Additive Manufacturing of Complex Components through 3D Plasma Metal Deposition—A Simulative Approach

Abstract

:1. Introduction

2. Approach–Development of Innovative Three-Dimensional Plasma Metal Deposition (3DPMD) Technology

2.1. Experimental Work

2.1.1. Materials

2.1.2. Process Parameter Determination for 3DPMD of a Layered System

2.1.3. Characterization of the Plasma Deposition-Welded Layer System

2.2. Thermo-Mechanical Simulation Model and Boundary Conditions

2.2.1. Basic Equations for Thermo-Elastic-Plastic Structural Analysis

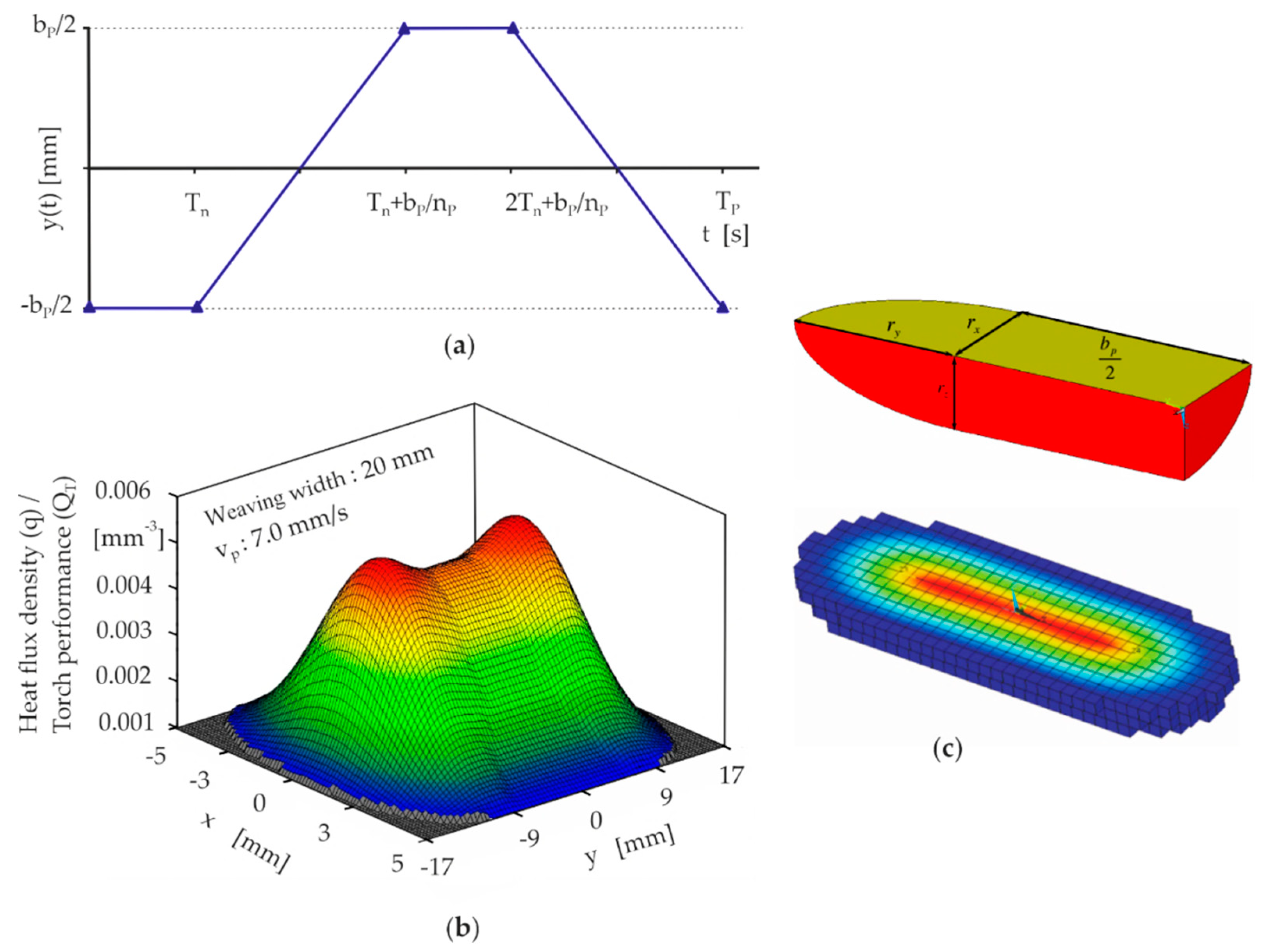

2.2.2. Heat Source Model for the 3DPMD Process

- the torch power (QT),

- the half-axes of the half-ellipsoid rx, ry, and rz.

- Torch still-situation at a reversal point during a dwell time (Td),

- Movement of the torch at a constant speed (vp) to the second reversal point,

- Still-situation of the torch at the second reversal point during the dwell time (Td),

- Movement of the torch at a constant speed (vp) to the first reversal point.

2.2.3. Discretization of Component Geometry and Definition of Temperature-Dependent Material Data

- Preheating of the basic body to T = 450 °C;

- Active thermal deposition process and short cooling time to read interpass temperature;

- Active thermal deposition process up to the thermal deposition of the entire contour surfaces; and

- Long cooling time up to complete component cooling.

