Plasma Printing of an AISI316 Micro-Meshing Punch Array for Micro-Embossing onto Copper Plates

Abstract

:1. Introduction

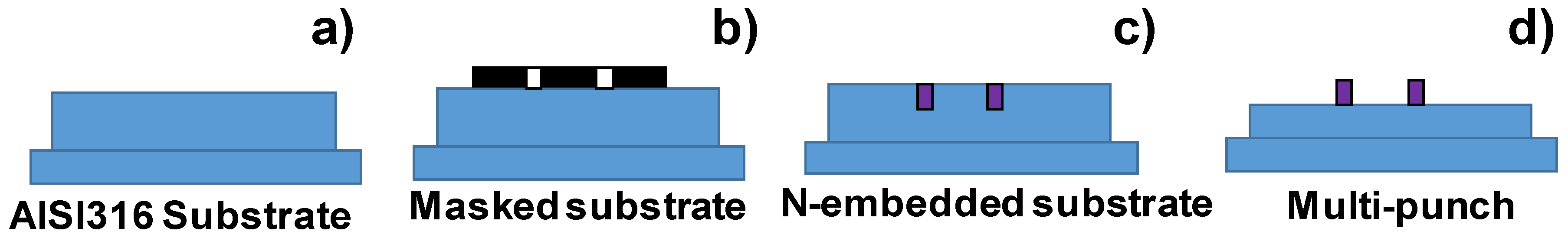

2. Experimental Procedure

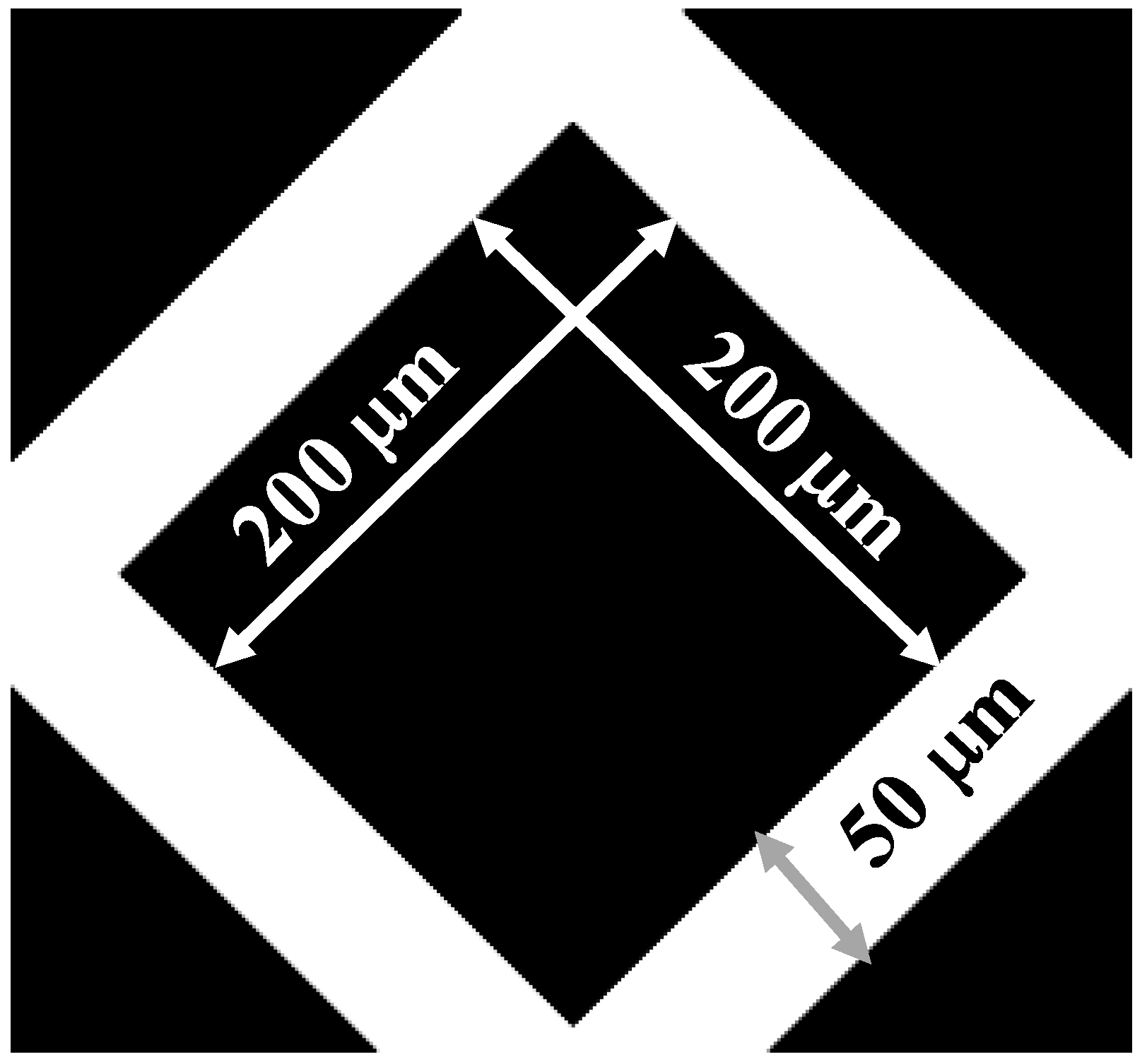

2.1. Screen Printing onto Die Substrate

2.2. Low-Temperature Plasma Nitriding

2.3. Mechanical Blasting Process

2.4. Micro-Embossing Process

2.5. Evaluation Method for Micro-Embossed AISI316 Die Substrate

3. Experimental Results

3.1. Two-Dimensional Micro-Patterning onto AISI316 Die Materials

3.2. Plasma Printing with Use of High-Density Nitrogen–Hydrogen Plasmas

