Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability

Abstract

:1. Introduction

2. Effect of Processing and Incorporation of Active Agents in Physical–Mechanical Properties

2.1. Optical Properties

2.2. Thermal Properties

2.3. Mechanical Properties

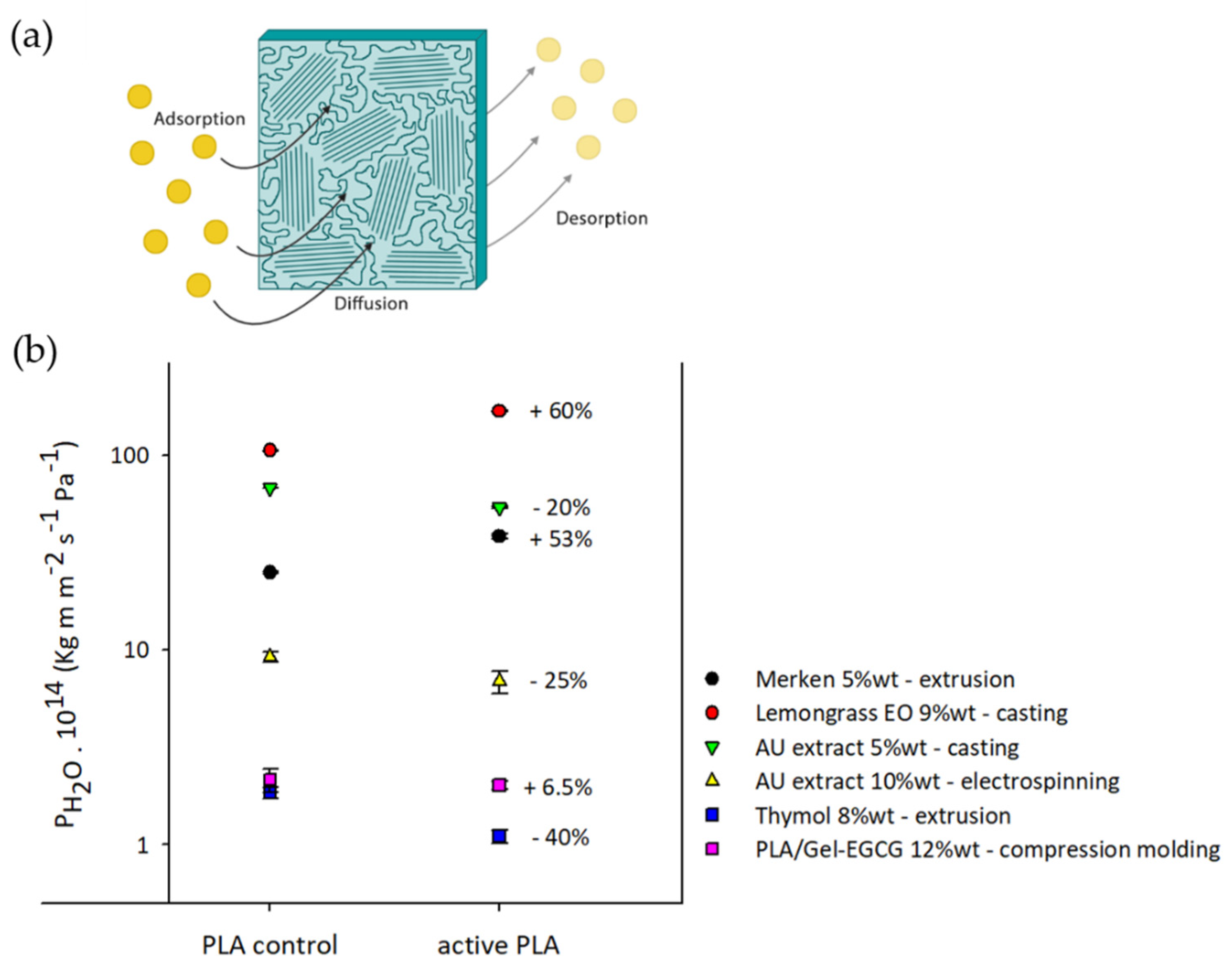

2.4. Moisture and Gas Barrier Properties

3. Release Kinetics of Active Agents and Their Functionalities

4. Disintegration under Composting

5. Conclusions and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Rydz, J.; Musiol, M.; Zawidlak-Wegrzyńska, B.; Sikorska, W. Present and Future of Biodegradable Polymers for Food Packaging Applications. Biopolym. Food Des. 2018, 14, 431–467. [Google Scholar] [CrossRef]

- García-Arroyo, P.; Arrieta, M.P.; Garcia-Garcia, D.; Cuervo-Rodríguez, R.; Fombuena, V.; Mancheño, M.J.; Segura, J.L. Plasticized poly(lactic acid) reinforced with antioxidant covalent organic frameworks (COFs) as novel nanofillers designed for non-migrating active packaging applications. Polymer 2020, 196, 122466. [Google Scholar] [CrossRef]

- Papadopoulou, E.L.; Paul, U.C.; Tran, T.N.; Suarato, G.; Ceseracciu, L.; Marras, S.; D’arcy, R.; Athanassiou, A. Sustainable Active Food Packaging from Poly(lactic acid) and Cocoa Bean Shells. ACS Appl. Mater. Interfaces 2019, 11, 31317–31327. [Google Scholar] [CrossRef] [PubMed]

- Armentano, I.; Bitinis, N.; Fortunati, E.; Mattioli, S.; Rescignano, N.; Verdejo, R.; Lopez-Manchado, M.A.; Kenny, J.M. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog. Polym. Sci. 2013, 38, 1720–1747. [Google Scholar] [CrossRef] [Green Version]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khosravi, A.; Fereidoon, A.; Khorasani, M.M.; Naderi, G.; Ganjali, M.R.; Zarrintaj, P.; Saeb, M.R.; Gutiérrez, T.J. Soft and hard sections from cellulose-reinforced poly(lactic acid)-based food packaging films: A critical review. Food Packag. Shelf Life 2020, 23, 100429. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Miltz, J.; Bigger, S.W. A Review of Poly(lactic acid)-Based Materials for Antimicrobial Packaging. J. Food Sci. 2014, 79, R1477–R1490. [Google Scholar] [CrossRef]

