Comparison of the Dislocation Structure of a CrMnN and a CrNi Austenite after Cyclic Deformation

Abstract

:1. Introduction

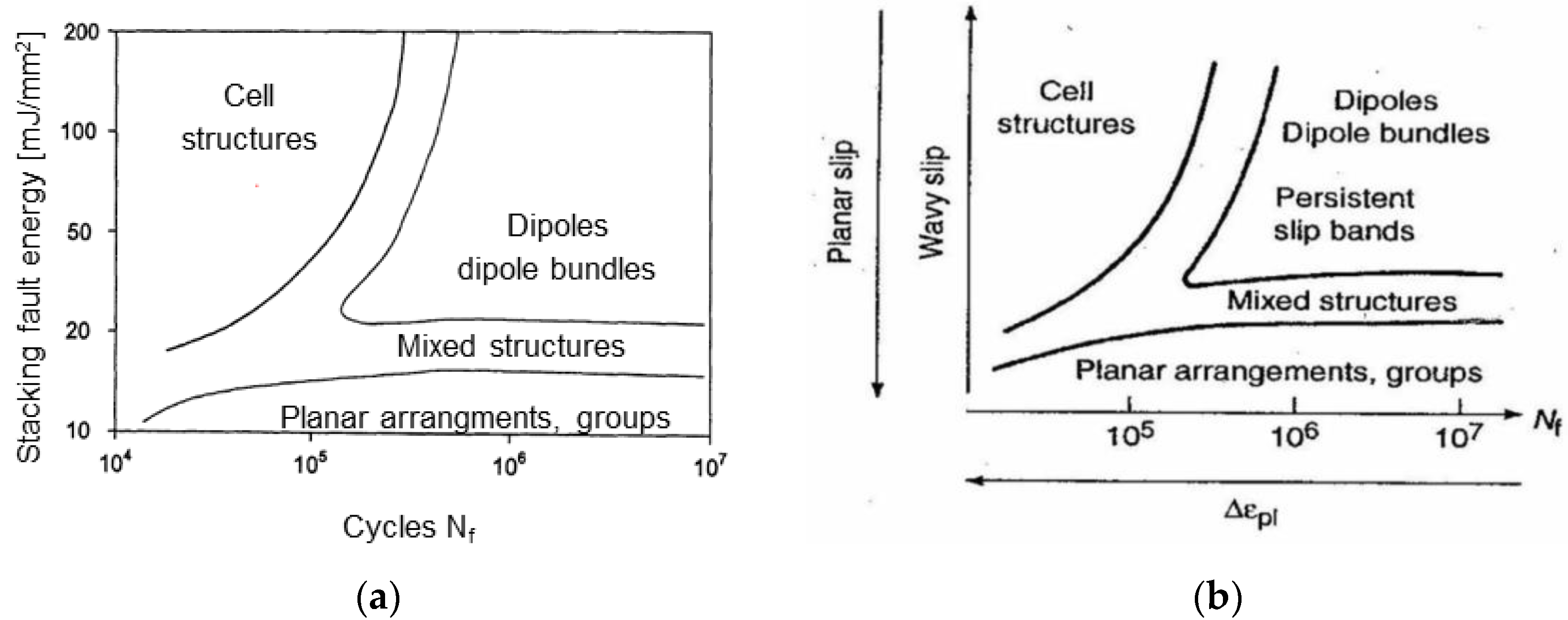

- Wavy slip due to high SFE is expected for CrNi alloys.

