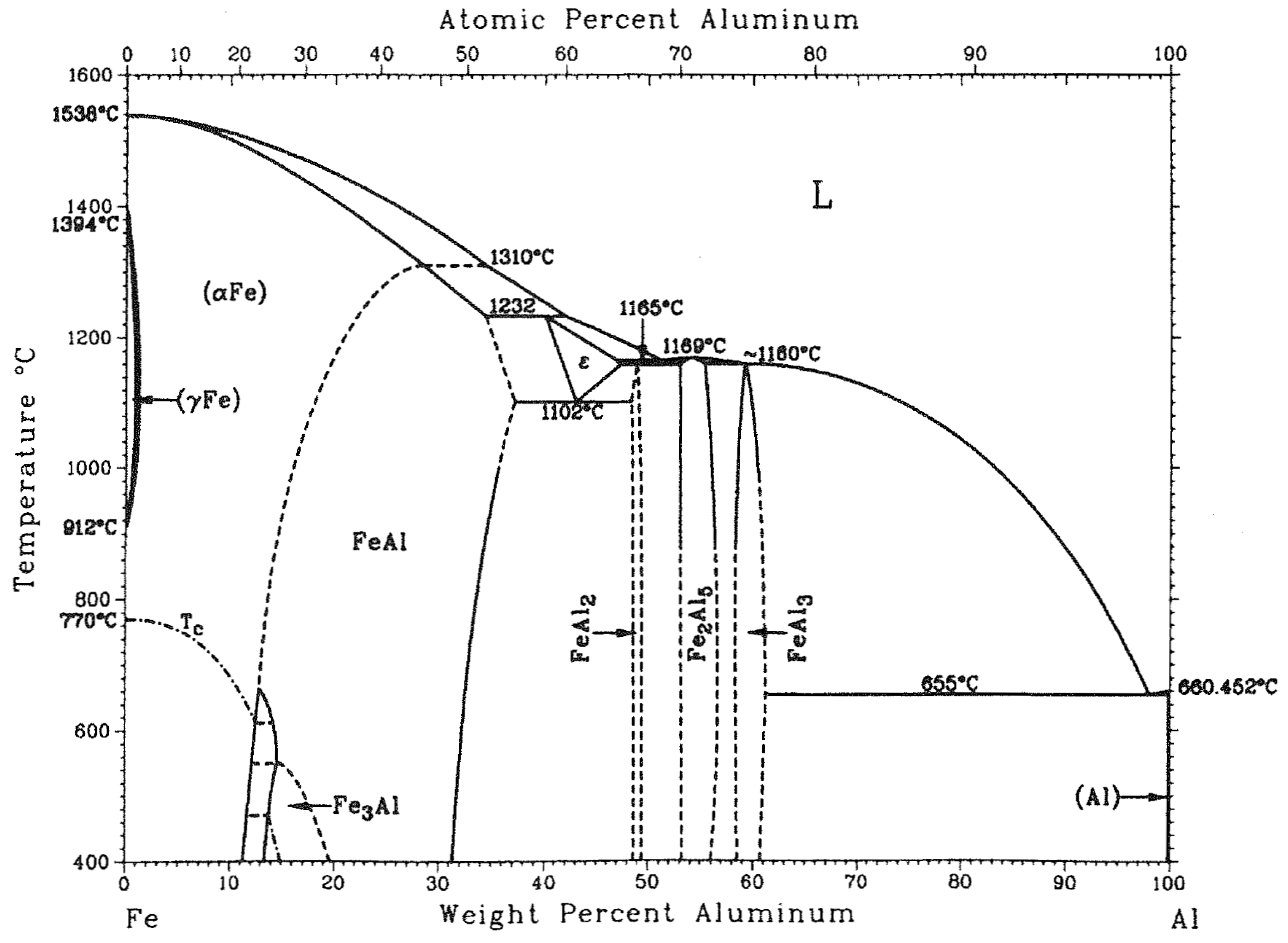

- Okamoto, H.; Schlesinger, E.; Mueller, E.M. (Eds.) ASM Handbook, Vol. 3, Alloy Phase Diagrams; ASM Int.: Materials Park, OH, USA, 2016. [Google Scholar]

- Dong, H.; Hu, W.; Duan, Y.; Wang, X.; Dong, C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J. Mater. Process. Technol. 2012, 212, 458–464. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y. Influence of alloy elements on microstructure and mechanical property of aluminum–steel lap joint made by gas metal arc welding. J. Mater. Process. Technol. 2014, 214, 750–755. [Google Scholar] [CrossRef]

- Milani, A.M.; Paidar, M.; Khodabandeh, A.; Nategh, S. Influence of filler wire and wire feed speed on metallurgical and mechanical properties of MIG welding–brazing of automotive galvanized steel/5754 aluminum alloy in a lap joint configuration. Int. J. Adv. Manuf. Technol. 2016, 82, 1495–1506. [Google Scholar] [CrossRef]