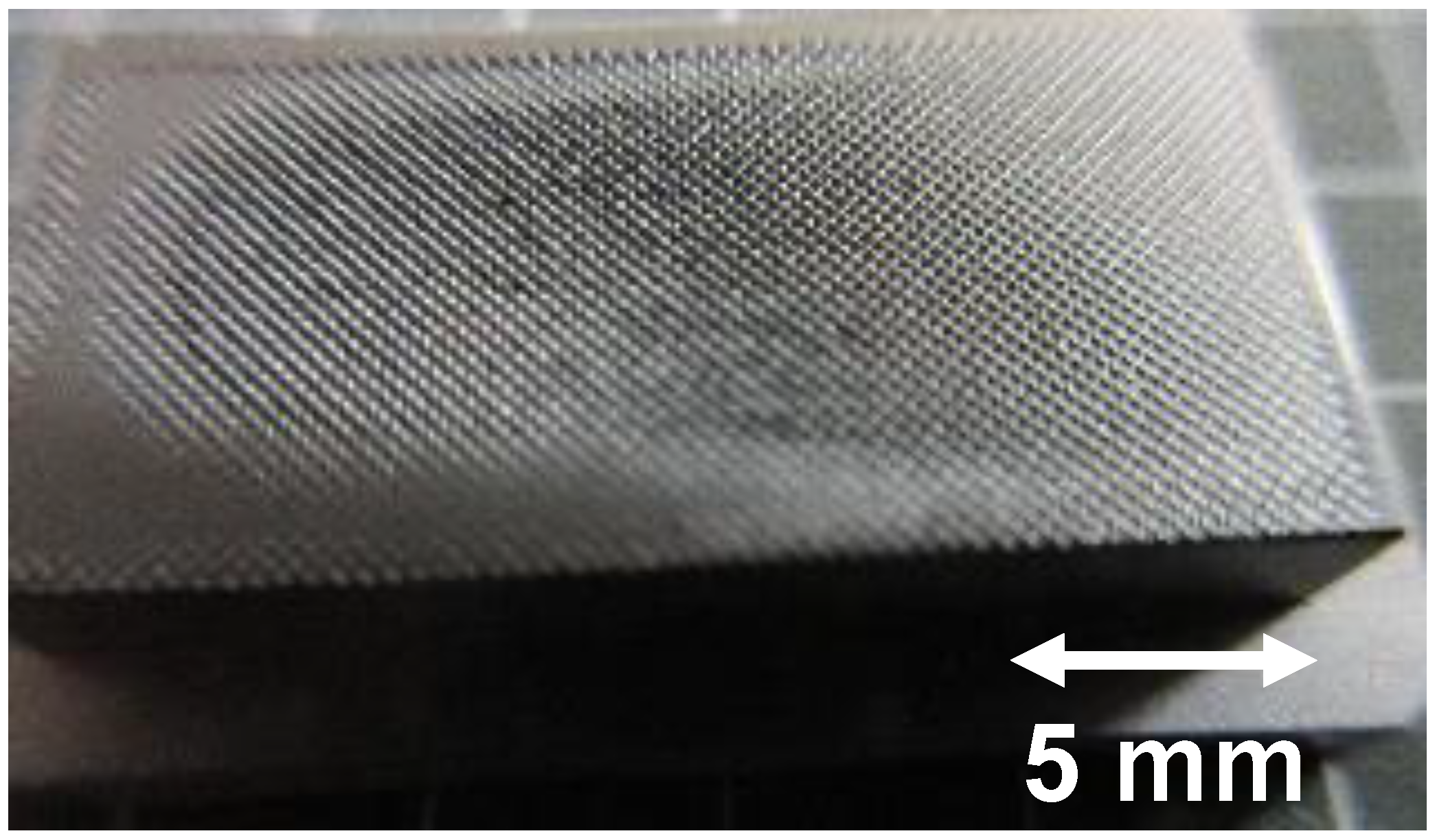

3.3. Formation of a Micro-Meshing Punch Array by Blasting Process

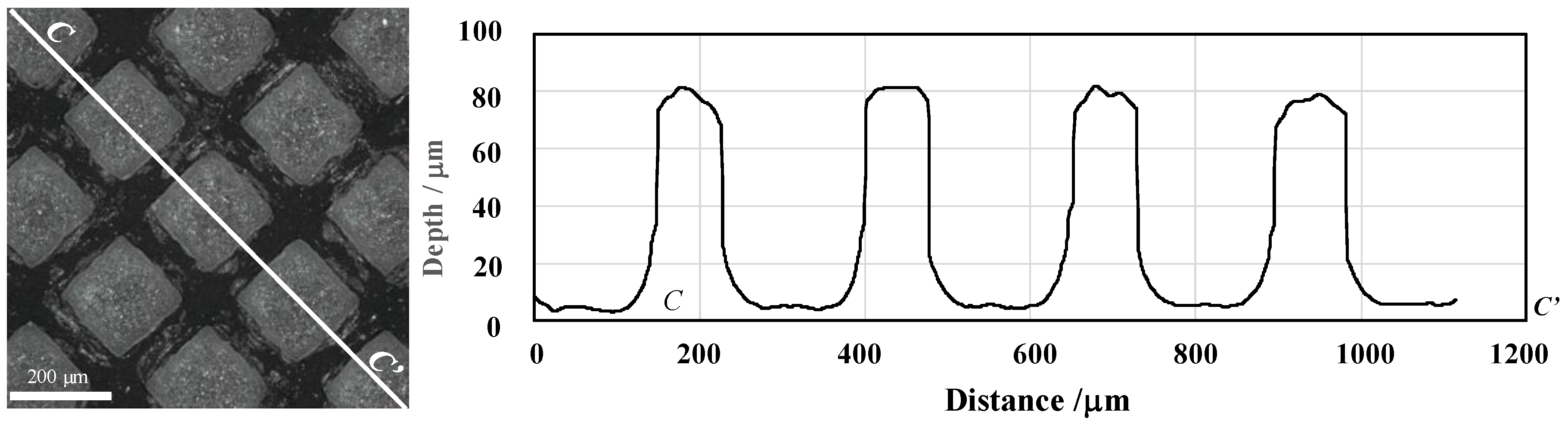

3.4. Micro-Embossing onto Copper Plates

3.5. Transcription Processes from Micropattern on Screen to Copper Micro-Textures

3.6. Roughness Profiles on the Punch Array Heads and the Meshed Cavities in Copper Substrate

3.7. Evaluation of the Dimensional Accuracy of the Punch Array

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Balden, A. Adhesively bonded joints and repairs in metallic alloy, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Satoh, T.; Aizawa, T.; Shiratori, T.; Sugita, Y.; Anzai, M. Micro-joining of multi stainless steel sheets into mechanical element by low temperature diffusion process. Procedia Manuf. 2018, 15, 1475–1480. [Google Scholar] [CrossRef]

- Doughetty, D.; Mahalingam, M.; Viswanathan, V.; Zimmerman, M. Multi-lead organic air-cavity package for high power high frequency RFICs. In Proceedings of the 2009 IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 7–12 June 2009; pp. 473–476. [Google Scholar]