- Ribeiro-Santos, R.; Andrade, M.; de Melo, N.R.; Sanches-Silva, A. Use of essential oils in active food packaging: Recent advances and future trends. Trends Food Sci. Technol. 2017, 61, 132–140. [Google Scholar] [CrossRef]

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential oils as additives in active food packaging. Food Chem. 2021, 343, 128403. [Google Scholar] [CrossRef] [PubMed]

- Carpena, M.; Nuñez-Estevez, B.; Soria-Lopez, A.; Garcia-Oliveira, P.; Prieto, M.A. Essential Oils and Their Application on Active Packaging Systems: A Review. Resources 2021, 10, 7. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Bigger, S.W. Release of thymol from poly(lactic acid)-based antimicrobial films containing kenaf fibres as natural filler. LWT-Food Sci. Technol. 2016, 66, 629–637. [Google Scholar] [CrossRef] [Green Version]

- Arfat, Y.A.; Ahmed, J.; Ejaz, M.; Mullah, M. Polylactide/graphene oxide nanosheets/clove essential oil composite films for potential food packaging applications. Int. J. Biol. Macromol. 2018, 107, 194–203. [Google Scholar] [CrossRef] [PubMed]

- Rojas, A.; Velásquez, E.; Garrido, L.; Galotto, M.J.; López de Dicastillo, C. Design of active electrospun mats with single and core-shell structures to achieve different curcumin release kinetics. J. Food Eng. 2020, 273, 109900. [Google Scholar] [CrossRef]

- Torres, A.; Ilabaca, E.; Rojas, A.; Rodríguez, F.; Galotto, M.J.; Guarda, A.; Villegas, C.; Romero, J. Effect of processing conditions on the physical, chemical and transport properties of polylactic acid films containing thymol incorporated by supercritical impregnation. Eur. Polym. J. 2017, 89, 195–210. [Google Scholar] [CrossRef]

- Velásquez, E.; Patiño Vidal, C.; Rojas, A.; Guarda, A.; Galotto, M.J.; López de Dicastillo, C. Natural antimicrobials and antioxidants added to polylactic acid packaging films. Part I: Polymer processing techniques. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3388–3403. [Google Scholar] [CrossRef]

- Villegas, C.; Arrieta, M.P.; Rojas, A.; Torres, A.; Faba, S.; Toledo, M.J.; Gutierrez, M.A.; Zavalla, E.; Romero, J.; Galotto, M.J.; et al. PLA/organoclay bionanocomposites impregnated with thymol and cinnamaldehyde by supercritical impregnation for active and sustainable food packaging. Compos. Part B Eng. 2019, 176, 107336. [Google Scholar] [CrossRef]

- Villegas, C.; Torres, A.; Rios, M.; Rojas, A.; Romero, J.; López de Dicastillo, C.; Valenzuela, X.; Galotto, M.J.; Guarda, A. Supercritical impregnation of cinnamaldehyde into polylactic acid as a route to develop antibacterial food packaging materials. Food Res. Int. 2017, 99, 650–659. [Google Scholar] [CrossRef]

- Arrieta, M.; López, J.; Hernández, A.; Rayón, E. Ternary PLA-PHB-Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Arrieta, M.P.P.; López, J.; López, D.; Kenny, J.M.M.; Peponi, L. Development of flexible materials based on plasticized electrospun PLA-PHB blends: Structural, thermal, mechanical and disintegration properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar] [CrossRef]

- Morelli, C.L.; Mahrous, M.; Belgacem, M.N.; Branciforti, M.C.; Bretas, R.E.S.; Bras, J. Natural copaiba oil as antibacterial agent for bio-based active packaging. Ind. Crops Prod. 2015, 70, 134–141. [Google Scholar] [CrossRef]

- Safaei, M.; Roosta, R.; Roosta Azad, R. Preparation and characterization of poly-lactic acid based films containing propolis ethanolic extract to be used in dry meat sausage packaging. J. Food Sci. Technol. 2020, 57, 1242–1250. [Google Scholar] [CrossRef] [PubMed]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef]

- de Carvalho, A.P.A.; Conte Junior, C.A. Green strategies for active food packagings: A systematic review on active properties of graphene-based nanomaterials and biodegradable polymers. Trends Food Sci. Technol. 2020, 103, 130–143. [Google Scholar] [CrossRef]

- Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control. 2020, 112, 107086. [Google Scholar] [CrossRef]

- Ghadermazi, R.; Hamdipour, S.; Sadeghi, K.; Ghadermazi, R.; Khosrowshahi Asl, A. Effect of various additives on the properties of the films and coatings derived from hydroxypropyl methylcellulose—A review. Food Sci. Nutr. 2019, 7, 3363–3377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cavallo, E.; He, X.; Luzi, F.; Dominici, F.; Cerrutti, P.; Bernal, C.; Foresti, M.L.; Torre, L.; Puglia, D. UV Protective, Antioxidant, Antibacterial and Compostable Polylactic Acid Composites Containing Pristine and Chemically Modified Lignin Nanoparticles. Molecules 2020, 26, 126. [Google Scholar] [CrossRef]

- González, A.; Alvarez Igarzabal, C.I. Soy protein—Poly(lactic acid) bilayer films as biodegradable material for active food packaging. Food Hydrocoll. 2013, 33, 289–296. [Google Scholar] [CrossRef]

- Bruna, J.E.; Peñaloza, A.; Guarda, A.; Rodríguez, F.; Galotto, M.J. Development of MtCu2+/LDPE nanocomposites with antimicrobial activity for potential use in food packaging. Appl. Clay Sci. 2012, 58, 79–87. [Google Scholar] [CrossRef]

