Microstructure and Compressive Behavior of Al–Y2O3 Nanocomposites Prepared by Microwave-Assisted Mechanical Alloying

Abstract

:1. Introduction

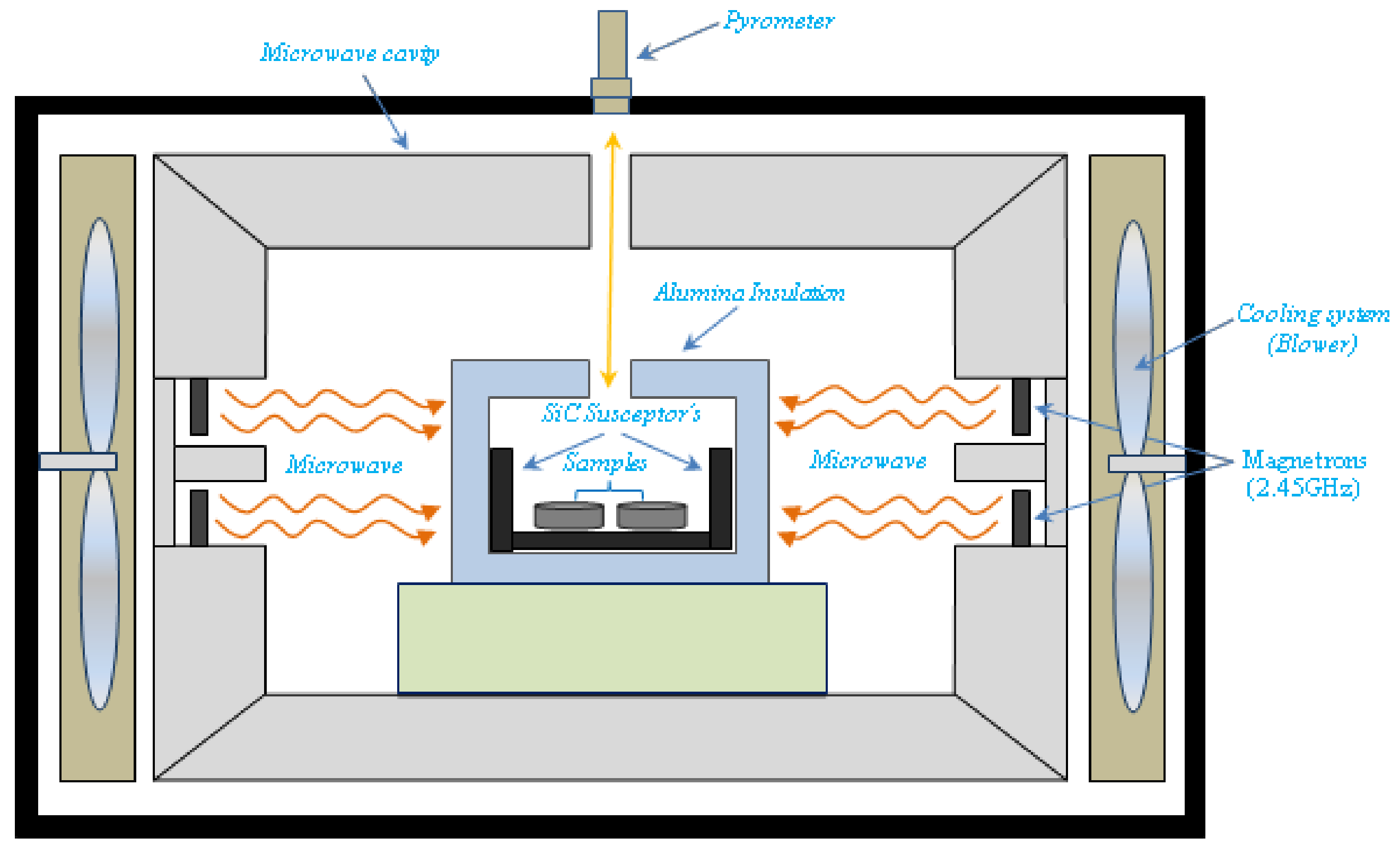

2. Materials and Methods

3. Results and Discussion

3.1. Density and Porosity of Al–Y2O3 Nanocomposites

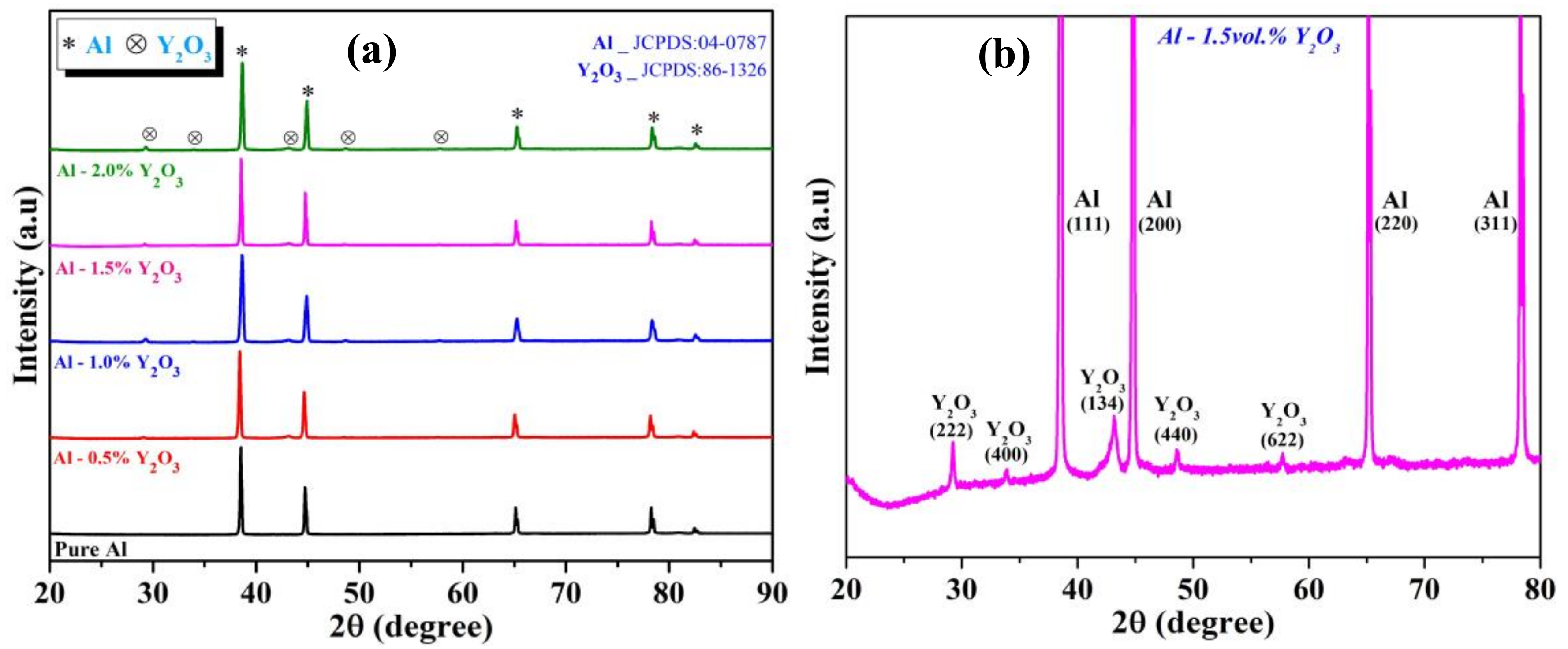

3.2. XRD Analysis of Al–Y2O3 Nanocomposites

3.3. SEM Analysis of Al–Y2O3 Nanocomposites

3.4. Microhardness of Al–Y2O3 Nanocomposites

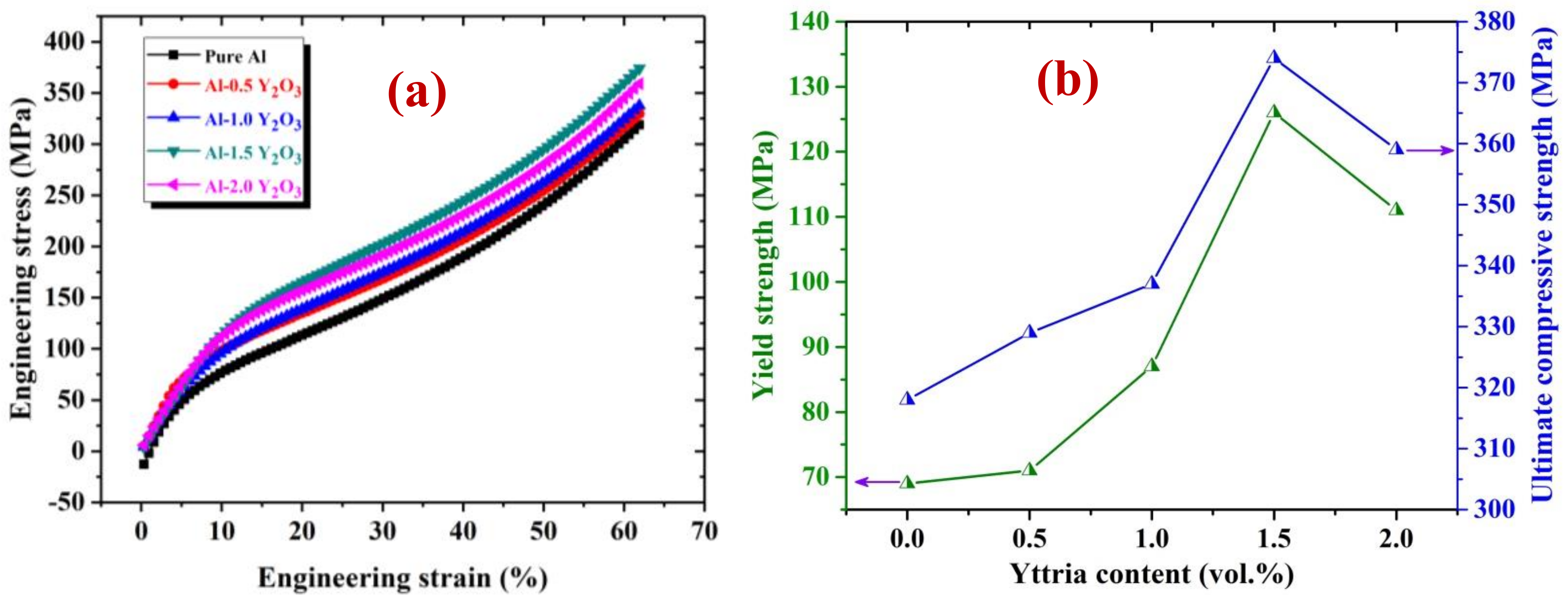

3.5. Compressive Analysis of Al–Y2O3 Nanocomposites

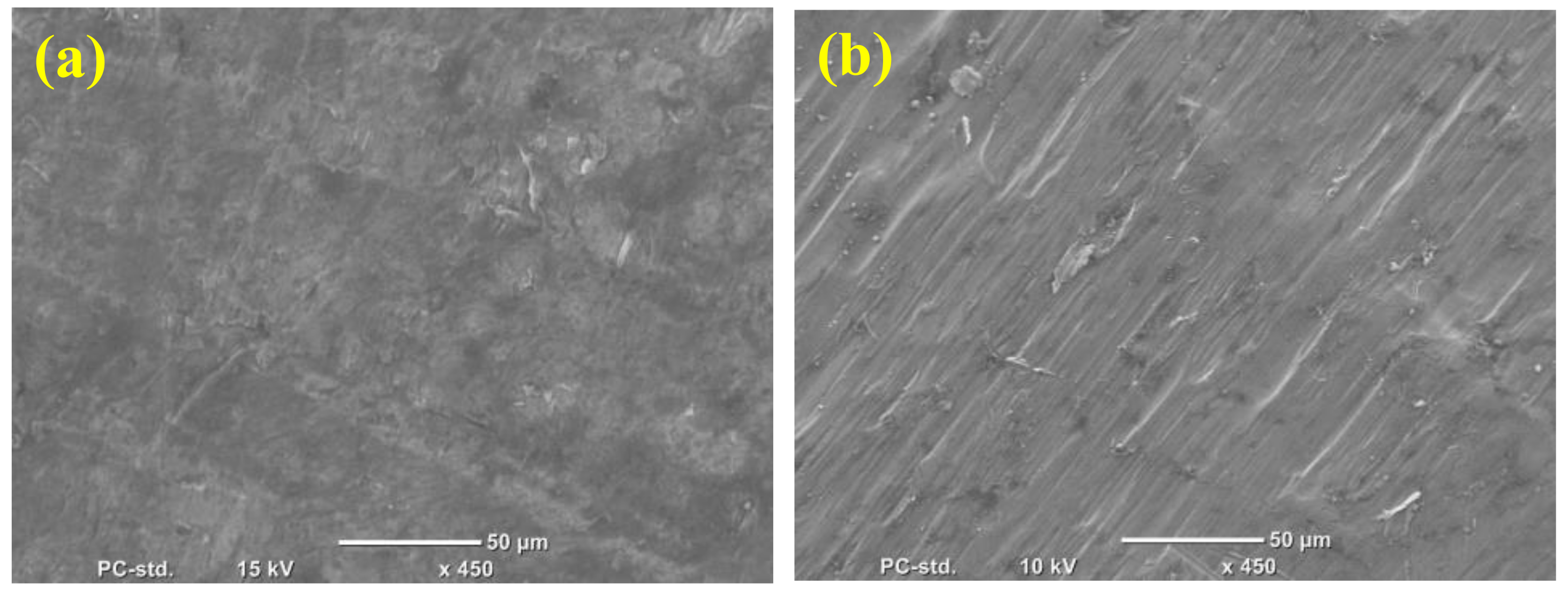