3. Results and Discussion

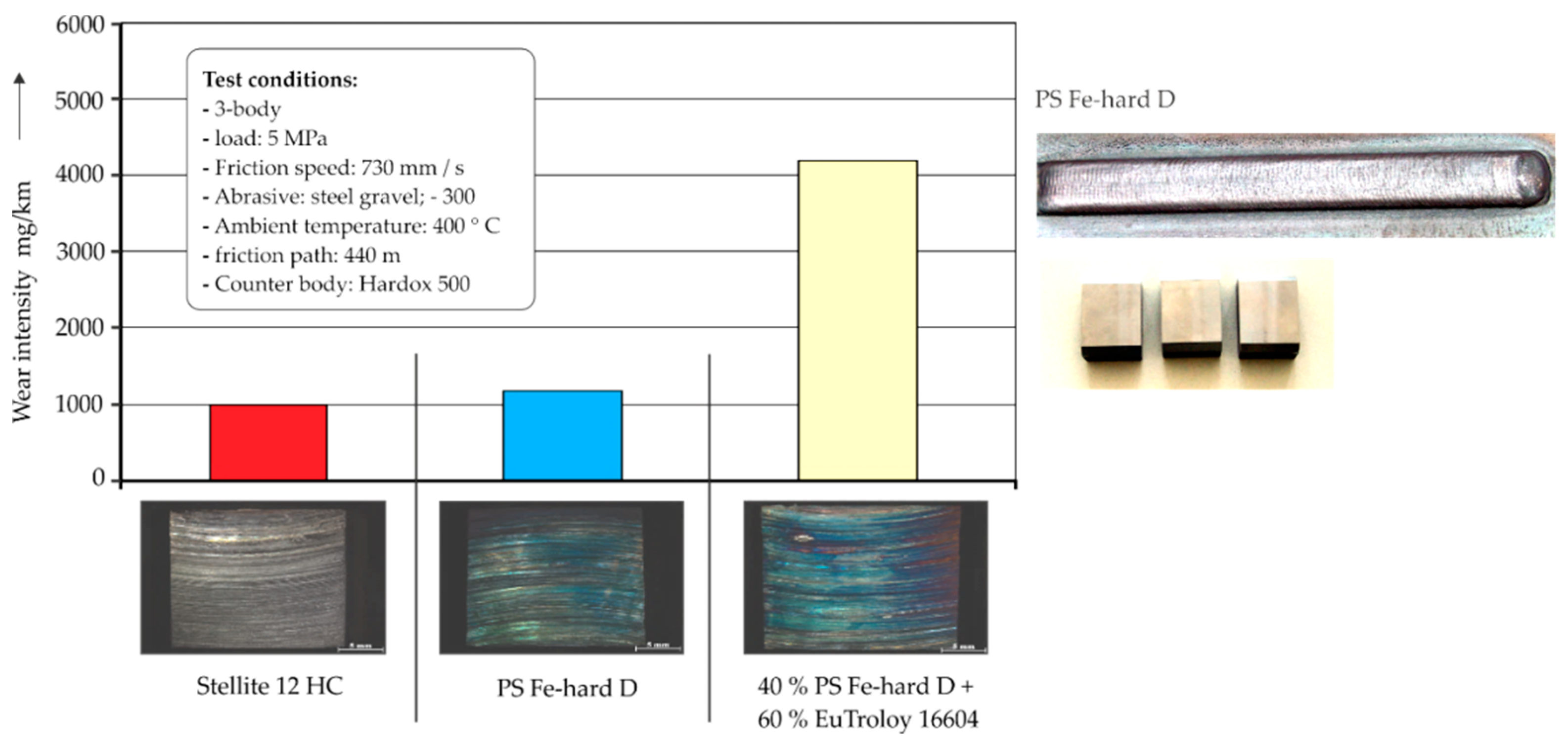

3.1. Investigation Results of the Plasma Deposition-Welded Layers

3.2. Simulation Results

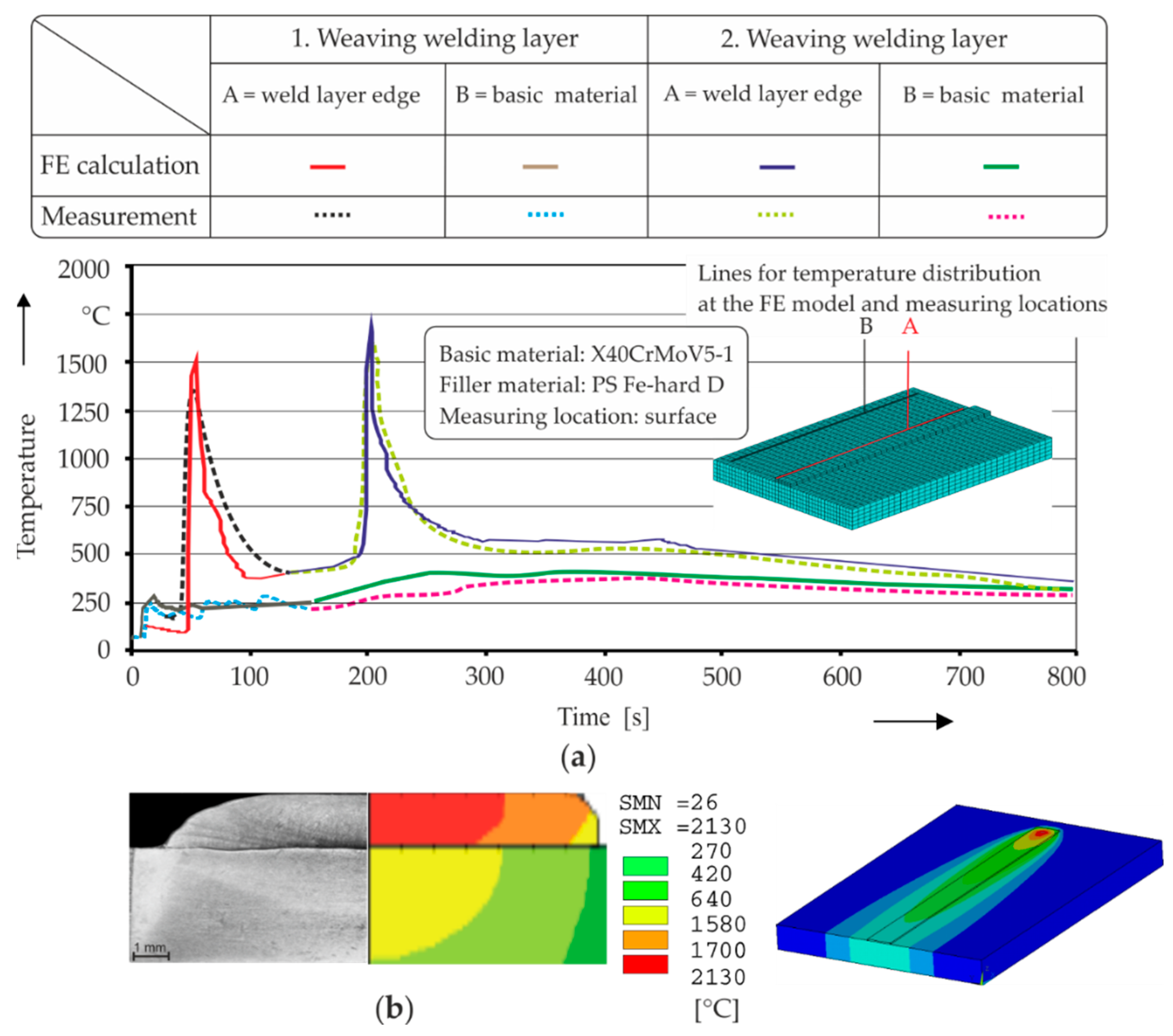

3.2.1. Temperature Field Distribution, Deformations and Residual Stresses

3.2.2. Comparison of Finite Element (FE) Results with Experiments

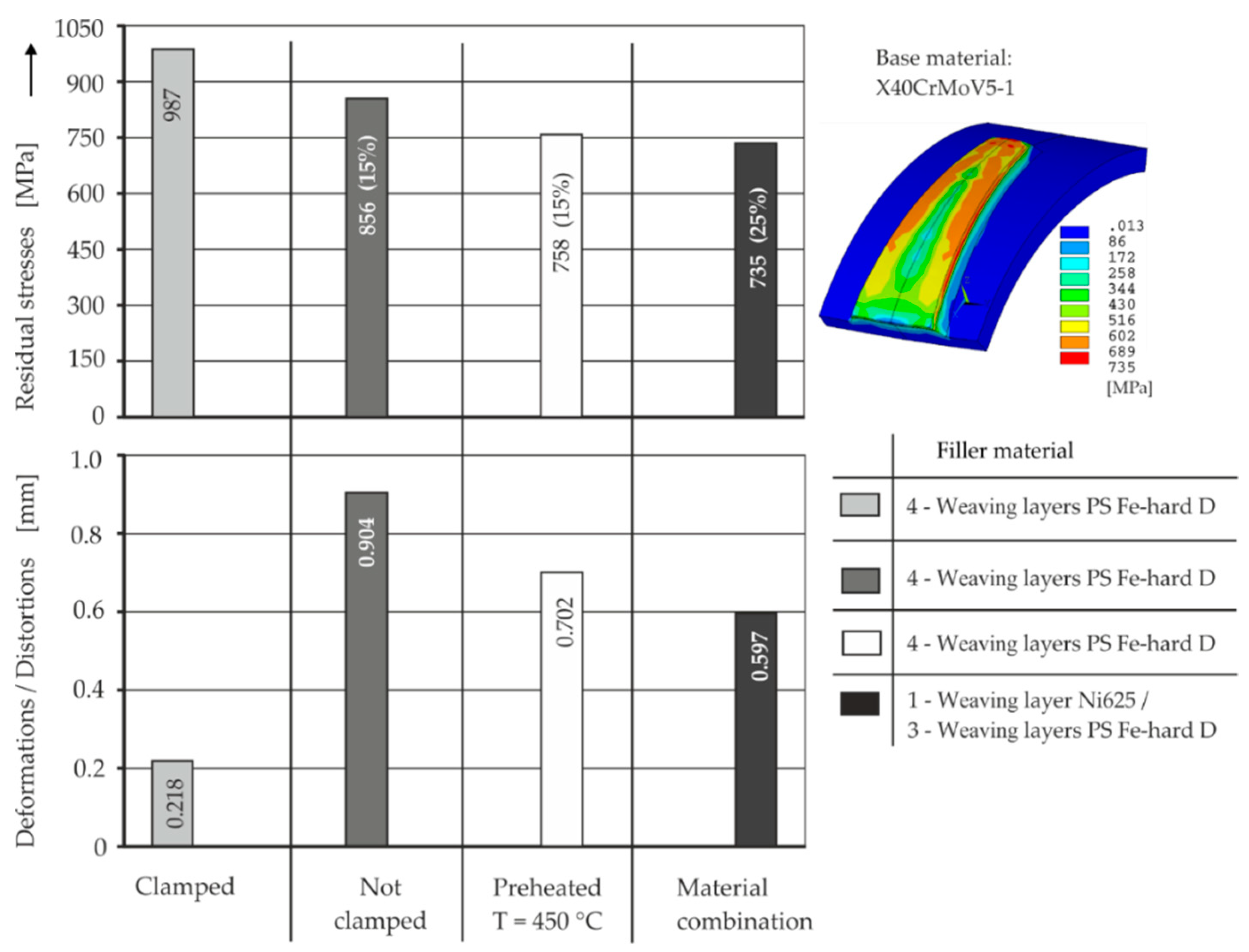

3.2.3. Material Technological Means to Minimize Deformation/Residual Stresses on Additive Plasma Deposition-Welded Component Structures

3.3. Additive 3DPMD of Structural Component Surfaces

4. Summary—Conclusions

- Using sophisticated additive 3DPMD, complex component geometries with predefined thermomechanical properties can be produced from large weld metal volumes. It possible to produce complex geometries with their shapes, functions and thermomechanical properties.

