Cavitation Damage Prediction of Stainless Steels Using an Artificial Neural Network Approach

Abstract

:1. Introduction

2. Experiments

2.1. Experimental Program

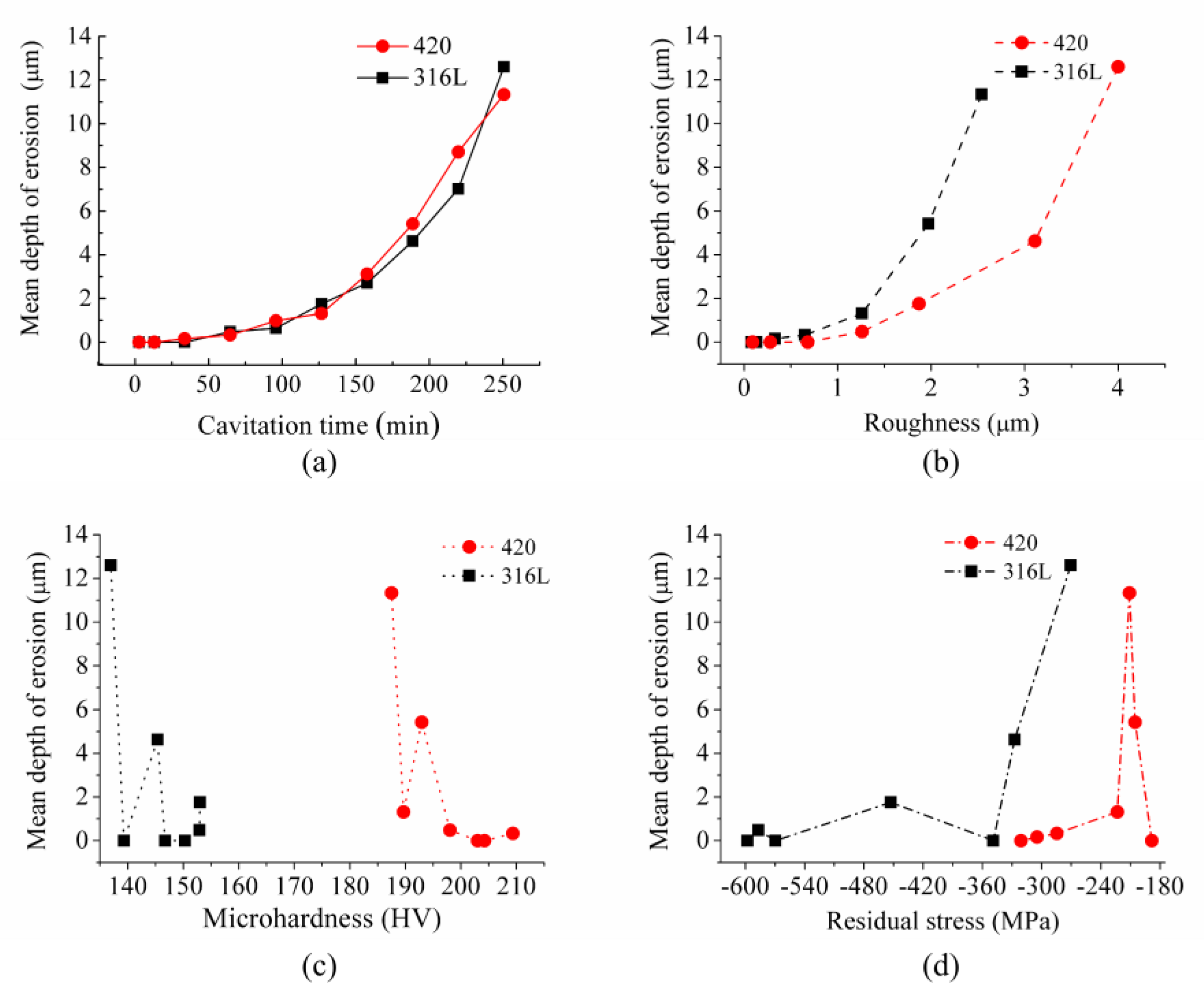

2.2. Significant Parameters of Cavitation Damage

3. Artificial Neural Network (ANN) Approach

3.1. Back-Propagation Neural Network

3.2. Damage Prediction Using ANN

4. Results and Discussion

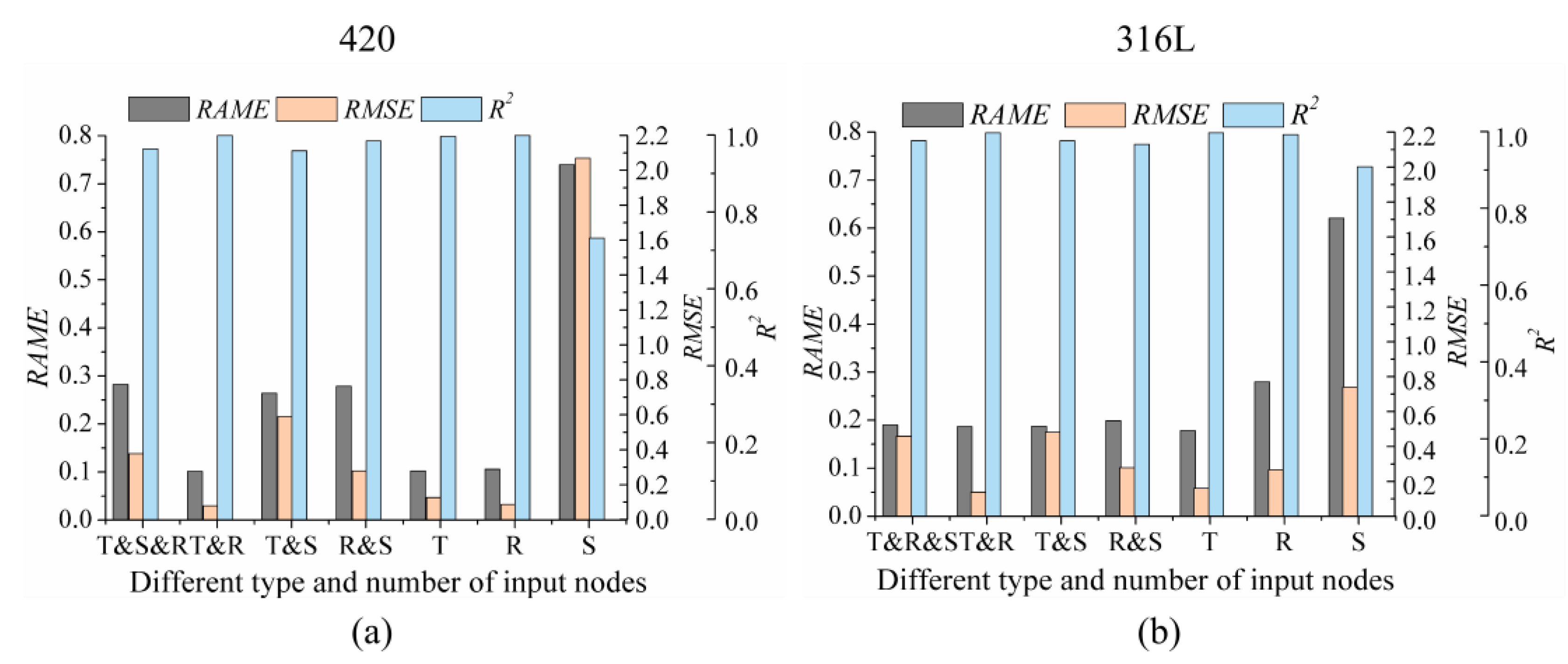

4.1. The Effects of Type and Number of Input Nodes on Prediction

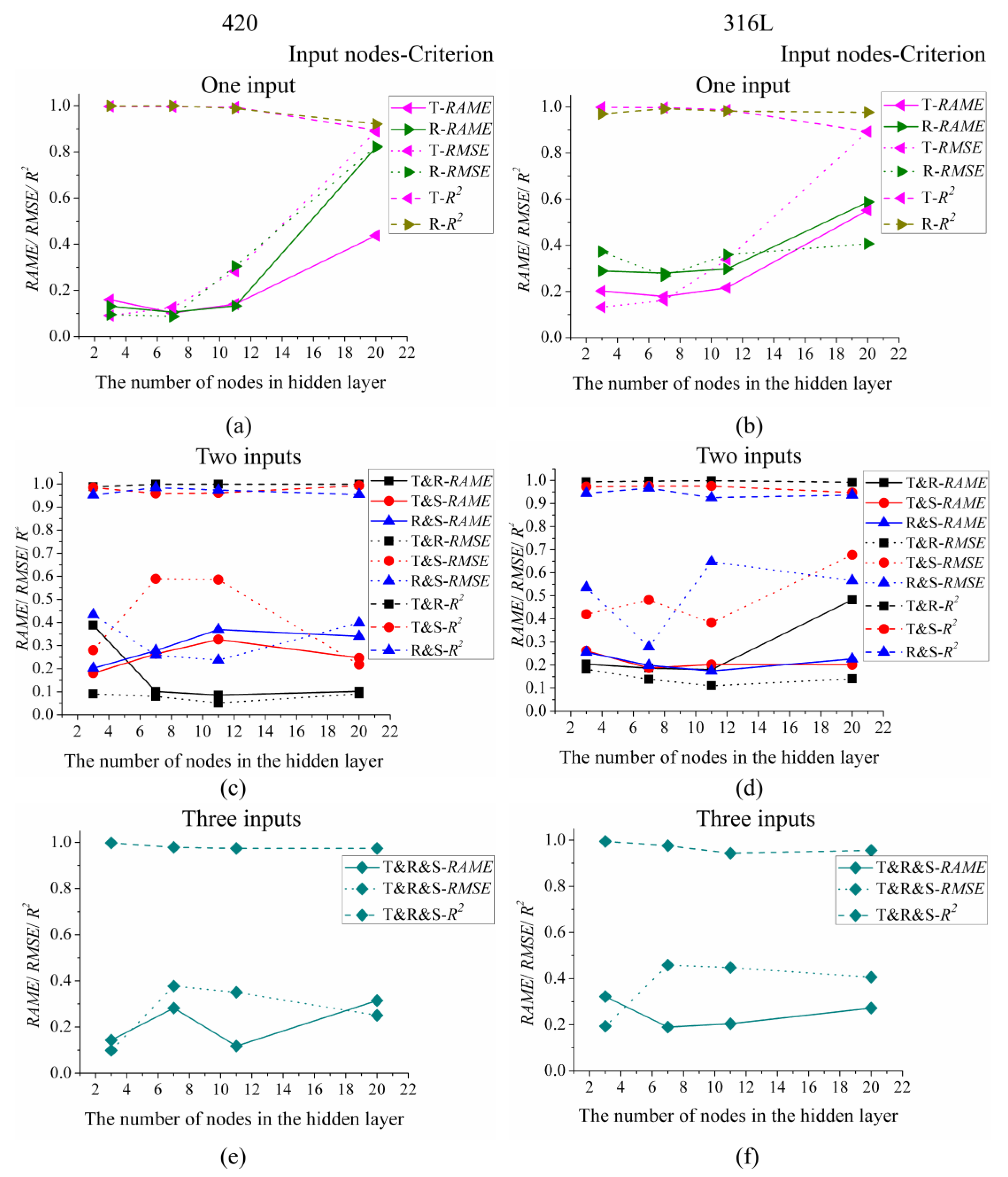

4.2. The Effects of the Number of Nodes in the Hidden Layers on Prediction

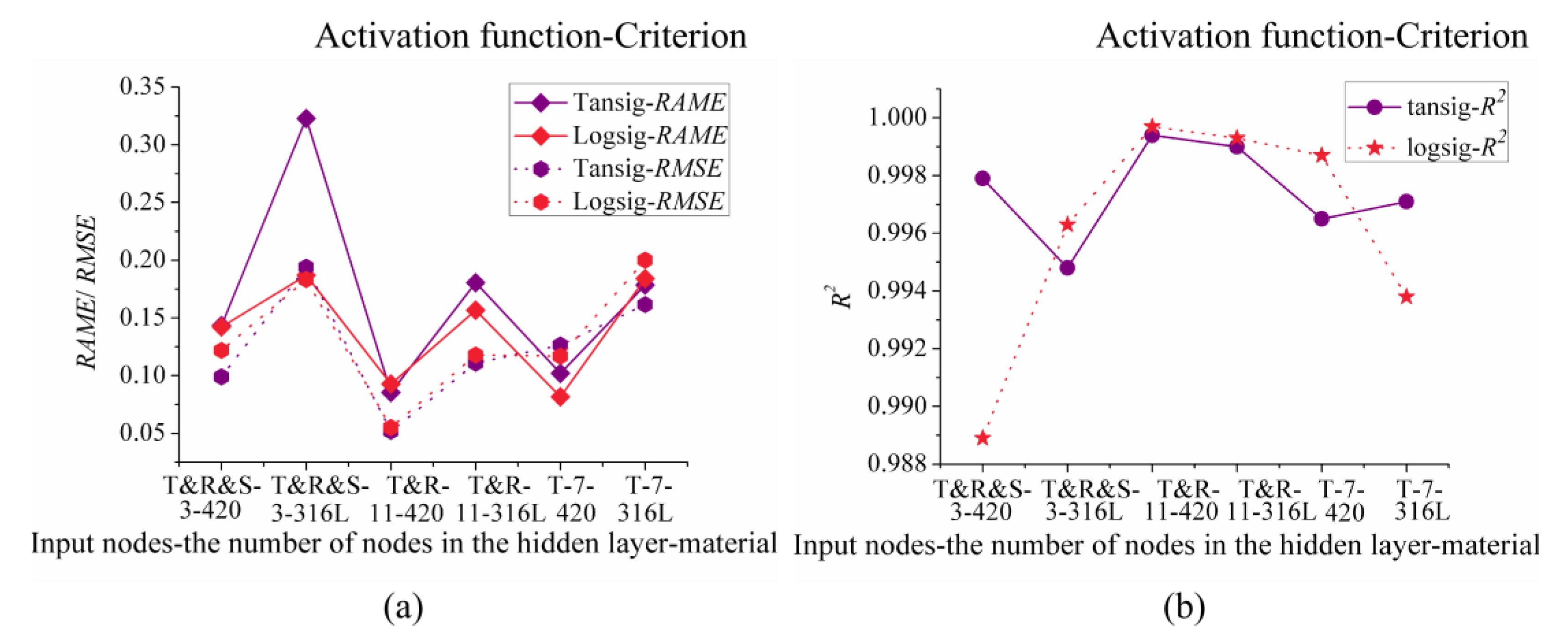

4.3. The Effects of Activation Functions on Prediction

5. Conclusions

- (1)

- A prediction approach using the artificial neural network for the cavitation damage is proposed.

- (2)