3.6. Fractography of Al–Y2O3 Nanocomposites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Warren, H.H. Metal matrix composites. In Comprehensive Composite Materials; Anthony, K., Carl, Z., Eds.; Pergamon Press: Oxford, UK, 2000; Volume 6, pp. 57–66. [Google Scholar]

- Miracle, D.B. Metal matrix composites-from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Guild, F.J.; Taylor, A.C.; Downes, J. Composite materials. In Encyclopedia of Maritime and Offshore Engineering, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Zweben, C. Composite materials. In Mechanical Engineers’ Handbook; Kutz, M., Ed.; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Ghasali, E.; Hossen, A.; Agheli, M. WC-Co particles reinforced aluminum matrix by conventional and microwave sintering. Mater. Res. 2015, 18, 1197–1202. [Google Scholar] [CrossRef]

- Sheasby, P.G.; Pinner, R. The Surface Treatment and Finishing of Aluminum and Its Alloys, 6th ed.; Finishing Publications Ltd.: Stevenage, UK; ASM International: Novelty, OH, USA, 2001; pp. 1–596. [Google Scholar]

- Pardeep, S.; Satpal, S.; Dinesh, K. A study on the microstructure of aluminum matrix composites. J. Asian Ceram. Soc. 2105, 3, 240–244. [Google Scholar]

- Manoj, S.; Deepak, D.D.; Lakhvir, S.; Vikas, C. Development of aluminium based silicon carbide particulate metal matrix composite. J. Miner. Mater. Charact. Eng. 2009, 8, 455–467. [Google Scholar]

- Rana, R.S.; Purohit, R. Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites. J. Sci. Eng. Res. 2012, 2, 1–7. [Google Scholar]

- Bharath, V.; Madev, N.; Auradi, V.; Kori, S.A. Preparation of 6061Al-Al2O3 MMC’s by stir casting and evaluation of mechanical and wear properties. Procedia Mater. Sci. 2014, 6, 1658–1667. [Google Scholar] [CrossRef]

- Narayan, S.; Rajeshkannan, A. Hardness, tensile and impact behavior of hot forged aluminum metal matrix composites. J. Mater. Res. Technol. 2017, 6, 213–219. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.; Ebadzadeh, T. Investigation on microstructure and mechanical behavior of Al–ZrB2 composite prepared by microwave and spark plasma sintering. Mater. Sci. Eng. A 2015, 627, 27–31. [Google Scholar] [CrossRef]