- 3DPMD thus enables the layer-by-layer production of metallic components based on a virtual CAD component model. By mixing several powders in an arc, the local properties of the deposited layers can be adapted locally to the defined service loads.

- With the layer-by-layer construction system that was developed on the basis of the selected and self-mixed thermal deposited powder alloys made of iron-based alloys, high wear resistance and high hardness at high temperature under the defined thermal conditions as well as crack-free component contour surfaces were additively plasma metal manufactured.

- A thermo-mechanical simulation model was successfully developed, validated and further used for the predetermination/minimization of deformation and residual stresses on 3D plasma deposition welded structures for complex component geometries.

- Depending on the alloys used, complex shrinkage and transformation stresses occur in the area of the thermal deposited contours.

- The difference between the FE calculations and the measurements is approximately 15%, and this shows the practical application potential of the simulation model.

- A minimization of the deformation/residual stresses on plasma deposition-welded component structures was demonstrated using preheating, fixed clamping and PMD with a ductile layer material.

- The knowledge gained was implemented in practice by producing complex, highly stress-resistant component geometries with defined layer properties–tool contours.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | Unit | Definition |

| bp | m | Weaving width |

| C | - | Constant |

| c | J·kg−1·K−1 | Specific heat capacity |

| C0 | 1.380651 × 10−23 J·K−1 | Stefan–Boltzmann constant |

| E | - | Half ellipsoid |

| FE model | - | Finite element model |

| I | A | Welding current |

| Q | W | Total performance |

| QT | W | Energy effect–torch power |

| q | J·m−²·s−1 | Source intensity–heat flux density |

| rx, ry and rz | m | Half axis of the half ellipsoid |

| T | K | Temperature |

| t | s | Time |

| Tp | m·s | Period duration |

| Td | s | Dwell time |

| U | V | Welding voltage |

| vw | m·s−1 | Welding speed |

| vp | m·s−1 | Weaving speed |

| ρ | kg·m−3 | Density |

| λ | W·m−1·K−1 | Thermal conductivity |

| αk | W·m−2·K−1 | Heat transfer coefficient |

| ε | W·m−3·sr | Emission coefficient |

| εel | - | Elastic strain |

| εtot | - | Total strain |

| εpl | - | Plastic strain |

| εth | - | Thermal strain |

| εc | - | Conversion-induced strain |

| ηT | % | Torch effectivity |

| σ | MPa | Surface stress |

| ∇ | - | Nabla-Operator |

| 3DPMD | - | Three dimensional plasma metal deposition |

References

- Gibson, I. Additive Manufacturing Technologies. Rapid Prototyping to Direct Digital Manufacturing; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Alaluss, K.; Matthes, K.-J. Minimal deformation and internal stress in the production of geometrically complex components using contour-building powder layer pulse plasma welding (IPTA). Int. J. Join. Mater. 2001, 13, 102–106. [Google Scholar]