- From the analysis of the relationship between cavitation damage and microhardness, microhardness seems not to be related to cavitation damage.

- (3)

- From analysis of the relationship between cavitation damage, residual stress, and the ANN model, residual stress seems not to be related to cavitation damage.

- (4)

- Cavitation damage is affected by cavitation time and roughness. The increase of cavitation time or the increase of roughness during the cavitation erosion process increases cavitation damage.

- (5)

- The model using BP method with input nodes of cavitation time and roughness, eleven nodes in the hidden layer, and the activation function of logsig has a good performance of forecasting cavitation damage.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brennen, C.E. Hydrodynamics of Pumps; Jiangsu University Press: Zhenjiang, China, 2012; pp. 1–52. [Google Scholar]

- Naudé, C.F.; Ellis, A.T. On the mechanism of cavitation damage by non-hemispherical cavities collapsing in contact with a solid boundary. J. Basic Eng. 1960, 83, 648–656. [Google Scholar] [CrossRef]

- Dojcinovic, M.; Eric, O.; Rajnovic, D.; Sidjanin, L.; Balos, S. Effect of austempering temperature on cavitation behaviour of unalloyed ADI material. Mater. Charact. 2013, 82, 66–72. [Google Scholar] [CrossRef]

- Zhen, L.; Han, J.; Lu, J.; Chen, J. Cavitation erosion behavior of Hastelloy C-276 nickel-based alloy. J. Alloy. Compd. 2015, 619, 754–759. [Google Scholar]

- Kim, K.H.; Chahine, G.; Franc, J.P.; Karimi, A. Advanced Experimental and Numerical Techniques for Cavitation Erosion Prediction; Springer: New York, NY, USA, 2014. [Google Scholar]

- Hattori, S.; Hirose, T.; Sugiyama, K. Prediction method for cavitation erosion based on measurement of bubble collapse impact loads. Wear 2009, 269, 507–514. [Google Scholar] [CrossRef]

- Szkodo, M. Mathematical description and evaluation of cavitation erosion resistance of materials. J. Mater. Process. Tech. 2005, 164, 1631–1636. [Google Scholar] [CrossRef]

- Hattori, S.; Maeda, K.; Zhang, Q. Formulation of cavitation erosion behavior based on logistic analysis. Wear 2004, 257, 1064–1070. [Google Scholar] [CrossRef]

- Shuji, H.; Kohei, M. Logistic curve model of cavitation erosion progress in metallic materials. Wear 2010, 268, 855–862. [Google Scholar]

- Wang, Y.; Stella, J.; Darut, G.; Poirier, T.; Liao, H.L.; Planche, M.P. APS prepared NiCrBSi-YSZ composite coatings for protection against cavitation erosion. J. Alloys Compd. 2017, 699, 1095–1103. [Google Scholar] [CrossRef]

