Evolution of White Etching Bands in 100Cr6 Bearing Steel under Rolling Contact-Fatigue

Abstract

:1. Introduction

2. Experiment

2.1. Material and Heat Treatment

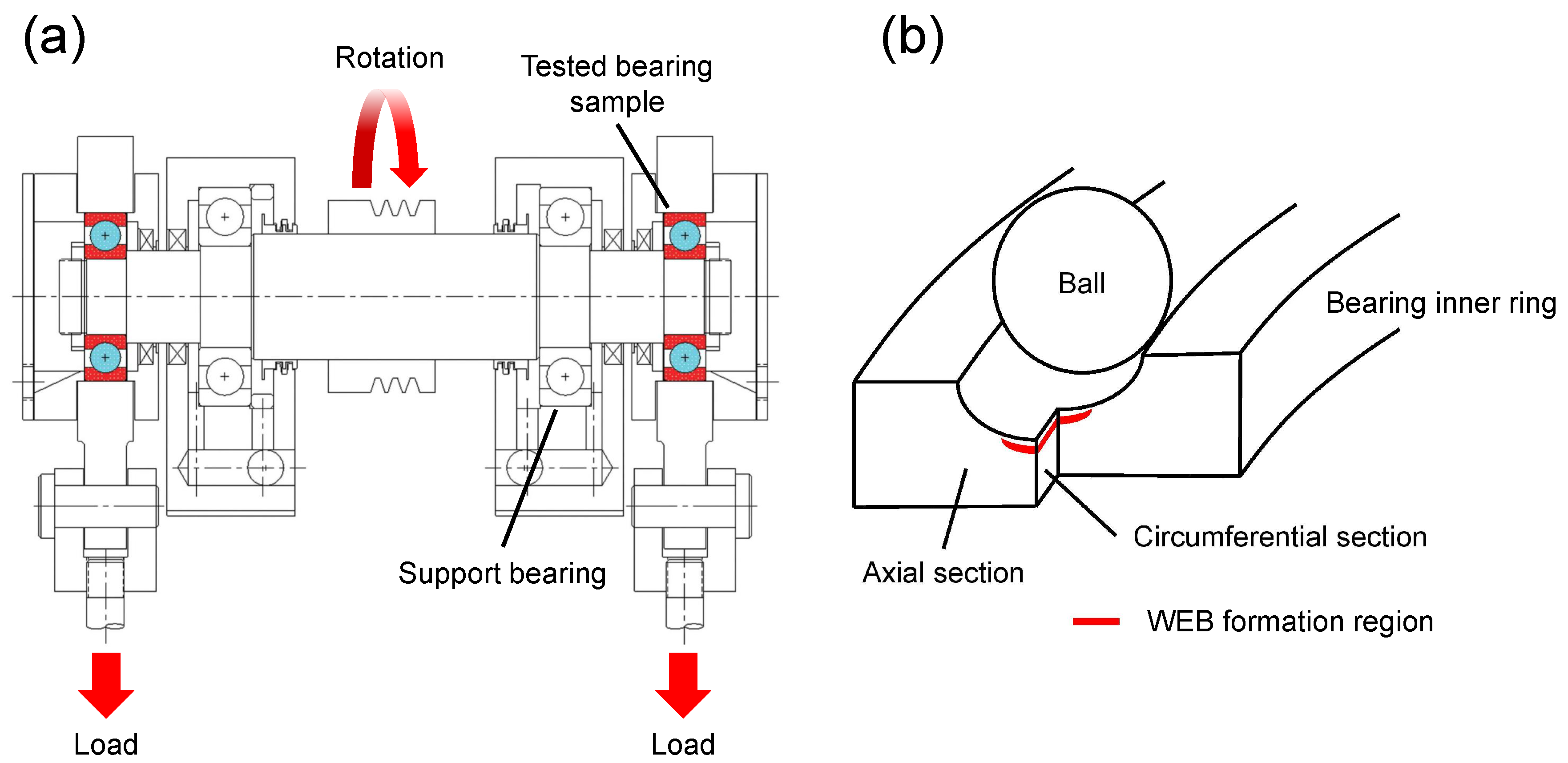

2.2. Rolling Contact-Fatigue Tests

2.3. Characterisation: Microindentation and Microscopy

3. Results

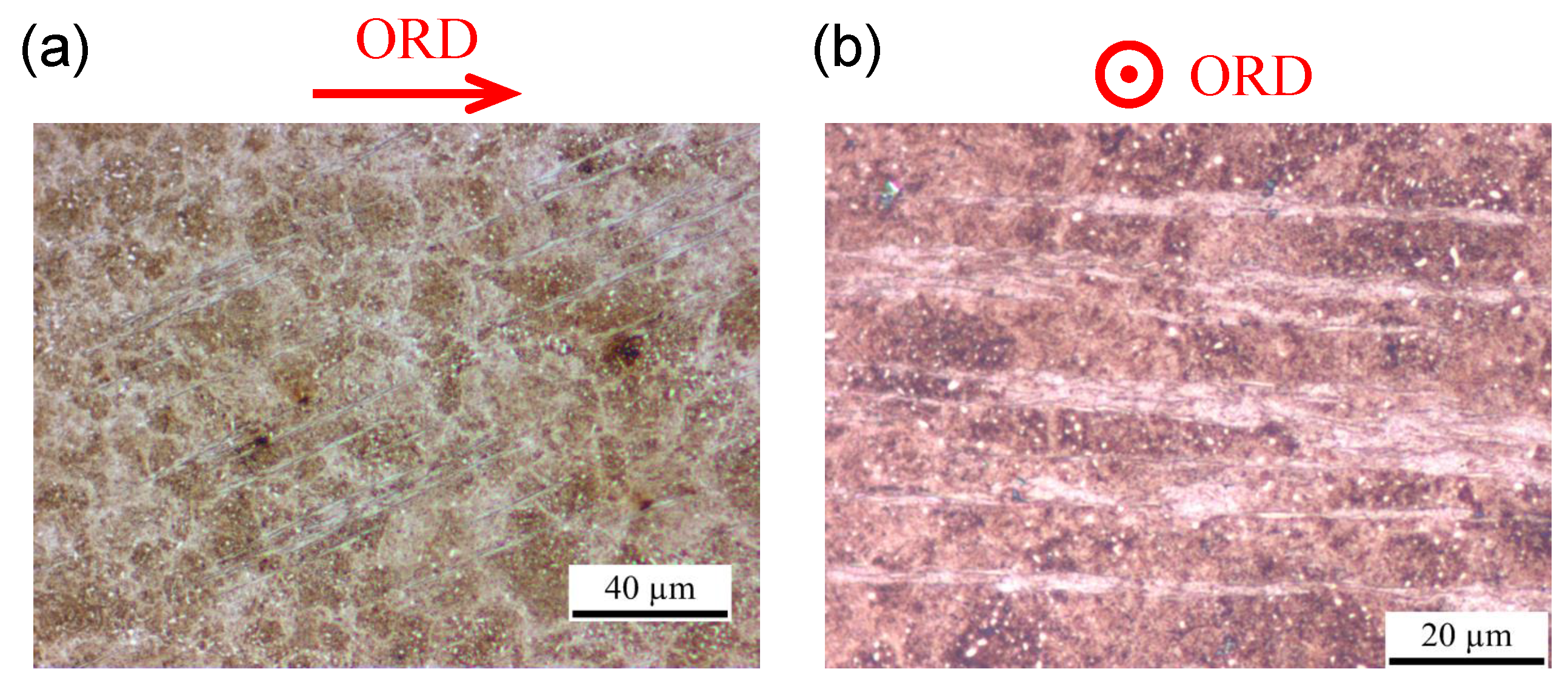

3.1. Web Distribution and Hardness Evolution

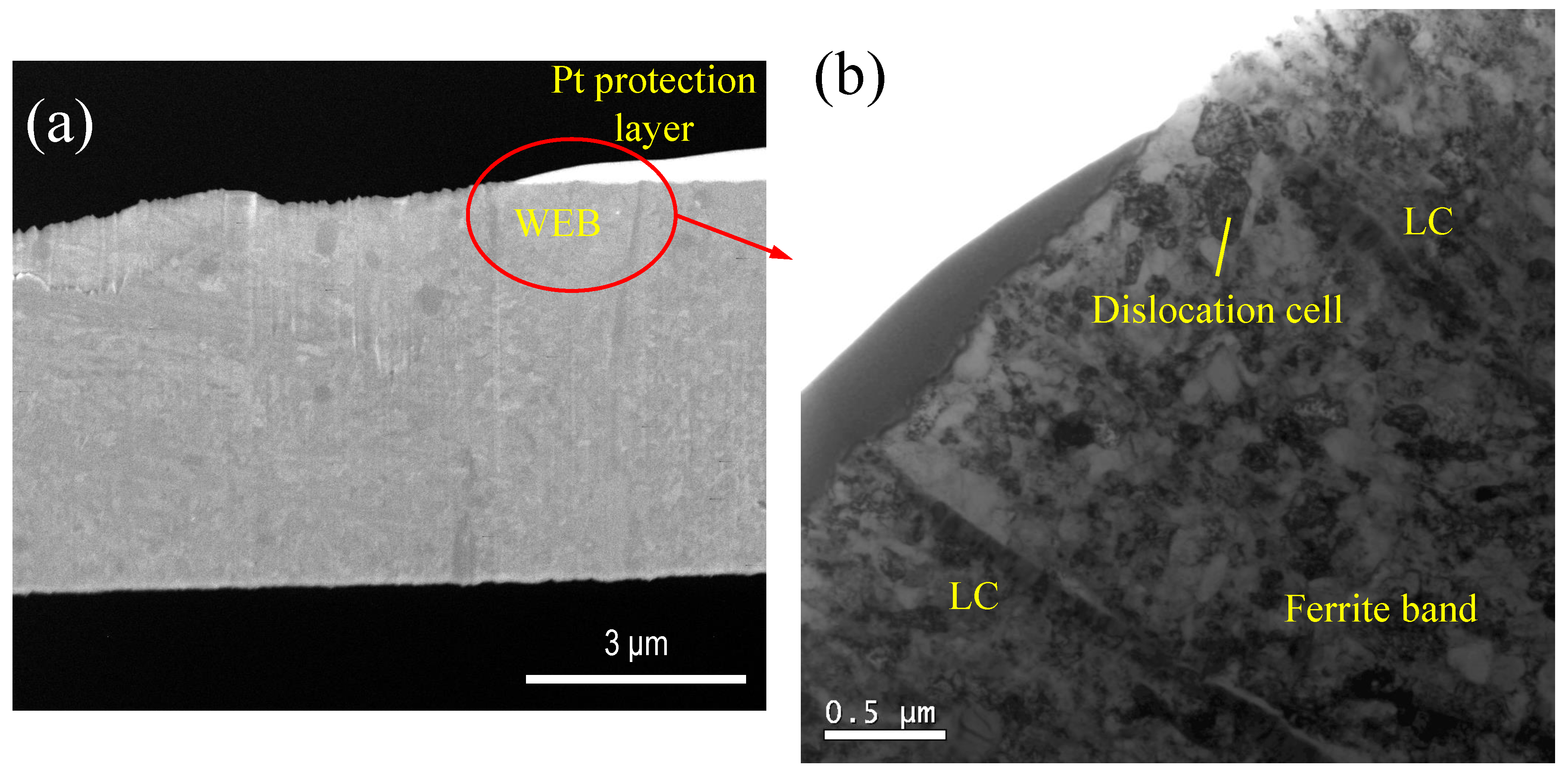

