Strength Characteristics of Clay-Rubber Waste Mixtures in UU Triaxial Tests

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Fine-Grained Soil

3.2. Rubber Waste

3.3. Red Clay-Rubber (RCR) Mixtures

4. Test Procedure

4.1. Preparation of Proper Specimens from Clay and from a Clay-Rubber Waste Mixture

4.2. Preparation of Proper Specimens from Pure Rubber Powder or Granulate

4.3. Tests Conditions

5. Results and Discussion

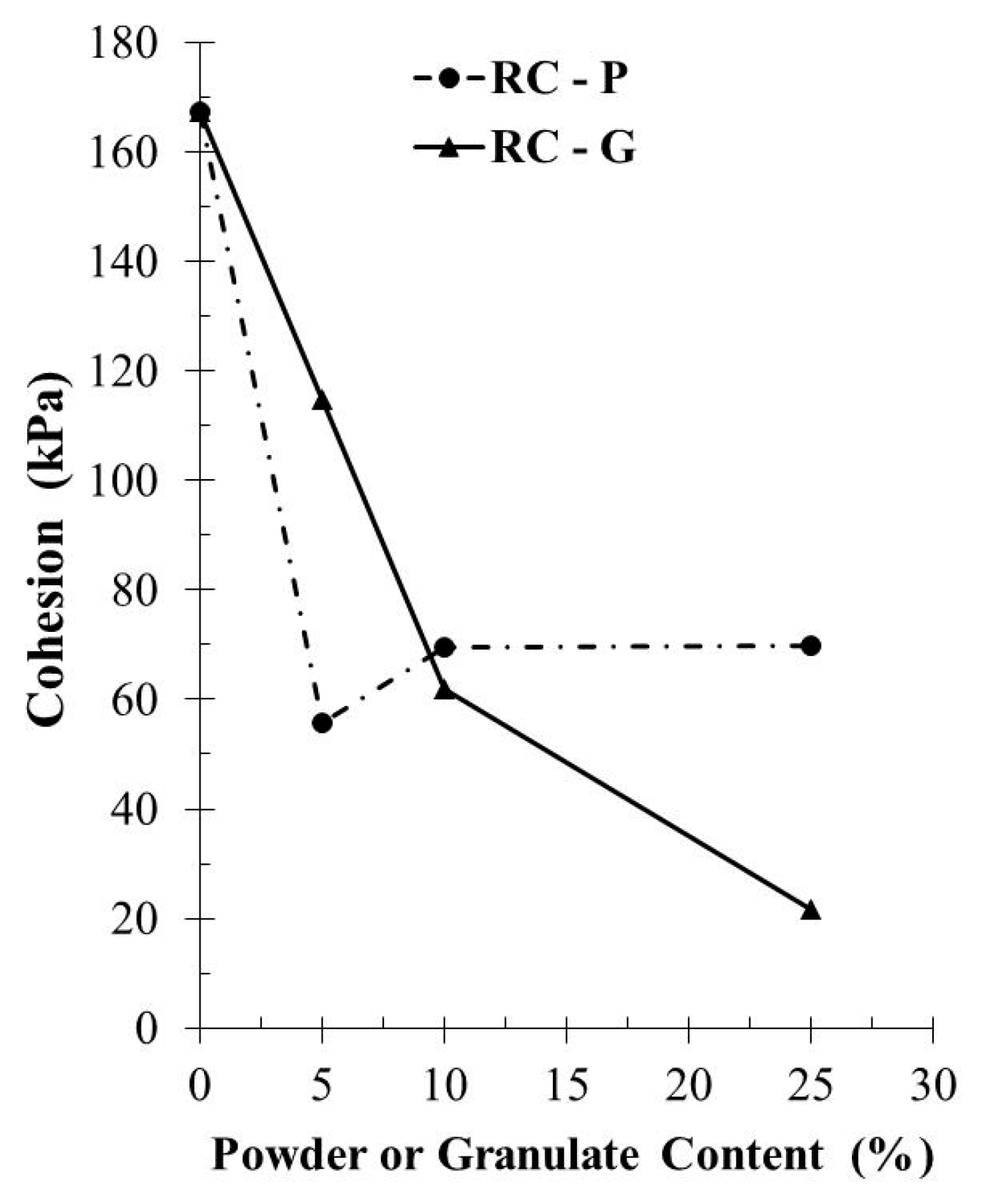

5.1. The Effect of Rubber Waste on the Shear Strength Parameters

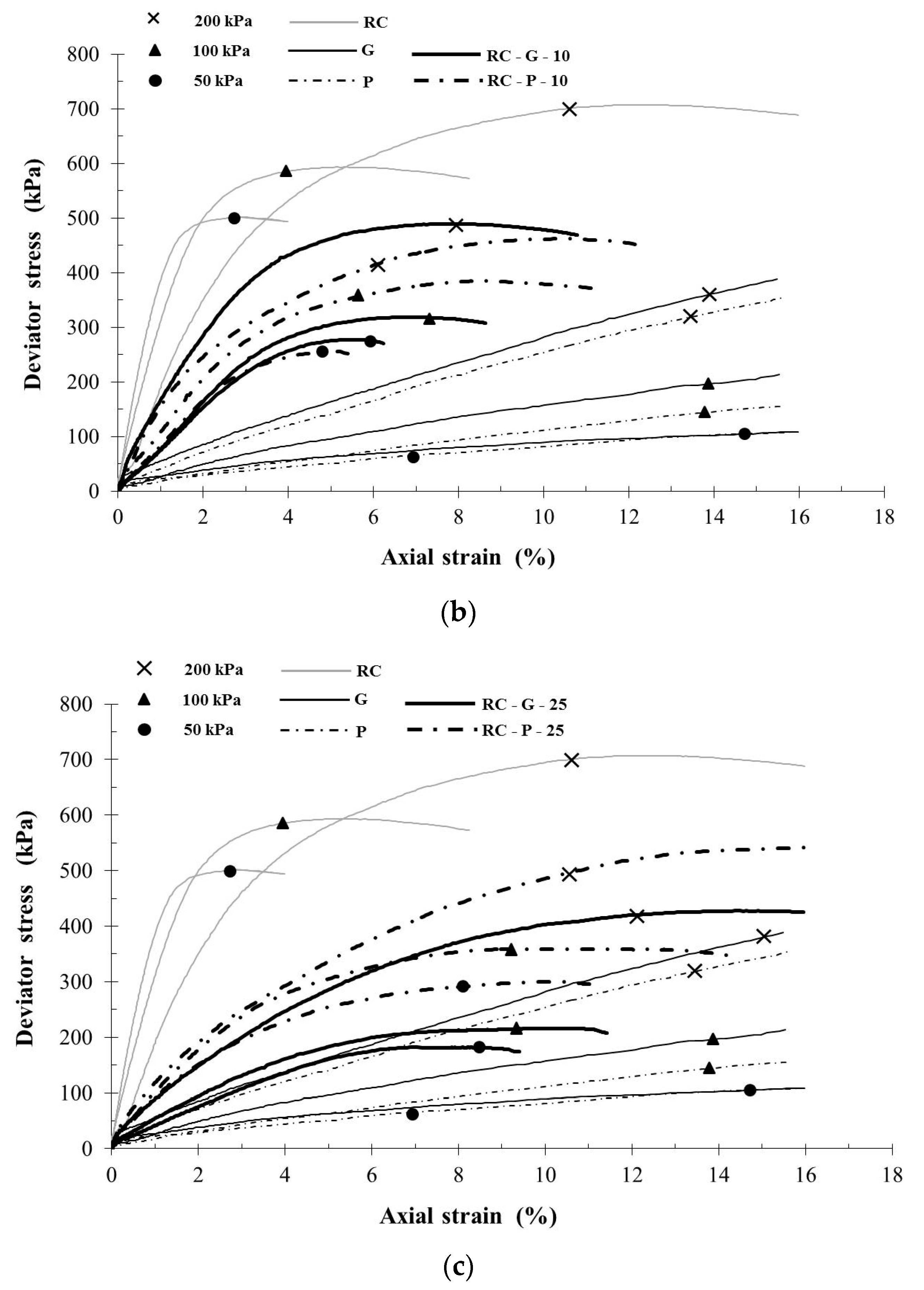

5.2. Analysis of Shear Strength Test Results

5.3. The Effect of Rubber Waste on Deformability

6. Conclusions

- (1)

- A general decrease in the shear strength by a much higher reduction of cohesion than increase in the angle of internal friction;

- (2)

- Various effects of shear strength decline due to the content (5%, 10%, or 15%) and the size of rubber waste particles (powder 0–1 mm or granulate 1–5 mm);

- (3)

- Reduction of the soil-rubber mixtures density;

- (4)

- Increase in the soil-rubber mixtures plasticity for certain ranges of confining stress;

- (5)

- Reduction of the swelling pressure and other swelling parameters [16].