- Emelyanenko, A.M.; Shagieva, F.M.; Domantovsky, A.G.; Boinovich, L.B. Nanosecond laser micro- and nanotexturing for the design of a superhydrophobic coating robust against long-term contact with water, cavitation, and abrasion. Appl. Surf. Sci. 2015, 332, 513–517. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.W.; Kang, N.; Darut, G.; Poirier, T.; Stella, J.; Liao, H.L.; Planche, M.P. Cavitation erosion of plasma-sprayed CoMoCrSi coatings. Tribol. Int. 2016, 102, 429–435. [Google Scholar] [CrossRef]

- Lin, J.R.; Wang, Z.H.; Lin, P.H.; Cheng, J.B.; Zhang, X.; Hong, S. Effects of post annealing on the microstructure, mechanical properties and cavitation erosion behavior of arc-sprayed FeNiCrBSiNbW coatings. Mater. Des. 2015, 65, 1035–1040. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.; Goel, S.K. Effect of heat treatment on microstructure, mechanical properties and erosion resistance of cast 23-8-N nitronic steel. Mater. Sci. Eng. 2015, 637, 56–62. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, J. Correlation of martensitic transformation and surface mechanical behavior with cavitation erosion resistance for some iron-based alloys. Wear 2004, 256, 1208–1213. [Google Scholar] [CrossRef]

- Thiruvengadam, A.; Waring, S. Mechanical Properties of Metals and Their Cavitation Damage Resistance; Technical Report 233-5; Hydronautics Inc.: Laurel, MD, USA, 1 June 1964; p. 47. [Google Scholar]

- Duraiselvam, M.; Galun, R.; Wesling, V.; Mordike, B.L.; Reiter, R.; Oligmüller, J. Cavitation erosion resistance of AISI 420 martensitic stainless steel laser-clad with nickel aluminide intermetallic composites and matrix composites with TiC reinforcement. Surf. Coat. Technol. 2006, 201, 1289–1295. [Google Scholar] [CrossRef]

- Mottyll, S.; Skoda, R. Numerical 3D flow simulation of ultrasonic horns with attached cavitation structures and assessment of flow aggressiveness and cavitation erosion sensitive wall zones. Ultrason. Sonochem. 2016, 31, 570–589. [Google Scholar] [CrossRef]

- Brennen, C.E. Cavitation and Bubble Dynamics; Oxford University Press: New York, NY, USA, 1995; pp. 71–85. [Google Scholar]

- Schijve, J. Fatigue of Structures and Materials, 2nd ed.; Aviation Industry Press: Beijing, China, 2004; pp. 11–363. [Google Scholar]

- Pędzich, Z.; Jasionowski, R.; Ziąbka, M. Cavitation wear of structural oxide ceramics and selected composite materials. J. Eur. Ceram. Soc. 2014, 34, 3351–3356. [Google Scholar] [CrossRef]

- Choi, J.K.; Chahine, G.L. Relationship between material pitting and cavitation field impulsive pressures. Wear 2016, 352–353, 42–53. [Google Scholar] [CrossRef]

- Hsu, K.L.; Gupta, H.V.; Sorooshian, S. Artificial neural network modeling of the rainfall-runoff process. Water Resour. Res. 1995, 31, 2517–2530. [Google Scholar] [CrossRef]

- Jeyasehar, C.A.; Sumangala, K. Damage assessment of prestressed concrete beams using artificial neural network (ANN) approach. Comput. Struct. 2006, 84, 1709–1718. [Google Scholar] [CrossRef]

- Ye, L.; Su, Z.; Yang, C.; He, Z.; Wang, X. Hierarchical development of training database for artificial neural network-based damage identification. Compos. Struct. 2006, 76, 224–233. [Google Scholar] [CrossRef]

- Zang, C.; Imregun, M. Structural damage detection using artificial neural networks and measured FRF data reduced via principal component projection. J. Sound Vib. 2001, 242, 813–827. [Google Scholar] [CrossRef]

- Strdczkiewicz, M.; Barszcz, T. Application of artificial neural network for damage detection in planetary gearbox of wind turbine. Shock Vib. 2015, 2016, 1–12. [Google Scholar]

- Xu, H.; Humar, J.M. Damage detection in a girder bridge by artificial neural network technique. Comput. Civ. Infrastruct. Eng. 2010, 21, 450–464. [Google Scholar] [CrossRef]