- Sundman, B.; Ohnuma, I.; Dupin, N.; Kattner, U.R.; Fries, S.G. An assessment of the entire Al–Fe system including D03 ordering. Acta Mater. 2009, 57, 2896–2908. [Google Scholar] [CrossRef]

- Kouadri-David, A.; PSM Team. Study of metallurgic and mechanical properties of laser welded heterogeneous joints between DP600 galvanised steel and aluminium 6082. Mater. Des. 2014, 54, 184–195. [Google Scholar] [CrossRef]

- Meco, S.; Pardal, G.; Ganguly, S.; Williams, S.; McPherson, N. Application of laser in seam welding of dissimilar steel to aluminium joints for thick structural components. Opt. Lasers Eng. 2015, 67, 22–30. [Google Scholar] [CrossRef]

- Aslanlar, S.; Ogur, A.; Ozsarac, U.; Ilhan, E. Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding. Mater. Des. 2008, 29, 1427–1431. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, D.; Han, L.; Gao, W.; Qiu, X. Characterization of intermetallic compounds in dissimilar material resistance spot welded joint of high strength steel and aluminum alloy. ISIJ Int. 2011, 51, 1870–1877. [Google Scholar] [CrossRef]

- Yang, D.; Sigler, D.R.; Carlson, B.E.; Schroth, J.G.; Karagoulis, M.J. Electrode for Resistance Spot Welding of Dissimilar Materials. U.S. Patent Application No. 14/181,020, 14 February 2014. [Google Scholar]

- Sigler, D.R.; Carlson, B.E.; Karagoulis, M.J. Resistance Spot Welding Steel and Aluminum Workpieces Using Electrode Weld Face Cover. U.S. Patent Application No. 14/462,655, 19 August 2014. [Google Scholar]

- Sigler, D.R.; Carlson, B.E.; Myasnikowa, Y.; Karagoulis, M.J. Multistep Direct Welding of an Aluminum Based Workpiece to a Steel Workpiece. U.S. Patent Application No. 14/464,476, 20 August 2014. [Google Scholar]

- GM prepping industry-first steel-to-aluminum welding process. Automotive Engineering, 19 May 2016.

- Kim, J.S.; Kim, I.J.; Kim, Y.G. Optimization of welding current waveform for dissimilar material with DP590 and Al5052 by Delta-spot welding process. J. Mech. Sci. Technol. 2016, 30, 2713–2721. [Google Scholar] [CrossRef]

- Che, Y.; Wang, L.; Sun, D.; Li, H.; Geng, W. Microstructures and mechanical properties of resistance spot-welded steel/aluminum alloy joints with process tapes. J. Mater. Eng. Perform. 2018, 27, 5532–5544. [Google Scholar]

- Qiu, R.; Iwamoto, C.; Satonaka, S. Interfacial microstructure and strength of steel/aluminum alloy joints welded by resistance spot welding with cover plate. J. Mater. Process. Technol. 2009, 209, 4186–4193. [Google Scholar] [CrossRef]

- Qiu, R.; Satonaka, S.; Iwamoto, C. Effect of interfacial reaction layer continuity on the tensile strength of resistance spot welded joints between aluminum alloy and steels. Mater. Des. 2009, 30, 3686–3689. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, D.; Han, L.; Liu, D. Interfacial microstructure and mechanical property of resistance spot welded joint of high strength steel and aluminium alloy with 4047 AlSi12 interlayer. Mater. Des. 2014, 57, 186–194. [Google Scholar] [CrossRef]

- Ibrahim, I.; Ito, R.; Kakiuchi, T.; Uematsu, Y.; Yun, K.; Matsuda, C. Fatigue behaviour of Al/steel dissimilar resistance spot welds fabricated using Al–Mg interlayer. Sci. Technol. Weld. Join. 2016, 21, 223–233. [Google Scholar] [CrossRef]

- Haynes, G.; Jha, B. Joining aluminum to steel with transition material. SAE Technical Paper, 1 March 1999; No. 1999-01-0660. [Google Scholar]

- Haynes, G.; Haynes, M.; Jha, B. Applications for Clad Metals in the Automotive Industry; SAE Technical Paper, No. 2000-01-0312; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Oikawa, H.; Ohmiya, S.; Yoshimura, T.; Saitoh, T. Resistance spot welding of steel and aluminium sheet using insert metal sheet. Sci. Technol. Weld. Join. 1999, 4, 80–88. [Google Scholar] [CrossRef]

- Sun, X.; Stephens, E.V.; Khaleel, M.A.; Shao, H.; Kimchi, M. Resistance spot welding of aluminum alloy to steel with transition material-from process to performance—Part I: Experimental study. Weld. J. 2004, 83, 188-S. [Google Scholar]