Funding

Acknowledgments

Conflicts of Interest

References

- Rogers, J.D.; Olshansky, R.; Rogers, R.B. Damage to Foundations from Expansive Soils. Claims People 1993, 3, 1–4. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D. An Introduction to Geotechnical Engineering; Prentice-Hall: Upper Saddle River, NJ, USA, 1981. [Google Scholar]

- WBCSD. World Business Council for Sustainable Development Home Page. Available online: https://docs.wbcsd.org/2008/08/EndOfLifeTires-FullReport.pdf (accessed on 10 August 2008).

- Gromysz, K.; Kowalska, M. Reduction of Vibrations Applied on Structures—Results of Chamber Tests with the Use of Tire Derived Aggregate. Procedia Eng. 2017, 193, 305–312. [Google Scholar] [CrossRef]

- Jurczuk, J. Zastosowanie Strzępów Gumowych Jako Lekkiego Wypełnienia w Nasypach Drogowych. [Application of Rubber Shreds as a Light Filling in Road Embankments]; Mostostal Warszawa, S.A.: Warsaw, Poland, 2011. [Google Scholar]

- Kowalska, M.; Chmielewski, M. Mechanical Parameters of Rubber-Sand Mixtures for Numerical Analysis of a Road Embankment. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Beijing, China, 24–27 October 2017. [Google Scholar]

- Signes, C.H.; Garzón-Roca, J.; Fernández, P.M.; de la Torre, M.E.G.; Franco, R.I. Swelling Potential Reduction of Spanish Argillaceous Marlstone Facies Tap Soil Through the Addition of Crumb Rubber Particles from Scrap Tires. Appl. Clay Sci. 2016, 132, 768–773. [Google Scholar] [CrossRef]

- Sybilski, D. Zastosowanie Odpadów Gumowych w Budownictwie Drogowym. Przegląd Bud. 2009, 5, 37–44. [Google Scholar]

- Yoon, S.; Prezzi, M.; Siddiki, N.Z.; Kim, B. Construction of a Test Embankment Using a Sand—Tire Shred Mixture as Fill Material. Waste Manag. 2006, 26, 1033–1044. [Google Scholar] [CrossRef]

- Karacasu, M.; Okur, V.; Er, A. A Study on the Rheological Properties of Recycled Rubber-Modified Asphalt Mixtures. Sci. World J. 2015. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tire Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Xu, X.; Lo, S.H.; Tsang, H.H.; Sheikh, M.N. Earthquake Protection by Tire—Soil Mixtures: Numerical Study. In Proceedings of the New Zealand Society for Earthquake Engineering (NZSEE) Conference, Wellington, New Zealand, 3–5 April 2009. [Google Scholar]

- Jastrzębska, M.; Kowalska, M. Triaxial Tests on Weak Cohesive Soils—Some Practical Remarks (part 2). Arch. Civ. Eng. Environ. 2016, 9, 81–94. [Google Scholar] [CrossRef]

- Kowalska, M.; Jastrzębska, M. Triaxial Tests on Weak Cohesive Soils—Some Practical Remarks (part 1). Arch. Civ. Eng. Environ. 2016, 9, 71–80. [Google Scholar] [CrossRef]

- Chen, F.H. Foundations on Expansive Soils (Developments in Geotechnical Engineering 12); Elsevier Science: Amsterdam, The Netherlands, 1975; ISBN 978-0-44-456962-2. [Google Scholar]

- Kowalska, M.; Jastrzębska, M. Pęcznienie Mieszanek Gruntu Spoistego z Granulatem Gumowym. [Swelling of Cohesive Soil with Rubber Granulate]. In Analizy i Doświadczenia w Geoinżynierii; Bzówka, J., Łupieżowiec, M., Eds.; Politechniki Śląskiej: Gliwice, Poland, 2017; Volume 651, pp. 261–270. ISBN 978-8-37-880446-8. [Google Scholar]

- Kowalska, M. Compactness of Scrap Tire Rubber Aggregates in Standard Proctor Test. Procedia Eng. 2016, 161, 975–979. [Google Scholar] [CrossRef]

- Ramirez, G.; Casagrande, M.; Folle, D.; Pereira, A.; Paulon, V. Behavior of Granular Rubber Waste Tire Reinforced Soil for Application in Geosynthetic Reinforced Soil Wall. Rev. IBRACON Estrut. Mater. 2015, 8, 567–576. [Google Scholar] [CrossRef]