3.2. Web Structure

4. Discussion

4.1. Webs without Dark Etching Region Formation

4.2. Stress Analysis

4.3. Plastic Strain Analysis

5. Conclusions

- In contrary to some previous studies, WEBs in this research are formed in the absence of DERs. The heat treatment resulting in the precipitates that are poorly bonded to the matrix is believed to be the cause of DER elimination. It is proposed that DERs are not formed in 100Cr6 bearing steel with a hardness lower than 720 HV after heat treatment.

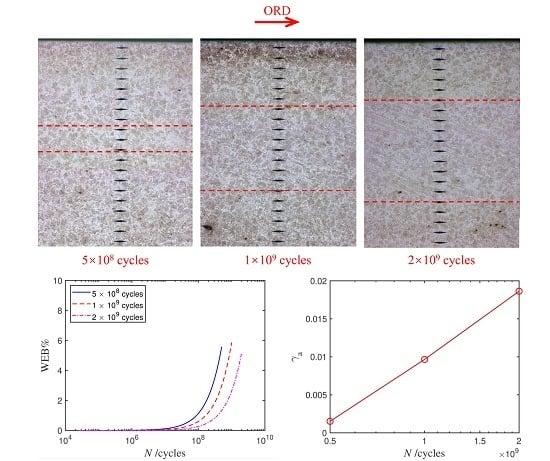

- OM clearly shows that plate-like WEBs grow in all three dimensions and in number density at the subsurface of rolling contact-fatigued bearing inner ring with increasing number of cycles. Micro-indentation results indicate an obvious hardness decrease of approximately 50 HV in the sample run to 2 × 10 cycles as a consequence of WEB formation.