- Baboian, R.; Haynes, G. Corrosion Resistance of Aluminum-Transition-Steel Joints for Automobiles; SAE Technical Paper, No. 932353; SAE International: Warrendale, PA, USA, 1993. [Google Scholar]

- Meschut, G.; Janzen, V.; Olfermann, T. Innovative and highly productive joining technologies for multi-material lightweight car body structures. J. Mater. Eng. Perform. 2014, 23, 1515–1523. [Google Scholar]

- Meschut, G.; Matzke, M.; Hoerhold, R.; Olfermann, T. Hybrid technologies for joining ultra-high-strength boron steels with aluminum alloys for lightweight car body structures. Procedia Cirp 2014, 23, 19–23. [Google Scholar] [CrossRef]

- Ling, Z.; Li, Y.; Luo, Z.; Feng, Y.; Wang, Z. Resistance element welding of 6061 aluminum alloy to uncoated 22MnMoB boron steel. Mater. Manuf. Process. 2016, 31, 2174–2180. [Google Scholar] [CrossRef]

- Ling, Z.; Li, Y.; Luo, Z.; Ao, S.; Yin, Z.; Gu, Y.; Chen, Q. Microstructure and fatigue behavior of resistance element welded dissimilar joints of DP780 dual-phase steel to 6061-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2017, 92, 1923–1931. [Google Scholar] [CrossRef]

- Ready, J.F.; Farson, D.F.; Feeley, T. (Eds.) LIA Handbook of Laser Materials Processing; Springer: New York, NY, USA, 2001. [Google Scholar]

- Zaeh, M.F.; Moesl, J.; Musiol, J.; Oefele, F. Material processing with remote technology—Revolution or evolution? Phys. Procedia 2010, 5, 19–33. [Google Scholar] [CrossRef]

- Sierra, G.; Peyre, P.; Deschaux-Beaume, F.; Stuart, D.; Fras, G. Steel to aluminium key-hole laser welding. Mater. Sci. Eng. A 2007, 447, 197–208. [Google Scholar] [CrossRef]

- Yan, S.; Hong, Z.; Watanabe, T.; Jingguo, T. CW/PW dual-beam YAG laser welding of steel/aluminum alloy sheets. Opt. Lasers Eng. 2010, 48, 732–736. [Google Scholar] [CrossRef]

- Torkamany, M.J.; Tahamtan, S.; Sabbaghzadeh, J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd: YAG pulsed laser. Mater. Des. 2010, 31, 458–465. [Google Scholar]

- Fan, J.; Thomy, C.; Vollertsen, F. Effect of thermal cycle on the formation of intermetallic compounds in laser welding of aluminum-steel overlap joints. Phys. Procedia 2011, 12, 134–141. [Google Scholar] [CrossRef]

- Pardal, G.; Meco, S.; Ganguly, S.; Williams, S.; Prangnell, P. Dissimilar metal laser spot joining of steel to aluminium in conduction mode. Int. J. Adv. Manuf. Technol. 2014, 73, 365–373. [Google Scholar] [CrossRef]

- Pardal, G.; Meco, S.; Dunn, A.; Williams, S.; Ganguly, S.; Hand, D.P.; Wlodarczyk, K.L. Laser spot welding of laser textured steel to aluminium. J. Mater. Process. Technol. 2017, 241, 24–35. [Google Scholar]

- Peyre, P.; Sierra, G.; Deschaux-Beaume, F.; Stuart, D.; Fras, G. Generation of aluminium–steel joints with laser-induced reactive wetting. Mater. Sci. Eng. A 2007, 444, 327–338. [Google Scholar]

- Sierra, G.; Peyre, P.; Deschaux-Beaume, F.; Stuart, D.; Fras, G. Galvanised steel to aluminium joining by laser and GTAW processes. Mater. Charact. 2008, 59, 1705–1715. [Google Scholar]

- Weller, D.; Simon, J.; Stritt, P.; Weber, R.; Graf, T.; Bezençon, C.; Bassi, C. Temperature controlled laser joining of aluminum to galvanized steel. Phys. Procedia 2016, 83, 515–522. [Google Scholar] [CrossRef]

- Sierra, G.; Peyre, P.; Deschaux-Beaume, F.; Stuart, D.; Fras, G. Steel to aluminium braze welding by laser process with Al–12Si filler wire. Sci. Technol. Weld. Join. 2008, 13, 430–437. [Google Scholar] [CrossRef]

- Mathieu, A.; Pontevicci, S.; Viala, J.C.; Cicala, E.; Mattei, S.; Grevey, D. Laser brazing of a steel/aluminium assembly with hot filler wire (88% Al, 12% Si). Mater. Sci. Eng. A 2006, 435, 19–28. [Google Scholar]

- Mathieu, A.; Shabadi, R.; Deschamps, A.; Suery, M.; Mattei, S.; Grevey, D.; Cicala, E. Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire). Opt. Laser Technol. 2007, 39, 652–661. [Google Scholar]