- Bambach, M.D.; Bambach, M.; Sviridov, A.; Weiss, S. New process chains involving additive manufacturing and metal forming—A chance for saving energy? Procedia Eng. 2017, 207, 1176–1181. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q.; Lu, J.; Liu, Y.; Shi, W. Selective laser melting-wire arc additive manufacturing hybrid fabrication of Ti-6Al-4V alloy: Microstructure and mechanical properties. Mater. Sci. Eng. 2017, 684, 196–204. [Google Scholar] [CrossRef]

- Williams, S.; Martina, F.; Addison, A.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Scippa, A.; Campatelli, G. Optimization of WAAM deposition patterns for T-crossing features. Procedia CIRP 2016, 55, 95–100. [Google Scholar] [CrossRef]

- Almeida, P.; Williams, S. Innovative process model of Ti–6Al–4V additive layer manufacturing using cold metal transfer (CMT). In Proceedings of the 21th Annual International Solid Freeform Fabrication Symposium, University of Texas at Austin, Austin, TX, USA, 9–11 August 2010. [Google Scholar]

- Martina, F.; Colegrove, P.; Williams, W. Microstructure of interpass rolled wire + arc additive manufacturing Ti-6Al-4V components. Metall. Mater. Trans. A 2015, 46, 6103–6118. [Google Scholar] [CrossRef]

- Simunovic, S.; Nycz, A.; Noakes, M.W.; Chin, C.; Oancea, V. Metal big area additive manufacturing: Process modeling and validation. In Proceedings of the NAFEMS World Congress 2017, Stockholm, Sweden, 11–14 June 2017. [Google Scholar]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Ma, P.; Zhai, Y. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys. J. Mater. Process. Technol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- Alaluss, K.; Bürkner, G.; Mayr, P. Simulation of micro-plasma powder deposition for advanced welding torch design. In Proceedings of the 10th International Seminar on Numerical Analysis of Weldability, Mathematical Modelling of Welding Phenomena 10, Graz, Austria, 24–26 September 2012; pp. 705–722. [Google Scholar]

- Bergmann, J.P.; Henckell, P.H.; Reimann, J.; Ali, Y.; Hildebrand, J. Grundlegende wissenschaftliche Konzepterstellung zu bestehenden Herausforderungen und Perspektiven für die Additive Fertigung mit Lichtbogen. Weld. Cut. 2018, 70, 1–52. [Google Scholar]

- Alaluss, K.; Semmler, U.; Matthes, J.-K. Distortion and stress assessment and optimization of PTA-welded tools and cutting blades using the F. E: Method. In Proceedings of the 7th International Seminar Numerical Analysis of Weldability, Mathematical Modelling of Welding Phenomena 7, Graz, Austria, 29 September–1 October 2003; pp. 731–746. [Google Scholar]

- Ding, J. Thermo-Mechanical Analysis of Wire and Arc Additive Manufacturing Process. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2012. [Google Scholar]

- Hua, Z.; Qina, X.; Shaoa, T. Welding thermal simulation and metallurgical characteristics analysis in WAAM for 5CrNiMo hot forging die remanufacturing. Procedia Eng. 2017, 207, 2203–2208. [Google Scholar] [CrossRef]

- PlasmaStar GmbH: Welded Powder Products—Iron-Based Alloys. Available online: http://www.plasma-star.de/ (accessed on 17 December 2018).

- Deloro Stellite GmbH: Welded Powder Products—Cobalt and Nickel Based Alloys. Available online: http://www.stellite.de/ (accessed on 17 December 2018).

- Norm DIN 50133. Prüfung metallische Werkstoffe, Härteprüfung nach Vickers, Bereich HV 0,2 bis HV100. Available online: https://www.beuth.de/de/norm/din-50133/1182285 (accessed on 18 April 2019).