- Planar slip appears in CrMnN alloys which show beside a lower SFE also SRO owing to the interstitially alloyed nitrogen

2. Materials and Methods

2.1. Test Materials

2.2. Fatigue Experiments

2.3. TEM Investigations

3. Results and Discussion

3.1. Fatigue Experiments

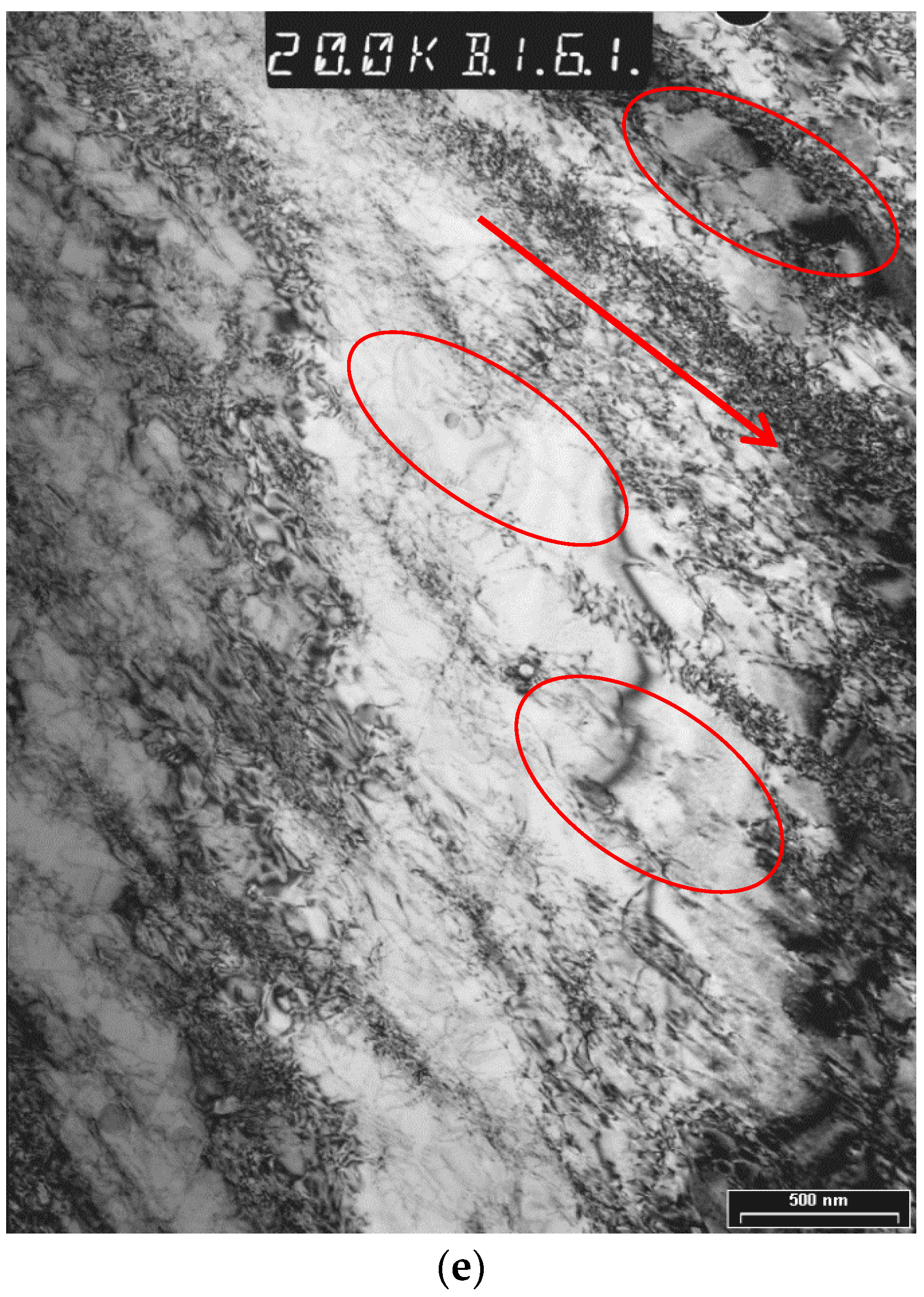

3.2. TEM Investigations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Feltner, C.E.; Laird, C. The role of slip character in steady state cyclic stress-strain behavior. Trans. TMS-AIME 1969, 245, 1372–1373. [Google Scholar]

