The Influence of Heat Treatment Parameters on the Cracks Growth under Cyclic Bending in St-Ti Clad Obtained by Explosive Welding

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

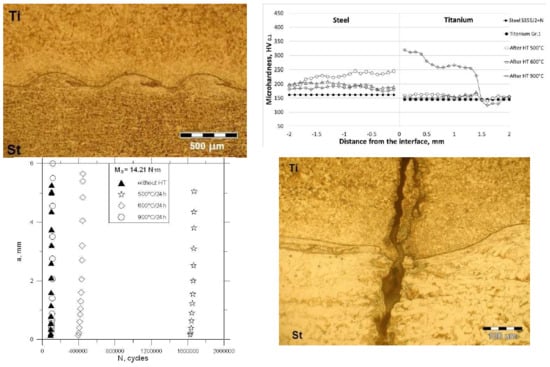

3.1. Microhardness Analysis

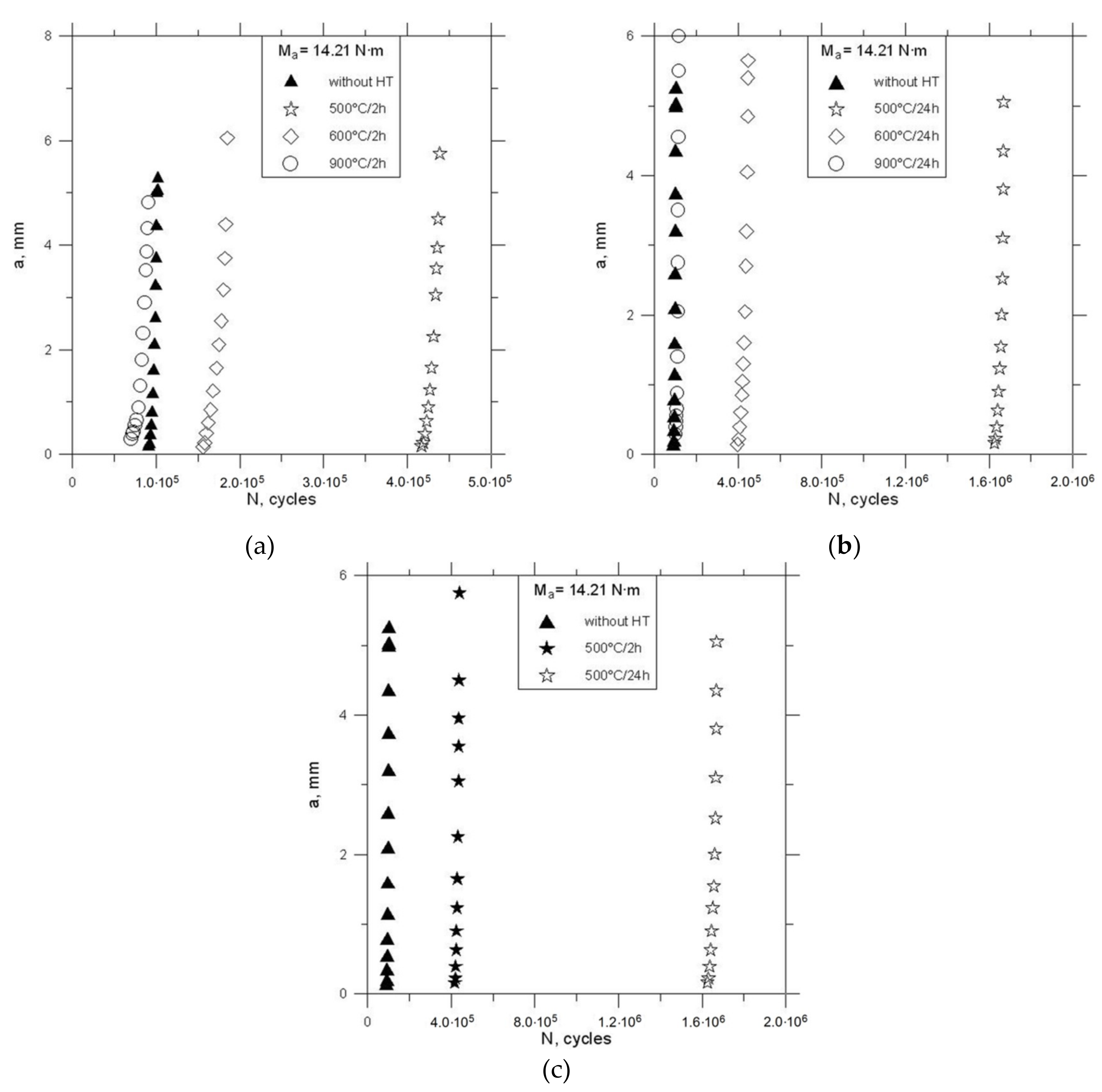

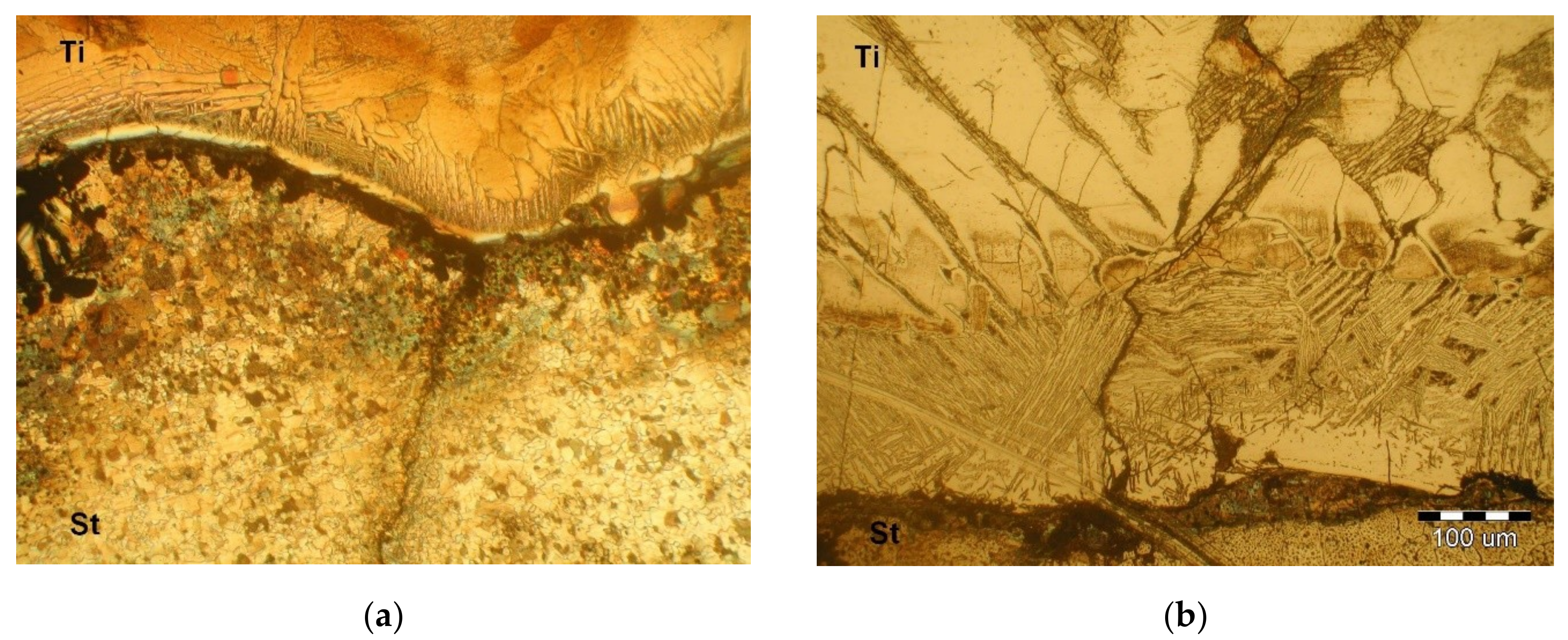

3.2. Fatigue Crack Growth and Metallography

4. Conclusions

- There was a clear relationship between temperature and time of heat treatment and the growth of fatigue cracks. As the annealing temperature increased, the fatigue life decreased. Also for a given annealing temperature, the longer annealing time, the higher the fatigue life.

- The heat treatment temperature has a significant effect on the distribution of the micro-hardness of the clad. The highest micro-hardness occurs in the bond zone on the titanium side.

- The temperature increase changes the metallographic structure bimetal. As the heat treatment temperature increases, recrystallization and grain growth (mainly in titanium) are observed. In steel, decarburization was observed to occur at the interface.