- Balasooriya, M.G.B.T.; Kumari, W.G.S.D.; Mallawarachchi, M.A.S.N.; Udakara, D.D.S. Study the Effect of Waste Rubber Materials on Shear Strength of Residual Soils. In Proceedings of the ICSBE-2012: International Conference on Sustainable Built Environment, Ipoh, Malaysia, 23–24 April 2012. [Google Scholar]

- Carraro, J.A.H.; Budagher, E.; Badanagki, M.; Kang, J.B. Sustainable Stabilization of Sulfate-Bearing Soil with Expansive Soil-Rubber Technology; Technical Report No. CDOT-2013-2; Colorado Department of Transportation: Washington, DC, USA, 2013. [Google Scholar]

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical Properties of Tire—Cohesive Clayey Soil Mixtures as a Fill Material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Daud, N.; Yusoff, Z.; Muhammed, A. Ground Improvement of Problematic Soft Soils Using Shredded Waste Tire. In Proceedings of the 6th Jordanian International Civil Engineering Conference (JICEC06), Amman, Jordan, 10–12 March 2015. [Google Scholar]

- Glinicka, M. Właściwości Mechaniczne Mieszaniny Gruntu i Odpadów z Opon Samochodowych. [Mechanical Properties of The Soil—Tire Waste Mixture]. Bud. Inżynieria Środowiska 2013, 4, 99–104. [Google Scholar]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Consistency Limits and Compaction Characteristics of Clays Soils Containing Rubber Waste. Proc. Inst. Civ. Eng. Geotech. Eng. 2019, 172, 174–188. [Google Scholar] [CrossRef]

- Srivastava, A.; Pandey, S.; Rana, J. Use of Shredded Tire Waste in Improving the Geotechnical Properties of Expansive Black Cotton Soil. Geomech. Geoeng. 2014, 9, 303–311. [Google Scholar] [CrossRef]

- Akbarimehr, D.; Aflaki, E. An Experimental Study on the Effect of Tire Powder on the Geotechnical Properties of Clay Soils. Civ. Eng. J. 2018, 4, 594–601. [Google Scholar] [CrossRef]

- Kalkan, E. Preparation of Scrap Tire Rubber Fiber-Silica Fume Mixtures for Modification of Clayey Soils. Appl. Clay Sci. 2013, 80, 117–125. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M.; Vanapalli, S.K. Swell-Shrink Behavior of Rubberized Expansive Clays During Alternate Wetting and Drying. Minerals 2019, 9, 224. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Swell-Shrink-Consolidation Behavior of Rubber-Reinforced Expansive Soils. Geotech. Test. J. 2018, 42, 761–788. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. Rubber Powder–Polymer Combined Stabilization of South Australian Expansive Soils. Geosynth. Int. 2018, 25, 304–321. [Google Scholar] [CrossRef]

- Tajdini, M.; Nabizadeh, A.; Taherkhani, H.; Zartaj, H. Effect of Added Waste Rubber on the Properties and Failure Mode of Kaolinite Clay. Int. J. Civ. Eng. 2016, 15, 949–958. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. The Impact of End-of-Life Tires on The Mechanical Properties of Fine-Grained Soil: A Review. Environ. Dev. Sustain. 2017, 21, 485–568. [Google Scholar] [CrossRef]

- Bałachowski, L.; Gotteland, P. Characteristics of Tire Chips—Sand Mixtures from Triaxial Tests. Arch. Hydro Eng. Environ. Mech. 2007, 54, 25–36. [Google Scholar]

- Dunham-Friel, J.; Carraro, J.A.H. Effects of Compaction Effort, Inclusion Stiffness, and Rubber Size on the Shear Strength and Stiffness of Expansive Soil-Rubber (ESR) Mixtures. In Proceedings of the Geo-Congress 2014: Geo-characterization and Modeling for Sustainability, Atlanta, GA, USA, 23–26 February 2014. [Google Scholar]

- Tafti, M.F.; Emadi, M.Z. Impact of Using Recycled Tire Fibers on the Mechanical Properties of Clayey and Sandy Soils. Electron. J. Geotech. Eng. 2016, 21, 7113–7125. [Google Scholar]

- Özkul, Z.H.; Baykal, G. Shear Behavior of Compacted Rubber Fiber-Clay Composite in Drained and Undrained Loading. J. Geotech. Geoenviron. Eng. 2007, 133, 767–781. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Deng, A.; Nikraz, H. Tire Rubber and Expansive Soils: Two Hazards, One Solution. Proc. Inst. Civ. Eng. Constr. Mater. 2019, 1–17. [Google Scholar] [CrossRef]

