The Microstructure Evolution and Mechanical Properties of TiBw/TA15 Composite with Network Structure Prepared by Rapid Current Assisted Sintering

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Initial Powders and Material Preparation

2.2. Microstructure Analysis and Mechanical Properties

3. Results

3.1. The Effect of Sintering Parameters on the Densification

3.2. Microstructure Evolution

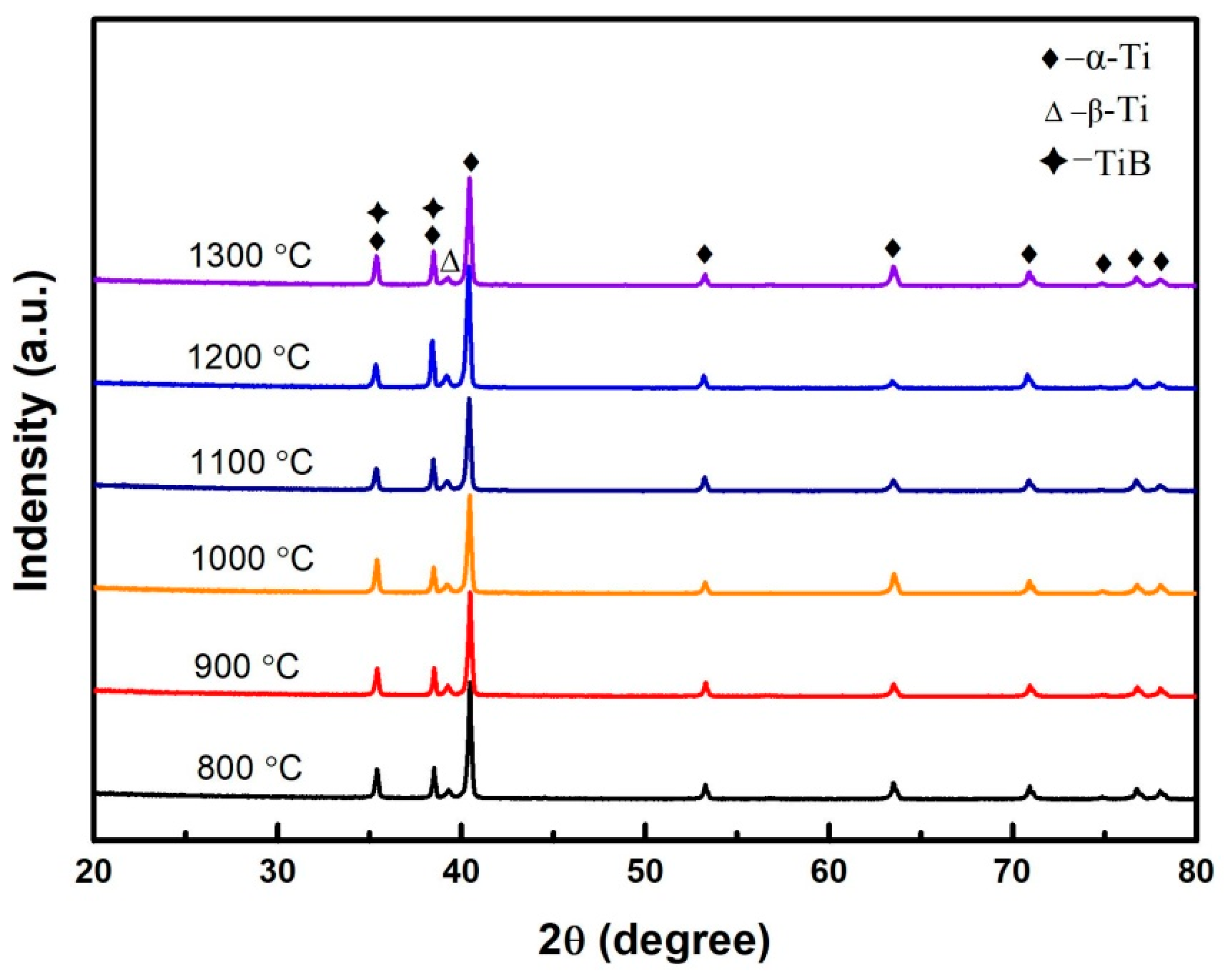

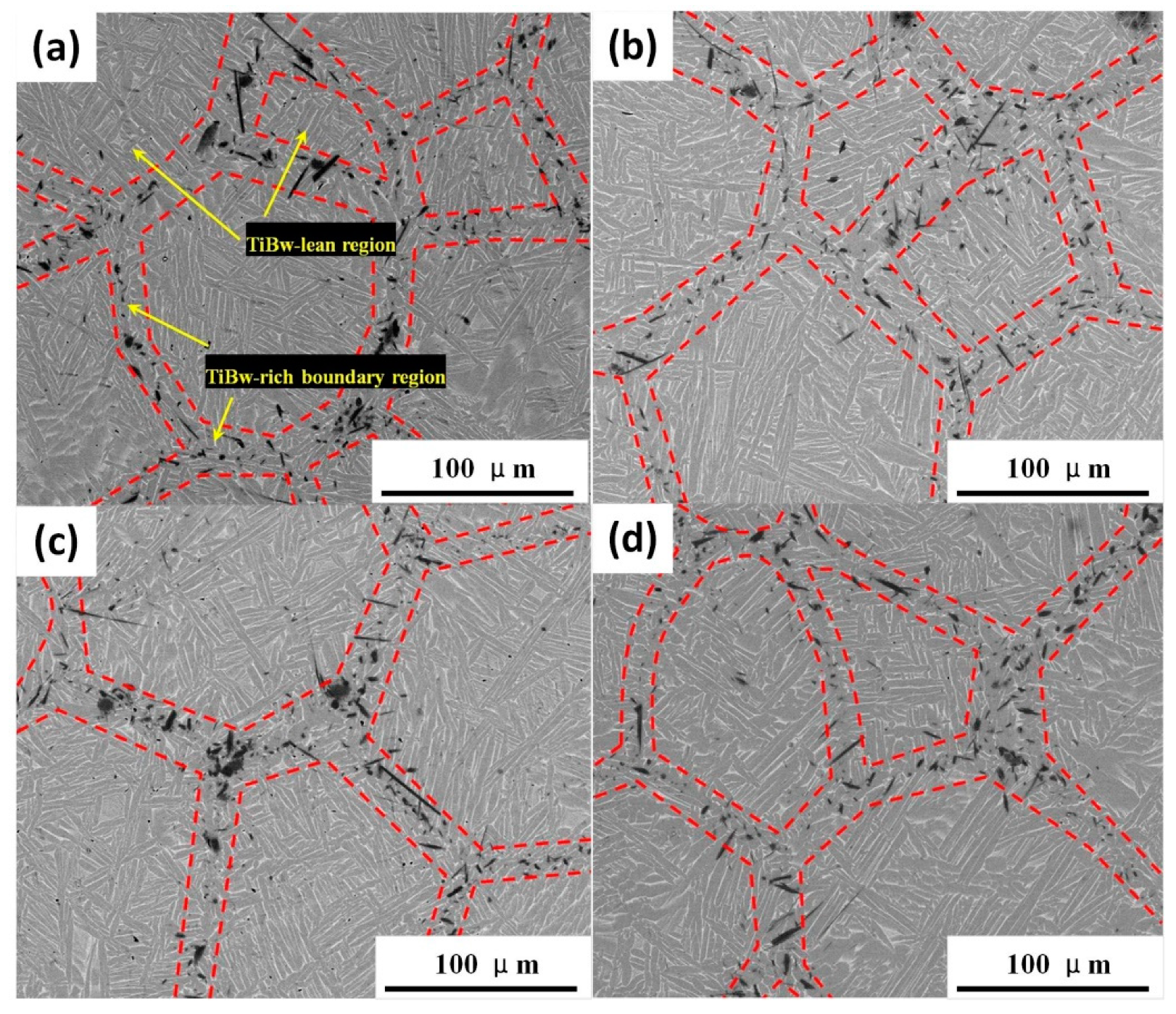

3.2.1. The Effects of Sintering Temperature on Microstructure