- Kong, J.; Xu, C.; Li, J.; Hou, H. Evolution of fractal features of pores in the compacting and sintering process. Adv. Powder Technol. 2011, 22, 439–442. [Google Scholar] [CrossRef]

- Breval, E.; Cheng, J.P.; Agrawal, D.K.; Gigl, P.; Dennis, M.; Roy, R.; Papworth, A.J. Comparison between microwave and conventional sintering of WC/Co composites. Mater. Sci. Eng. A 2005, 391, 285–295. [Google Scholar] [CrossRef]

- Shen, Z.; Johnsson, M.; Zhao, Z.; Nygren, M. Spark plasma sintering of alumina. J. Mater. Process. Technol. 2002, 85, 1921–1927. [Google Scholar] [CrossRef]

- Jin, L.; Zhou, G.; Shimai, S.; Zhang, J.; Wang, S. ZrO2-doped Y2O3 transparent ceramics via slip casting and vacuum sintering. J. Eur. Ceram. Soc. 2010, 30, 2139–2143. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Microwave sintering of copper–graphite composites. J. Mater. Process. Technol. 2009, 209, 5601–5605. [Google Scholar] [CrossRef]

- Reddy, M.P.; Ubaid, F.; Shakoor, R.A.; Gururaj, P.; Vyasaraj, M.; Mohamed, A.M.A.; Gupta, M. Effect of reinforcement concentration on the properties of hot extruded Al-Al2O3 composites synthesized through microwave sintering process. Mater. Sci. Eng. A 2017, 696, 60–69. [Google Scholar] [CrossRef]

- Reddy, M.P.; Ubaid, F.; Shakoor, R.A.; Gururaj, P.; Vyasaraj, M.; Mohamed, A.M.A.; Gupta, M. Enhanced performance of nano-sized SiC reinforced Al metal matrix nanocomposites synthesized through microwave sintering and hot extrusion techniques. Prog. Nat. Sci. Mater. 2017, 27, 607–614. [Google Scholar] [CrossRef]

- Wang, M.; Wang, D.; Kups, T.; Schaaf, P. Size effect on mechanical behavior of Al/Si3N4 multilayers by nanoindentation. Mater. Sci. Eng. A 2015, 644, 275–283. [Google Scholar] [CrossRef]

- Kim, C.S.; Kim, I.H. Effect of Al and Y2O3 on mechanical properties in mechanically alloyed nanograin Ni-based alloys. J. Nanosci. Nanotechnol. 2105, 15, 6160–6163. [Google Scholar] [CrossRef]

- Karantzalis, A.E.; Wyatt, S.; Kennedy, A.R. The mechanical properties of Al-TiC metal matrix composites fabricated by a flux-casting technique. Mater. Sci. Eng. A 1997, 237, 200–206. [Google Scholar] [CrossRef]

- Hossein-Zadeh, M.; Razavi, M.; Mirzaee, O.; Ghaderi, R. Characterization of properties of Al–Al2O3 nano-composite synthesized via milling and subsequent casting. J. King Saud Univ. Eng. Sci. 2013, 25, 75–80. [Google Scholar] [CrossRef]

- Ianos, R.; Babuta, R.; Lazau, R. Characteristics of Y2O3 powders prepared by solution combustion synthesis in the light of a new thermodynamic approach. Ceram. Int. 2014, 40, 12207–12211. [Google Scholar] [CrossRef]

- Chaim, R.; Shlayer, A.; Estournes, C. Densification of nanocrystalline Y2O3 ceramic powder by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 91–98. [Google Scholar] [CrossRef]

- Kakuoz, Y.B.; Serivalsatit, K.; Kokuoz, B.; Geiculescu, O.; McCormick, E.; Ballato, J. Er-doped Y2O3 nanoparticles: A comparison of different synthesis methods. J. Am. Ceram. Soc. 2009, 92, 2247–2253. [Google Scholar] [CrossRef]

- Bouaeshi, W.B.; Li, D. Effects of Y2O3 addition on microstructure, mechanical properties, electrochemical behavior, and resistance to corrosive wear of aluminum. Tribol. Int. 2007, 40, 188–199. [Google Scholar] [CrossRef]