- Saito, Y.; Aizawa, T.; Wasa, K.; Nogami, Y. Leak-proof packaging for GaN chip with controlled thermal spreading and transients. In Proceedings of the 2018 IEEE BiCMOS and Compound Semiconductor Integrated Circuits and Technology Symposium, San Diego, CA, USA, 14–17 October 2018. in press. [Google Scholar]

- Denkena, B.; Koehler, J.; Laestner, J. Efficient machining of micro-dimples for friction reduction. In Proceedings of the 7th ICOMM, Chicago, IL, USA, 12 March 2012; pp. 85–89. [Google Scholar]

- Jiang, Y.; Zhao, W.S.; Kang, X.M.; Gu, L. Adaptive control for micro-hole EDM process with wavelet transform detecting method. In Proceedings of the 6th ICOMM, Tokyo, Japan, 7 September 2011; pp. 207–211. [Google Scholar]

- Aizawa, T.; Inohara, T. Pico- and Femtosecond Laser Micromachining for Surface Texturing; IntechOpen: London, UK, 2019. [Google Scholar]

- Aizawa, T.; Yamaguchi, T. Plasma nitriding assisted micro-texturing into martensitic stainless steel molds for injection molding. In Proceedings of the 9th 4M/ICOMM-2015, Milan, Italy, 26 March 2015; pp. 114–118. [Google Scholar]

- Aizawa, T. Micro-texturing onto amorphous carbon materials as a mold die for micro-forming. Appl. Mech. Mater. 2014, 289, 23–37. [Google Scholar] [CrossRef]

- Aizawa, T.; Wasa, K.; Tamagaki, H. A DLC-punch array to fabricate the micro-textured aluminum sheet for boiling heat transfer control. Micromechanics 2018, 9, 147. [Google Scholar] [CrossRef]

- Aizawa, T.; Saito, Y.; Yoshihara, S.-I. Micro-embossing into copper plates for mold-packaging into power semiconducting devices. In Proceedings of the 44th Autumnal Meeting of JSTP, Kumamoto, Japan, 27 October 2018; pp. 3–4. [Google Scholar]

- Duriagina, Z. (Ed.) Low Temperature Plasma Nitriding of Austenitic Stainless Steels; InTechOpen: London, UK, 2019; Chapter 3; pp. 31–50. [Google Scholar]

- Marcos, G.; Guilet, S.; Clymand, F.; Thiriet, T.; Czerwuec, T. Stainless steel patterning by combination of micro-patterning and driven strain produced by plasma assisted nitriding. Surf. Coat. Technol. 2011, 205, 5275–5279. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshino, T. Plastic straining for microstructural refinement in stainless steels by low temperature plasma nitriding. In Proceedings of the 12nd SEATUC Conference, YagYakarta, Indonesia, 8 March 2018; pp. 121–126. [Google Scholar]

- Shiratori, T.; Yoshino, T.; Suzuki, Y.; Nakano, S.; Yang, M. Effects of ion processing of cutting edge of tools on tool wear and punching characteristics in micropunching process. J. JSTP 2019, 60, 58–63. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shiratori, T.; Aizawa, T.; Saito, Y.; Wasa, K. Plasma Printing of an AISI316 Micro-Meshing Punch Array for Micro-Embossing onto Copper Plates. Metals 2019, 9, 396. https://doi.org/10.3390/met9040396

Shiratori T, Aizawa T, Saito Y, Wasa K. Plasma Printing of an AISI316 Micro-Meshing Punch Array for Micro-Embossing onto Copper Plates. Metals. 2019; 9(4):396. https://doi.org/10.3390/met9040396

Chicago/Turabian StyleShiratori, Tomomi, Tatsuhiko Aizawa, Yasuo Saito, and Kenji Wasa. 2019. "Plasma Printing of an AISI316 Micro-Meshing Punch Array for Micro-Embossing onto Copper Plates" Metals 9, no. 4: 396. https://doi.org/10.3390/met9040396

APA StyleShiratori, T., Aizawa, T., Saito, Y., & Wasa, K. (2019). Plasma Printing of an AISI316 Micro-Meshing Punch Array for Micro-Embossing onto Copper Plates. Metals, 9(4), 396. https://doi.org/10.3390/met9040396