- Lukáš, P.; Klesnil, M. Dislocation structures in fatigued single crystals of Cu-Zn system. Phys. Stat. Sol. 1971, 5, 247–258. [Google Scholar] [CrossRef]

- Mughrabi, H. Mikrostrukturelle Ursachen der Ermüdungsrissbildung. In Ermüdungsverhalten Metallischer Werkstoffe, Symposium der Deutschen Gesellschaft für Materialkunde; Bad Nauheim, Germany, 1984. [Google Scholar]

- Mughrabi, H. Fatigue, an everlasting materials problem—Still en vogue. Procedia Eng. 2010, 2, 3–26. [Google Scholar] [CrossRef]

- Uggowitzer, P.J. Stickstofflegierte Stähle. In Ergebnisse der Werkstoffforschung; Thubal-Kain: Zürich, Switzerland, 1991; pp. 87–101. [Google Scholar]

- Simmons, J.W. Strain hardening and plastic flow properties of nitrogen-alloyed Fe-17Cr-(8–10) Mn-5Ni austenitic stainless steels. Acta Mater. 1997, 45, 2467–2475. [Google Scholar] [CrossRef]

- Llewellyn, D.T. Work hardening effects in austenitic stainless steels. Mater. Sci. Technol. 1997, 13, 389–400. [Google Scholar] [CrossRef]

- Kikuchi, M.; Mishima, Y. (Eds.) High Nitrogen Steels HNS95; ISIJ International: Kyoto, Japan, 1996. [Google Scholar]

- Hänninen, H. Application and performance of high nitrogen steels. In High Nitrogen Steels 2004; GRIPS Media: Ostend, Belgium, 2004. [Google Scholar]

- Fawley, R.; Quader, M.A.; Dodd, R.A. Compositional effects on the deformation modes, annealing twin frequencies, and stacking fault energies of austenitic stainless steels. TMS AIME 1968, 242, 771–778. [Google Scholar]

- Schramm, R.E.; Reed, R.P. Stacking fault energies of seven commercial austenitic stainless steels. Metall. Trans. A 1975, 6, 1345–1351. [Google Scholar] [CrossRef]

- Stoltz, R.E.; Sande, J.B.V. The effect of nitrogen on stacking fault energy of Fe-Ni-Cr-Mn steels. Metall. Trans. A 1980, 11, 1033–1037. [Google Scholar] [CrossRef]

- Petrov, Y. Defects and Diffusionless Transformation in Steel (Russian); Naukova Dumka: Kiew, Ukraine, 1978; p. 262. [Google Scholar]

- Fujikura, M.; Takada, K.; Ishida, K. Effect of manganese and nitrogen on the mechanical properties of Fe-18%Cr-10%Ni stainless steels. Trans. Iron Steel Inst. Jan. 1975, 15, 464–469. [Google Scholar]

- Mosecker, L.; Saeed-Akbari, A. Nitrogen in chromium–manganese stainless steels: A review on the evaluation of stacking fault energy by computational thermodynamics. Sci. Technol. Adv. Mater. 2013, 14, 033001. [Google Scholar] [CrossRef] [PubMed]

- Razumovskiy, V.I.; Hahn, C.; Lukas, M.; Romaner, L. Ab Initio Study of Elastic and Mechanical Properties in FeCrMn Alloys. Materials 2019, 12, 1129. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-J.; Fujii, H.; Ushioda, K. Thermodynamic calculation of the stacking fault energy in Fe-Cr-Mn-C-N steels. J. Alloys Compd. 2018, 749, 776–782. [Google Scholar] [CrossRef]

- Douglas, D.L.; Thomas, G.; Roser, W.R. Ordering, Stacking Faults and Stress Corrosion Cracking In Austenitic Alloys. Corrosion 1964, 20, 15–28. [Google Scholar] [CrossRef]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in F.C.C. alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Grujicic, M.; Nilsson, J.-O.; Owen, W.S.; Thorvaldsson, T. Basic deformation mechanisms in nitrogen strengthened stable austenitic stainless steels. In High Nitrogen Steels, HNS 88; The Institute of Metals: London, UK, 1988. [Google Scholar]

