Zn and P Alloying Effect in Sub-Rapidly Solidified LaFe11.6Si1.4 Magnetocaloric Plates

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

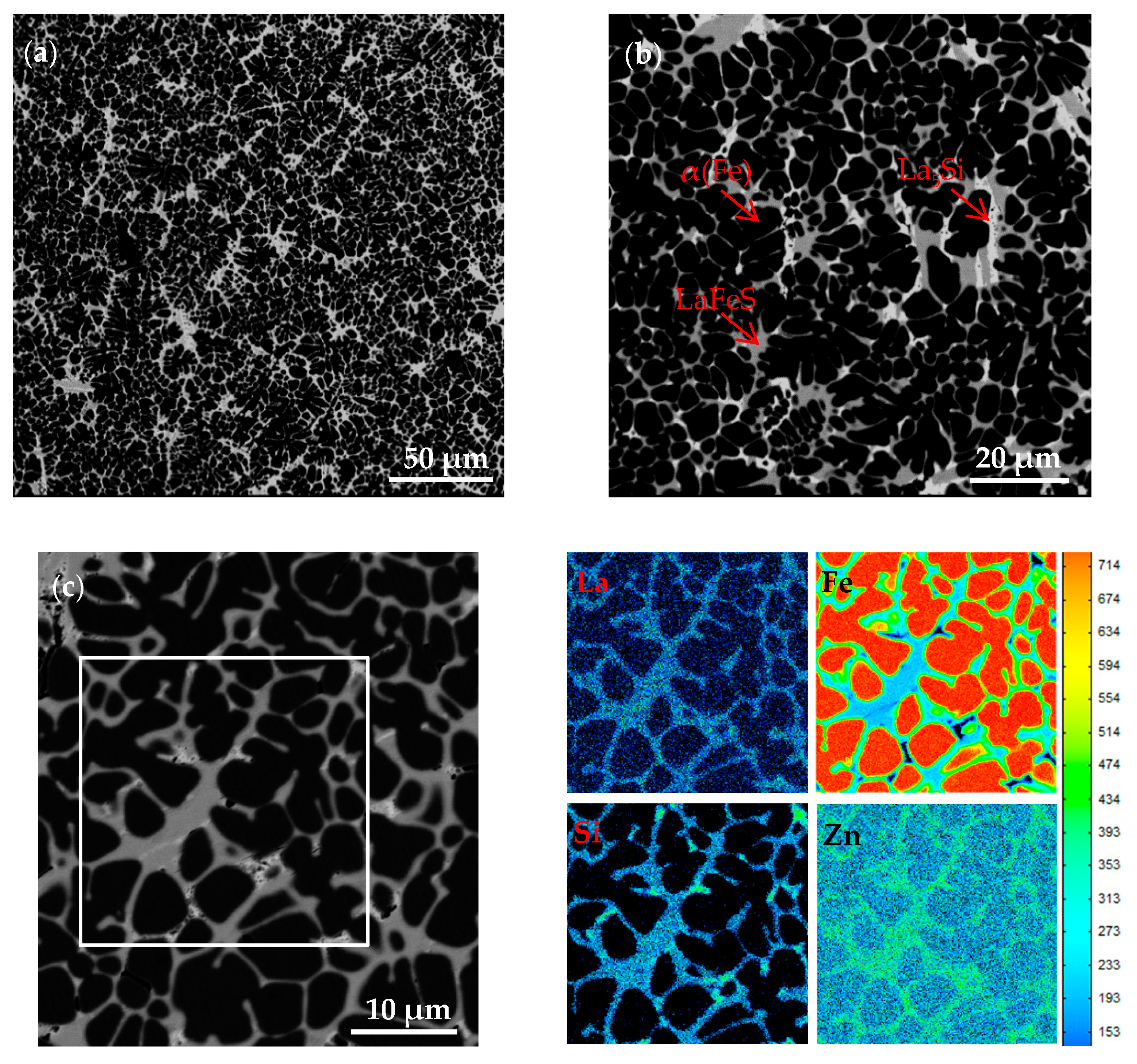

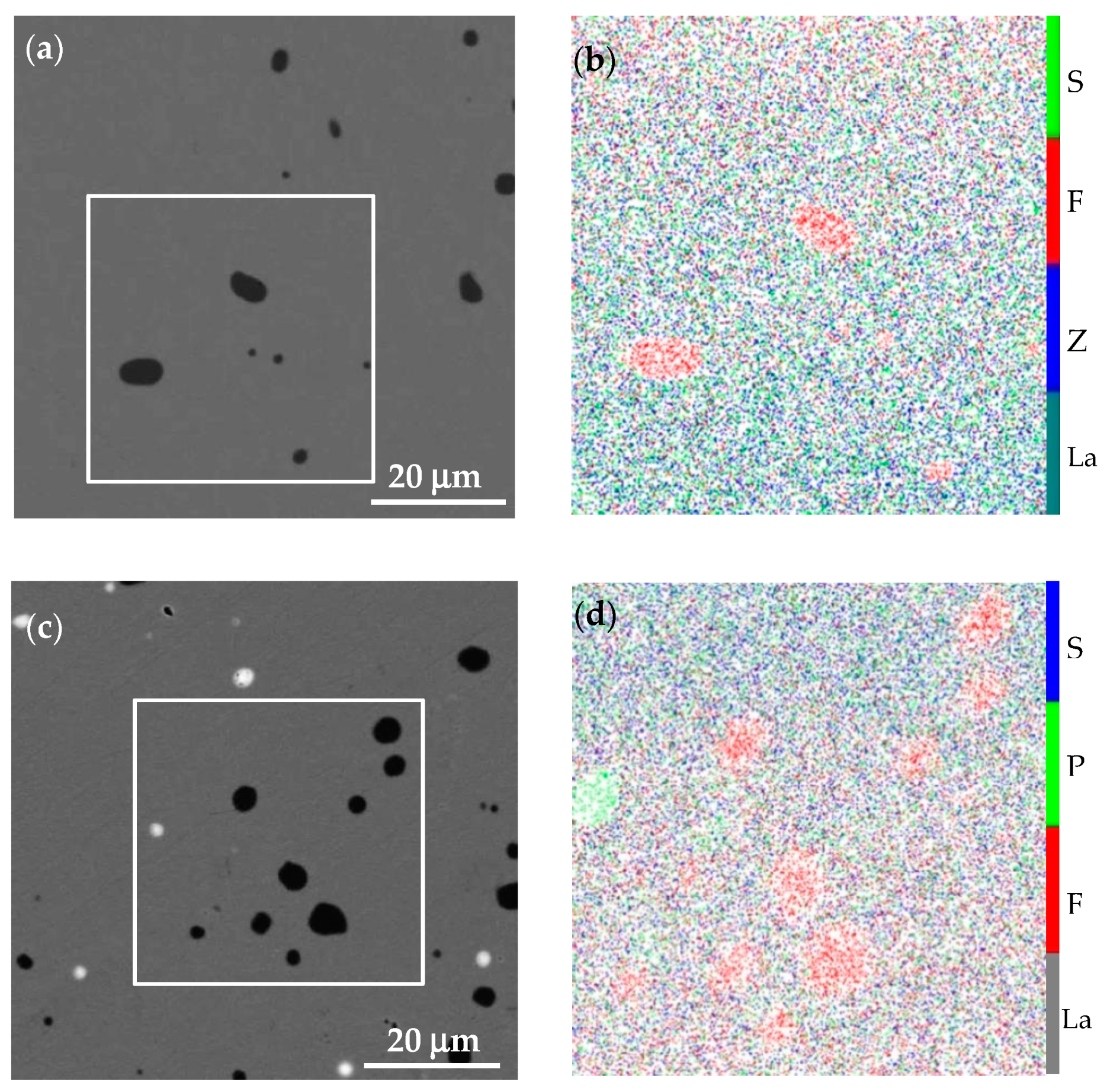

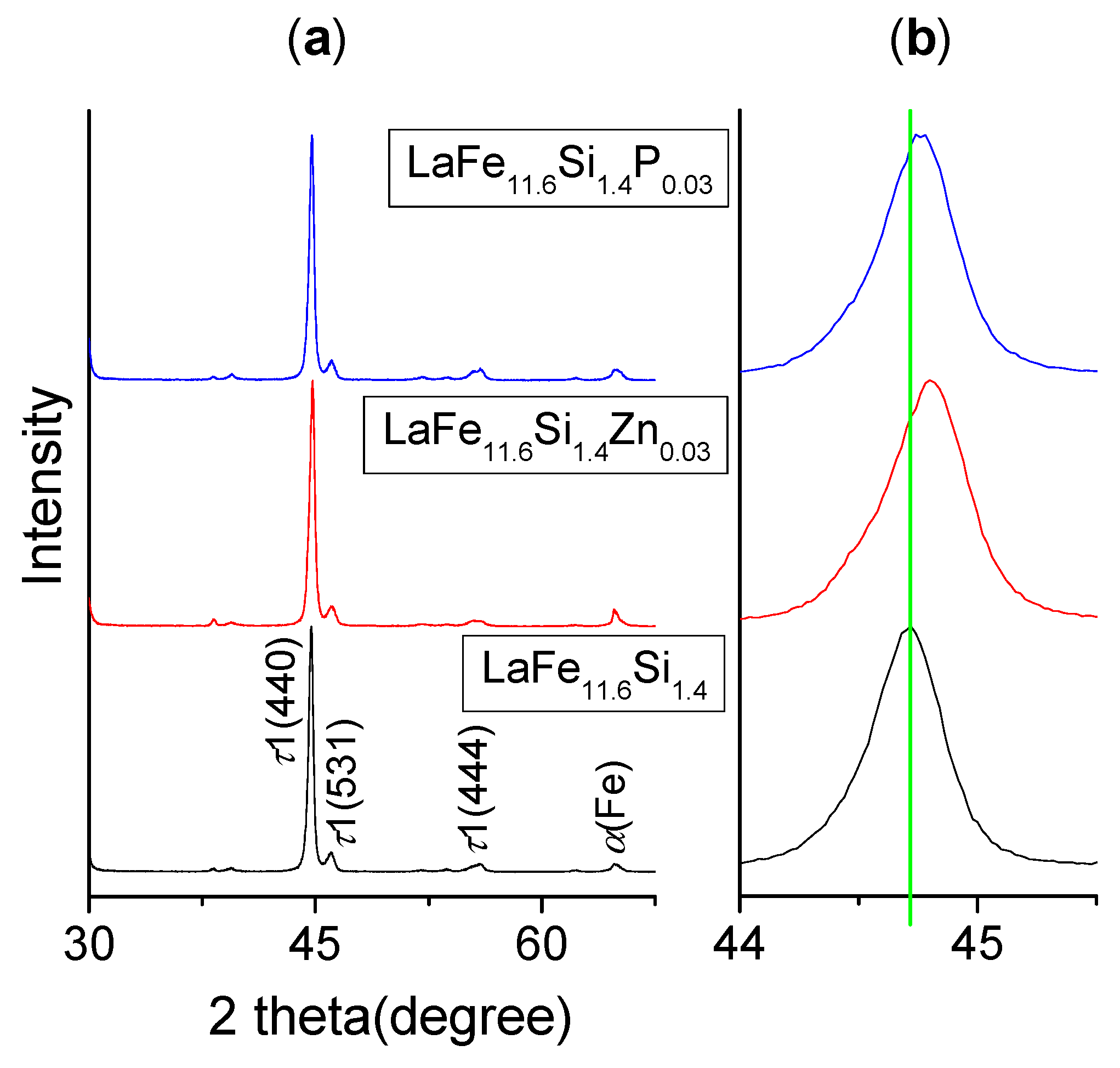

3.1. Phase and Microstructure

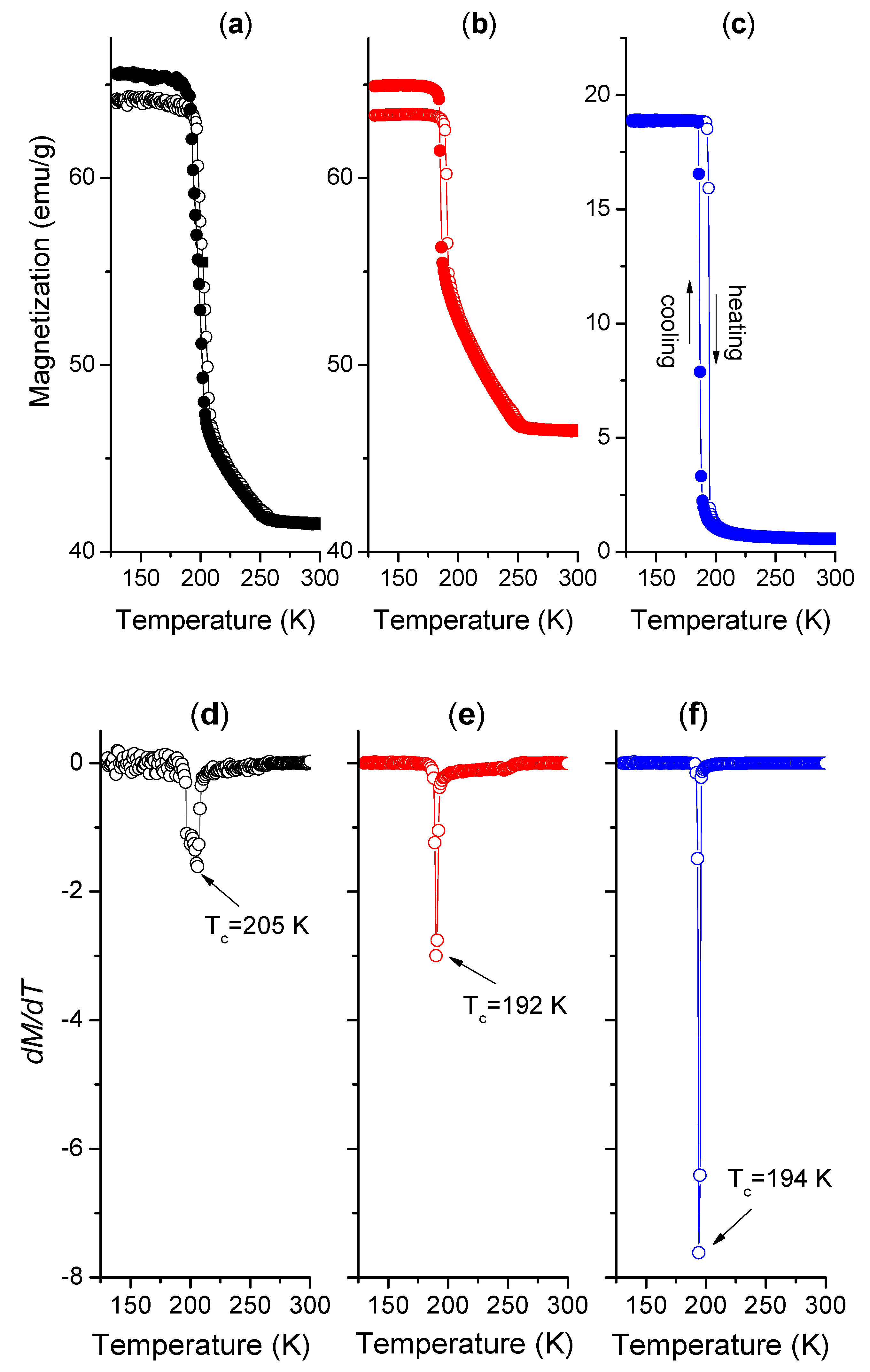

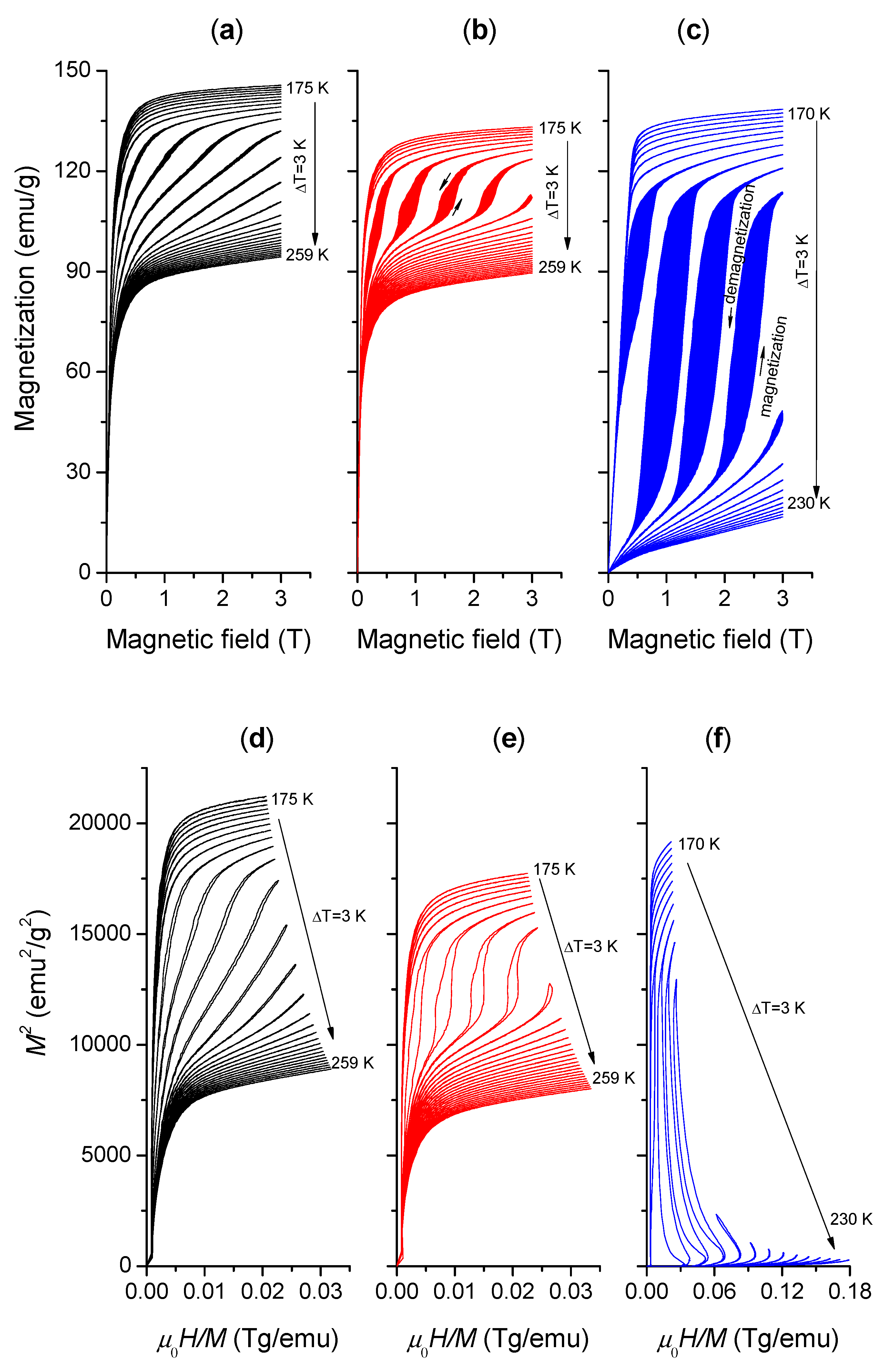

3.2. Magnetic Transition and Magnetocaloric Effect

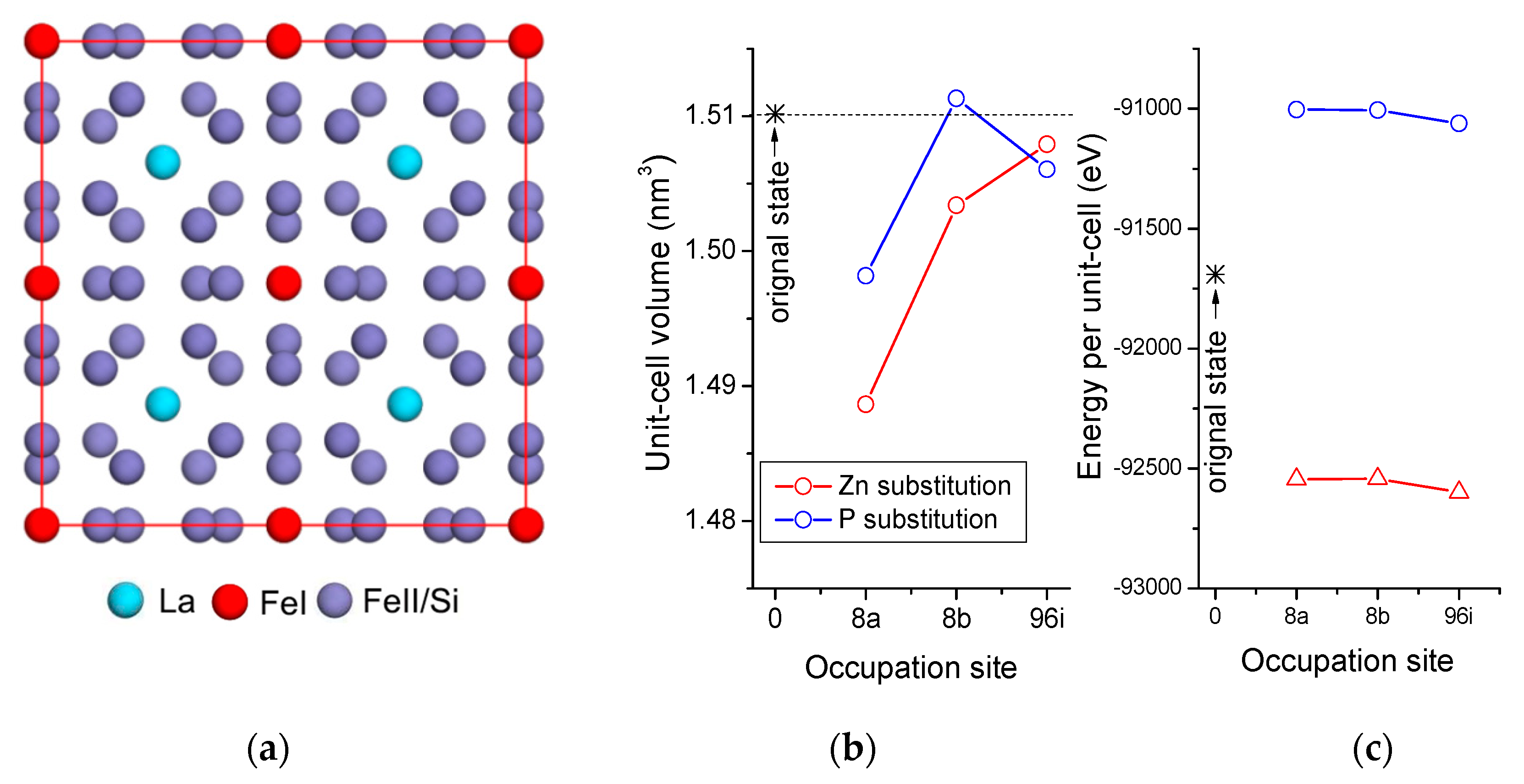

3.3. Occupation Mechanism

4. Conclusions

- (1)