Author Contributions

Conflicts of Interest

References

- Crossland, B. Explosive Welding of Metals and its Application; Oxford University Press: New York, NY, USA, 1982. [Google Scholar]

- Deribas, A.A.; Kudinov, V.M.; Matveenko, F. Effect of initial parameters on process of wave formation in 683 explosive welding. Combust. Explos. Shock Waves 1967, 3, 344–348. [Google Scholar] [CrossRef]

- Xie, M.X.; Shang, X.T.; Zhang, L.J.; Bai, Q.L.; Xu, T.T. Interface characteristic of explosive-welded and hot-rolled TA1/X65 bimetallic plate. Metals 2018, 8, 159. [Google Scholar] [CrossRef]

- Xie, M.X.; Zhang, L.J.; Zhang, G.F.; Zhang, J.X.; Bi, Z.Y.; Li, P.C. Microstructure and mechanical properties of CP-Ti/X65 bimetallic sheets fabricated by explosive welding and hot rolling. Mater. Des. 2015, 87, 181–197. [Google Scholar] [CrossRef]

- Szachogluchowicz, I.; Sniezek, L.; Hutsaylyuk, V. Low cycle fatigue properties of AA2519–Ti6Al4V laminate bonded by explosion welding. Eng. Fail. Anal. 2016, 69, 77–87. [Google Scholar] [CrossRef]

- Prażmowski, M.; Rozumek, D.; Paul, H. Static and fatigue tests of bimetal Zr-steel made by explosive welding. Eng. Fail. Anal. 2017, 75, 71–81. [Google Scholar] [CrossRef]

- Prażmowski, M.; Paul, H. The effect of stand-off distance on the structure and properties of zirconium—Carbon steel bimetal produced by explosion welding. Arch. Metall. Mater. 2012, 57, 1201–1210. [Google Scholar] [CrossRef][Green Version]

- Rozumek, D.; Marciniak, Z. Fatigue tests of bimetal zirconium-steel made by explosive welding. Procedia Eng. 2016, 160, 137–142. [Google Scholar] [CrossRef]

- Banker, J. Advances in Explosion Welding. The Handbook of Advanced Welding; Woodhead Publishing Ltd.: London, UK, 2004. [Google Scholar]

- Prażmowski, M.; Paul, H.; Żok, F. The effect of heat treatment on the properties of zirconium-carbon steel bimetal produced by explosion welding. Arch. Metal. Mater. 2014, 59, 1143–1149. [Google Scholar] [CrossRef]

- Mousavi, S.A.A.; Al-Hassani, S.T.S.; Atkins, A.G. Bond strength of explosively welded specimens. Mater. Des. 2008, 29, 1334–1352. [Google Scholar] [CrossRef]

- Mousavi, S.A.A.; Farhadi, S.P. Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel. Mater. Des. 2009, 30, 459–468. [Google Scholar] [CrossRef]

- Deribas, A.A.; Kudinov, V.M.; Sobolenko, T.M. Shock hardening of low-carbon steel plates at variable impact angle. Combust. Explos. Shock Waves 1967, 3, 424–431. [Google Scholar] [CrossRef]

- Gloc, M.; Wachowski, M.; Plocinski, T.; Kurzydlowski, K.J. Microstructural and microanalysis investigations of bond titanium grade1/low alloy steel st52-3N obtained by explosive welding. J. Alloys Compd. 2016, 671, 446–451. [Google Scholar] [CrossRef]

- Rao, N.V.; Reddy, G.M.; Nagarjuna, S. Structure and properties of explosive clad HSLA steel with titanium. Trans. Indian Inst. Metals 2014, 67, 67–77. [Google Scholar]

- Nishida, M.; Chiba, A.; Honda, Y.; Hirazumi, J.I.; Horikiri, K. Electron microscopy studies of bonding interface in explosively welded Ti/steel clads. ISIJ Int. 1995, 35, 217–219. [Google Scholar] [CrossRef]

- Karolczuk, A.; Kowalski, M.; Bański, R.; Zok, F. Fatigue phenomena in explosively welded steel-titanium clad components subjected to push-pull loading. Int. J. Fatigue 2013, 48, 101–108. [Google Scholar] [CrossRef]