- During RCF, work hardening is controlled by orthogonal shear stress component and reaches a saturation (25–30 HV hardness increase) at the early stage of bearing life; while WEB formation is dominated by maximum shear stress with the WEB formation region being gradually broadened along the depth with increasing number of cycles.

- A WEB consists of a ferrite band and LCs adjacent to it. AFM reveals the order of the resistant to Nital etchant of the microstructural features in the steel to be primary -carbides ≃ LCs > matrix > ferrite bands, which suggests that carbon improves the etching resistance of the features.

- TEM shows that ferrite bands contains dislocation cells with their average size to be 174 nm, indicative of plastic deformation.

- WEBs manifest the accumulated plastic strain induced by RCF. Based on the characterisation results, the dislocation density in ferrite bands is theoretically estimated to be 5.69 × 10 m, and the magnitudes of accumulated plastic strain in the three samples with the increasing number of cycles are estimated to be 0.001518, 0.00966 and 0.01863, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| RCF | Rolling contact-fatigue |

| WEBs | White etching bands |

| DERs | Dark etching regions |

| LCs | Lenticular carbides |

| OM | Optical microscopy |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| AFM | Atomic force microscopy |

References

- Warhadpande, A.; Sadeghi, F.; Evans, R.D. Microstructural Alterations in Bearing Steels under Rolling Contact Fatigue Part 1—Historical Overview. Tribol. Trans. 2013, 56, 349–358. [Google Scholar] [CrossRef]

- Kang, J.H.; Hosseinkhani, B.; Rivera-Díaz-del Castillo, P.E.J. Rolling contact-fatigue in bearings: Multiscale overview. Mater. Sci. Technol. 2012, 28, 44–49. [Google Scholar] [CrossRef]

- Swahn, H.; Becker, P.C.; Vingsbo, O. Martensite decay during rolling contact-fatigue in ball bearings. Metall. Trans. A 1976, 7, 1099–1110. [Google Scholar] [CrossRef]

- Martin, J.A.; Borgese, S.F.; Eberhardt, A.D. Microstructural Alterations of Rolling—Bearing Steel Undergoing Cyclic Stressing. J. Fluids Eng. 1966, 88, 555–565. [Google Scholar] [CrossRef]

- Bush, J.J.; Grube, W.L.; Robinson, G.H. Microstructural and residual stress changes in hardened steel due to rolling contact. Trans. ASM 1961, 54, 390–412. [Google Scholar]

- Fu, H.; Galindo-Nava, E.; Rivera-Díaz-del Castillo, P.E.J. Modelling and characterisation of stress-induced carbide precipitation in bearing steels under rolling contact-fatigue. Acta Mater. 2017, 128, 176–187. [Google Scholar] [CrossRef]

- Johnson, K. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Buchwald, J.; Heckel, R.W. An analysis of microstructural changes in 52100 steel bearings during cyclic stressing(Microstructural changes in 52100 steel bearing inner rings during cyclic stressing, obtaining thickening rate data on white-etching regions and lenticular carbides). ASM Trans. Q. 1968, 61, 750–756. [Google Scholar]

- Polonsky, I.A.; Keer, L.M. On white etching band formation in rolling bearings. J. Mech. Phys. Solids 1995, 43, 637–669. [Google Scholar] [CrossRef]

- Grabulov, A.; Petrov, R.; Zandbergen, H.W. EBSD investigation of the crack initiation and TEM/FIB analyses of the microstructural changes around the cracks formed under rolling contact fatigue (RCF). Int. J. Fatigue 2010, 32, 576–583. [Google Scholar] [CrossRef]

- Grabulov, A.; Ziese, U.; Zandbergen, H.W. TEM/SEM investigation of microstructural changes within the white etching area under rolling contact-fatigue and 3-D crack reconstruction by focused ion beam. Scr. Mater. 2007, 57, 635–638. [Google Scholar] [CrossRef]

- Fu, H.; Rivera-Díaz-del Castillo, P.E.J. A unified theory for microstructural alterations in bearing steels under rolling contact-fatigue. Acta Mater. 2018, 155, 43–55. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Bilby, B.A. Dislocation theory of yielding and strain ageing of iron. Proc. Phys. Soc. A 1949, 62, 49. [Google Scholar] [CrossRef]

- Österlund, R.; Vingsbo, O. Phase changes in fatigued ball bearings. Metall. Trans. A 1980, 11, 701–707. [Google Scholar] [CrossRef]