- Zn/P elements were mainly distributed in the LaFeSi and La5Si3 phases during centrifugal solidification. After annealing at 1373 K for 72 h, Zn/P elements were homogeneously dispersed in the τ1 matrix and led to slight volume shrinkage of the unit-cell. Both Zn/P atoms prefer to enter the 96i (FeII/Si) substitution site according to the density-functional reconstruction of crystallographic structure.

- (2)

- A second-order magnetic transition occurred in the annealed LaFe11.6Si1.4 plate, and a first-order transition in both the LaFe11.6Si1.4Zn0.03 and LaFe11.6Si1.4P0.03 plates. The addition of Zn/P decreased the characteristic transition temperature 11–13 K owing to lattice shrinkage.

- (3)

- P alloying resulted in a striking increase for the maximum magnetic entropy changes from 7.0 to 31.4 J/(kg⋅K) under a magnetic field change of 3 T, while Zn alloying caused a slight decrease to 5.9 J/(kg⋅K). The effective refrigeration capacity of the annealed LaFe11.6Si1.4P0.03 plate reached 189.9 J/kg.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, G.F.; Zhao, Z.R.; Jing, T.; Li, Y.F.; Ma, Q.; Zhang, X.F. Enhanced magnetocaloric properties in off-stoichiometric LaxFe11.5Si1.5 alloys. Intermetallics 2018, 93, 355–359. [Google Scholar] [CrossRef]

- Brown, G.V. Magnetic heat pumping near room temperature. J. Appl. Phys. 1976, 47, 3673–3680. [Google Scholar] [CrossRef]

- Provenzano, V.; Shull, R.D.; Kletetschka, G.; Stutzman, P.E. Gd90Co2.5Fe7.5 alloy displaying enhanced magnetocaloric properties. J. Alloy. Compd. 2015, 622, 1061–1067. [Google Scholar] [CrossRef]

