Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition

Abstract

:1. Introduction

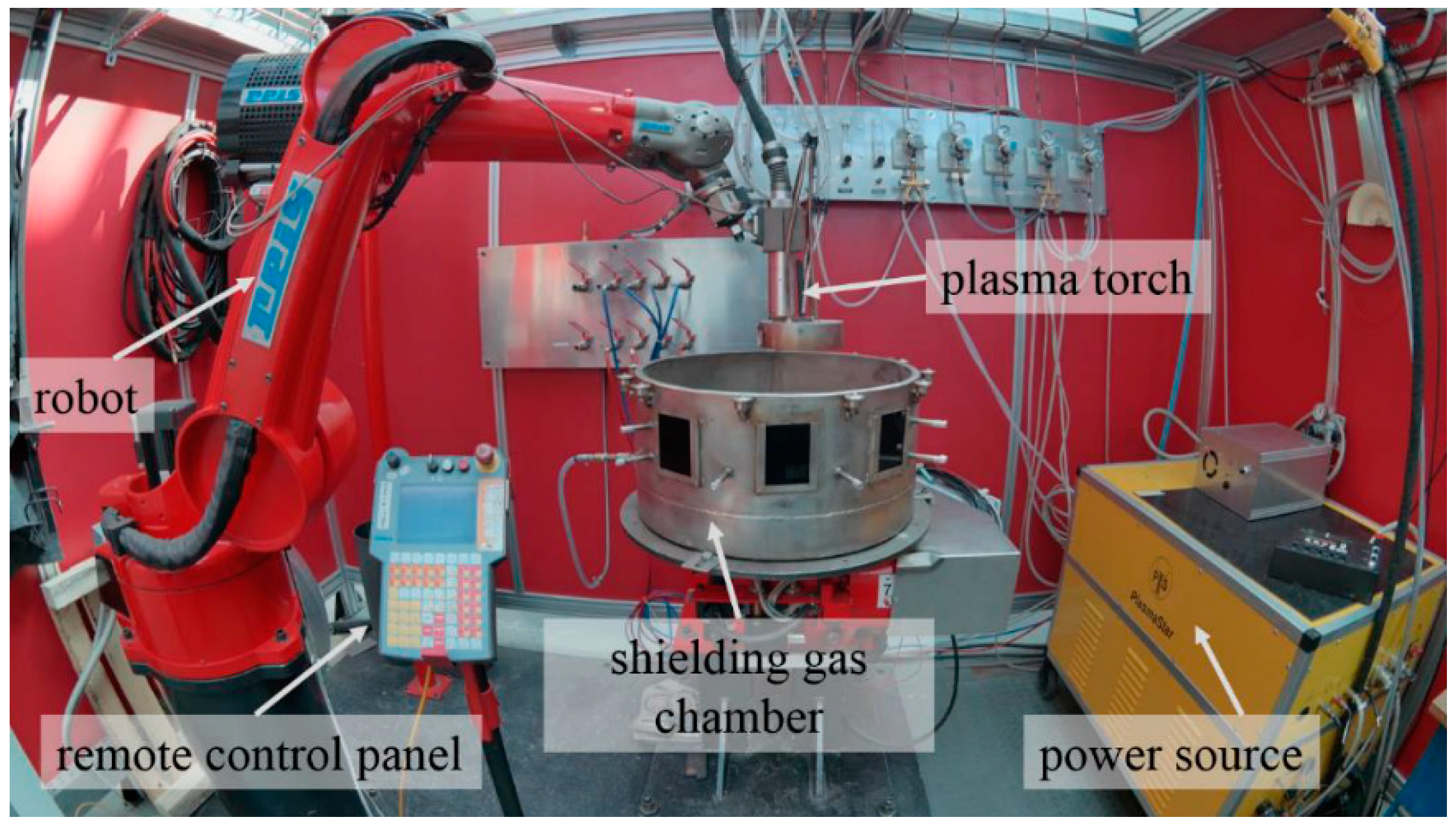

2. Materials and Methods

3. Results and Discussion

3.1. 3DPMD Process

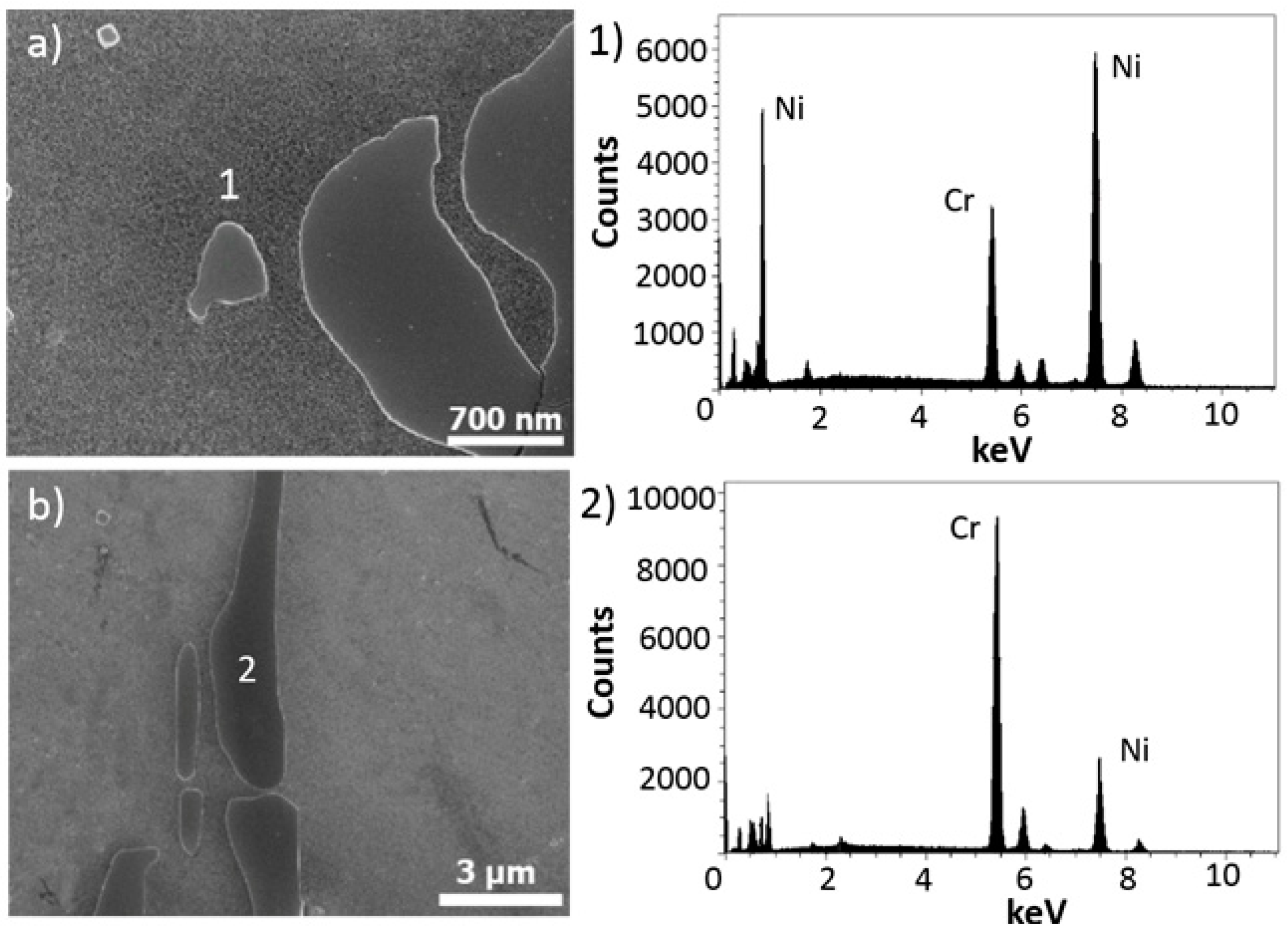

3.2. Microstructural Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bandyopadhyay, A.; Krishna, B.V.; Xue, W.; Bose, S. Application of laser engineered net shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants. J. Mater. Sci. Mater. Med. 2009, 20, 29–34. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. Int. J. Biomater. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Hoefer, K.; Nitsche, A.; Abstoss, K.G.; Ertugrul, G.; Haelsig, A.; Mayr, P. Multi-Material additive manufacturing by 3D plasma metal deposition for graded structures of super duplex alloy 1.4410 and the austenitic corrosion resistant alloy 1.4404. JOM 2019. [Google Scholar] [CrossRef]

- Sampath, S.; Herman, H.; Shimoda, N.; Saito, T. Thermal spray processing of FGMs. MRS Bull 1995, 20, 27–31. [Google Scholar] [CrossRef]

- Suresh, S.; Giannakopoulos, A.E.; Alcalá, J. Sherical indentation of compositionally graded materials: Theory and experiments. Acta Mater. 1997, 45, 1307–1321. [Google Scholar]