3.2.2. The Effects of Sintering Time on Microstructure

3.3. Mechanical Properties

4. Discussion

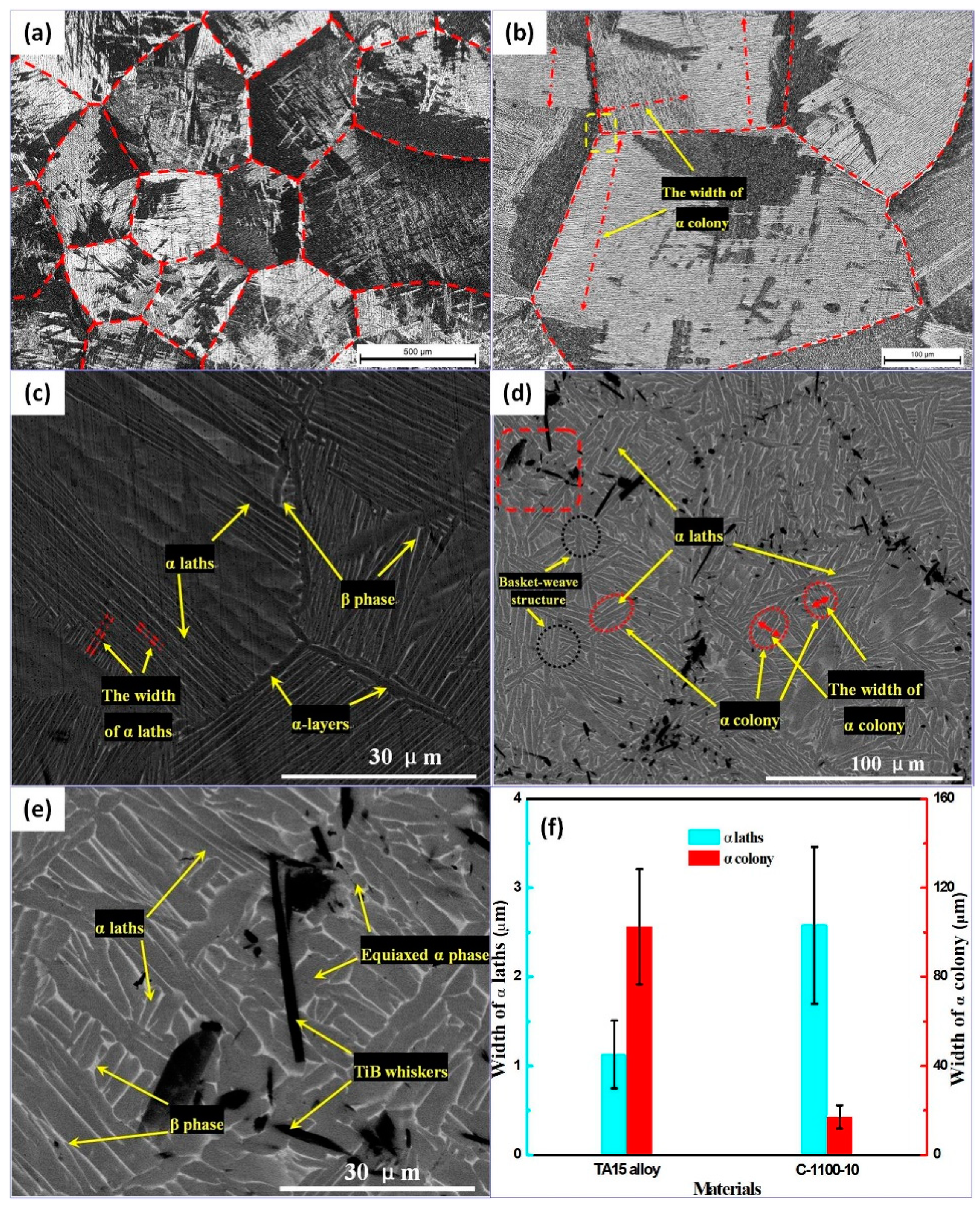

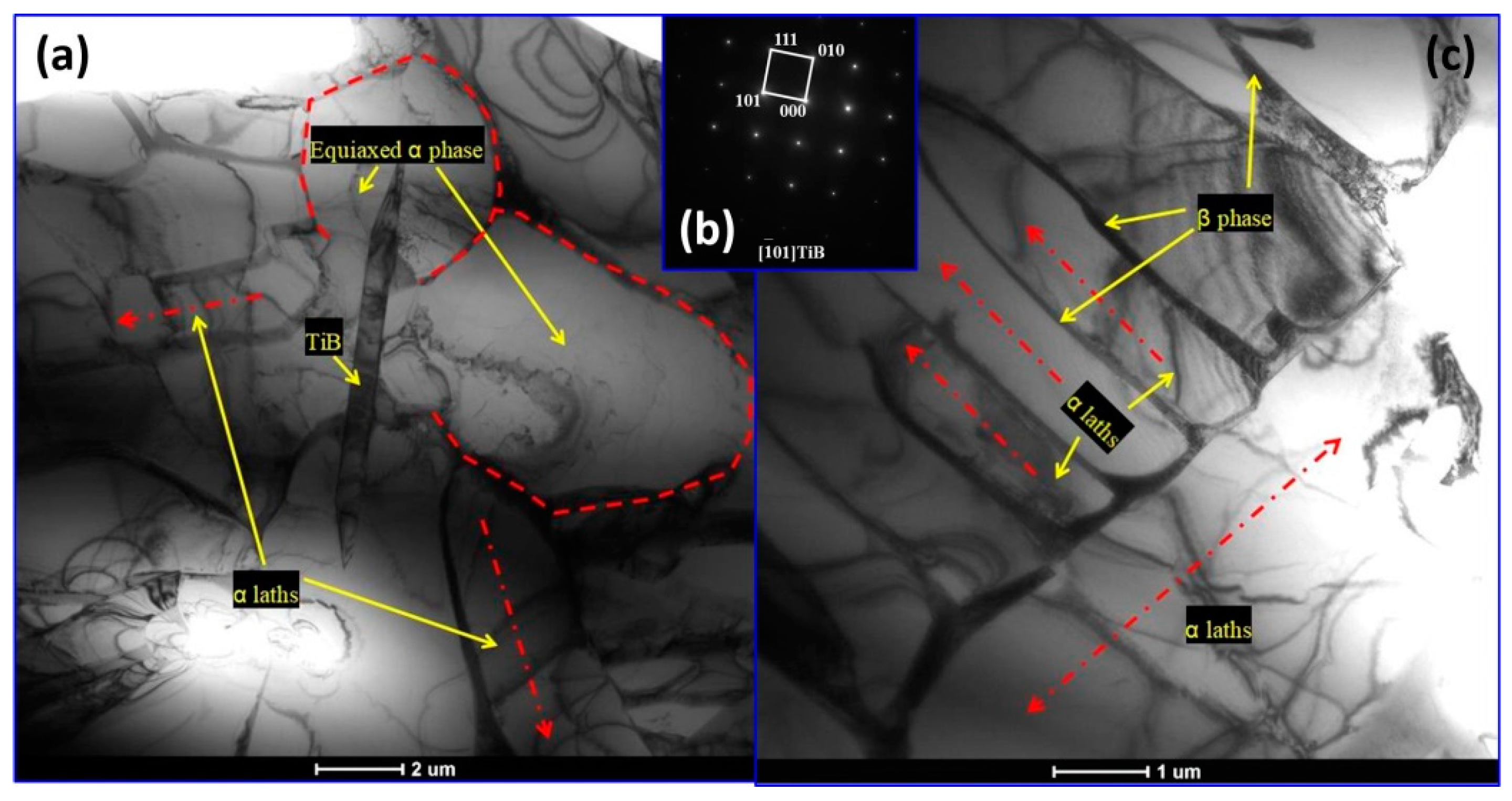

4.1. Effect of in situ Reinforcement on Microstructural Evolution

4.2. The Strengthening Mechanism of TiBw/TA15 Composites

4.2.1. Effect of matrix microstructure Evolution on Mechanical Properties

4.2.2. Effect of in situ Reinforcement on Mechanical Properties

5. Conclusions

- (1)

- TiBw/TA15 composites possessing excellent mechanical properties have been successfully fabricated by rapid current-assisted sintering at 1100 °C for 10 min. The density of this sample is 4.43 g/cm3. Meanwhile, the YS values of the composites at ambient temperature and 600 °C are 1172.5 MPa and 616.3 MPa, respectively.

- (2)

- The sintering temperature is the main factor affecting the aspect ratio of TiBw. The average aspect ratios of TiBw obtained at 1100 °C, 1200 °C, and 1300 °C are 11.08, 7.41, and 7.40, respectively. The effect of holding time on the average aspect ratio of TiBw is not evident.

- (3)

- The influence of TiBw on the modification of the microstructure for the titanium alloy matrix is mainly manifested in the following aspects: (a) the high-temperature initial β grains of TA15 titanium alloy are refined from ~424.8 μm to ~140 μm, (b) providing effective nucleation sites for the equiaxed α phase, and (c) refining the width of the α colony from 102.5μm of TA15 titanium alloy to 17.1μm of TiBw/TA15 composites when sintered at 1100 °C.