- Sun, J.; Yan, Q.; Li, Z.; Huang, J. Effect of bevel angle on microstructure and mechanical property of Al/steel butt joint using laser welding-brazing method. Mater. Des. 2016, 90, 468–477. [Google Scholar]

- Zhang, Y.; Li, F.; Guo, G.; Wang, G.; Wei, H. Effects of different powders on the micro-gap laser welding-brazing of an aluminium-steel butt joint using a coaxial feeding method. Mater. Des. 2016, 109, 10–18. [Google Scholar]

- Li, L.; Xia, H.; Tan, C.; Ma, N. Effect of groove shape on laser welding-brazing Al to steel. J. Mater. Process. Technol. 2018, 252, 573–581. [Google Scholar]

- Li, L.; Xia, H.; Tan, C.; Ma, N. Influence of laser power on interfacial microstructure and mechanical properties of laser welded-brazed Al/steel dissimilar butted joint. J. Manuf. Process. 2018, 32, 160–174. [Google Scholar] [CrossRef]

- Tan, C.; Zang, C.; Xia, H.; Zhao, X.; Zhang, K.; Meng, S.; Chen, B.; Song, X.; Li, L. Influence of Al additions in Zn–based filler metals on laser welding–brazing of Al/steel. J. Manuf. Process. 2018, 34, 251–263. [Google Scholar] [CrossRef]

- Xia, H.; Zhao, X.; Tan, C.; Chen, B.; Song, X.; Li, L. Effect of Si content on the interfacial reactions in laser welded-brazed Al/steel dissimilar butted joint. J. Mater. Process. Technol. 2018, 258, 9–21. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, L.; Tan, C.; Wu, L.; Chen, B.; Li, L. Effect of heat input on a laser powder deposited Al/steel butt joint. Opt. Laser Technol. 2019, 111, 459–469. [Google Scholar] [CrossRef]

- Zhang, H.T.; Feng, J.C.; He, P.; Hackl, H. Interfacial microstructure and mechanical properties of aluminium–zinc-coated steel joints made by a modified metal inert gas welding–brazing process. Mater. Charact. 2007, 58, 588–592. [Google Scholar] [CrossRef]

- Zhang, H.T.; Feng, J.C.; He, P.; Zhang, B.B.; Chen, J.M.; Wang, L. The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel. Mater. Sci. Eng. A 2009, 499, 111–113. [Google Scholar] [CrossRef]

- Lin, J.; Ma, N.; Lei, Y.; Murakawa, H. Shear strength of CMT brazed lap joints between aluminum and zinc-coated steel. J. Mater. Process. Technol. 2013, 213, 1303–1310. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, J.; Lian, J.; Lei, Y. Welding of aluminum alloy to zinc coated steel by cold metal transfer. Mater. Des. 2013, 49, 602–612. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Acarer, M.; Demir, B. An investigation of mechanical and metallurgical properties of explosive welded aluminum–dual phase steel. Mater. Lett. 2008, 62, 4158–4160. [Google Scholar] [CrossRef]

- Tricarico, L.; Spina, R. Experimental investigation of laser beam welding of explosion-welded steel/aluminum structural transition joints. Mater. Des. 2010, 31, 1981–1992. [Google Scholar] [CrossRef]

- Han, J.H.; Ahn, J.P.; Shin, M.C. Effect of interlayer thickness on shear deformation behavior of AA5083 aluminum alloy/SS41 steel plates manufactured by explosive welding. J. Mater. Sci. 2003, 38, 13–18. [Google Scholar] [CrossRef]

- Aceves, S.M.; Espinosa-Loza, F.; Elmer, J.W.; Huber, R. Comparison of Cu, Ti and Ta interlayer explosively fabricated aluminum to stainless steel transition joints for cryogenic pressurized hydrogen storage. Int. J. Hydrog. Energy 2015, 40, 1490–1503. [Google Scholar] [CrossRef]

- Sherpa, B.B.; Upadhyay, A.; Kumar, S.; Kumar, P.D.; Agarwal, A. Examination of Joint Integrity in parallel plate configuration of explosive welded SS-Al combination. Mater. Today Proc. 2017, 4, 1260–1267. [Google Scholar] [CrossRef]

- Technical Brochure; Dynamic Materials Corp.: Boulder, CO, USA, 2012.

- Technical Brochure; Merrem & La Porte, B.V.: Zaltbommel, The Netherlands, 2005.