- Vishnu Priya, N.; Vinitha, U.G.; Meenakshi Sundaram, M. Preparation of chitosan-based antimicrobial active food packaging film incorporated with Plectranthus amboinicus essential oil. Biocatal. Agric. Biotechnol. 2021, 34, 102021. [Google Scholar] [CrossRef]

- Radusin, T.; Tomšik, A.; Šarić, L.; Ristić, I.; Giacinti Baschetti, M.; Minelli, M.; Novaković, A. Hybrid Pla/wild garlic antimicrobial composite films for food packaging application. Polym. Compos. 2019, 40, 893–900. [Google Scholar] [CrossRef]

- Bassani, A.; Montes, S.; Jubete, E.; Palenzuela, J.; Peñas Sanjuán, A.; Spigno, G. Incorporation of Waste Orange Peels Extracts into PLA Films. Chem. Eng. Trans. 2019, 74, 1063–1068. [Google Scholar] [CrossRef]

- Velásquez, E.; Rojas, A.; Piña, C.; Galotto, M.J.; López de Dicastillo, C. Development of bilayer biodegradable composites containing cellulose nanocrystals with antioxidant properties. Polymers 2019, 11, 1945. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nilsuwan, K.; Guerrero, P.; de la Caba, K.; Benjakul, S.; Prodpran, T. Properties and application of bilayer films based on poly(lactic acid) and fish gelatin containing epigallocatechin gallate fabricated by thermo-compression molding. Food Hydrocoll. 2020, 105, 105792. [Google Scholar] [CrossRef]

- Iglesias Montes, M.L.; Luzi, F.; Dominici, F.; Torre, L.; Cyras, V.P.; Manfredi, L.B.; Puglia, D. Design and Characterization of PLA Bilayer Films Containing Lignin and Cellulose Nanostructures in Combination with Umbelliferone as Active Ingredient. Front. Chem. 2019, 7, 157. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Lin, S.; An, S.; Liu, L.; Hu, Y.; Wan, L. Preparation, characterization and anti-aflatoxigenic activity of chitosan packaging films incorporated with turmeric essential oil. Int. J. Biol. Macromol. 2019, 131, 420–434. [Google Scholar] [CrossRef] [PubMed]

- Abarca, R.L.; Rodríguez, F.J.; Guarda, A.; Galotto, M.J.; Bruna, J.E.; Fávaro Perez, M.A.; Ramos Souza Felipe, F.; Padula, M. Application of β-Cyclodextrin/2-Nonanone Inclusion Complex as Active Agent to Design of Antimicrobial Packaging Films for Control of Botrytis cinerea. Food Bioprocess Technol. 2017, 10, 1585–1594. [Google Scholar] [CrossRef]

- Celebi, H.; Gunes, E. Combined effect of a plasticizer and carvacrol and thymol on the mechanical, thermal, morphological properties of poly(lactic acid). J. Appl. Polym. Sci. 2018, 135, 45895. [Google Scholar] [CrossRef]

- Ljungberg, N.; Wesslén, B. The effects of plasticizers on the dynamic mechanical and thermal properties of poly(lactic acid). J. Appl. Polym. Sci. 2002, 86, 1227–1234. [Google Scholar] [CrossRef]

- Simmons, H.; Tiwary, P.; Colwell, J.E.; Kontopoulou, M. Improvements in the crystallinity and mechanical properties of PLA by nucleation and annealing. Polym. Degrad. Stab. 2019, 166, 248–257. [Google Scholar] [CrossRef]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing Polylactic acid (PLA). Polimeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- López de Dicastillo, C.; Villegas, C.; Garrido, L.; Roa, K.; Torres, A.; Galotto, M.; Rojas, A.; Romero, J. Modifying an Active Compound’s Release Kinetic Using a Supercritical Impregnation Process to Incorporate an Active Agent into PLA Electrospun Mats. Polymers 2018, 10, 479. [Google Scholar] [CrossRef] [Green Version]

- López de Dicastillo, C.; Bruna, J.; Torres, A.; Alvarado, N.; Guarda, A.; Galotto, M.J.; López-de-Dicastillo, C.; Bruna, J.; Torres, A.; Alvarado, N.; et al. A traditional aboriginal condiment as an antioxidant agent in the development of biodegradable active packaging. J. Appl. Polym. Sci. 2017, 134, 1–10. [Google Scholar] [CrossRef]

- Gao, H.; Fang, X.; Chen, H.; Qin, Y.; Xu, F.; Jin, T.Z. Physiochemical properties and food application of antimicrobial PLA film. Food Control 2017, 73, 1522–1531. [Google Scholar] [CrossRef] [Green Version]

- Javidi, Z.; Hosseini, S.F.; Rezaei, M. Development of flexible bactericidal films based on poly(lactic acid) and essential oil and its effectiveness to reduce microbial growth of refrigerated rainbow trout. LWT-Food Sci. Technol. 2016, 72, 251–260. [Google Scholar] [CrossRef] [Green Version]

- Alvarado, N.; Romero, J.; Torres, A.; López de Dicastillo, C.; Rojas, A.; Galotto, M.J.; Guarda, A. Supercritical impregnation of thymol in poly(lactic acid) filled with electrospun poly(vinyl alcohol)-cellulose nanocrystals nanofibers: Development an active food packaging material. J. Food Eng. 2017, 217, 1–10. [Google Scholar] [CrossRef]

- Moeini, A.; Cimmino, A.; Masi, M.; Evidente, A.; Van Reenen, A. The incorporation and release of ungeremine, an antifungal Amaryllidaceae alkaloid, in poly(lactic acid)/poly(ethylene glycol) nanofibers. J. Appl. Polym. Sci. 2020, 137, 49098. [Google Scholar] [CrossRef]