- Cho, J.; Harmer, M.P.; Chan, H.M.; Rickman, J.M.; Thompson, A.M. Effect of yttrium and lanthanum on the tensile creep behavior of aluminum oxide. J. Am. Ceram. Soc. 1993, 28, 6466–6473. [Google Scholar] [CrossRef]

- Borovkova, L.B.; Lukin, E.S.; Poluboyarinov, D.N.; Sapozhnikova, E.B. Sintering and properties of yttrium oxide ceramics. Refract. Ind. Ceram. 1970, 11, 717–722. [Google Scholar] [CrossRef]

- Ranjan, S. Sintering and Mechanical Properties of Alumina-Yttrium Aluminate Composites. Ph.D. Thesis, National Institute of Technology, Rourkela, India, May 2015. [Google Scholar]

- Meena, K.L.; Manna, A.; Banwait, S.S.; Jaswanti, D. An analysis of mechanical properties of the developed Al/SiC-MMC’s. Am. J. Mech. Eng. 2013, 1, 14–19. [Google Scholar] [CrossRef]

- Vamsi Krishna, M.; Xavior, M.A. Experiment and statistical analysis of end milling parameters for al/sic using response surface methodology. Int. J. Eng. Technol. 2015, 7, 2274–2285. [Google Scholar]

- Dong, G.; Chi, Y.; Xiao, X.; Liu, X.; Qian, B.; Ma, Z.; Wu, E.; Zeng, H.; Chen, D.; Qiu, J. Fabrication and optical properties of Y2O3: Eu3+ nanofibers prepared by electrospinning. Opt. Express 2009, 17, 22514–22519. [Google Scholar] [CrossRef]

- Reddy, M.P.; Himyan, M.A.; Ubaid, F.; Shakoor, R.A.; Gururaj, P.; Vyasaraj, M.; Mohamed, A.M.A.; Gupta, M. Enhancing thermal and mechanical response of aluminium using nanolength scale TiC reinforcement. Ceram. Int. 2018, 44, 9247–9254. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of nano-Y2O3 containing magnesium nanocomposites using solidification processing. J. Alloy Compd. 2007, 429, 176–183. [Google Scholar] [CrossRef]

- Zhao, N.Q.; Jiang, B.; Du, X.W.; Li, J.J.; Shi, C.S.; Zhao, W.X. Effect of Y2O3 on the mechanical properties of open cell aluminum foams. Mater. Lett. 2006, 60, 1665–1668. [Google Scholar] [CrossRef]

- Reddy, M.P.; Ubaid, F.; Shakoor, R.A.; Parande, G.; Vyasaraj, M.; Yusuf, M.; Mohamed, A.M.A.; Gupta, M. A comparative study of structural and mechanical properties of Al-Cu composites prepared by vacuum and microwave sintering techniques. J. Mater. Res. Technol. 2017, 7, 165–172. [Google Scholar]

- Pasquale, C.; Farhad, J.; Ali, S.; Behzad, S. Influence of SiO2 nanoparticles on the microstructure and mechanical properties of Al matrix nanocomposites fabricated by spark plasma sintering. Compos. Part B Eng. 2108, 146, 60–68. [Google Scholar]

- Mahmut, C.S.; Gürbüz, M.; Koç, E. Fabrication and characterization of SiC and Si3N4 reinforced aluminum matrix composites. Univers. J. Mater. Sci. 2017, 5, 95–101. [Google Scholar]

- Pakdel, A.; Farhangi, H.E. Effect of extrusion process on ductility and fracture behavior of SiCp/aluminum alloy composites. Proceedings of 8th International Fracture Conference, Istanbul Turkey, 7–9 November 2007. [Google Scholar]

- Moustafa, M.M.M.; Omayma, A.E.; Abdelhameed, W.A. Effect of alumina particles addition on physico-mechanical properties of Al-matrix composites. Open J. Metal 2013, 3, 72–79. [Google Scholar]