- Giannakopoulos, A.E.; Suresh, S. Indentation of solids with gradients in elastic properties: Part II axisysmmetric indentors. Int. J. Solids. Struct. 1997, 34, 2393–2428. [Google Scholar] [CrossRef]

- Giannakopoulos, A.E.; Suresh, S.; Finot, M.; Olsson, M. Elastoplastic analysis of thermal cycling: Layered materials with compositional gradients. Acta Metall. Mater. 1995, 43, 1335–1354. [Google Scholar] [CrossRef]

- Williamson, R.L.; Rabin, R.H.; Drake, J.T. Finite elements analysis of thermal residual stresses at graded ceramic-metal interfaces. J. Appl. Phys. 1993, 74, 1310–1320. [Google Scholar] [CrossRef]

- Drake, J.T.; Williamson, R.L.; Rabin, R.H. Finite elemete analysis of thermal residual stresses at graded ceramic-metal interfaces—part II microstructure. J. Appl. Phys. 1993, 74, 1321–1326. [Google Scholar] [CrossRef]

- Erdogan, F. Fracture mechanics of functionally graded materials. Compos. Eng. 1995, 5, 753–770. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015 (ASTM F2792). Additive manufacturing—General principles—Terminology. International Organization for Standardization. Available online: https://www.iso.org/standard/69669.html (accessed on 28 April 2019).

- Jhavar, S.; Jain, N.K.; Paul, C.P. Development of micro-plasma transferred arc (µ-PTA) wire deposition process for additive layer manufacturing applications. J. Mater. Process Tech. 2014, 214, 1102–1110. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, H.; Wang, G.; Li, J. Rapid manufacturing of FGM components by using electromagnetic compressed plasma deposition. In Proceedings of the Electromagnetics Research Symposium, Moskva, Russia, 18–21 August 2009. [Google Scholar]

- Hoefer, K.; Hälsig, A.; Mayr, P. Arc-based additive manufacturing of steel components—comparison of wire- and powder-based variants. Weld World 2018, 62, 243–247. [Google Scholar] [CrossRef]

- Hoefer, K.; Mayr, P. 3DPMD – Additive manufacturing of titanium parts using 3D plasma metal deposition. Mater. Sci. Forum 2018, 941, 2137–2141. [Google Scholar] [CrossRef]

- Hoefer, K.; Teichgraeber, C.; Mayr, P.; Berger, M. Arc-based additive Manufacturing—3DPMD (Generative Fertigung mit Lichtbogenprozessen). In Fümotec 2017; Mayr, P., Berger, M., Eds.; Chemnitz University of Technology: Chemnitz, Germany, 2017; pp. 1–14. (In German) [Google Scholar]

- Chen, X.; Li, J.; Cheng, X.; He, B.; Wang, Y.; Huang, Z. Microstructure and mechanical properties of the austenitic stainless steel 316L fabricated by gas metal arc additive manufacturing. Mater. Sci. Eng. 2017, 703, 567–577. [Google Scholar] [CrossRef]

- Feng, Y.; Luo, Z.; Liu, Z.; Li, Y.; Luo, Y.; Huang, Y. Keyhole gas tungsten arc welding of AISI 316L stainless steel. Mater. Des. 2015, 85, 24–31. [Google Scholar] [CrossRef]

- Soltani, H.M.; Tayebi, M. Comparative study of AISI 304L to AISI 316L stainless steels joints by TIG and Nd:YAG laser welding. J. Alloy Compd. 2018, 767, 112–121. [Google Scholar] [CrossRef]

- ElCheikh, H.; Courant, B.; Branchu, S.; Huang, X.; Hasco, J.Y.; Guille, R. Direct laser fabrication process with coaxial powder projection of 316L steel. Opt. Lasers Eng. 2012, 50, 1779–1784. [Google Scholar] [CrossRef]

- Järvinen, J.P.; Matilainen, V.; Li, X.; Piili, H.; Salminen, A.; Mäkelä, I.; Nyrhilä, O. Characterization of effect of support structures in laser additive manufacturing of stainless steel. Phys. Procedia 2014, 56, 72–81. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, B.; Li, X.; Li, R. Effects of metal-vapor jet force on the physical behavior of melting wire transfer in electron beam additive manufacturing. J. Mater. Process. Technol. 2015, 220, 243–250. [Google Scholar] [CrossRef]