- CEN CWA 14243-2002. Post-Consumer Tire Materials and Applications; PKN: Warszawa, Poland, 2002. [Google Scholar]

- ASTM D 6270-08. Standard Practice for Use a Scrap Tires in Civil Engineering Applications; ASTM: Philadelphia, PA, USA, 2014. [Google Scholar]

- Yadav, J.S.; Tiwari, S.K. Assessment of Geotechnical Properties of Uncemented/Cemented Clayey Soil Incorporated with Waste Crumb Rubber. J. Mater. Eng. Struct. 2017, 4, 37–50. [Google Scholar]

- Yadav, J.S.; Tiwari, S.K. Effect of Waste Rubber Fibres on the Geotechnical Properties of Clay Stabilized with Cement. Appl. Clay Sci. 2017, 149, 97–110. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. Influence of Crumb Rubber on the Geotechnical Properties of Clayey Soil. Environ. Dev. Sustain. 2017, 20, 2565–2586. [Google Scholar] [CrossRef]

- Stempkowska, A. Badanie Właściwości Glin i Mas Klinkierowych. Glina Czerwona. [Determination of Properties of Clays and Clinker Masses. Red Clay]; AGH University of Science and Technology: Kraków, PL, USA, 2014; unpublished report. [Google Scholar]

- PN-EN ISO 14688-2:2006. Geotechnical Investigation and Testing—Determination and Classification of Soils—Part 2: Classification Rules; PKN: Warszawa, Poland, 2006. [Google Scholar]

- ASTM D2487-11. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: Philadelphia, PA, USA, 2017. [Google Scholar]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of Clayey Soils Using Scrap Tire Rubber and Synthetic Fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- PKN-CEN ISO/TS 17892-3:2009. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 3: Determination of Particle Density—Pycnometer Method; PKN: Warszawa, Poland, 2009. [Google Scholar]

- PKN-CEN ISO/TS 17892-12:2009. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Atterberg Limits; PKN: Warszawa, Poland, 2009. [Google Scholar]

- PN EN ISO 17892-3: 2016. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 3: Determination of Particle Density (ISO 17892-3:2015); PKN: Warszawa, Poland, 2016. [Google Scholar]

- PN-EN ISO 17892-5:2017-06. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 5: Incremental Loading Oedometer Test; PKN: Warszawa, Poland, 2017. [Google Scholar]

- Head, K.H. Manual of Soil Laboratory Testing: Soil Classification and Compaction Test, 3rd ed.; Whittles Publishing: Scotland, UK, 2006; Volume 1. [Google Scholar]

- ASTM D422-63:(2007)e2. Standard Test Method for Particle-Size Analysis of Soils; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- PKN CEN ISO/TS 17892-4: 2009. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution; PKN: Warszawa, Poland, 2009. [Google Scholar]

- PN EN 13286-2: 2010. Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction; PKN: Warszawa, Poland, 2010. [Google Scholar]

- Kowalska, M.; Rios, S.; Kijanka, M.; Jastrzębska, M. The Use of Scrap Tire Rubber in Geotechnical Engineering. Available online: https://www.researchgate.net/project/The-use-of-scrap-tire-rubber-in-geotechnical-engineering (accessed on 28 October 2016).

- Wolner, T.; Ksel, M. Analiza Wpływu Odpadów Gumowych na Parametry Wytrzymałościowe Gruntów Spoistych na Przykładzie Badań Typu UU w Aparacie Trójosiowym. [Analysis of the Rubber Waste Impact on the Strength Parameters of Cohesive Soils on the Example of UU Triaxial Tests]. Master’s Thesis, The Silesian University of Technology, Gliwice, Poland, 2016. [Google Scholar]

- PKN-CEN ISO/TS 17892-8:2009. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 8: Unconsolidated Undrained Triaxial Test; PKN: Warszawa, Poland, 2009. [Google Scholar]

- Yadav, J.S.; Tiwari, S.K. Effect of Inclusion of Crumb Rubber on the Unconfined Compressive Strength and Wet-Dry Durability of Cement Stabilized Clayey Soil. J. Build. Mater. Struct. 2016, 3, 68–84. [Google Scholar] [CrossRef]