- Jayaraman, T.V.; Boone, L.; Shield, J.E. Magnetocaloric effect and refrigerant capacity in melt-spun Gd−Mn alloys. J. Magn. Magn. Mater. 2013, 345, 153–158. [Google Scholar] [CrossRef]

- Pecharsky, A.O.; Gschneidner, K.A.; Pecharsky, V.K. The giant magnetocaloric effect between 190 and 300 K in the Gd5SixGe4−x alloys for 1.4 ≤ x ≤ 2.2. J. Magn. Magn. Mater. 2003, 267, 60–68. [Google Scholar] [CrossRef]

- Gschneidner, K.A.; Pecharsky, V.K. Magnetic refrigeration materials. J. Appl. Phys. 1999, 85, 5365–5368. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, A.; Maiorino, A.; Masselli, C. A comparison between rare earth and transition metals working as magnetic materials in an AMR refrigerator in the room temperature range. Appl. Therm. Eng. 2015, 91, 767–777. [Google Scholar] [CrossRef]

- Tegus, O.; Brück, E.; Buschow, K.H.J.; de Boer, F.R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 2012, 415, 150–152. [Google Scholar] [CrossRef]

- Yibole, H.; Guillou, F.; Zhang, L.; van Dijk, N.H.; Brück, E. Direct measurement of the magnetocaloric effect in MnFe(P, X) (X = As, Ge, Si) materials. J. Phys. D: Appl. Phys. 2014, 47, 186–187. [Google Scholar] [CrossRef]

- Sushmita, D.; Roy, R.K.; Ghosh, M.; Mallick, A.B.; Mitra, A.; Panda, A.K. Enhancement in magnetocaloric properties of NiMnGa alloy through stoichiometric tuned phase transformation and magneto-thermal transitions. J. Magn. Magn. Mater. 2017, 439, 305–311. [Google Scholar] [CrossRef]

- Gao, B.; Hu, F.X.; Shen, J.; Wang, J.; Sun, J.R.; Shen, B.G. Field-induced structural transition and the related magnetic entropy change in Ni43Mn43Co3Sn11 alloy. J. Magn. Magn. Mater. 2009, 321, 2571–2574. [Google Scholar] [CrossRef]

- Zheng, H.X.; Wang, W.; Xue, S.C.; Zhai, Q.J.; Frenzel, J.; Luo, Z.P. Composition-dependent crystal structure and martensitic transformation in Heusler Ni−Mn−Sn alloys. Acta Mater. 2013, 61, 4648–4656. [Google Scholar] [CrossRef]

- Hu, F.X.; Shen, B.G.; Sun, J.R.; Cheng, Z.H.; Rong, G.H.; Zhang, X.X. Influence of negative lattice expansion and metamagnetic transition on magnetic entropy change in the compound LaFe11.4Si1.6. Appl. Phys. Lett. 2001, 78, 3675–3677. [Google Scholar] [CrossRef]

- Liu, J.; Krautz, M.; Skokov, K.; Woodcock, T.G.; Gutfleisch, O. Systematic study of the microstructure, entropy change and adiabatic temperature change in optimized La–Fe–Si alloys. Acta Mater. 2011, 59, 3602–3611. [Google Scholar] [CrossRef]

- Hamad, M.A. Tailoring Magnetocaloric Effect in La0.7Sr0.3MnO3–TiO2. J. Supercond. Nov. Magn. 2018, 31, 337–340. [Google Scholar] [CrossRef]

- Dahal, B.R.; Kyle, S.; Allyn, M.M.; Tackett, R.J.; Huh, Y.; Kharel, P. Near-room-temperature magnetocaloric properties of La1−xSrxMnO3 (x = 0.11, 0.17, and 0.19) nanoparticles. Mater. Res. Express 2018, 5, 106103. [Google Scholar] [CrossRef]

- Zehani, K.; Guetari, R.; Mliki, N.; Bessais, L. Study of the Magnetocaloric Effect in (Pr, Dy)2Fe17 and Pr2(Fe, Al)17 Intermetallic Compounds. Phys. Procedia 2015, 75, 1435–1441. [Google Scholar] [CrossRef][Green Version]

- Dahal, B.; Kharel, P.; Ott, T.; Zhang, W.Y.; Valloppilly, A.; Skomski, R.; Sellmyer, D. Magnetic and magnetocaloric properties of Pr2−xNdxFe17 ribbons. AIP Adv. 2019, 9, 035211. [Google Scholar] [CrossRef]

- Lyubina, J.; Gutfleisch, O.; Kuz’min, D.M.; Richter, M. La(Fe,Si)13-based magnetic refrigerants obtained by novel processing routes. J. Magn. Magn. Mater. 2009, 320, 2252–2258. [Google Scholar] [CrossRef]

- Katter, M.; Zellmann, V.; Reppel, G.W.; Uestuener, K. Magnetocaloric properties of La(Fe,Co,Si)13 bulk material prepared by powder metallurgy. IEEE Trans. Magn. 2008, 44, 3044–3047. [Google Scholar] [CrossRef]

- Hansen, B.R.; Kuhn, L.T.; Bahl, C.R.H.; Lundberg, M.; Ancona-Torres, C.; Katter, M. Properties of magnetocaloric La(Fe,Co,Si)13 produced by powder metallurgy. J. Magn. Magn. Mater. 2010, 322, 3447–3454. [Google Scholar] [CrossRef]

- Zhong, X.C.; Feng, X.L.; Huang, X.W.; Shen, X.Y.; Liu, Z.W. Structure and magnetocaloric effect of La0.7Ce0.3(Fe0.92Co0.08)11.4Si1.6 bulk alloy prepared by powder metallurgy. J. Alloy. Compd. 2016, 685, 913–916. [Google Scholar] [CrossRef]

- Bao, L.H.; Wei, W.; Fan, W.D.; Tegus, O. A novel preparation method and magnetic properties of NaZn13-type La(Fe,Si)13 compounds. J. Alloy. Compd. 2014, 589, 416–419. [Google Scholar] [CrossRef]