- Skiba, T.; Baufeld, B.; Biest, O.V.D. Microstructure and mechanical properties of stainless steel component manufactured by shaped metal deposition. ISIJ Int. 2009, 49, 1588–1591. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; Wiley-Interscience: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kotecki, D.J.; Siewert, T.A. WRC-1992 constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram. Weld. J. 1992, 71, 171–178. [Google Scholar]

- Silva, C.C.; de Miranda, H.C.; de Sant’Ana, H.B.; Farias, J.P. Microstructure, hardness and petroleum corrosion evaluation of 316L/AWS E309MoL-16 weld metal. Mater Charact. 2009, 60, 346–352. [Google Scholar] [CrossRef]

- DuPont, J.N.; Lipoold, J.C.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloy: A Technical Guide; ASM international: Novelty, OH, USA, 2002. [Google Scholar]

- Ramkumar, K.D.; Mithilesh, P.; Varun, D.; Reddy, A.R.G.; Arivazhagan, N.; Narayanan, S.; Kumar, K.G. Characterization of microstructure and mechanical properties of Inconel 625 and AISI 304 dissimilar weldments. J. Int. Ste. Inst. Jap. 2014, 54, 900–908. [Google Scholar] [CrossRef]

- Subsea Structure Demands. Available online: https://app.aws.org/wj/2002/06/feature2/ (accessed on 23 February 2019).

- Dreshfield, R.L.; Moore, T.J.; Bartolotta, P.A. Post-Test Examination of a Pool Boiler Receiver; DOE/NASA/33408-6; U.S Department of Energy Conservation and Renewable Energy Office of Solar Heat Technologies: Washington, WA, USA, 1992; pp. 1–4.

- Dokme, F.; Kulekci, M.K.; Ugur, U. Microstructural and mechanical characterization of dissimilar metal welding of Inconel 625 and AISI 316L. Metals 2018, 8, 797. [Google Scholar] [CrossRef]

- Mithilesh, P.; Varun, D.; Reddy, A.R.G.; Ramkumar, K.D.; Arivazhagan, N.; Narayanan, S. Investigations on dissimilar weldments of Inconel 625 and AISI 304. Procedia Eng. 2014, 75, 66–70. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An overview of functionally graded additive manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Banait, S.M.; Jinoop, A.N.; Paul, C.P.; Kumar, H.; Pawade, R.S.; Bindra, K.S. Investigating laser additive manufacturing of functionally graded Ni-Cr-B-Si and SS 316L. In Proceedings of the International Conference on Advances in Thermal Systems, Materials and Design Engineering (ATSMDE2017), Mumbai, India, 21–22 December 2017. [Google Scholar]

- Varghese, P.; Vetrivendan, E.; Dash, M.K.; Ningshen, S.; Kamaraj, M.; Kamachi Mudali, U. Weld overlay coating of Inconel 617M on type 316L stainless steel by cold metal transfer process. Surf. Coat. Tech. 2019, 357, 1004–1013. [Google Scholar] [CrossRef]

- Pulugurtha, S.R.; Newkirk, J.; Liou, F.; Chou, H. Functionally Graded Materials by Laser Metal Deposition (preprint). In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010; University of Texas Press: Austin, TX, USA. [Google Scholar]

- Abboud, J.H.; Rawlings, R.D.; West, D.R.F. Functionally graded nickel-aluminide and iron-aluminide coatings produced via laser cladding. J. Mater. Sci. 1995, 30, 5931–5938. [Google Scholar] [CrossRef]

- Xu, X.; Lin, X.; Chen, J.; He, F.; Huang, W. Laser Rapid Forming of Ti-Ni Functionally Graded Alloy. Mater. Sci. Forum. 2007, 561, 227–230. [Google Scholar] [CrossRef]

- Khor, K.A.; Dong, Z.L.; Gu, Y.W. Plasma sprayed functionally graded thermal barrier coatings. Mater. Lett. 1999, 38, 437–444. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Microstructure and phase evolution in laser rapid forming of a functionally graded Ti–Rene88DT alloy. Acta Mater. 2006, 54, 1901–1915. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Solidification Behavior and the Evolution of Phase in Laser Rapid Forming of Graded Ti6Al4V-Rene88DT Alloy. Metall. Mater. Trans. A 2007, 38A, 127–137. [Google Scholar] [CrossRef]

- Hälsig, A.; Kusch, M.; Mayr, P. New findings on the efficiency of gas shielded arc welding. Weld. World 2012, 56, 98–104. [Google Scholar] [CrossRef]

- ASTM E3-95. Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 1995; Available online: www.astm.org (accessed on 10 January 2019).