- Boonruang, K.; Chinsirikul, W.; Hararak, B.; Kerddonfag, N.; Chonhenchob, V. Antifungal Poly(lactic acid) Films Containing Thymol and Carvone. MATEC Web Conf. 2016, 67, 06107. [Google Scholar] [CrossRef]

- Qin, Y.; Li, W.; Liu, D.; Yuan, M.; Li, L. Development of active packaging film made from poly(lactic acid) incorporated essential oil. Prog. Org. Coatings 2017, 103, 76–82. [Google Scholar] [CrossRef]

- Gavril, G.L.; Wrona, M.; Bertella, A.; Świeca, M.; Râpă, M.; Salafranca, J.; Nerín, C. Influence of medicinal and aromatic plants into risk assessment of a new bioactive packaging based on polylactic acid (PLA). Food Chem. Toxicol. 2019, 132, 110662. [Google Scholar] [CrossRef]

- Llana-Ruiz-Cabello, M.; Pichardo, S.; Bãnos, A.; Núñez, C.; Bermúdez, J.M.; Guillamón, E.; Aucejo, S.; Cameán, A.M. Characterisation and evaluation of PLA films containing an extract of Allium spp. to be used in the packaging of ready-to-eat salads under controlled atmospheres. LWT-Food Sci. Technol. 2015, 64, 1354–1361. [Google Scholar] [CrossRef]

- Friné, V.C.; Hector, A.P.; Manuel, N.D.S.; Estrella, N.D.; Antonio, G.J. Development and characterization of a biodegradable PLA food packaging hold monoterpene-cyclodextrin complexes against Alternaria alternata. Polymers 2019, 11, 1720. [Google Scholar] [CrossRef] [Green Version]

- Auras, R.; Singh, S.P.; Singh, J. Performance Evaluation of PLA against Existing PET and PS Containers. J. Test. Eval. 2006, 34, 530–536. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S.; Hernandez, R. Mechanical, Physical, and Barrier Properties of Poly(Lactide) Films. J. Plast. Film Sheeting 2003, 19, 123–135. [Google Scholar] [CrossRef]

- Vasile, C.; Stoleru, E.; Darie-Niţa, R.N.; Dumitriu, R.P.; Pamfil, D.; Tarţau, L. Biocompatible materials based on plasticized poly(lactic acid), chitosan and rosemary ethanolic extract I. effect of chitosan on the properties of plasticized poly(lactic acid) materials. Polymers 2019, 11, 941. [Google Scholar] [CrossRef] [Green Version]

- Zakaria, Z.; Islam, M.S.; Hassan, A.; Mohamad Haafiz, M.K.; Arjmandi, R.; Inuwa, I.M.; Hasan, M. Mechanical Properties and Morphological Characterization of PLA/Chitosan/Epoxidized Natural Rubber Composites. Adv. Mater. Sci. Eng. 2013, 2013, 629092. [Google Scholar] [CrossRef] [Green Version]

- Ding, T.; Li, T.; Li, J. Preparation of Coaxial Polylactic Acid-Propyl Gallate Electrospun Fibers and the Effect of Their Coating on Salmon Slices during Chilled Storage. ACS Appl. Mater. Interfaces 2019, 11, 6463–6474. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Wang, S.; Qin, W.; Zhang, Q. Electrospun antimicrobial polylactic acid/tea polyphenol nanofibers for food-packaging applications. Polymers 2018, 10, 561. [Google Scholar] [CrossRef] [Green Version]

- Llana-Ruiz-Cabello, M.; Pichardo, S.; Bermúdez, J.M.; Baños, A.; Núñez, C.; Guillamón, E.; Aucejo, S.; Cameán, A.M. Development of PLA films containing oregano essential oil (Origanum vulgare L. virens) intended for use in food packaging. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2016, 33, 1374–1386. [Google Scholar] [CrossRef]

- Martins, C.; Vilarinho, F.; Sanches Silva, A.; Andrade, M.; Machado, A.V.; Castilho, M.C.; Sá, A.; Cunha, A.; Vaz, M.F.; Ramos, F. Active polylactic acid film incorporated with green tea extract: Development, characterization and effectiveness. Ind. Crops Prod. 2018, 123, 100–110. [Google Scholar] [CrossRef] [Green Version]

- Ulloa, P.A.; Vidal, J.; Dicastillo, C.; Rodriguez, F.; Guarda, A.; Cruz, R.M.S.; Galotto, M.J. Development of poly(lactic acid) films with propolis as a source of active compounds: Biodegradability, physical, and functional properties. J. Appl. Polym. Sci. 2019, 136, 47090. [Google Scholar] [CrossRef]

- Sutjarittangtham, K.; Sanpa, S.; Tunkasiri, T.; Chantawannakul, P.; Intatha, U.; Eitssayeam, S. Bactericidal effects of propolis/polylactic acid (PLA) nanofibres obtained via electrospinning. J. Apic. Res. 2014, 53, 109–115. [Google Scholar] [CrossRef]

- Yampolskii, Y. Permeability of polymers. In Membrane Materials for Gas and Vapor Separation: Synthesis and Application of Silicon-Containing Polymers; Wiley: Hoboken, NJ, USA, 2016; pp. 1–15. ISBN 9781119112747. [Google Scholar]

- Colomines, G.; Ducruet, V.; Courgneau, Ć.; Guinault, A.; Domenek, S. Barrier properties of poly(lactic acid) and its morphological changes induced by aroma compound sorption. Polym. Int. 2010, 59, 818–826. [Google Scholar] [CrossRef] [Green Version]

- Radusin, T.; Torres-Giner, S.; Stupar, A.; Ristic, I.; Miletic, A.; Novakovic, A.; Lagaron, J.M. Preparation, characterization and antimicrobial properties of electrospun polylactide films containing Allium ursinum L. extract. Food Packag. Shelf Life 2019, 21, 100357. [Google Scholar] [CrossRef]