- Nobili, D.; Gauthier, A. Specification Number NC 630a; Nobelclad Europe SA: Rivesaltes, France, 2011. [Google Scholar]

- Aizawa, T. Magnetic pressure seam welding method for aluminium sheets. Weld. Int. 2003, 17, 929–933. [Google Scholar] [CrossRef]

- Aizawa, T. Magnetic pressure seam welding method for sheet metals. J. Jpn. Inst. Light Met. 2004, 54, 153–158. [Google Scholar] [CrossRef]

- Watanabe, M.; Kumai, S.; Aizawa, T. Interfacial microstructure of magnetic pressure seam welded Al-Fe, Al-Ni and Al-Cu lap joints. Mater. Sci. Forum 2006, 519–521, 1145–1150. [Google Scholar] [CrossRef]

- Manogaran, A.P.; Manoharan, P.; Priem, D.; Marya, S.; Racineux, G. Magnetic pulse spot welding of bimetals. J. Mater. Process. Technol. 2014, 214, 1236–1244. [Google Scholar] [CrossRef]

- Lee, K.J.; Kumai, S.; Arai, T.; Aizawa, T. Interfacial microstructure and strength of steel/aluminum alloy lap joint fabricated by magnetic pressure seam welding. Mater. Sci. Eng. A 2007, 471, 95–101. [Google Scholar] [CrossRef]

- Kore, S.D.; Date, P.P.; Kulkarni, S.V. Electromagnetic impact welding of aluminum to stainless steel sheets. J. Mater. Process. Technol. 2008, 208, 486–493. [Google Scholar] [CrossRef]

- Thibaudeau, E.; Kinsey, B.L. Analytical design and experimental validation of uniform pressure actuator for electromagnetic forming and welding. J. Mater. Process. Technol. 2015, 215, 251–263. [Google Scholar] [CrossRef]

- Nezhad, M.S.A.; Ardakani, A.H. A study of joint quality of aluminum and low carbon steel strips by warm rolling. Mater. Des. 2009, 30, 1103–1109. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Reihani, S.S. Investigation on the bond strength of Al-1100/St-12 roll bonded sheets, optimization and characterization. Mater. Des. 2011, 32, 3143–3149. [Google Scholar] [CrossRef]

- Akramifard, H.R.; Mirzadeh, H.; Parsa, M.H. Cladding of aluminum on AISI 304L stainless steel by cold roll bonding: Mechanism, microstructure, and mechanical properties. Mater. Sci. Eng. A 2014, 613, 232–239. [Google Scholar] [CrossRef]

- Gao, C.; Li, L.; Chen, X.; Zhou, D.; Tang, C. The effect of surface preparation on the bond strength of Al-St strips in CRB process. Mater. Des. 2016, 107, 205–211. [Google Scholar] [CrossRef]

- Danesh Manesh, H.; Karimi Taheri, A. Study of mechanisms of cold roll welding of aluminium alloy to steel strip. Mater. Sci. Technol. 2004, 20, 1064–1068. [Google Scholar] [CrossRef]

- Pircher, H.; Kawalla, R.; Poprawe, R.; Sussek, G. Laser-Assisted Plating of Strip. U.S. Patent Application No. 08/875,676, 23 January 1996. [Google Scholar]

- Jahn, A.; Brenner, B.; Wagner, M.; Pautzsch, R.; Bellmann, J. Laser joined steel-aluminum hybrid structures. Presented at the “Materials in Car-Body Engineering” Conference, Bad Nauheim, Germany, 13–14 May 2014. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Welding. U.S. Patent Application No. 244,612, 1 August 1994. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Friction stir welding of aluminum alloy to steel. Weld. J. 2004, 83, 277. [Google Scholar]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Tanaka, T.; Morishige, T.; Hirata, T. Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr. Mater. 2009, 61, 756–759. [Google Scholar] [CrossRef]

- Colwell, K.C. Two metals enter, one leaves: The miracle of friction stir welding. Car and Driver, 15 May 2013. [Google Scholar]

- Connolly, C. Friction spot joining in aluminium car bodies. Ind. Robot Int. J. 2007, 34, 17–20. [Google Scholar] [CrossRef]

- Liyanage, T.; Kilbourne, J.; Gerlich, A.P.; North, T.H. Joint formation in dissimilar Al alloy/steel and Mg alloy/steel friction stir spot welds. Sci. Technol. Weld. Join. 2009, 14, 500–508. [Google Scholar] [CrossRef]

- Miyagawa, K.; Tsubaki, M.; Yasui, T.; Fukumoto, M. Spot welding between aluminium alloy and Zn-coated steel by friction stirring. Weld. Int. 2009, 23, 648–653. [Google Scholar] [CrossRef]

- Dong, H.; Chen, S.; Song, Y.; Guo, X.; Zhang, X.; Sun, Z. Refilled friction stir spot welding of aluminum alloy to galvanized steel sheets. Mater. Des. 2016, 94, 457–466. [Google Scholar] [CrossRef]

- Chen, Y.C.; Gholinia, A.; Prangnell, P.B. Interface structure and bonding in abrasion circle friction stir spot welding: A novel approach for rapid welding aluminium alloy to steel automotive sheet. Mater. Chem. Phys. 2012, 134, 459–463. [Google Scholar] [CrossRef]