- (4)

- Besides the modification of the microstructure induced by TiBw, the TiBw/TA15 composites with network microstructures exhibiting better mechanical properties than TA15 titanium alloy, which is also attributed to the load-bearing and dislocation strengthening effects of TiBw. Moreover, TiBw exhibits similar strengthening effects as the average aspect ratio of TiBw exceeds the critical value (~1.95).

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Khanna, N.; Davim, J.P. Design-of-experiments application in machining titanium alloys for aerospace structural components. Measurement 2015, 61, 280–290. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A., Jr. Progress in structural materials for aerospace systems. Acta Mater. 2003, 55, 5775–5799. [Google Scholar] [CrossRef]

- Singh, P.; Pungotra, H.; Kalsi, N.S. On the characteristics of titanium alloys for the aircraft applications. Mater. Today Proc. 2017, 4, 8971–8982. [Google Scholar] [CrossRef]

- Gao, A.; Hang, R.Q.; Bai, L.; Tang, B.; Chu, P.K. Electrochemical surface engineering of titanium-based alloys for biomedical application. Electrochim. Acta 2018, 271, 699–718. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Tjong, S.C.; Gen, L. In-sit Ti-TiB metal-matrix composite prepared by a reactive pressing process. Scr. Mater. 2000, 42, 367–373. [Google Scholar] [CrossRef]

- Grützner, S.; Krüger, L.; Radajewski, M.; Schneider, I. Characterization of In-Situ TiB/TiC Particle-Reinforced Ti-5Al-5Mo-5V-3Cr Matrix Composites Synthesized by Solid-State Reaction with B4C and Graphite through SPS. Metals 2018, 8, 377. [Google Scholar] [CrossRef]

- Indrani, S.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural effects on the mechanical behavior of B-modified Ti-6Al-4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar]

- Han, J.C.; Lü, Z.D.; Zhang, C.J.; Zhang, S.Z.; Zhang, H.Z.; Lin, P.; Cao, P. The Microstructural Characterization and Mechanical Properties of 5 vol.% (TiBw + TiCp)/Ti Composite Produced by Open-Die Forging. Metals 2018, 8, 485. [Google Scholar] [CrossRef]

- Huang, L.J.; Xu, H.Y.; Wang, B.; Zhang, Y.Z.; Geng, L. Effects of heat treatment parameters on the microstructure and mechanical properties of in situ TiBw/Ti6Al4V composite with a network architecture. Mater. Des. 2012, 36, 694–698. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X.; Zhang, J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture. Scr. Mater. 2011, 64, 844–847. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Wang, B.; Wu, L.Z. Effects of volume fraction on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with novel network microstructure. Mater. Des. 2013, 45, 532–538. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Li, A.B.; Yang, F.Y.; Peng, H.X. In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 2009, 60, 996–999. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.J.; Huang, L.J.; Yuan, S.J. Effects of heat treatment on microstructure and high temperature tensile properties of TiBw/TA15 composite billet with network architecture. Mater. Sci. Eng. A 2017, 679, 314–322. [Google Scholar] [CrossRef]

- Azevedo, J.M.C.; Serrenho, A.C.; Allwood, J.M. Energy and material efficiency of steel powder metallurgy. Powder Technol. 2018, 328, 329–336. [Google Scholar] [CrossRef]

- Omkar, M.P.; Nitin, N.K.; Sachit, T.S.; Singh, T.P. A review on effect of powder metallurgy process on mechanical and tribological properties of Hybrid nano composites. Mater. Today Proc. 2018, 5, 5802–5808. [Google Scholar]

- Wang, D.J.; Yuan, H.; Qiang, J.M. The microstructure Evolution, Mechanical Properties and Densification Mechanism of TiAl-Based Alloys Prepared by Spark Plasma Sintering. Metals 2017, 7, 201. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Z.F.; Lu, J.F.; Shen, X.B.; Wang, F.C.; Wang, Y.D. The sintering mechanism in spark plasma sintering-Proof of the occurrence of spark discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Oh, H.C.; Lee, S.H.; Choi, S.C. The reaction mechanism for the low temperature synthesis of Cr2AlC under electronic field. J. Alloys Compd. 2014, 587, 296–302. [Google Scholar] [CrossRef]