- Ramos, M.; Fortunati, E.; Peltzer, M.; Jimenez, A.; Kenny, J.M.; Garrigós, M.C. Characterization and disintegrability under composting conditions of PLA-based nanocomposite films with thymol and silver nanoparticles. Polym. Degrad. Stab. 2016, 132, 2–10. [Google Scholar] [CrossRef] [Green Version]

- Auras, R.; Harte, B.; Selke, S. Effect of water on the oxygen barrier properties of poly(ethylene terephthalate) and polylactide films. J. Appl. Polym. Sci. 2004, 92, 1790–1803. [Google Scholar] [CrossRef]

- Duan, Z.; Thomas, N.L. Water vapour permeability of poly(lactic acid): Crystallinity and the tortuous path model. J. Appl. Phys. 2014, 115, 064903. [Google Scholar] [CrossRef] [Green Version]

- Roy, S.; Rhim, J.W. Preparation of bioactive functional poly(lactic acid)/curcumin composite film for food packaging application. Int. J. Biol. Macromol. 2020, 162, 1780–1789. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Tang, C.H.; Yin, S.W.; Yang, X.Q. Development and characterization of novel antimicrobial bilayer films based on Polylactic acid (PLA)/Pickering emulsions. Carbohydr. Polym. 2018, 181, 727–735. [Google Scholar] [CrossRef] [PubMed]

- Aydogdu, A.; Yildiz, E.; Ayhan, Z.; Aydogdu, Y.; Sumnu, G.; Sahin, S.; Ayca, A.; Eda, Y.; Zehra, A.; Yıldırım, A.; et al. Nanostructured poly(lactic acid)/soy protein/HPMC films by electrospinning for potential applications in food industry. Eur. Polym. J. 2019, 112, 477–486. [Google Scholar] [CrossRef]

- Mohamad, N.; Mazlan, M.M.; Tawakkal, I.S.M.A.; Talib, R.A.; Kian, L.K.; Fouad, H.; Jawaid, M. Development of active agents filled polylactic acid films for food packaging application. Int. J. Biol. Macromol. 2020, 163, 1451–1457. [Google Scholar] [CrossRef] [PubMed]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Cherpinski, A.; Torres-Giner, S.; Cabedo, L.; Lagaron, J.M. Post-processing optimization of electrospun submicron poly(3-hydroxybutyrate) fibers to obtain continuous films of interest in food packaging applications. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2017, 34, 1817–1830. [Google Scholar] [CrossRef]

- Rocca-Smith, J.R.; Lagorce-Tachon, A.; Iaconelli, C.; Bellat, J.P.; Marcuzzo, E.; Sensidoni, A.; Piasente, F.; Debeaufort, F.; Karbowiak, T. How high pressure CO2 impacts PLA film properties. Express Polym. Lett. 2017, 11, 320–333. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Liu, B.; Xia, Y.; Lin, Q. Migration of polymer additives and radiolysis products from irradiated PET/PE films into a food simulant. Food Control 2021, 124, 107886. [Google Scholar] [CrossRef]

- Bouwmeester, H.; Brandhoff, P.; Marvin, H.J.P.; Weigel, S.; Peters, R.J.B. State of the safety assessment and current use of nanomaterials in food and food production. Trends Food Sci. Technol. 2014, 40, 200–210. [Google Scholar] [CrossRef]

- Wang, X.; Song, M.; Liu, S.; Wu, S.; Thu, A.M. Analysis of phthalate plasticizer migration from PVDC packaging materials to food simulants using molecular dynamics simulations and artificial neural network. Food Chem. 2020, 317, 126465. [Google Scholar] [CrossRef]

- Muller, J.; Casado Quesada, A.; González-Martínez, C.; Chiralt, A. Antimicrobial properties and release of cinnamaldehyde in bilayer films based on polylactic acid (PLA) and starch. Eur. Polym. J. 2017, 96, 316–325. [Google Scholar] [CrossRef]

- Ramos, M.; Fortunati, E.; Peltzer, M.; Dominici, F.; Jiménez, A.; Garrigós, M.D.C.; Kenny, J.M. Influence of thymol and silver nanoparticles on the degradation of poly(lactic acid) based nanocomposites: Thermal and morphological properties. Polym. Degrad. Stab. 2014, 108, 158–165. [Google Scholar] [CrossRef] [Green Version]

- Rojas, A.; Torres, A.; José Galotto, M.; Guarda, A.; Julio, R. Supercritical impregnation for food applications: A review of the effect of the operational variables on the active compound loading. Crit. Rev. Food Sci. Nutr. 2020, 60, 1290–1301. [Google Scholar] [CrossRef]

- Bouarab Chibane, L.; Degraeve, P.; Ferhout, H.; Bouajila, J.; Oulahal, N. Plant antimicrobial polyphenols as potential natural food preservatives. J. Sci. Food Agric. 2019, 99, 1457–1474. [Google Scholar] [CrossRef] [Green Version]

- Lourenço, S.C.; Moldão-Martins, M.; Alves, V.D. Antioxidants of natural plant origins: From sources to food industry applications. Molecules 2019, 24, 4132. [Google Scholar] [CrossRef] [Green Version]

- Kwiatkowski, P.; Giedrys-Kalemba, S.; Mizielińska, M.; Bartkowiak, A. Modification of pla foil surface by ethylcellulose and essential oils. J. Microbiol. Biotechnol. Food Sci. 2016, 5, 440–444. [Google Scholar] [CrossRef] [Green Version]

- Chi, H.; Song, S.; Luo, M.; Zhang, C.; Li, W.; Li, L.; Qin, Y. Effect of PLA nanocomposite films containing bergamot essential oil, TiO 2 nanoparticles, and Ag nanoparticles on shelf life of mangoes. Sci. Hortic. 2019, 249, 192–198. [Google Scholar] [CrossRef]