- Jiahe Zhang, J.; Soltani, A.; Deng, A.; Jaksa, M.B. Mechanical Performance of Jute Fiber-Reinforced Micaceous Clay Composites Treated with Ground-Granulated Blast-Furnace Slag. Materials 2019, 12, 576. [Google Scholar] [CrossRef] [PubMed]

| Properties | Value | Standard Designation |

|---|---|---|

| Specific gravity, Gs (g/cm3) | 2.77 | PKN-CEN ISO/TS 17892-3 [47] |

| Consistency limits: | ||

| Plastic limit, PL (%) | 25 | PKN-CEN ISO/TS 17892-12 [48] |

| Liquid limit-cone penetrometer method, LL (%) | 65 | PN EN ISO 17892-3 [49] |

| Liquid limit-Casagrande method, LL (%) | 75 | PKN-CEN ISO/TS 17892-12 [48] |

| Swelling properties: | ||

| Swelling pressure, σsp (kPa) | 97 | PN-EN ISO 17892-5 [50] |

| Free-swell, FS (%) | 31.50 | Head [51] |

| Grain-size distribution: | ASTM D422 [52] | |

| Gravel (>2000 μm), (%) | 0 | |

| Sand (75–2000 μm), (%) | 0 | |

| Silt (2–75 μm), (%) | 71 | |

| Clay (<2 μm), (%) | 29 | PKN CEN ISO/TS 17892-4 [53] |

| Mineralogy: | ||

| Quartz, (%) | 41.8 | |

| Kaolinite, (%) | 31.5 | |

| Illite, (%) | 19.5 | |

| Siderite, (%) | 5.6 | |

| Goethite, (%) | 2.0 | |

| EC7 soil classification | siCL | PN-EN ISO 14688-2 [44] |

| USCS soil classification | CH | ASTM D2487-11 [45] |

| Compaction characteristics: | PN EN 13286-2 [54] | |

| Optimum moisture content (OMC), wopt (%) | 18.0 | |

| Maximum dry density, ρdmax (g/cm3) | 1.75 |

| Effective Diameter/Properties | Red Clay | Powder | Granulate |

|---|---|---|---|

| d10, (mm) | 0.0008 | 0.165 | 1.12 |

| d30, (mm) | 0.002 | 0.34 | 1.45 |

| d50, (mm) | 0.0045 | 0.5 | 2.0 |

| d60, (mm) | 0.008 | 0.58 | 2.35 |

| d90, (mm) | 0.02 | 0.85 | 4.0 |

| Coefficient of uniformity, Cu | 100 | 3.5 | 2.1 |

| Coefficient of curvature, Cc | 0.063 | 1.2 | 0.8 |

| Material | Rubber Content (%) | Internal Angle of Friction Φuu (⁰) | Ratio of Improvement in Angle of Friction | Cohesion cuu (kPa) | Ratio of Reduction in Cohesion | Density for w = 18% (g/cm3) |

|---|---|---|---|---|---|---|

| RC | 0 | 21.03 | - | 167.45 | - | 1.85 |

| RC-P-5 | 5 | 21.21 | 1.0 | 55.66 | 0.33 | 1.81 |

| RC-P-10 | 10 | 23.12 | 1.1 | 69.60 | 0.42 | 1.74 |

| RC-P-25 | 25 | 24.93 | 1.19 | 69.71 | 0.42 | 1.59 |

| P | 100 | 27.50 | - | 1.72 | - | 0.56 |

| RC-G-5 | 5 | 21.17 | 1.0 | 114.88 | 0.69 | 1.78 |

| RC-G-10 | 10 | 24.37 | 1.16 | 62.00 | 0.37 | 1.71 |

| RC-G-25 | 25 | 27.63 | 1.31 | 21.51 | 0.13 | 1.54 |

| G | 100 | 28.74 | - | 6.06 | - | 0.61 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jastrzębska, M. Strength Characteristics of Clay-Rubber Waste Mixtures in UU Triaxial Tests. Geosciences 2019, 9, 352. https://doi.org/10.3390/geosciences9080352

Jastrzębska M. Strength Characteristics of Clay-Rubber Waste Mixtures in UU Triaxial Tests. Geosciences. 2019; 9(8):352. https://doi.org/10.3390/geosciences9080352

Chicago/Turabian StyleJastrzębska, Małgorzata. 2019. "Strength Characteristics of Clay-Rubber Waste Mixtures in UU Triaxial Tests" Geosciences 9, no. 8: 352. https://doi.org/10.3390/geosciences9080352

APA StyleJastrzębska, M. (2019). Strength Characteristics of Clay-Rubber Waste Mixtures in UU Triaxial Tests. Geosciences, 9(8), 352. https://doi.org/10.3390/geosciences9080352