- Sniezek, L.; Szachogluchowicz, I.; Wachowski, M.; Torzewski, J.; Mierzynski, J. High cycle fatigue properties of explosively welded laminate AA2519/AA1050/Ti6A14V. Procedia Struct. Integr. 2017, 5, 422–429. [Google Scholar] [CrossRef]

- Rozumek, D.; Bański, R. Crack growth rate under cyclic bending in the explosively welded steel/titanium bimetals. Mater. Des. 2012, 38, 139–146. [Google Scholar] [CrossRef]

- Rozumek, D.; Hepner, M. Influence of microstructure on fatigue crack propagation under bending in the alloy Ti-6Al-4V after heat treatment. Mat. Wiss. Werkstofftech. 2015, 46, 1088–1095. [Google Scholar] [CrossRef]

- Rozumek, D.; Marciniak, Z. The investigation of crack growth in specimens with rectangular cross-sections under out-of-phase bending and torsional loading. Int. J. Fatigue 2012, 39, 81–87. [Google Scholar] [CrossRef]

- Lewandowski, J.; Rozumek, D. Cracks growth in S355 steel under cyclic bending with fillet welded joint. Theor. Appl. Fract. Mech. 2016, 86, 342–350. [Google Scholar] [CrossRef]

- Walczak, W. Explosive Welding of Metals; WNT: Warsaw, Poland, 1989. [Google Scholar]

- Karolczuk, A.; Paul, H.; Szulc, Z.; Kluger, K.; Najwer, M.; Kwiatkowski, G. Residual Stresses in Explosively Welded Plates Made of Titanium Grade 12 and Steel with Interlayer. J. Mater. Eng. Perform. 2018, 27, 4571–4581. [Google Scholar] [CrossRef]

| Materials | Chemical Composition (≤%) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S355J2 + N | C | Mn | Si | P | S | Cu | Ni | Cr | Mo | V | Al | Nb | Fe | |||||

| 0.19 | 1.41 | 0.30 | 0.01 | 0.03 | 0.23 | 0.03 | 0.05 | 0.04 | 0.03 | 0.03 | 0.003 | Bal. | ||||||

| Ti Gr.1 | C | Fe | H | O | N | Ti | ||||||||||||

| 0.1 | 0.2 | 0.01 | 0.18 | 0.03 | Bal. | |||||||||||||

| Materials | σu (MPa) | σy (MPa) | E (GPa) | ν |

|---|---|---|---|---|

| S355J2 + N | 578 | 368 | 210 | 0.3 |

| Ti Gr.1 | 308 | 193 | 104 | 0.37 |

| Temp. HT (°C)/Time (h) | Average Wave-Length (μm) | Average Wave-Height (μm) | Value of ETR (μm) | Detonation Velocity (m/s) |

|---|---|---|---|---|

| Without HT | 217 | 41 | 1.5 | 2200 |

| 500/2 | 2112 | 518 | 19.6 | 3000 |

| 600/2 | 2252 | 480 | 50.1 | 3000 |

| 900/2 | 2214 | 462 | 46.2 | 3000 |

| 500/24 | 843 | 99 | 3.0 | 2200 |

| 600/24 | 781 | 79 | 3.1 | 2200 |

| 900/24 | 822 | 92 | 3.1 | 2200 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rozumek, D.; Kwiatkowski, G. The Influence of Heat Treatment Parameters on the Cracks Growth under Cyclic Bending in St-Ti Clad Obtained by Explosive Welding. Metals 2019, 9, 338. https://doi.org/10.3390/met9030338

Rozumek D, Kwiatkowski G. The Influence of Heat Treatment Parameters on the Cracks Growth under Cyclic Bending in St-Ti Clad Obtained by Explosive Welding. Metals. 2019; 9(3):338. https://doi.org/10.3390/met9030338

Chicago/Turabian StyleRozumek, Dariusz, and Grzegorz Kwiatkowski. 2019. "The Influence of Heat Treatment Parameters on the Cracks Growth under Cyclic Bending in St-Ti Clad Obtained by Explosive Welding" Metals 9, no. 3: 338. https://doi.org/10.3390/met9030338

APA StyleRozumek, D., & Kwiatkowski, G. (2019). The Influence of Heat Treatment Parameters on the Cracks Growth under Cyclic Bending in St-Ti Clad Obtained by Explosive Welding. Metals, 9(3), 338. https://doi.org/10.3390/met9030338