- Hou, X.L.; Tian, Y.; Xue, Y.; Liu, C.Y.; Xia, W.X.; Xu, H.; Kelley, P.L.; Srikanth, H.; Phan, M.H. Formation of tree-like and vortex magnetic domains of nanocrystalline α-(Fe,Si) in La−Fe−Si ribbons during rapid solidification and subsequent annealing. J. Alloy. Compd. 2016, 669, 205–209. [Google Scholar] [CrossRef][Green Version]

- Blazquez, J.S.; Moreno-Ramírez, L.M.; Ipus, J.J.; Kiss, L.F.; Kaptas, D.; Kemeny, T.; Franco, V.; Conde, A. Effect of α-Fe impurities on the field dependence of magnetocaloric response in LaFe11.5Si1.5. J. Alloy. Compd. 2015, 646, 101–105. [Google Scholar] [CrossRef]

- Pulko, B.; Tušek, J.; Moore, J.D.; Weise, B.; Skokov, K.; Mityashkin, O.; Kitanovski, A.; Favero, C.; Fajfar, P.; Gutfleisch, O.; et al. Epoxy-bonded La−Fe−Co−Si magnetocaloric plates. J. Magn. Magn. Mater. 2015, 375, 65–73. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Y.J.; Li, Y.W.; Wu, Y.Y.; Long, Y.; Shen, J.; Hu, F.X.; Sun, J.R.; Shen, B.G. Mechanical properties and magnetocaloric effects in La(Fe,Si)13 hydrides bonded with different epoxy resins. J. Appl. Phys. 2015, 117, 063902. [Google Scholar] [CrossRef]

- Zhong, X.C.; Feng, X.L.; Huang, J.H.; Huang, Y.L.; Liu, Z.W.; Ramanujan, R.V. Influence of particle size on the mechanical properties and magnetocaloric effect of La0.8Ce0.2(Fe0.95Co0.05)11.8Si1.2/Sn composites. J. Magn. Magn. Mater. 2018, 463, 23–27. [Google Scholar] [CrossRef]

- Zhong, X.C.; Feng, X.L.; Huang, J.H.; Jiao, D.L.; Zhang, H.; Qiu, W.Q.; Liu, Z.W.; Ramanujan, R.V. A bimodal particle size distribution enhances mechanical and magnetocaloric properties of low-temperature hot pressed Sn-bonded La0.8Ce0.2(Fe0.95Co0.05)11.8Si1.2 bulk composites. J. Magn. Magn. Mater. 2019, 469, 133–137. [Google Scholar] [CrossRef]

- Dong, X.T.; Zhong, X.C.; Peng, D.R.; Huang, J.H.; Zhang, H.; Jiao, D.L.; Liu, Z.W.; Ramanujan, R.V. La0.8Ce0.2(Fe0.95Co0.05)11.8Si1.2/Sn42Bi58 magnetocaloric composites prepared by low temperature hot pressing. J. Alloy. Compd. 2018, 737, 568–574. [Google Scholar] [CrossRef]

- Funk, A.; Freudenberger, J.; Waske, A.; Krautz, M. Getting magnetocaloric materials into good shape: Cold-working of La(Fe,Co,Si)13 by powder-in-tube-processing. Mater. Today Energy 2018, 9, 223. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, H.; Liu, E.K.; Zhong, X.C.; Tao, K.; Wu, M.L.; Xing, C.F.; Xiao, Y.N.; Liu, J.; Long, Y. Outstanding comprehensive performance of/In composite with durable service life for magnetic refrigeration. Adv. Electro. Mater. 2018, 4, 1700636. [Google Scholar] [CrossRef]

- Dai, Y.T.; Xu, Z.S.; Luo, Z.P.; Han, K.; Zhai, Q.J.; Zheng, H.X. Phase formation kinetics, hardness and magnetocaloric effect of sub-rapidly solidified LaFe11.6Si1.4 plates during isothermal annealing. J. Magn. Magn. Mater. 2018, 454, 356–361. [Google Scholar] [CrossRef]

- Fu, S.; Long, Y.; Sun, Y.Y.; Hu, J. Microstructural evolution and phase transition dependent on annealing temperature and carbon content for LaFe11.5Si1.5Cx compounds prepared by arc-melting. Intermetallics 2013, 39, 79–83. [Google Scholar] [CrossRef]

- Bez, H.N.; Eggert, B.G.F.; Lozano, J.A.; Bahl, C.R.H.; Barbosa, J.R., Jr.; Teixeira, C.S.; Wendhausen, P.A.P. Magnetocaloric effect and H gradient in bulk La(Fe,Si)13Hy magnetic refrigerants obtained by HDSH. J. Magn. Magn. Mater. 2015, 386, 125–128. [Google Scholar] [CrossRef]

- Löwe, K.; Liu, J.; Skokov, K.; Moore, J.D.; Sepehri-Amin, H.; Hono, K.; Katter, M.; Gutfleisch, O. The effect of the thermal decomposition reaction on the mechanical and magnetocaloric properties of La(Fe,Si,Co)13. Acta Mater. 2012, 60, 4268–4276. [Google Scholar] [CrossRef]

- Zong, S.T.; Long, Y. The influence of Cr and Ni on the character of magnetic phase transition in LaFe11.52−xMxSi1.48 alloys. AIP Adv. 2018, 8, 048101. [Google Scholar] [CrossRef]

- Md Din, M.F.; Wang, J.L.; Zeng, R.; Shamba, P.; Debnath, J.C.; Dou, S.X. Effects of Cu substitution on structural and magnetic properties of La0.7Pr0.3Fe11.4Si1.6 compounds. Intermetallics 2013, 36, 1–7. [Google Scholar] [CrossRef]

- Mican, S.; Tetean, R. Magnetic properties and magnetocaloric effect in La0.7Nd0.3Fe13−xSix compounds. J. Solid State Chem. 2012, 187, 238–243. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.G.; Tang, Y.B.; Xiao, D.Q. Effect of Ce, Co, B on formation of LaCo13-structure phase in La(Fe,Si)13 alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 705–711. [Google Scholar] [CrossRef]

- Anh, D.T.K.; Thuy, N.P.; Duc, N.H.; Nhien, T.T.; Nong, N.V. Magnetism and magnetocaloric effect in La1−yNdy(Fe0.88Si0.12)13 compounds. J. Magn. Magn. Mater. 2003, 262, 427–431. [Google Scholar] [CrossRef]