- Aytac, Z.; Kusku, S.I.; Durgun, E.; Uyar, T. Encapsulation of gallic acid/cyclodextrin inclusion complex in electrospun polylactic acid nanofibers: Release behavior and antioxidant activity of gallic acid. Mater. Sci. Eng. C 2016, 63, 231–239. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Velázquez-Contreras, F.; García-Caldera, N.; de la Rosa, J.D.P.; Martínez-Romero, D.; Núñez-Delicado, E.; Gabaldón, J.A. Effect of PLA Active Packaging Containing Monoterpene-Cyclodextrin Complexes on Berries Preservation. Polymers 2021, 13, 1399. [Google Scholar] [CrossRef] [PubMed]

- Mousavi Khaneghah, A.; Hashemi, S.M.B.; Limbo, S. Antimicrobial agents and packaging systems in antimicrobial active food packaging: An overview of approaches and interactions. Food Bioprod. Process. 2018, 111, 1–19. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Ramos, M.; Beltrán, A.; Peltzer, M.; Valente, A.J.M.; Garrigós, M. del C. Release and antioxidant activity of carvacrol and thymol from polypropylene active packaging films. LWT-Food Sci. Technol. 2014, 58, 470–477. [Google Scholar] [CrossRef] [Green Version]

- Ramos, M.; Fortunati, E.; Beltrán, A.; Peltzer, M.; Cristofaro, F.; Visai, L.; Valente, A.J.M.; Jiménez, A.; María Kenny, J.; Carmen Garrigós, M. Controlled release, disintegration, antioxidant, and antimicrobial properties of poly(lactic acid)/thymol/nanoclay composites. Polymers 2020, 12, 1878. [Google Scholar] [CrossRef] [PubMed]

- Cerro, D.; Bustos, G.; Villegas, C.; Buendia, N.; Truffa, G.; Godoy, M.P.; Rodríguez, F.; Rojas, A.; Galotto, M.J.; Constandil, L.; et al. Effect of supercritical incorporation of cinnamaldehyde on physical-chemical properties, disintegration and toxicity studies of PLA/lignin nanocomposites. Int. J. Biol. Macromol. 2021, 167, 255–266. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.M.M.; Peponi, L. Effect of chitosan and catechin addition on the structural, thermal, mechanical and disintegration properties of plasticized electrospun PLA-PHB biocomposites. Polym. Degrad. Stab. 2016, 132, 145–156. [Google Scholar] [CrossRef]

- Iglesias-Montes, M.L.; Soccio, M.; Luzi, F.; Puglia, D.; Gazzano, M.; Lotti, N.; Manfredi, L.B.; Cyras, V.P. Evaluation of the Factors Affecting the Disintegration under a Composting Process of Poly(lactic acid)/Poly(3-hydroxybutyrate) (PLA/PHB) Blends. Polymers 2021, 13, 3171. [Google Scholar] [CrossRef] [PubMed]

| PLA | |||||||

|---|---|---|---|---|---|---|---|

| Processing Technique | PLA | Processing Condition * | Tg (°C) | Tm (°C) | Xc (%) | Td (°C) | References |

| Cast-extrusion | NW2003D | Temperature: 170–185 °C | 61.7 | 170.8 | 19.5 | 362.0 | [37] |

| NW ** | Temperature: 155–165 °C | 63.2 | 155.6 | 4.6 | 365.1 | [43] | |

| Electro-spinning | NW2003D | Solvent: CHCl3:DMF 1:1 | 53.1 | 153.2 | 1.1 | 334.0 | [42] |

| Casting | NW ** | Solvent: Methylene chloride Evaporation: 25 °C for 24 h under a chemical hood | 59.7 | 168.4 | N/R | N/R | [44] |

| NW2002D | Solvent: Chloroform Evaporation: room temperature and 3 days under a chemical hood | 44.3 | 166.4 | N/R | N/R | [45] | |

| Active PLA Films | ||||||||

|---|---|---|---|---|---|---|---|---|

| Processing Technique | Active Agent/Condition | PLA | AA Composition (wt%) | Tg (°C) | Tm (°C) | Xc (%) | Td (°C) | References |

| Casting | Allium ursinum extract Solvent: CHCl3 | Esun | 0 | 42.6 | 147.9; 158.5 | 7.3 | N/R | [31] |

| 0.5 | 45.9 | 143.6; 155.6 | 13.2 | |||||

| 5 | 45.5 | 149.6; 159.2 | 6.4 | |||||

| Bergamot and clove oil | NW * | 0 | 55.0 | 166.7 | 11.7 | 361 | [49] | |

| 9% Bergamot in CHCl3 | 52.0 | 164.5 | 13.0 | 58–173; 361 | ||||

| 9% Clove in CHCl3 | 49.2 | 159.6 | 16.6 | 76–186; 363 | ||||

| Electro-spinning | Curcumin | NW2003D | 0 | 40.2 | 136.9; 147.3 | 21 | 331.5 | [14] |

| 1.23% in solution CHCl3:DMF 7:3 | 54.7 | 149.2 | 6.2 | 353.6 | ||||

| Ungeremine | NW4042D | 0 | 59.3 | 148.6 | 4.1 | N/R | [47] | |

| 1 | 54.2 | 147.8 | 8.53 | |||||

| Extrusion-biaxial stretching | Thymol or R-(−)-carvone | NW4043D | 0 | 57.0 | 150.0 | 27.6 | N/R | [48] |

| 20 wt% thymol | 56.0 | 140.0 | 13.6 | N/R | ||||

| 20 wt% R-(−)-carvone | 54.0 | 144.0 | 34.9 | N/R | ||||

| Injection ** | Thymol | PLI005 | 0 | 61 | 154.0 | 31.0 | 367 | [38] |

| 5 | 56 | 154.0 | 29.0 | N/R | ||||

| 20 | 35 | 135.0 | 33.0 | 117–300; 1366 | ||||

| Processing Technique | PLA/Active Agent | YM (MPa) | TS (MPa) | EB (%) | References |