- Alber, U. Friction element welding–Innovations for hybrid body parts. Presented at the "Joining in Car-Body Engineering" Conference, Bad Nauheim, Germany, 17–19 April 2012. [Google Scholar]

- Miles, M.; Hong, S.T.; Woodward, C.; Jeong, Y.H. Spot welding of aluminum and cast iron by friction bit joining. Int. J. Precis. Eng. Manuf. 2013, 14, 1003–1006. [Google Scholar] [CrossRef]

- Squires, L.; Lim, Y.C.; Miles, M.P.; Feng, Z. Mechanical properties of dissimilar metal joints composed of DP 980 steel and AA 7075-T6. Sci. Technol. Weld. Join. 2015, 20, 242–248. [Google Scholar] [CrossRef]

- Miles, M.P.; Kohkonen, K.; Packer, S.; Steel, R.; Siemssen, B.; Sato, Y.S. Solid state spot joining of sheet materials using consumable bit. Sci. Technol. Weld. Join. 2009, 14, 72–77. [Google Scholar] [CrossRef]

- Miles, M.P.; Feng, Z.; Kohkonen, K.; Weickum, B.; Steel, R.; Lev, L. Spot joining of AA 5754 and high strength steel sheets by consumable bit. Sci. Technol. Weld. Join. 2010, 15, 325–330. [Google Scholar] [CrossRef]

- Lim, Y.C.; Squires, L.; Pan, T.Y.; Miles, M.; Song, G.L.; Wang, Y.; Feng, Z. Study of mechanical joint strength of aluminum alloy 7075-T6 and dual phase steel 980 welded by friction bit joining and weld-bonding under corrosion medium. Mater. Des. 2015, 69, 37–43. [Google Scholar] [CrossRef]

- Zebisch, S.; Mielisch, M. Friction Welding Element. U.S. Patent Application No. 14/135,208, 19 December 2013. [Google Scholar]

- Lim, Y.C.; Squires, L.; Pan, T.Y.; Miles, M.; Keum, J.K.; Song, G.L.; Wang, Y.; Feng, Z. Corrosion behaviour of friction-bit-joined and weld-bonded AA7075-T6/galvannealed DP980. Sci. Technol. Weld. Join. 2017, 22, 455–464. [Google Scholar]

- Daniels, H.P.C.; Botden, T.Р.; Philips, N.V. Ultrasonic welding in microminiaturization. IFAC Proc. Vol. 1965, 2, 473–484. [Google Scholar] [CrossRef]

- Gould, J.E. Joining aluminum sheet in the automotive industry—A 30 year history. Weld. J. 2012, 91, 23s–34s. [Google Scholar]

- Chen, Y.C.; Bakavos, D.; Gholinia, A.; Prangnell, P.B. HAZ development and accelerated post-weld natural ageing in ultrasonic spot welding aluminium 6111-T4 automotive sheet. Acta Mater. 2012, 60, 2816–2828. [Google Scholar] [CrossRef]

- Bakavos, D.; Prangnell, P.B. Mechanisms of joint and microstructure formation in high power ultrasonic spot welding 6111 aluminium automotive sheet. Mater. Sci. Eng. A 2010, 527, 6320–6334. [Google Scholar] [CrossRef]

- Haddadi, F. Microstructure reaction control of dissimilar automotive aluminium to galvanized steel sheets ultrasonic spot welding. Mater. Sci. Eng. A 2016, 678, 72–84. [Google Scholar] [CrossRef]

- Haddadi, F.; Abu-Farha, F. The effect of interface reaction on vibration evolution and performance of aluminium to steel high power ultrasonic spot joints. Mater. Des. 2016, 89, 50–57. [Google Scholar] [CrossRef]

- Zhao, D.; Ren, D.; Zhao, K.; Pan, S.; Guo, X. Effect of welding parameters on tensile strength of ultrasonic spot welded joints of aluminum to steel—By experimentation and artificial neural network. J. Manuf. Process. 2017, 30, 63–74. [Google Scholar] [CrossRef]

- Prangnell, P.; Haddadi, F.; Chen, Y.C. Ultrasonic spot welding of aluminium to steel for automotive applications—Microstructure and optimisation. Mater. Sci. Technol. 2011, 27, 617–624. [Google Scholar]

- Shakil, M.; Tariq, N.H.; Ahmad, M.; Choudhary, M.A.; Akhter, J.I.; Babu, S.S. Effect of ultrasonic welding parameters on microstructure and mechanical properties of dissimilar joints. Mater. Des. 2014, 55, 263–273. [Google Scholar] [CrossRef]

- Watanabe, T.; Sakuyama, H.; Yanagisawa, A. Ultrasonic welding between mild steel sheet and Al–Mg alloy sheet. J. Mater. Process. Technol. 2009, 209, 5475–5480. [Google Scholar] [CrossRef]