- Rosca, M.; Balli, M.; Fruchart, D.; Gignoux, D.; Hlil, E.K.; Miraglia, S.; Ouladdiaf, B.; Wolfers, P. Neutron diffraction study of LaFe11.31Si1.69 and LaFe11.31Si1.69H1.45 compounds. J. Alloy. Compd. 2010, 490, 50–55. [Google Scholar] [CrossRef]

- Hai, X.; Mayer, C.; Colin, C.V.; Miraglia, S. In-situ neutron investigation of hydrogen absorption kinetics in La(FexSi1−x)13 magnetocaloric alloys for room-temperature refrigeration application. J. Magn. Magn. Mater. 2016, 400, 344–348. [Google Scholar] [CrossRef]

- Bao, L.F.; Hu, F.X.; Chen, L.; Wang, J.; Sun, J.R.; Shen, B.G. Magnetocaloric properties of La(Fe,Si)13-based material and its hydride prepared by industrial mischmetal. Appl. Phys. Lett. 2012, 101, 162406. [Google Scholar] [CrossRef]

- Shao, Y.Y.; Lu, B.F.; Zhang, M.X.; Liu, J. An X-ray absorption spectroscopy study of La−Fe−Si−(H) magnetocaloric alloys. Acta Mater. 2018, 150, 206–212. [Google Scholar] [CrossRef]

- Liu, J.P.; Fullerton, E.; Gutfleisch, O.; Sellmyer, D.J. Nanoscale Magnetic Materials and Applications; Springer: Boston, MA, USA, 2009; ISBN 978-0-387-85600-1. [Google Scholar]

- Phejar, M.; Paul-Boncour, V.; Bessais, L. Investigation on structural and magnetocaloric properties of LaFe13−xSix(H,C)y compounds. J. Solid. State. Chem. 2016, 233, 95–102. [Google Scholar] [CrossRef]

- Dai, Y.T.; Li, Y.Q.; Xu, Z.S.; Luo, Z.P.; Han, K.; Zhai, Q.J.; Zheng, H.X. Studying of doping boron and carbon in LaFe11.6Si1.4 magnetocaloric alloy by experimental and density-functional methods. J. Alloy. Compd. 2018, 765, 538–543. [Google Scholar] [CrossRef]

- Demuner, A.S.; Takeuchi, A.Y.; Passamani, E.C.; Proveti, J.R.; Larica, C.; Favre-Nicolin, E.; Gomes, A.M. Magnetocaloric properties of the (La−Gd)Fe11.4Si1.6 metamagnetic compound. J. Magn. Magn. Mater. 2009, 321, 1809–1813. [Google Scholar] [CrossRef]

- Wu, D.Z.; Xue, S.C.; Frenzel, J.; Eggeler, G.; Zhai, Q.J.; Zheng, H.X. Atomic ordering effect in Ni50Mn37Sn13 magnetocaloric ribbons. Mater. Sci. Eng. A 2012, 534, 568–572. [Google Scholar] [CrossRef]

- Li, H.W.; Fang, Y.; Feng, S.T.; Zhai, Q.J.; Luo, Z.P.; Zheng, H.X. Magneto-structural transition behavior in Fe-doped Heusler Mn−Ni−In ribbon materials. J. Magn. Magn. Mater. 2016, 417, 267–271. [Google Scholar] [CrossRef]

- Jia, L.; Sun, J.R.; Shen, J.; Dong, Q.Y.; Hu, F.X.; Zhao, T.Y.; Shen, B.G. Magnetic coupling between rare-earth and iron atoms in the La1−xRxFe11.5Si1.5(R = Ce, Pr, and Nd) intermetallics. Appl. Phys. Lett. 2008, 92, 182503. [Google Scholar] [CrossRef]

- Fujieda, S.; Fujita, A.; Fukamichi, K.; Hirano, N.; Nagaya, S. Large magnetocaloric effects enhanced by partial substitution of Ce for La in La(Fe0.88Si0.12)13 compound. J. Alloy. Compd. 2006, 408–412, 1165–1168. [Google Scholar] [CrossRef]

- Fujieda, S.; Fujita, A.; Fukamichi, K. Enhancements of magnetocaloric effects in La(Fe0.90Si0.10)13 and its hydride by partial substitution of Ce for La. Mater. Trans. 2004, 45, 3228–3231. [Google Scholar] [CrossRef]

- Jia, L.; Sun, J.R.; Shen, J.; Dong, Q.Y.; Zou, J.D.; Gao, B.; Zhao, T.Y.; Zhang, H.W.; Hu, F.X.; Shen, B.G. Magnetocaloric effects in the La(Fe,Si)13 intermetallics doped by different elements. J. Appl. Phys. 2009, 105, 07A924. [Google Scholar] [CrossRef]

- Balli, M.; Fruchart, D.; Gignoux, D. Optimization of La(Fe,Co)13−xSix based compounds for magnetic refrigeration. J. Phys.: Condens. Matter 2007, 19, 236230. [Google Scholar] [CrossRef]

- Wang, F.W.; Kurbakov, A.; Wang, G.J.; Hu, F.X.; Shen, B.G.; Cheng, Z.H. Strong interplay between structure and magnetism in LaFe11.3Co0.6Si1.1: A neutron diffraction study. Phys. B 2006, 385−386, 343–345. [Google Scholar] [CrossRef]

- Krautz, M.; Skokov, K.; Gottschall, T.; Teixeira, C.S.; Waske, A.; Liu, J.; Schultz, L.; Gutfleisch, O. Systematic investigation of Mn substituted La(Fe,Si)13 alloys and their hydrides for room-temperature magnetocaloric application. J. Alloy. Compd. 2014, 598, 27–32. [Google Scholar] [CrossRef]

- Makarov, S.I.; Krautz, M.; Salamon, S.; Skokov, K.; Teixeira, C.S.; Gutfleisch, O.; Wende, H.; Keune, W. Local electronic and magnetic properties of pure and Mn-containing magnetocaloric LaFe13−xSix compounds inferred from Mössbauer spectroscopy and magnetometry. J. Phys. D Appl. Phys. 2015, 48, 305006. [Google Scholar] [CrossRef]

- Bratko, M.; Lovell, E.; Caplin, A.D.; Basso, V.; Barcza, A.; Katter, M.; Cohen, L.F. Determining the first-order character of La(Fe,Mn,Si)13. Phys. Rev. B. 2017, 95, 064411. [Google Scholar] [CrossRef]