|---|---|---|---|---|---|

| Melt blending-hot pressing | PLA control | 3361 | 56.82 | 2.21 | [32] |

| Waste orange peel extract Rosemary ethanolic extract with or without chitosan | ↓ | ↓ | ≈ or ↑ | [32,55] | |

| Chitosan | ↑ | ↑ | ↓ | [55] | |

| Cast extrusion | PLA control | 3000 | 65 | 3.1 | [51] |

| Allium spp. Extract Oregano essential oil Merkén | ↓ | ↓ | ↓ | [43,51,59] | |

| Extrusion-stretching | PLA control | - | - | 40 | [48] |

| Thymol, R-(−)-carvone | ↓ | ↓ | ↑ | ||

| Blown extrusion | PLA control | - | 40.2 | 3.63 | [60] |

| Green tea extract | ↓ | ↓ | ↑ | ||

| Injection molding | PLA control | 3100 | 52.7 | 2.9 | [38] |

| Thymol and Carvacrol β-CD-thymol and β-CD-carvacrol | ↓ | ↓ | ↑ | [38,52] | |

| Casting | PLA control | 1702 | 45.8 | 5.4 | [49] |

| Clove essential oil Bergamot, lemongrass, rosemary and clove Ethanolic extract of propolis | ↓ | ↓ | ↑ | [13,49,61] | |

| Allyl isothyocianate Wild garlic | ↓ | ≈ or ↑ | ≈ or ↓ | [31,44] | |

| Electrospinning | PLA control | - | 12.24 | 57.28 | [58] |

| Tea polyphenol Propolis powder extract | ↓ | ↓ | ↓ | [58,62] | |

| Propyl gallate | ↓ | ↑ | ↑ | [57] | |

| Supercritical impregnation | PLA control | 1607 | 47.9 | 3.4 | [46] |

| Thymol | ↓ | ↓ | ↑ | [15,46] | |

| Cinnamaldehyde | ≈ | ↓ | ↑ | [17,18] |

| Processing Technique | AA | Thick (µm) | Xc (%) | PH2O | PO2 | References |

|---|---|---|---|---|---|---|

| Casting | Clove oil (CLO) 15–30 (wt%) | 65–70 | PLA: 15.58; PLA.15CLO: 14.39; PLA.30CLO: 8.23 | N/R | PLA: 16.3; PLA-15CLO: 20.5; PLA.30CLO: 26.6 | [13] |

| Allyl isoctiocyanate (AIT) 5 (wt%) | N/R | PLA: 20.97; PLA.5AIT: 17.29 | PLA: 2.38 PLA.5AIT: 1.93 × 10−6 kg m−2 s−1 | PLA: 3.77 ×10−6; PLA.5AIT: 2.3 × 10−6 (m3 m−2 s−1) | [44] | |

| Oregano essential oil (EO) 0.5, 1 and 1.5 (wt%) | N/R | N/R | PLA: 1.89; PLA.0.5EO: 1.25; PLA.1.5EO: 1.72 × 10−8 kg m m−2 s−1 Pa−1 | N/R | [45] | |

| Bergamot (BEO), lemongrass (LEO), rosemary (REO), clove CEO) 9 (wt%) | N/R | PLA: 11.7; PLA.9BEO: 13.0; PLA.9LEO: 16.3; PLA.9REO: 15.5; PLA.9CEO: 16.6 | PLA: 1.06; PLA.9BEO: 2.03; PLA.9LEO: 1.69; PLA.9REO: 1.54; PLA.9CEO: 1.91 × 10−14 kg m m−2 s−1 Pa−1 | N/R | [49] | |

| Garlic extract powder (AU) 0.5 and 5 (wt%) | N/R | PLA: 7.3; PLA.0.5AU:13.2; PLA. 5AU: 6.4 | PLA: 6.84; PLA.0.5AU: 6.12; PLA.5AU: 5.47 × 10−15 kg m−1 s−1 Pa−1 | RH = 0%: PLA: 4.8; PLA.0.5AU: 3.84; PLA.5AU: 3.84; RH = 50%: PLA.5GE: 6.08 × 10−18 kg m−1 s−1 Pa−1 | [31] | |

| Coating | Zein-Quercetin (ZN-Q) 5 (wt%) | N/R | N/R | PLA/ZN: 1.66; PLA/ZN-5Q: 1.83 × 10−14 kg m m−2 s−1 Pa−1 | N/R | [33] |

| Pickering emulsion-Thymol (PE-T) 20–40 (wt%) | N/R | N/R | PLA: 2.43; PLA/PE-T: 3.98 × 10−14 kg m m−2 s Pa−1 | PLA: 4.03; PLA/PE-T: 2.07 × 10−18m3 m m−2 s−1 Pa−1 | [70] | |

| Extrusion | Merkén (M) 3 and 5 (wt%) | 85–100 | PLA: 4.6; PLA.3M: 2.1; PLA.5M: 1.7 | PLA: 2.50; PLA.3M: 3.04; PLA.5M: 3.83 × 10−15 kg m m−2 s−1 Pa−1 | N/R | [43] |

| Thymol (T) & R-(−)-carvone oil (C) 10, 15 and 20 (wt%) | 30–45 | PLA: 27.6; PLA.10T: 25.6; PLA.15T: 16.4; PLA.20T: 13.6; PLA.10C: 32.3; PLA.15C: 32.5; PLA.20C: 34.9 | N/R | PLA: 21; PLA.10T: 17; PLA.15T: 24; PLA.20T: 50; PLA.10C: 20; PLA.15C: 18; PLA.20C: 22 | [48] | |

| Green tea e×tract (GT) 1 and 2 (wt%) | 47–78 | N/R | PLA: 9.31; PLA.1GT: 7.31; PLA.2GT: 6.0 × 10−7 kg m−2 s−1 | N/R | [60] | |