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Ultrasonic spot welding of aluminum to high-strength low-alloy steel: Microstructure, tensile and fatigue properties. Metall. Mater. Trans. A 2014, 45, 2055–2066. [Google Scholar] [CrossRef]

- Arghavani, M.R.; Movahedi, M.; Kokabi, A.H. Role of zinc layer in resistance spot welding of aluminium to steel. Mater. Des. 2016, 102, 106–114. [Google Scholar]

- Chen, N.; Wang, H.P.; Carlson, B.E.; Sigler, D.R.; Wang, M. Fracture mechanisms of Al/steel resistance spot welds in lap shear test. J. Mater. Process. Technol. 2017, 243, 347–354. [Google Scholar]

- Piccini, J.M.; Svoboda, H.G. Tool geometry optimization in friction stir spot welding of Al-steel joints. J. Manuf. Process. 2017, 26, 142–154. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y. Effect of input current modes on intermetallic layer and mechanical property of aluminum–steel lap joint obtained by gas metal arc welding. Mater. Sci. Eng. A 2013, 578, 340–345. [Google Scholar] [CrossRef]

- Basak, S.; Das, H.; Pal, T.K.; Shome, M. Characterization of intermetallics in aluminum to zinc coated interstitial free steel joining by pulsed MIG brazing for automotive application. Mater. Charact. 2016, 112, 229–237. [Google Scholar] [CrossRef]

- Yagati, K.P.; Bathe, R.N.; Rajulapati, K.V.; Rao, K.B.S.; Padmanabham, G. Fluxless arc weld-brazing of aluminium alloy to steel. J. Mater. Process. Technol. 2014, 214, 2949–2959. [Google Scholar]

- Pouranvari, M.; Abbasi, M. Dissimilar gas tungsten arc weld-brazing of Al/steel using Al-Si filler metal: Microstructure and strengthening mechanisms. J. Alloys Compd. 2018, 749, 121–127. [Google Scholar] [CrossRef]

- Coelho, R.S.; Kostka, A.; Sheikhi, S.; Dos Santos, J.; Pyzalla, A.R. Microstructure and mechanical properties of an AA6181-T4 aluminium alloy to HC340LA high strength steel friction stir overlap weld. Adv. Eng. Mater. 2008, 10, 961–972. [Google Scholar]

- Cui, L.; Chen, B.; Qian, W.; He, D.; Chen, L. Microstructures and mechanical properties of dissimilar Al/Steel butt joints produced by autogenous laser keyhole welding. Metals 2017, 7, 492. [Google Scholar] [CrossRef]

- Qin, G.; Ji, Y.; Ma, H.; Ao, Z. Effect of modified flux on MIG arc brazing-fusion welding of aluminum alloy to steel butt joint. J. Mater. Process. Technol. 2017, 245, 115–121. [Google Scholar] [CrossRef]

| Method | Al Alloy Sheet | Steel Sheet | Interlayer, Cover Plate or Bit Material | Nugget or Bit Diameter (mm) | Tensile Shear Force (N) | IMC th. (µm) | Reference | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Grade | th. (mm) | Grade | th. (mm) | Zn | ||||||

| Plain Resistance Spot Welding (RSW) | 5052 | 2 | DC01 | 1 | N | - | 8.5 | 5300 | 5.5 | [114] |

| 5052 | 2 | Low C | 1 | Y | - | 9.3 | 6500 | 4 | [114] | |

| 5083 | 1.5 | DP980 | 1 | N | - | 7 | 4000 | 1 | [22] | |

| 6022 | 1.2 | Low C | 2 | Y | - | 7.8 | 5000 | 2.5 | [115] | |

| RSW with process tape | 5083 | 1.5 | DP980 | 1 | N | - | 9.5 | 4500 | 2.4 | [22] |

| RSW with interlayer | 5182 | 2 | SAE 1008 | 1.4 | N | Al 0.3/steel 1.2 mm | 8.2–10 | 7500 | 8.5 | [30] |

| RSW with cover plate | 5052 | 1 | SPCC (DC01) | 1 | N | SPCC (1 mm) | 8.9 | 4680 | 2.5 | [23] |

| Resistance Element Welding | 6061 | 2 | 22MnMoB | 1.8 | N | Steel Q235 | 5 | 7086 | 4 | [34] |

| 6061 | 2 | DP780 | 1.4 | N | Steel Q235 | 5 | 7368 | n. d. | [35] | |

| Friction Bit Joining | 5754 | 1.8 | DP980 | 1.4 | N | Steel 4140 | 6 | 6300 | n. r. | [98] |

| 5754 | 1.8 | DP590 | 1.6 | N | Steel 4140 | 6.5 | 6400 | n. r. | [99] | |

| Ultrasonic Spot welding | 6111 | 1 | DX 56-Z | 1 | Y | - | - | 2700 | 10 | [107] |