- Moreno-Ramírez, L.M.; Romero-Muñiz, C.; Law, J.Y.; Franco, V.; Conde, A.; Radulov, I.; Maccari, F.; Skokov, K.P.; Gutfleisch, O. The role of Ni in modifying the order of the phase transition of La(Fe,Ni,Si)13. Acta Mater. 2018, 160, 137–146. [Google Scholar] [CrossRef]

- Xu, Z.S.; Dai, Y.T.; Fang, Y.; Luo, Z.P.; Han, K.; Song, C.J.; Zhai, Q.J.; Zheng, H.X. High temperature phase transition behavior and magnetocaloric effect in a sub-rapidly solidified La−Fe−Si plate produced by centrifugal casting. J. Mater. Sci. Technol. 2018, 34, 1337–1342. [Google Scholar] [CrossRef]

- Lai, J.W.; Zheng, Z.G.; Zhong, X.C.; Montemayor, R.; Liu, Z.W.; Zeng, D.C. Magnetocaloric effect of nonstoichiometric La1−xFe11.4+xSi1.6 alloys with first-order and second-order magnetic transitions. Intermetallics 2015, 63, 7–11. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.G.; Tang, Y.B. High-temperature phase transition and magnetic property of LaFe11.6Si1.4 compound. J. Alloy. Compd. 2011, 509, 8534–8541. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.G.; Tang, Y.B. The influence of different cooling processes on phase, microstructure, and magnetocaloric properties of LaFe11.6Si1.4 compounds. Solid State Commun. 2014, 186, 56–63. [Google Scholar] [CrossRef]

- Fujieda, S.; Fukamichi, K.; Suzuki, S. Microstructure and isothermal magnetic entropy change of La(Fe0.89Si0.11)13 in a single-phase formation process by annealing. J. Alloy. Compd. 2013, 566, 196–200. [Google Scholar] [CrossRef]

- Shamba, P.; Zeng, R.; Wang, J.L.; Campbell, S.J.; Dou, S.X. Enhancement of the refrigerant capacity in low level boron doped La0.8Gd0.2Fe11.4Si1.6. J. Magn. Magn. Mater. 2013, 331, 102–108. [Google Scholar] [CrossRef][Green Version]

- Gebara, P.; Pawlik, P.; Hasiak, M. Alteration of negative lattice expansion of the La(Fe,Si)13-type phase in LaFe11.14-xCo0.66NixSi1.2 alloys. J. Magn. Magn. Mater. 2017, 422, 61–65. [Google Scholar] [CrossRef]

- Zhang, Z.T.; He, C.; Zhang, M.X.; Liu, J. Influence of extra La and annealing temperature on microstructure and magnetocaloric properties of La–Fe–Co–Si alloys. Phys. B. 2015, 476, 167–170. [Google Scholar] [CrossRef]

- Goto, T.; Fukamichi, K.; Yamada, H. Itinerant electron metamagnetism and peculiar magnetic properties observed in 3d and 5f intermetallics. Phys. B 2001, 300, 167–185. [Google Scholar] [CrossRef]

- Qian, H.Y.; Dahal, B.; Halbritter, L.; Hu, J.; Huh, Y.; Kharel, P. Structural, magnetic and magnetocaloric properties of Ni43Mn46−xFexSn11 (x = 0, 6, 8, 10) alloys. AIP Adv. 2019, 9, 035005. [Google Scholar] [CrossRef]

- Law, J.Y.; Franco, V.; Moreno-Ramírez, L.M.; Conde, A.; Karpenkov, D.Y.; Radulov, L.; Skokov, K.P.; Gutfleisch, O. A quantitative criterion for determining the order of magnetic phase transitions using the magnetocaloric effect. Nat. Commun. 2018, 9, 2680. [Google Scholar] [CrossRef]

- Inoue, J.; Shimizu, M. Volume dependence of the first-order transition temperature for RCo2 compounds. J. Phys. F Met. Phys. 1982, 12, 1811. [Google Scholar] [CrossRef]

- Segall, M.D.; Lindan, P.J.D.; Probert, M.J.; Pickard, C.J.; Hasnip, P.J.; Clark, S.J.; Payne, M.C. First-principles simulation: ideas, illustrations and the CASTEP code. J. Phys. Condens. Matter 2002, 14, 2717–2744. [Google Scholar] [CrossRef]

- Perdew, J.P.; Chevary, J.A.; Vosko, S.H.; Jackson, K.A.; Pederson, M.R.; Singh, D.J.; Fiolhais, C. Erratum: atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 1993, 48, 4978. [Google Scholar] [CrossRef]

- Slater, J.C. Atomic Radii in Crystals. J. Chem. Phys. 1964, 41, 3199–3204. [Google Scholar] [CrossRef]

- Greenwood, N.N.; Earnshaw, A. Chemistry of the Elements, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 1997; pp. 944–1226. ISBN 978-0-7506-3365-9. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, P.; Li, Y.; Dai, Y.; Xu, Z.; Song, C.; Luo, Z.; Zhai, Q.; Han, K.; Zheng, H. Zn and P Alloying Effect in Sub-Rapidly Solidified LaFe11.6Si1.4 Magnetocaloric Plates. Metals 2019, 9, 432. https://doi.org/10.3390/met9040432

Jin P, Li Y, Dai Y, Xu Z, Song C, Luo Z, Zhai Q, Han K, Zheng H. Zn and P Alloying Effect in Sub-Rapidly Solidified LaFe11.6Si1.4 Magnetocaloric Plates. Metals. 2019; 9(4):432. https://doi.org/10.3390/met9040432

Chicago/Turabian StyleJin, Pingxia, Yuqiang Li, Yuting Dai, Zhishuai Xu, Changjiang Song, Zhiping Luo, Qijie Zhai, Ke Han, and Hongxing Zheng. 2019. "Zn and P Alloying Effect in Sub-Rapidly Solidified LaFe11.6Si1.4 Magnetocaloric Plates" Metals 9, no. 4: 432. https://doi.org/10.3390/met9040432

APA StyleJin, P., Li, Y., Dai, Y., Xu, Z., Song, C., Luo, Z., Zhai, Q., Han, K., & Zheng, H. (2019). Zn and P Alloying Effect in Sub-Rapidly Solidified LaFe11.6Si1.4 Magnetocaloric Plates. Metals, 9(4), 432. https://doi.org/10.3390/met9040432