- Winkelmann, R.; Serafinski, D.; Franz, R. Vergleichende Verschleißuntersuchungen von dynamisch und gleitend beanspruchten; eisenbasierten Verbundschichtungen mit eingelagerten keramischen Hartstoffen. In Proceedings of the Tagungsband zum 17, Werkstofftechnischen Kolloquium, Werkstoffe und Werkstofftechnische Anwendungen, Chemnitz, Germany, 11–12 September 2014. [Google Scholar]

- ASTM-Standard E 837-92. Standard Test Method for Determining Residual Stresses by the Hole-Drilling-Strain-Gage-Method; ASTM International: West Conshohocken, PA, USA, 1992. [Google Scholar]

- Alaluss, K.; Semmler, U.; Matthes, J.-K. Residual Stress Assessment and PTA Welding Optimization of Valve cones and Seat Rings Using the F.E. Method. In Proceedings of the 8th International Seminar Numerical Analysis of Weldability, Mathematical Modelling of Welding Phenomena 8, Graz, Austria, 25–27 September 2006; pp. 1129–1140. [Google Scholar]

- Radaj, D. Simulation von Temperaturfeld, Eigenspannungen und Verzug beim Schweißen. DVS-Berichte Band 214 2001, S, 32–59. [Google Scholar]

- Goldak, J.A. Computational Welding Mechanics; Springer: New York, NY, USA, 2005. [Google Scholar]

- Goldak, J.; Charavarti, A.; Biiby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Alaluss, K.A. Beitrag zur Ermittlung und Beeinflussung der Verformungen und Eigenspannungen formgebend plasma-pulverauftraggeschweißter Bauteile. Ph.D. Thesis, Chemnitz University of Technology, Chemnitz, Germany, 2001. [Google Scholar]

- Alaluss, K.A. Modellbildung und Simulation des Plasma-Schweißens zur Entwicklung innovativer Schweißbrenner. Habilitation Thesis, Chemnitz University of Technology, Chemnitz, Germany, 2017. [Google Scholar]

- Richter, F. Die wichtigsten physikalischen Eigenschaften von Stählen und ihre Temperaturabhängigkeit; Stahleisen Sonderberichte; GmbH: Düsseldorf, Germany, 1983. [Google Scholar]

- Touloukian, Y.S. Thermophysical Properties of Matter; Springer: New York, NY, USA, 1979. [Google Scholar]

| Materials | Chemical Composition (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Co | Mn | Mo | Ni | Fe | Si | V | W | |

| X40CrMoV5-1 | 0.40 | 5.2 | - | 0.4 | 1.3 | - | bal. | 1.0 | 1.0 | - |

| PS Fe-hard D | 1.0 | 4.0 | - | - | 5.0 | - | bal. | - | 2.10 | 6.20 |

| EuTroloy 16604 | 0.20 | 15 | 15 | - | 2.5 | - | bal. | - | - | - |

| Stellite 12 HC | 1.90 | 32 | bal. | - | - | <3.0 | <3.0 | 1.0 | - | 9.5 |

| Ni 625 | 0.03 | 21 | - | - | 8.60 | bal. | - | 0.50 | 3.40 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alaluss, K.; Mayr, P. Additive Manufacturing of Complex Components through 3D Plasma Metal Deposition—A Simulative Approach. Metals 2019, 9, 574. https://doi.org/10.3390/met9050574

Alaluss K, Mayr P. Additive Manufacturing of Complex Components through 3D Plasma Metal Deposition—A Simulative Approach. Metals. 2019; 9(5):574. https://doi.org/10.3390/met9050574

Chicago/Turabian StyleAlaluss, Khaled, and Peter Mayr. 2019. "Additive Manufacturing of Complex Components through 3D Plasma Metal Deposition—A Simulative Approach" Metals 9, no. 5: 574. https://doi.org/10.3390/met9050574

APA StyleAlaluss, K., & Mayr, P. (2019). Additive Manufacturing of Complex Components through 3D Plasma Metal Deposition—A Simulative Approach. Metals, 9(5), 574. https://doi.org/10.3390/met9050574