| 6111 | 1 | DX 53-ZF | 1 | Y | - | - | 3200 | 15 | [107] | |

| 6061 | 1 | A36 | 1.5 | N | - | 10 | 3919 | n. r. | [109] | |

| 6111 | 0.93 | DC04 | 1 | N | - | - | 2800 | 1.8 | [110] | |

| 5754 | 1.5 | HSLA | 0.8 | Y | - | - | 3700 | n. r. | [113] | |

| Friction Stir Spot Welding | 6111 | 1 | DC04 | 1 | N | - | 8 | 3500 | n. d. | [94] |

| 6111 | 1.15 | Low C | 1.8 | Y | - | - | 2070 | n. r. | [91] | |

| 5052 | 1 | Low C | 0.65 | N | - | - | 2700 | < 5 | [116] | |

| Method | Al Sheet | Steel Sheets | Filler | Tensile Shear Stress | IMC th. (µm) | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade | th. (mm) | UTS (MPa) | Grade | th. (mm) | Zn | (MPa) | (%) | ||||

| MIG-CMT Arc welding | 6061 | 2 | 235 | DP600 | 1.2 | Y | AlSi5 | 104 | 44 | N. A. | [59] |

| 6061 | 2 | n. r. | Low C | 1.2 | Y | AlSi5 | 133 | n. a. | <5 | [60] | |

| 5052 | 1 | n. r. | mild steel | 1 | Y | AlSi12 | 201 | n. a. | 2–3 | [117] | |

| MIG Arc welding | 6061 | 2 | 295 | IF | 1 | Y | AlSi5 | 122 | 41 | 6.1–14 | [118] |

| 5754 | 3 | n. r. | Low C | 2 | Y | AlSi3Mn | 188 | n. a. | 5.4 | [11] | |

| 6061 | 2 | n. r. | IF Steel | 1.2 | Y | AlSi5 | 111 | n. a. | 1.5–3.5 | [119] | |

| TIG Arc welding | 5A02 | 2 | n. r. | Q235 | 1.5 | Y | AlSi12 | 136 | n. a. | 2 | [9] |

| 6061 | 2 | n. r. | DQSK | 1.5 | Y | AlSi5 | 103 | n. a. | 2–4 | [120] | |

| Laser welding | 6016 | 1 | 260 | DC04 | 1.2 | N | AlSi12 | 190 | 73 | <2 | [47] |

| 6016 | 1 | 260 | DC04 | 1.2 | Y | - | 250 | 96 | 12 | [45] | |

| 6451 | 1 | 230 | Low C | 0.8 | Y | - | 146 | 63 | 5 | [46] | |

| Friction Stir Welding | 6181 | 1.5 | n. r. | HC340LA | 1.5 | N | - | 230 | n. a. | 0.2 | [121] |

| Method | Al Sheet | Steel Sheet | Filler | Tensile Strength | IMC th. (µm) | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade | th. (mm) | UTS (MPa) | Grade | th. (mm) | Zn | (MPa) | (%) | ||||

| Laser welding | 6061 | 2.5 | n. r. | Q235 | 2.5 | Y | AlSi5 | 150 | n. a. | 8.3 | [50] |

| 5251 | 1 | 190 | 0.1% C, 5% Mn | 1 | N | AlSi12 | 128 | 67 | 4 | [51] | |

| 6061 | 2 | 310 | DP590 | 2 | N | AlSi10Mg | 194 | 63 | 10 | [56] | |

| 5083 | 6 | n. r. | Q235 | 6 | N | - | 110 | n. a. | >10 | [122] | |

| 6061 | 1.5 | 310 | DP590 | 1.2 | N | ZnAl22 | 274 | 88 | 8.4–13 | [54] | |

| 6061 | 1.5 | 310 | DP590 | 1.2 | N | AlSi5 | 208 | 67 | 3.8–7.5 | [55] | |

| 6061 | 2 | 310 | DP590 | 2 | N | AlSi12 | 140 | 45 | 4.9–8.6 | [52,53] | |

| MIG | 5052 | 1.5 | n. r. | Low C | 1.2 | Y | AlSi5 | 120 | n. a. | >2 | [123] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gullino, A.; Matteis, P.; D’Aiuto, F. Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals 2019, 9, 315. https://doi.org/10.3390/met9030315

Gullino A, Matteis P, D’Aiuto F. Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals. 2019; 9(3):315. https://doi.org/10.3390/met9030315

Chicago/Turabian StyleGullino, Alessio, Paolo Matteis, and Fabio D’Aiuto. 2019. "Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications" Metals 9, no. 3: 315. https://doi.org/10.3390/met9030315

APA StyleGullino, A., Matteis, P., & D’Aiuto, F. (2019). Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals, 9(3), 315. https://doi.org/10.3390/met9030315