- Ehsan, G.; Masoud, A.; Touradj, E.; Amir, H.P.; Ali, R. Investigation on microstructural and mechanical properties of B4C–aluminum matrix composites prepared by microwave sintering. J. Mater. Res. Technol. 2015, 4, 411–415. [Google Scholar]

- Hasan, K.I.; Aboozar, T.; Ali, M.; Abbas, G. Development of an aluminum/amorphous nano-SiO2 composite using powder metallurgy and hot extrusion processes. Ceram. Int. 2017, 43, 14582–14592. [Google Scholar]

- Zeng, X.; Liu, W.; Xu, B.; Shu, G.; Li, Q. Microstructure and mechanical properties of Al-SiC nanocomposites synthesized by surface-modified aluminium powder. Metals 2018, 8, 253. [Google Scholar] [CrossRef]

- Ramezanalizadeh, H.; Emamy, M.; Shokouhimehr, M. A novel aluminum based nanocomposite with high strength and good ductility. J. Alloys Compd. 2015, 649, 461–473. [Google Scholar] [CrossRef]

- Reddy, M.P.; Ubaid, F.; Shakoor, R.A.; Parande, G.; Vyasaraj, M.; Yusuf, M.; Mohamed, A.M.A.; Gupta, M. Improved properties of Al–Si3N4 nanocomposites fabricated through a microwave sintering and hot extrusion process. RSC Adv. 2017, 7, 34401–34410. [Google Scholar]

| Composition | Theoretical Density (g/cc) | Experimental Density (g/cc) | Porosity (%) |

|---|---|---|---|

| Pure Al | 2.700 | 2.679 ± 0.005 | 0.78 |

| Al–0.5 vol. % Y2O3 | 2.712 | 2.701 ± 0.004 | 0.41 |

| Al–1.0 vol. % Y2O3 | 2.723 | 2.741 ± 0.007 | 0.33 |

| Al–1.5 vol. % Y2O3 | 2.735 | 2.728 ± 0.006 | 0.26 |

| Al–2.0 vol. % Y2O3 | 2.746 | 2.741 ± 0.008 | 0.18 |

| Composition | Microhardness (Hv) | YS (MPa) | UCS (MPa) | Compression Strain (%) |

|---|---|---|---|---|

| Pure Al | 38 ± 3 | 69 ± 2 | 318 ± 5 | >60 |

| Al–0.5 vol. % Y2O3 | 46 ± 4 | 71 ± 4 | 329 ± 6 | >60 |

| Al–1.0 vol. % Y2O3 | 63 ± 2 | 87 ± 3 | 337 ± 3 | >60 |

| Al–1.5 vol. % Y2O3 | 81 ± 3 | 126 ± 5 | 374 ± 6 | >60 |

| Al–2.0 vol. % Y2O3 | 74 ± 5 | 111 ± 5 | 359 ± 7 | >60 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mattli, M.R.; Shakoor, R.A.; Matli, P.R.; Amer Mohamed, A.M. Microstructure and Compressive Behavior of Al–Y2O3 Nanocomposites Prepared by Microwave-Assisted Mechanical Alloying. Metals 2019, 9, 414. https://doi.org/10.3390/met9040414

Mattli MR, Shakoor RA, Matli PR, Amer Mohamed AM. Microstructure and Compressive Behavior of Al–Y2O3 Nanocomposites Prepared by Microwave-Assisted Mechanical Alloying. Metals. 2019; 9(4):414. https://doi.org/10.3390/met9040414

Chicago/Turabian StyleMattli, Manohar Reddy, R. A. Shakoor, Penchal Reddy Matli, and Adel Mohamed Amer Mohamed. 2019. "Microstructure and Compressive Behavior of Al–Y2O3 Nanocomposites Prepared by Microwave-Assisted Mechanical Alloying" Metals 9, no. 4: 414. https://doi.org/10.3390/met9040414

APA StyleMattli, M. R., Shakoor, R. A., Matli, P. R., & Amer Mohamed, A. M. (2019). Microstructure and Compressive Behavior of Al–Y2O3 Nanocomposites Prepared by Microwave-Assisted Mechanical Alloying. Metals, 9(4), 414. https://doi.org/10.3390/met9040414