- Lee, S.H.; Oh, H.C.; An, B.H.; Kim, H.D. Ultra-low temperature synthesis of Al4SiC4 powder using spark plasma sintering. Scr. Mater. 2013, 69, 135–138. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, G.Q.; Zhang, J.; Wu, C.D.; Li, J.; Shen, Q. Phase transition, microstructure and mechanical properties of TC4 titanium alloy prepared by plasma activated sintering. J. Alloys Compd. 2018, 741, 918–926. [Google Scholar] [CrossRef]

- Feng, H.B.; Jia, D.C.; Zhou, Y. Spark plasma sintering reaction synthesized TiB reinforced titanium matrix composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 558–563. [Google Scholar] [CrossRef]

- Feng, H.B.; Zhou, Y.; Jia, D.C.; Meng, Q.C. Microstructure and mechanical properties of in situ TiB reinforced titanium matrix composites based on Ti-Fe-Mo-B prepared by spark plasma sintering. Compos. Sci. Technol. 2004, 64, 2495–2500. [Google Scholar] [CrossRef]

- Feng, H.B.; Zhou, Y.; Jia, D.C.; Meng, Q.C. Rapid synthesis of Ti alloy with B addition by spark plasma sintering. Mater. Sci. Eng. A 2005, 390, 344–349. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.J.; Yuan, S.J. Effect of multi-directional forging on the microstructure and mechanical properties of TiBw/TA15 composite with network architecture. Mater. Des. 2017, 134, 250–258. [Google Scholar] [CrossRef]

- Mondet, M.; Barraud, E.; Lemonnier, S.; Guyon, J.; Allain, N.; Grosdidier, T. Microstructure and mechanical properties of AZ91 magnesium alloy developed by Spark Plasma Sintering. Acta Mater. 2016, 119, 55–67. [Google Scholar] [CrossRef]

- Li, X.G.; Jiang, D.L.; Zhang, J.X.; Lin, Q.L.; Chen, Z.M.; Huang, Z.R. Densification behavior and related phenomena of spark plasma sintered boron carbide. Ceram. Int. 2014, 40, 4359–4366. [Google Scholar] [CrossRef]

- Guillaume, B.G.; Ahmed, A.; Gilbert, F.; Guillaume, B.; Christian, G.; Dorothée, V. Spark plasma sintering of a commercially available granulated zirconia powder: Comparison with hot-pressing. Acta Mater. 2010, 58, 3390–3399. [Google Scholar]

- Huang, L.J.; Yang, F.Y.; Guo, Y.L.; Zhang, J.; Geng, L. Effect of sintering temperature on microstructure of Ti6Al4V matrix composites. Int. J. Mod. Phys. B 2009, 23, 1444–1448. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.J.; Huang, L.J.; Yuan, S.J.; Geng, L. Deformation behaviors and microstructure evolution of TiBw/TA15composite with novel network architecture. J. Alloys Compd. 2017, 722, 970–980. [Google Scholar] [CrossRef]

- Marder, R.; Estournès, C.; Chevallier, G.; Chaim, R. Plasma in spark plasma sintering of ceramic particle compacts. Scr. Mater. 2014, 82, 57–60. [Google Scholar] [CrossRef] [Green Version]

- Li, X.P.; Yan, M.; Imai, H.; Kondoh, K.; Schaffer, G.B.; Qian, M. The critical role of heating rate in enabling the removal of surface oxide films during spark plasma sintering of Al-based bulk metallic glass powder. J. Non-Cryst. Solids 2013, 375, 95–98. [Google Scholar] [CrossRef]

- Bonifacio, C.S.; Holland, T.B.; Benthem, K.V. Evidence of surface cleaning during electric field assisted sintering. Scr. Mater. 2013, 69, 769–772. [Google Scholar] [CrossRef]

- Song, X.Y.; Liu, X.M.; Zhang, J.X. Neck Formation and Self-Adjusting Mechanism of Neck Growth of Conducting Powders in Spark Plasma Sintering. J. Am. Ceram. Soc. 2006, 89, 494–500. [Google Scholar] [CrossRef]

- Zofia, T.; Alain, C.; Jean-Philippe, M. Spark plasma sintering mechanisms at the necks between TiAl powder particles. Acta Mater. 2016, 118, 100–108. [Google Scholar]