| Compression-molding | Gelatin-Epigallocatechin gallate (Gel-EGCG) 3, 6, 9 and 12 (wt%) | 179–195 | N/R | PLA/Gel:2.01; PLA/Gel.3EGCG: 2.06; PLA/Gel.6EGCG: 2.01; PLA/Gel.9EGCG: 2.02; PLA/Gel.12EGCG: 2.15 × 10−14 kg m−1 s−1 Pa−1 | N/R | [34] |

| Electro-spinning | Garlic extract (AU) 10 (wt%) | 1–2 | PLA: 13.2; PLA.10AU: 7.9 | PLA: 9.21; PLA.10AU: 6.9 × 10−14 kg m m−2 s−1 Pa−1 | N/R | [65] |

| Soy protein + HPMC + PEG nanofibers (SP/HPMC/PEG) 33.3/33.3/33.33 (wt%) | 31 | N/R | PLA: 2.6; PLA/SP-HPMC-PEG: 4.869 × 10−14 kg m−1 s−1 Pa−1 | N/R | [71] |

| Active Agent | Processing Technique | Release Conditions | Diffusion Coefficient (m2 s−1) | References |

|---|---|---|---|---|

| Merkén | Extrusion | EtOH 50% at 40 °C | 2.0 × 10−13 | [43] |

| Thymol | Extrusion | EtOH 95% at 40 °C | 6.0 × 10−13 | [12] |

| Solvent Casting | EtOH 10% at 40 °C | 2.5 × 10−13 | [46] | |

| Supercritical impregnation | EtOH 10% at 40 °C | 1.5 × 10−13 | [15] | |

| EtOH 95% at 40 °C | 2.8 × 10−11 | |||

| Cinnamaldehyde | Electrospinning | EtOH 50% at 40 °C | 1.0 × 10−12 | [42] |

| Supercriticalimpregnation | 6.0 × 10−14 | |||

| Casting (PLA monolayer) | EtOH 50% at 20°C | 6.3 × 10−14 | [79] | |

| Thermo-compression (PLA-bilayer) | 9.0 × 10−15 |

| Active Agent | Processing Technique | Methodology | Antimicrobial Activity | References |

|---|---|---|---|---|

| Carvacrol and thymol | Extrusion | * Disk diffusion | S. aureus: 1.5–2.5; S. Thyphimurium: 0.7–0.8; L. monocytogenes: 0.9–0.8 | [38] |

| Allium spp. extract | Cast Extrusion | ** Dilution method | Bacteria: 0–4.9; Moulds: 0–3.9; Yeats: 0–3.9 | [51] |

| β-CD inclusion complexes of thymol and carvacrol | Injection molding | * Vapor phase diffusion | A. alternate: 0–29.7 (5 days) and 0–69 (10 days) | [52] |

| Cinnamaldehyde | Casting | ** Disk diffusion | L. innocua: 0–4; E. coli: 1–7 | [79] |

| Bergamot, lemongrass, clove and rosemary essential oils | Casting | ** Liquid culture test | E. coli: 2–3; B. subtilis: 3.5. | [49] |

| Copaifera multijuga oil | Coating | * Disk diffusion | B. subtilis: 20 | [21] |

| Rosemary, caraway and fennel oils | Coating | Normative ASTM E 2180-07 | S. aureus: 81–85%; E. coli: 66–70% | [84] |

| Propolis extract | Electrospinning | Direct contact | S. aureus, E. coli, S. epidermis, B. cereus; P. mirabilis: Bactericidal effect (4 wt%) | [62] |

| Allium ursinum L. extract | Electrospinning | ** Direct contact | E. coli: 5.9; S. aureus: 2.1 | [65] |

| Cinnamaldehyde | scCO2 impregnation | Dynamic contact | E. coli; S. aureus: total inhibition | [18] |

| Thymol and CIN | scCO2 impregnation | Dynamic contact | E. coli; S. aureus: total inhibition | [17] |

| Active Agent | Processing Technique | Methodology | Activity | References |

|---|---|---|---|---|

| Green tea (GT) extract | Extrusion | Packaged salmon analysis: PV (peroxides value), p-anisidine value, TBARS | Salmon packaged for 60 days: PV: no detected; p-anisidine and TBARS: 33% reduction on aldehydes | [60] |

| Propolis extract | Casting | Packaged sausage analysis: Folin–Ciocalteu | Sausage packaged for 4 days: PC between 0.6 and 1.7 *** | [22] |

| Bergamot essential oil | Casting | Packaged mangoes analysis: Vitamin C quantification | Mangoes packaged for 15 days: Vitamin C was maintained between 42% to 75% | [85] |

| Tea polyphenol | Electrospinning | DPPH | DPPH inhibition: 70 to 95% | [58] |

| HPβ-CD inclusion complexes of gallic acid | Electrospinning | DPPH | DPPH inhibition higher than 95% | [86] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas, A.; Velásquez, E.; Patiño Vidal, C.; Guarda, A.; Galotto, M.J.; López de Dicastillo, C. Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability. Antioxidants 2021, 10, 1976. https://doi.org/10.3390/antiox10121976

Rojas A, Velásquez E, Patiño Vidal C, Guarda A, Galotto MJ, López de Dicastillo C. Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability. Antioxidants. 2021; 10(12):1976. https://doi.org/10.3390/antiox10121976

Chicago/Turabian StyleRojas, Adrián, Eliezer Velásquez, Cristian Patiño Vidal, Abel Guarda, María José Galotto, and Carol López de Dicastillo. 2021. "Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability" Antioxidants 10, no. 12: 1976. https://doi.org/10.3390/antiox10121976

APA StyleRojas, A., Velásquez, E., Patiño Vidal, C., Guarda, A., Galotto, M. J., & López de Dicastillo, C. (2021). Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability. Antioxidants, 10(12), 1976. https://doi.org/10.3390/antiox10121976