- Altarazi, S.; Ammouri, M.; Hijazi, A. Artificial neural network modeling to evaluate polyvinylchloride composites’ properties. Comput. Mater. Sci. 2018, 153, 1–9. [Google Scholar] [CrossRef]

- Adoption, P.N. Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries; API Publishing Services: Washington, DC, USA, 2003. [Google Scholar]

- Astm, N.G. Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Karimi, A.; Martin, J.L. Cavitation erosion of materials. Metall. Rev. 2013, 31, 1–26. [Google Scholar] [CrossRef]

- Santa, J.F.; Blanco, J.A.; Giraldo, J.E. Cavitation erosion of martensitic and austenitic stainless steel welded coatings. Wear 2011, 271, 1445–1453. [Google Scholar] [CrossRef]

- Xiaojun, Z.; Procopiak, L.A.J.; Souza, N.C.; D’Oliveira, A.S.C.M. Phase transformation during cavitation erosion of a Co stainless steel. Mater. Sci. Eng. A 2003, 358, 199–204. [Google Scholar] [CrossRef]

- Li, D.G.; Wang, J.D.; Chen, D.R.; Liang, P. Ultrasonic cavitation erosion of Ti in 0.35% NaCl solution with bubbling oxygen and nitrogen. Ultrason. Sonochem. 2015, 26, 99–110. [Google Scholar] [CrossRef]

- Hugo, V.; De Albuquerque, C.; Tavares, M.R.S.; Durão, L.M.P.; João, P. Evaluation of Delamination Damage on Composite Plates using an Artificial Neural Network for the Radiographic Image Analysis. J. Compos. Mater. 2010, 44, 548–553. [Google Scholar]

- Kůrková, V. Kolmogorov’s theorem and multilayer neural networks. Neural Networks 1992, 5, 501–506. [Google Scholar] [CrossRef]

- Singh, K.P.; Basant, A.; Malik, A.; Jain, G. Artificial neural network modeling of the river water quality—A case study. Ecol. Modell. 2009, 220, 888–895. [Google Scholar] [CrossRef]

- Chen, M. Neural Network Principle and Example Elaboration of MATLAB; Tsinghua University Press: Beijing, China, 2003; pp. 21–157. [Google Scholar]

| Material | Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Mn | Si | Mo | P | S | N | Fe | |

| 420 | 0.20 | 12.10 | 0.28 | 0.34 | 0.29 | - | 0.026 | 0.015 | - | Bal. |

| 316L | 0.019 | 16.96 | 10.52 | 0.95 | 0.37 | 2.14 | 0.045 | 0.0027 | 0.036 | Bal. |

| Material | Yield Strength σ0.2 (MPa) | Tensile Strength (MPa) | Vickers Microhardness (HV) | Density (g/cm3) |

|---|---|---|---|---|

| 420 | 536 | 705 | 185 | 7.85 |

| 316L | 401 | 651 | 152 | 7.98 |

| Stainless Steels | 420 | 316L | ||||

|---|---|---|---|---|---|---|

| Input Nodes | Criteria | |||||

| RAME | RMSE | R2 | RAME | RMSE | R2 | |

| T&R | 0.1015 | 0.0797 | 0.9990 | 0.1868 | 0.1385 | 0.9968 |

| T | 0.1020 | 0.0866 | 0.9993 | 0.1785 | 0.1616 | 0.9971 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, G.; Zhang, Z.; Cai, C.; Zhang, J.; Nie, B. Cavitation Damage Prediction of Stainless Steels Using an Artificial Neural Network Approach. Metals 2019, 9, 506. https://doi.org/10.3390/met9050506

Gao G, Zhang Z, Cai C, Zhang J, Nie B. Cavitation Damage Prediction of Stainless Steels Using an Artificial Neural Network Approach. Metals. 2019; 9(5):506. https://doi.org/10.3390/met9050506

Chicago/Turabian StyleGao, Guiyan, Zheng Zhang, Cheng Cai, Jianglong Zhang, and Baohua Nie. 2019. "Cavitation Damage Prediction of Stainless Steels Using an Artificial Neural Network Approach" Metals 9, no. 5: 506. https://doi.org/10.3390/met9050506

APA StyleGao, G., Zhang, Z., Cai, C., Zhang, J., & Nie, B. (2019). Cavitation Damage Prediction of Stainless Steels Using an Artificial Neural Network Approach. Metals, 9(5), 506. https://doi.org/10.3390/met9050506