- Zhang, Z.H.; Shen, X.B.; Wen, S.; Luo, J.; Lee, S.K.; Wang, F.C. In situ reaction synthesis of Ti-TiB composites containing high volume fraction of TiB by spark plasma sintering process. J. Alloys Compd. 2010, 503, 145–150. [Google Scholar] [CrossRef]

- Feng, H.B.; Zhou, Y.; Jia, D.C.; Meng, Q.C. Stacking faults formation mechanism of in situ synthesized TiB whiskers. Scr. Mater. 2006, 55, 667–670. [Google Scholar] [CrossRef]

- Fan, Z.; Guo, Z.X.; Cantor, B. The kinetics and mechanism of interfacial reaction in sigma fibre-reinforced Ti MMCs. Compos. Part A Appl. Sci. Manuf. 1997, 28, 131–140. [Google Scholar] [CrossRef]

- Hill, D.; Banerjee, R.; Huber, D.; Tiley, J.; Fraser, H.L. Formation of equiaxed alpha in TiB reinforced Ti alloy composites. Scr. Mater. 2005, 52, 387–392. [Google Scholar] [CrossRef]

- Wang, D.J.; Zhang, R.; Yuan, S.J. Flow behavior and microstructure evolution of a TiBw/TA15 composite with network-distributed reinforcements during interrupted hot compression. Mater. Sci. Eng. A 2018, 725, 428–436. [Google Scholar] [CrossRef]

- Lȕtjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Ryu, H.J.; Cha, S.I.; Hong, S.H. Generalized shear-lag model for load transfer in SiC/Al metal-matrix composites. J. Mater. Res. 2003, 18, 2851–2858. [Google Scholar] [CrossRef] [Green Version]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Sahoo, B.N.; Khan, F.M.D.; Babu, S.; Panigrahi, S.K.; Ram, G.D.J. Microstructural modification and its effect on strengthening mechanism and yield asymmetry of in-situ TiC-TiB2/AZ91 magnesium matrix composite. Mater. Sci. Eng. A 2018, 724, 269–282. [Google Scholar] [CrossRef]

| Al | Zr | Mo | V | Fe | Si | Ti |

|---|---|---|---|---|---|---|

| 6.62 | 1.9 | 1.7 | 2.25 | 0.04 | 0.02 | Bal. |

| Material Notation | Sintering Temperature (°C) | Holding Time (min) | Density (g/cm3) |

|---|---|---|---|

| C800-60 | 800 | 60 | 4.13 |

| C900-60 | 900 | 60 | 4.43 |

| C1000-60 | 1000 | 60 | 4.45 |

| C1100-60 | 1100 | 60 | 4.44 |

| C1200-60 | 1200 | 60 | 4.45 |

| C1300-60 | 1300 | 60 | 4.43 |

| C1100-10 | 1100 | 10 | 4.43 |

| C1100-20 | 1100 | 20 | 4.43 |

| C1100-30 | 1100 | 30 | 4.44 |

| C1100-45 | 1100 | 45 | 4.44 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Li, H.; Wang, X.; Zheng, W.; Lin, Z.; Liu, G. The Microstructure Evolution and Mechanical Properties of TiBw/TA15 Composite with Network Structure Prepared by Rapid Current Assisted Sintering. Metals 2019, 9, 540. https://doi.org/10.3390/met9050540

Wang D, Li H, Wang X, Zheng W, Lin Z, Liu G. The Microstructure Evolution and Mechanical Properties of TiBw/TA15 Composite with Network Structure Prepared by Rapid Current Assisted Sintering. Metals. 2019; 9(5):540. https://doi.org/10.3390/met9050540

Chicago/Turabian StyleWang, Dongjun, Hao Li, Xiaosong Wang, Wei Zheng, Zhangqian Lin, and Gang Liu. 2019. "The Microstructure Evolution and Mechanical Properties of TiBw/TA15 Composite with Network Structure Prepared by Rapid Current Assisted Sintering" Metals 9, no. 5: 540. https://doi.org/10.3390/met9050540

APA StyleWang, D., Li, H., Wang, X., Zheng, W., Lin, Z., & Liu, G. (2019). The Microstructure Evolution and Mechanical Properties of TiBw/TA15 Composite with Network Structure Prepared by Rapid Current Assisted Sintering. Metals, 9(5), 540. https://doi.org/10.3390/met9050540