- Ochi, T.; Kusano, Y. Change in Microstructure and Properties in the Rolling Contact Fatigue of Bearing Steel. Nippon Steel Tech. Rep. 1999, 80, 19–25. [Google Scholar]

- Zwirlein, O.; Schlicht, H. Rolling contact-fatigue mechanisms—Accelerated testing versus field performance. Roll. contact-fatigue Test. Bear. Steels 1982, 771, 358–379. [Google Scholar]

- Voskamp, A.P. Material response to rolling contact loading. J. Tribol. 1985, 107, 359–364. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Silani, M.; Zhuang, X.; He, P.; Rabczuk, T. Stochastic analysis of the fracture toughness of polymeric nanoparticle composites using polynomial chaos expansions. Int. J. Fract. 2017, 206, 215–227. [Google Scholar] [CrossRef]

- Vu-Bac, N.; Lahmer, T.; Zhuang, X.; Nguyen-Thoi, T.; Rabczuk, T. A software framework for probabilistic sensitivity analysis for computationally expensive models. Adv. Eng. Softw. 2016, 100, 19–31. [Google Scholar] [CrossRef]

- Jones, A.B. Metallographic observations of ball bearing fatigue phenomena. In Proceedings of the STP70-EB Symposium on Testing of Bearings, West Conshohocken, PA, USA, 24–28 June 1946; pp. 35–52. [Google Scholar] [CrossRef]

- Lund, T. Structural alterations in fatigue-tested ball-bearing steel. Jemkonter A 1969, 153, 337–343. [Google Scholar]

- Barrow, A.T.W.; Kang, J.H.; Rivera-Díaz-del Castillo, P.E.J. The ϵ→η→θ transition in 100Cr6 and its effect on mechanical properties. Acta Mater. 2012, 60, 2805–2815. [Google Scholar] [CrossRef]

- Fu, H.; Song, W.; Galindo-Nava, E.I.; Rivera-Díaz-del Castillo, P.E.J. Strain-induced martensite decay in bearing steels under rolling contact-fatigue: Modelling and atomic-scale characterisation. Acta Mater. 2017, 139, 163–173. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del Castillo, P.E.J. A thermodynamic theory for dislocation cell formation and misorientation in metals. Acta Mater. 2012, 60, 4370–4378. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Sietsma, J.; Rivera-Díaz-del Castillo, P.E.J. Dislocation annihilation in plastic deformation: II. Kocks-Mecking Analysis. Acta Mater. 2012, 60, 2615–2624. [Google Scholar] [CrossRef]

- Budarapu, P.R.; Gracie, R.; Yang, S.W.; Zhuang, X.; Rabczuk, T. Efficient coarse graining in multiscale modeling of fracture. Theor. Appl. Fract. Mech. 2014, 69, 126–143. [Google Scholar] [CrossRef]

- Talebi, H.; Silani, M.; Bordas, S.P.; Kerfriden, P.; Rabczuk, T. A computational library for multiscale modeling of material failure. Comput. Mech. 2014, 53, 1047–1071. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R. Steels: Microstructure and Properties; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

| Fe | C | Cr | Mn | Si | Cu | Ni | Mo | Al |

|---|---|---|---|---|---|---|---|---|

| Balanced | 0.97 | 1.38 | 0.28 | 0.28 | 0.21 | 0.18 | 0.06 | 0.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, H.; Rivera-Díaz-del-Castillo, P.E.J. Evolution of White Etching Bands in 100Cr6 Bearing Steel under Rolling Contact-Fatigue. Metals 2019, 9, 491. https://doi.org/10.3390/met9050491

Fu H, Rivera-Díaz-del-Castillo PEJ. Evolution of White Etching Bands in 100Cr6 Bearing Steel under Rolling Contact-Fatigue. Metals. 2019; 9(5):491. https://doi.org/10.3390/met9050491

Chicago/Turabian StyleFu, Hanwei, and Pedro E. J. Rivera-Díaz-del-Castillo. 2019. "Evolution of White Etching Bands in 100Cr6 Bearing Steel under Rolling Contact-Fatigue" Metals 9, no. 5: 491. https://doi.org/10.3390/met9050491

APA StyleFu, H., & Rivera-Díaz-del-Castillo, P. E. J. (2019). Evolution of White Etching Bands in 100Cr6 Bearing Steel under Rolling Contact-Fatigue. Metals, 9(5), 491. https://doi.org/10.3390/met9050491