- ASTM E384-99. Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 1999; Available online: www.astm.org (accessed on 10 January 2018).

- DuPont, J.N. Dilution in Fusion Welding. In ASM handbook Volume 6A. Welding fundamentals and Process; ASM International: Novelty, OH, USA, 2011. [Google Scholar]

- Xu, F.; Lv, Y.; Liu, Y.; Shu, F.; He, P.; Xu, B. Microstructural evolution and mechanical properties of Inconel 625 alloy during pulsed plasma arc deposition process. J. Mater. Sci. Technol. 2013, 29, 480–488. [Google Scholar] [CrossRef]

- ASM International. Heat-Resistant Casting Alloys: Metallographic Techniques and Microstructures. In ASM handbook Volume 9. Metallography and Microstructures; ASM International: Novelty, OH, USA, 1998. [Google Scholar]

- Ram, G.D.J.; Reddy, A.V.; Rao, K.P.; Reddy, G.M.; Sundar, J.K.S. Control of Laves phase in Inconel 718 GTA welds with current pulsing. Sci. Technol. Weld. Join. 2004, 9, 390–398. [Google Scholar]

| Alloy | C | Si | Nb | Mn | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| SS316L | 0.03 | 0.7 | - | 0.5 | 16.5 | 2.1 | 13.0 | Bal. |

| Ni80-20 | - | 1.2 | - | - | 22.0 | - | Bal. | 0.6 |

| Ni625 | 0.03 | 0.5 | 3.2 | 0.4 | 21.1 | 8.5 | Bal. | 4.2 |

| Configuration | Layers | Powder Type | Welding Current (A) | Heat Input (KJ·mm−1) |

|---|---|---|---|---|

| HI | 1–15 | SS316L | 120 | 0.197 |

| 16–30 | Ni80-20 | 105 | 0.173 | |

| ST | 1–10 | SS316L | 120 | 0.197 |

| 11–20 | 50% SS316L 50% Ni80-20 | 110 | 0.181 | |

| 21–30 | Ni80-20 | 105 | 0.173 |

| HI | Layers (#) | Powder Type | Voltage (V) | Welding Current (A) | Heat Input (KJ·mm−1) |

|---|---|---|---|---|---|

| Low (L) | 1–10 | SS316L | 22.73 | 105 | 0.176 |

| 11–20 | 50% SS316L 50% Ni625 | 23.04 | 95 | 0.162 | |

| 21–30 | Ni625 | 22.87 | 90 | 0.151 | |

| Standard (S) | 1–10 | SS316L | 22.82 | 120 | 0.200 |

| 11–20 | 50% SS316L 50% Ni625 | 22.84 | 110 | 0.181 | |

| 21–30 | Ni625 | 22.90 | 105 | 0.177 | |

| High (H) | 1–10 | SS316L | 23.30 | 135 | 0.241 |

| 11–20 | 50% SS316L 50% Ni625 | 23.57 | 125 | 0.214 | |

| 21–30 | Ni625 | 23.73 | 120 | 0.204 |

| HI | Wall Thickness (mm) | Part Height (mm) | Layer Thickness (mm) |

|---|---|---|---|

| Low | 6.5 | 27.5 | 0.92 |

| Standard | 5.8 | 30.5 | 1.02 |

| High | 4.8 | 35.2 | 1.17 |

| Interface | %D |

|---|---|

| Low (L) HI | |

| SS316L to mixed zone | 38.9 |

| mixed zone to Ni625 | 26.3 |

| Standard (S) HI | |

| SS316L to mixed zone | 55.2 |

| mixed zone to Ni625 | 25 |

| High (H) HI | |

| SS316L to mixed zone | 51.1 |

| mixed zone to Ni625 | 23.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez, J.; Hoefer, K.; Haelsig, A.; Mayr, P. Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals 2019, 9, 620. https://doi.org/10.3390/met9060620

Rodriguez J, Hoefer K, Haelsig A, Mayr P. Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals. 2019; 9(6):620. https://doi.org/10.3390/met9060620

Chicago/Turabian StyleRodriguez, Johnnatan, Kevin Hoefer, Andre Haelsig, and Peter Mayr. 2019. "Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition" Metals 9, no. 6: 620. https://doi.org/10.3390/met9060620

APA StyleRodriguez, J., Hoefer, K., Haelsig, A., & Mayr, P. (2019). Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals, 9(6), 620. https://doi.org/10.3390/met9060620