- Gavriljuk, V.G.; Berns, H. High Nitrogen Steels: Structure, Properties, Manufacture, Applications; Springer-Verlag: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Ojima, M.; Adachi, Y.; Tomota, Y.; Katada, Y.; Kaneko, Y.; Kuroda, K.; Saka, H. Weak Beam TEM Study on Stacking Fault Energy of High Nitrogen Steels. Steel Res. Int. 2009, 80, 477–481. [Google Scholar]

- Noh, H.; Kang, J.-H.; Kim, K.-M.; Kim, S.-J. Different Effects of Ni and Mn on Thermodynamic and Mechanical Stabilities in Cr-Ni-Mn Austenitic Steels. Metall. Mater. Trans. A 2019, 50, 616–624. [Google Scholar] [CrossRef]

- Degallaix, S.; Foct, J.; Hendry, A. Mechanical behaviour of high-nitrogen stainless steels. Mater. Sci. Technol. 1986, 2, 946–950. [Google Scholar] [CrossRef]

- Taillard, R.; Foct, J. Mechanisms of the action of nitrogen interstitials upon low cicle fatigue behaviour of 316 stainless steels. In High Nitrogen Steels, HNS88; The Institute of Metals: London, UK, 1988. [Google Scholar]

- Panzenböck, M.H. Ermüdungsverhalten Stickstofflegierter Cr-Mn-Austenite. Ph.D. Thesis, University of Leoben, Leoben, Austria, 1995. [Google Scholar]

- Degallaix, S. Role of nitrogen on the monotonic and cyclic plasticity of Type 316L SS at Room temperature. In Basic Mechanisms in Fatigue of Metals; Lukas, P., Polak, J., Eds.; Academia: Prague, Czech Republic, 1988; pp. 65–72. [Google Scholar]

| Grade | %C | %Mn | %Cr | %Mo | %Ni | %N | SFE [mJ·m−2] |

|---|---|---|---|---|---|---|---|

| CrNi S31673 | <0.04 | 1.80 | 17.50 | 2.80 | 14.70 | 0.10 | 26 |

| CrMnN | <0.04 | 23.00 | 21.10 | 0.30 | 1.50 | 0.85 | 35 |

| Grade | Condition | Rp0.2 [MPa] | Rm [MPa] | A5 [%] |

|---|---|---|---|---|

| S31673 | SA | 410 | 637 | 54 |

| CW | 653 | 718 | 32 | |

| CrMnN | SA | 563 | 949 | 62 |

| CW | 941 | 1165 | 38 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fluch, R.; Kapp, M.; Spiradek-Hahn, K.; Brabetz, M.; Holzer, H.; Pippan, R. Comparison of the Dislocation Structure of a CrMnN and a CrNi Austenite after Cyclic Deformation. Metals 2019, 9, 784. https://doi.org/10.3390/met9070784

Fluch R, Kapp M, Spiradek-Hahn K, Brabetz M, Holzer H, Pippan R. Comparison of the Dislocation Structure of a CrMnN and a CrNi Austenite after Cyclic Deformation. Metals. 2019; 9(7):784. https://doi.org/10.3390/met9070784

Chicago/Turabian StyleFluch, Rainer, Marianne Kapp, Krystina Spiradek-Hahn, Manfred Brabetz, Heinz Holzer, and Reinhard Pippan. 2019. "Comparison of the Dislocation Structure of a CrMnN and a CrNi Austenite after Cyclic Deformation" Metals 9, no. 7: 784. https://doi.org/10.3390/met9070784

APA StyleFluch, R., Kapp, M., Spiradek-Hahn, K., Brabetz, M., Holzer, H., & Pippan, R. (2019). Comparison of the Dislocation Structure of a CrMnN and a CrNi Austenite after Cyclic Deformation. Metals, 9(7), 784. https://doi.org/10.3390/met9070784